A kind of method for producing chromium oxide green by sodium cycle

A technology of chromium oxide green and chromium oxide, applied in the direction of chromium trioxide, chromium oxide/hydrate, etc., can solve the problems of long production process, high cost, human health damage, etc., and achieve short production process and low production cost , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

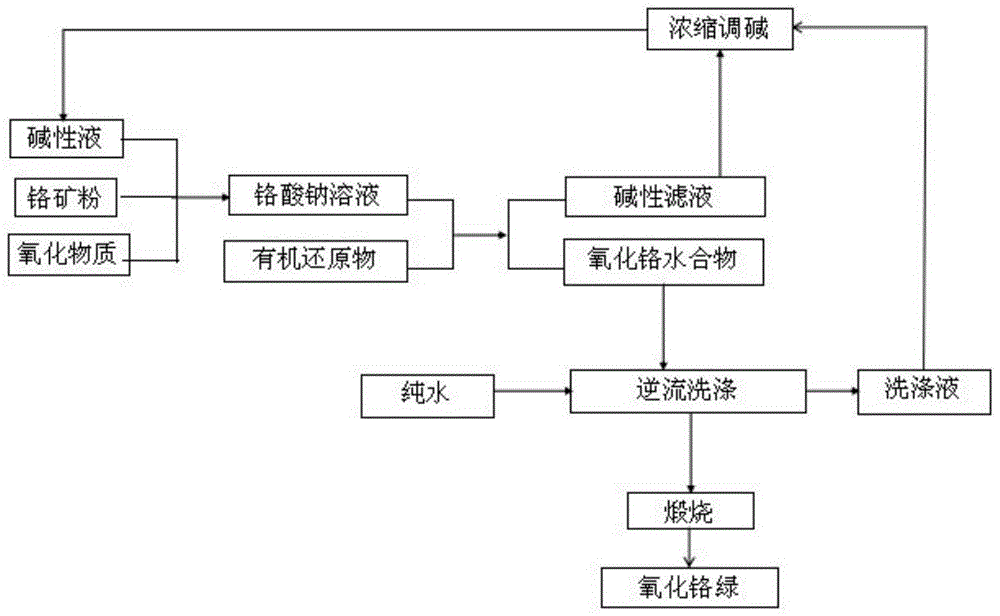

Method used

Image

Examples

Embodiment 1

[0030] Step 1, the chromite ore is ground to obtain chromite ore powder with a particle size less than 80um;

[0031] Step two, mix 2.50t chromite powder, 3.50t sodium hydroxide and 5.85m 3 Add water into the oxidation reaction kettle, feed oxygen, heat to 300°C and react for 3 hours, after the reaction is completed, cool down and separate to obtain sodium chromate alkaline liquid;

[0032] Step 3: Add 1.35t of starch to the sodium chromate alkaline solution, heat it to 193°C in a reducing kettle, keep it warm for hydrothermal reaction for 0.6 hours, cool down to 20°C, and separate by filtration to obtain chromium oxide hydrate and 4.71m 3 Alkaline filtrate, wherein the alkaline filtrate kind of Na + Ion concentration 16.56mol / L;

[0033] Step 4: Wash the chromium oxide hydrate countercurrently 5 times, and recover the washing solution; then calcinate the washed chromium oxide hydrate in a high-temperature furnace at 1000°C for 2 hours to obtain 0.96t of chromium oxide green...

Embodiment 2

[0036] Step 1, the chromite ore is ground to obtain chromite ore powder with a particle size less than 80um;

[0037] Step 2, after mixing the alkaline filtrate and washing liquid in Example 1 and adjusting the base, use it as alkaline solution, get 2.40t chromite powder, 3.65m 3 Alkaline solution (Na + ion concentration 23.63mol / L) into the oxidation reaction kettle, feed oxygen, heat to 275 ° C for 1 hour, after the reaction is completed, cool down and separate to obtain sodium chromate alkaline liquid;

[0038] Step 3: Add 1.28t of starch to the sodium chromate alkaline solution, heat it to 152°C in a reducing kettle, keep it warm for hydrothermal reaction for 1.8 hours, cool down to normal temperature, and separate by filtration to obtain chromium oxide hydrate and 2.92m 3 Alkaline filtrate, wherein the alkaline filtrate kind of Na + Ion concentration 28.56mol / L;

[0039] Step 4: Wash the chromium oxide hydrate countercurrently 5 times, and recover the washing solution;...

Embodiment 3

[0042] Step 1, ferrochromium is obtained through grinding ferrochrome powder with a particle size less than 80um;

[0043] Step 2, after mixing the alkaline filtrate and washing liquid in Example 2 to adjust the base, use it as an alkaline solution, get 1.85t ferrochrome powder, 5.32m 3 Alkaline solution (Na + ion concentration 7.35mol / L) into the oxidation reaction kettle, feed oxygen, heat to 285 ° C for 1.3 hours, after the reaction is completed, cool down and separate to obtain sodium chromate alkaline liquid;

[0044] Step 3: Add 1.86t of starch to the sodium chromate alkaline solution, heat it to 178°C in a reducing kettle, keep it warm for hydrothermal reaction for 1.2 hours, cool down to normal temperature, and separate by filtration to obtain chromium oxide hydrate and 4.78m 3 Alkaline filtrate, wherein the alkaline filtrate kind of Na + Ion concentration 8.08mol / L;

[0045] Step 4: Wash the chromium oxide hydrate countercurrently for 3 times, and recover the washi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com