Polyamide microspheres and preparation method thereof

A technology of polyamide and microspheres, which is applied in the field of polyamide microspheres and its preparation, can solve the problems of high toxicity of etching solvent toluene or tetrahydrofuran, long polymer dissolution time, unfavorable application requirements of polyamide microspheres, etc., to achieve The effect of shortening the process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Poly 4-vinylpyridine (P 4 VP) is fully dissolved in caprolactam (PA6), where P 4 The weight ratio of VP / PA6 is 15:85, under the protection of nitrogen, at 140°C, after constant temperature stirring for 3 hours; 160°C, 0.0015MPa to remove water under reduced pressure for 20min, add 4wt% sodium caprolactam and 4wt% toluene diisocyanate, mix well After uniformity; quickly pour it into a preheated mold, the mold temperature is controlled at 150 ° C, and anionic ring-opening polymerization is carried out at a reaction temperature of 150 ° C and a reaction time of 15 minutes to obtain P 4 VP / PA6 alloy 1; then use 200wt% ethanol to P 4 VP / PA6 alloy 1 was dissolved, and the solvent was naturally volatilized at room temperature to obtain polyamide microspheres, whose average particle size is shown in Table 1.

Embodiment 2

[0037] Poly 4-vinylpyridine (P 4 VP) is fully dissolved in caprolactam (PA6), where P 4The weight ratio of VP / PA6 is 20:80, under the protection of nitrogen, at 140°C, after constant temperature stirring for 2 hours; 140°C, -0.1MPa to remove water under reduced pressure for 30min, add 2wt% sodium caprolactam and 4wt% toluene diisocyanate, fully After mixing evenly; quickly pour it into a preheated mold, the mold temperature is controlled at 160°C, and carry out anionic ring-opening polymerization reaction, the reaction temperature is 160°C, the reaction time is 15min, and P 4 VP / PA6 alloy 2; then use 200wt% ethanol to P 4 VP / PA6 alloy 2 was dissolved, and the solvent was naturally volatilized at room temperature to obtain polyamide microspheres. The average particle size is shown in Table 1.

Embodiment 3

[0039] Poly 4-vinylpyridine (P 4 VP) is fully dissolved in caprolactam (PA6), where P 4 The weight ratio of VP / PA6 is 25:75, under the protection of nitrogen, at 160°C, after constant temperature stirring for 2 hours; 160°C, 0.0015MPa to remove water under reduced pressure for 30min, add 4wt% sodium caprolactam and 4wt% toluene diisocyanate, and mix well After uniformity; quickly pour it into a preheated mold, the mold temperature is controlled at 150 ° C, and anionic ring-opening polymerization is carried out at a reaction temperature of 150 ° C and a reaction time of 15 minutes to obtain P 4 VP / PA6 alloy 3; then use 200wt% ethanol to P 4 VP / PA6 alloy 3 was dissolved, and the solvent was naturally volatilized at room temperature to obtain polyamide microspheres, whose average particle size is shown in Table 1.

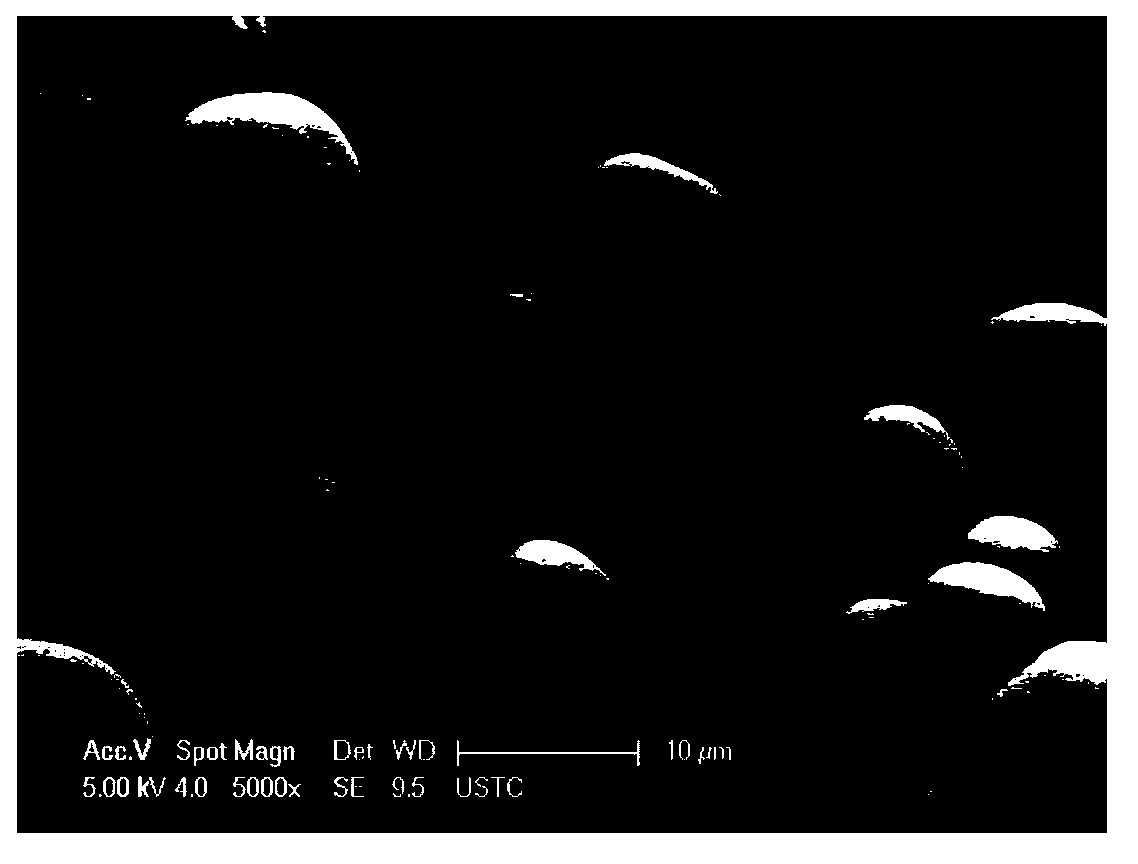

[0040] figure 1 It is the scanning electron microscope (SEM) image of the surface morphology of polyamide microspheres.

[0041] The test conditions of the scanni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com