Fine-grained polypiperazine phosphate flame retardant as well as preparation method and application thereof

A polyphosphoric acid, fine-grained technology, applied in the field of flame retardants, can solve the problems of reducing the mechanical properties or processing properties of flame-retardant polymer materials, piperazine polyphosphate cannot be directly used in flame-retardant polymer materials, and poor dispersibility, etc., to achieve Achieve the effect of solvent recycling, low cost and avoid yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

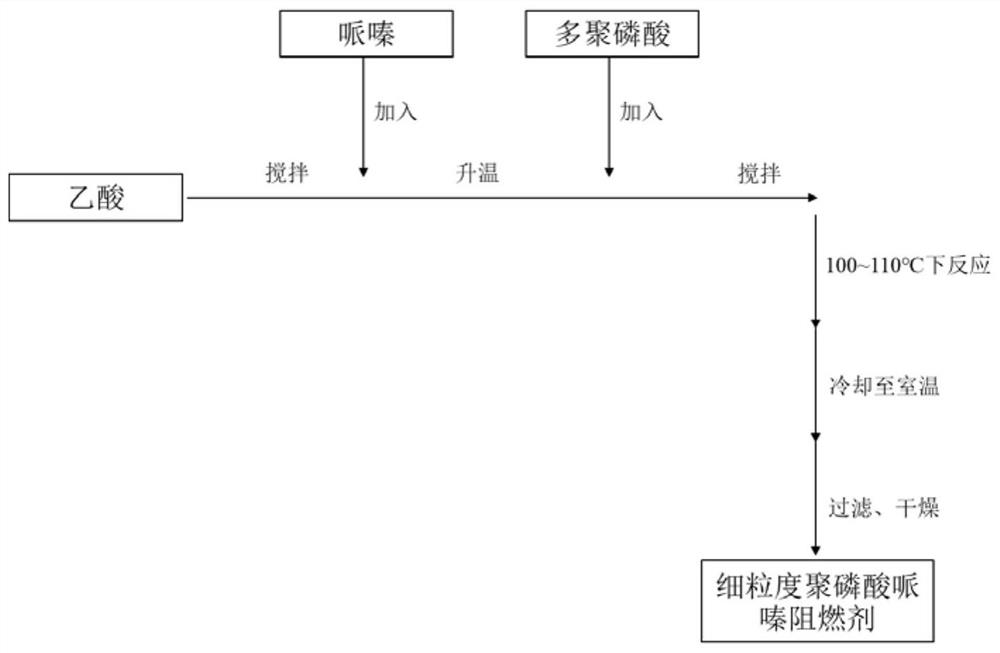

Method used

Image

Examples

Embodiment 1

[0040] Add 338g of acetic acid (industrial grade) and 22.5g of piperazine into a 500ml three-necked flask, raise the temperature to 80°C and add 59.0g of polyphosphoric acid, react at 100°C for 8 hours, stop heating, cool to room temperature, filter, and dry to obtain 67.3g fine-grained piperazine polyphosphate flame retardant, yield 82.5%.

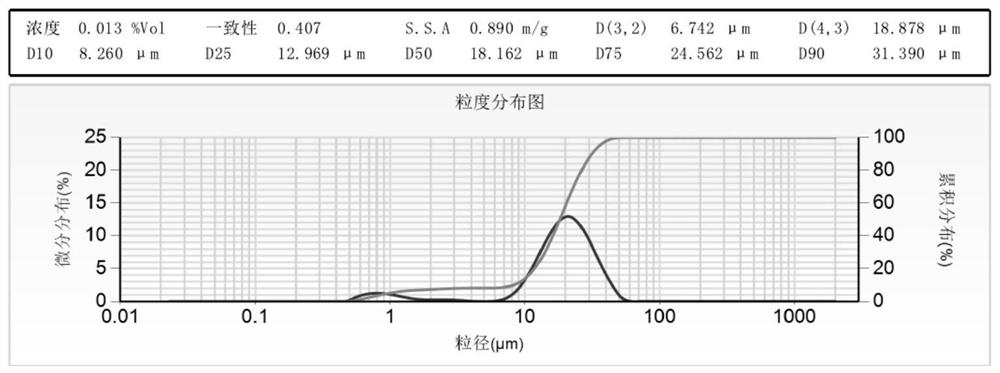

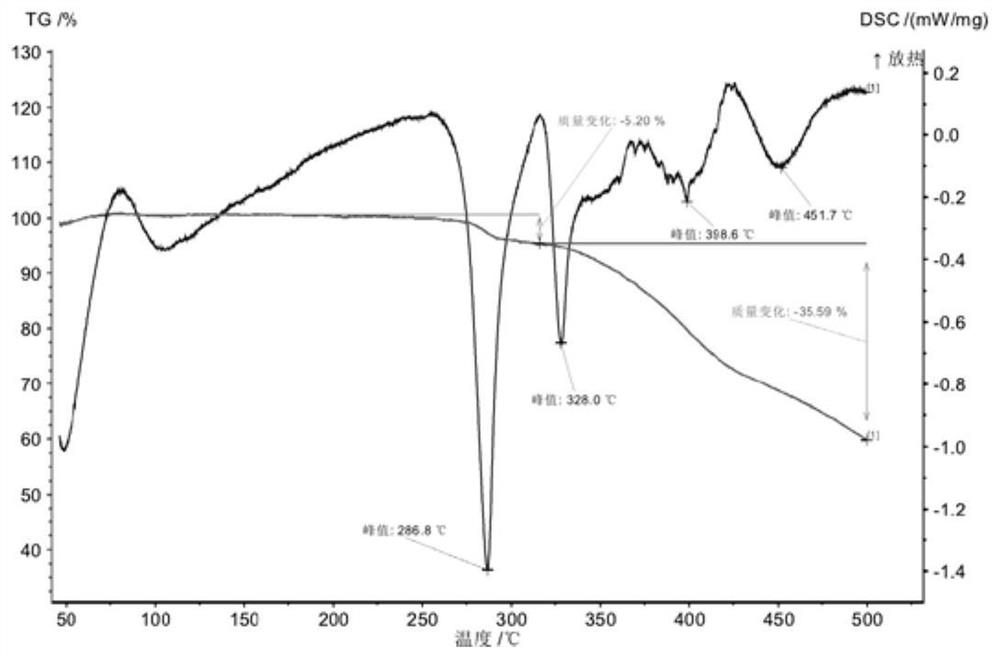

[0041] The particle size of the prepared fine-grained piperazine polyphosphate flame retardant was detected by a laser particle size analyzer. The test results are shown in Table 1. The product particle size D50 is 18.2 μm, and the particle size of the fine-grained piperazine polyphosphate flame retardant distributed as figure 2 Shown; its thermal decomposition temperature is as image 3 shown, from image 3 It can be concluded that the 5% initial decomposition temperature of the fine-grained piperazine polyphosphate flame retardant is higher than 300°C, and has good flame retardancy.

[0042] The whiteness of the prepared fine-graine...

Embodiment 2

[0046] Add 155g of recovered acetic acid filtrate and 25.75g of piperazine to a 500ml three-necked flask, heat up to 70°C and add 25.30g of polyphosphoric acid, react at 105°C for 6 hours, stop heating, cool to room temperature, filter, and dry to obtain 47.1g Fine-grained piperazine polyphosphate flame retardant with a yield of 92.3%.

[0047] The particle size of the prepared fine-grained piperazine polyphosphate flame retardant was detected by a laser particle size analyzer. The test results are shown in Table 2. The product particle size D50 is 17.7 μm, and the particle size of the fine-grained piperazine polyphosphate flame retardant distributed as Figure 4 Shown; its thermal decomposition temperature is as Figure 5 shown, from Figure 5 It can be concluded that the 5% initial decomposition temperature of the fine-grained piperazine polyphosphate flame retardant is higher than 300°C, and has good flame retardancy.

[0048] The whiteness of the prepared fine-grained p...

Embodiment 3

[0052]Add 230g of acetic acid (industrial grade) and 22.6g of piperazine into a 500ml three-necked flask, raise the temperature to 77°C and add 34.7g of polyphosphoric acid, react the resulting mixture at 110°C for 4 hours, stop heating, cool to room temperature, filter, and dry to obtain 48.7g fine-grained piperazine polyphosphate flame retardant, yield 85.0%.

[0053] The particle size of the prepared fine-grained piperazine polyphosphate flame retardant was detected by a laser particle size analyzer. The test results are shown in Table 3. The product particle size D50 is 13.2 μm, and the particle size of the fine-grained piperazine polyphosphate flame retardant distributed as Figure 6 Shown; its thermal decomposition temperature is as Figure 7 shown, from Figure 7 It can be concluded that the 5% initial decomposition temperature of the fine-grained piperazine polyphosphate flame retardant is higher than 300°C, and has good flame retardancy.

[0054] The whiteness of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Solution temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com