Method for preparing high-purity gamma-Fe2O3 iron oxide red pigment

A technology of iron oxide red and -fe2o3, applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of excessive washing water, high water content, and difficult industrial operation, and achieve the effect of excellent products and strong magnetic functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

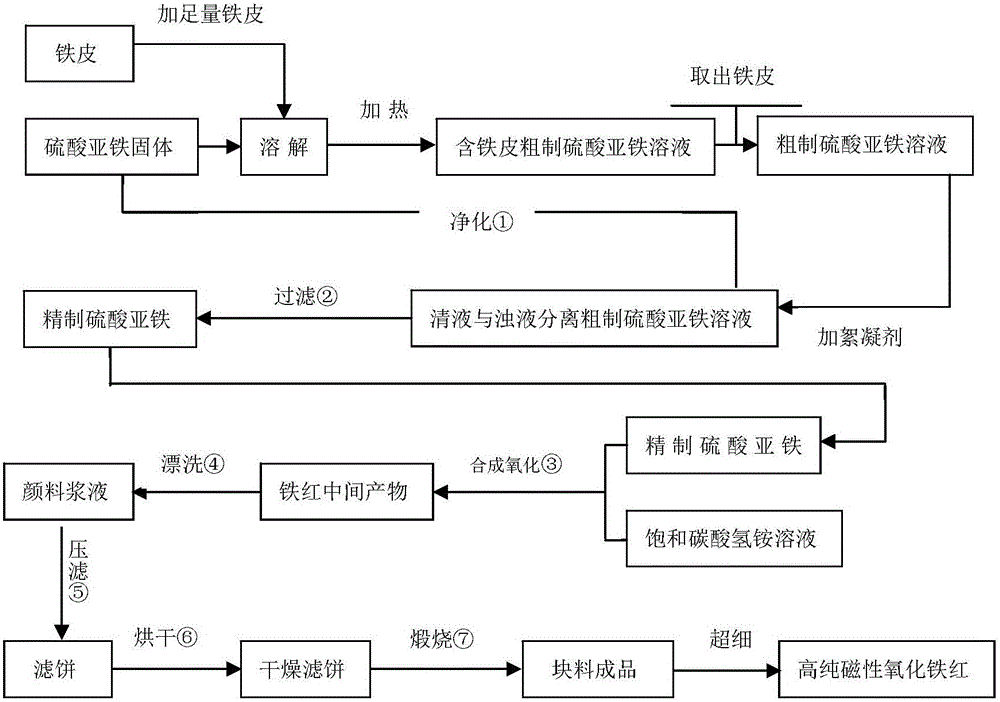

Method used

Image

Examples

Embodiment Construction

[0023] Take 40kg titanium dioxide by-product FeSO 4 Dissolve the solid in 60kg of water to make a ferrous sulfate solution, put enough iron sheet in the ferrous sulfate solution, put steam into the ferrous sulfate solution, control the temperature at 80°C, and control the pH at about 5, Take out the liquid and put it into the storage tank, and add a flocculant with a mass of 1 / 100 of the liquid mass into the storage tank, let it stand for 48 hours, and take out the clarified liquid.

[0024] Add 104 liters of ferrous sulfate with a concentration of 37.5% to the reaction barrel, heat the ferrous sulfate with air, control the temperature between 60°C, turn on the stirring, and turn on the air to control the air flow at 2.1m3 / h. Slowly add the ammonium bicarbonate solution with a prepared concentration of 14.3% into the reaction barrel, and measure the pH of the reactants in the barrel and the remaining ferrous sulfate content in about half an hour after adding the ammonium bica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com