Preparation method of yttrium oxide with central grain size being 20-50 microns

A central particle size, yttrium oxide technology, applied in chemical instruments and methods, rare earth metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of excessive ammonia nitrogen, not meeting wastewater discharge standards, etc., and achieve high bulk density. , Easy to filter and wash, easy to handle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

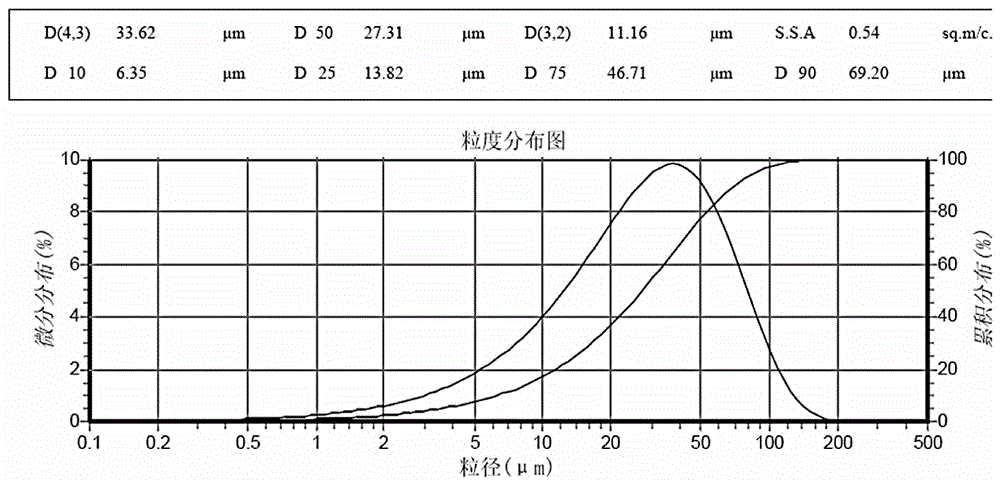

Embodiment 1

[0021] Add 30L of deionized water into the enamel pot, the temperature is 35°C, and start stirring. The concentration of yttrium chloride solution is 50g / L, the acidity is 3mol / L, and the concentration of oxalic acid solution is 117g / L. Add the yttrium chloride solution and the oxalic acid solution to the precipitation pot at a mass ratio of 1:1.8. After the addition, add oxalic acid to make the mass ratio reach 1:2.5. After the reaction was complete, stir for 10 minutes. Turn on the steam for heating, the temperature is controlled at 95-100°C, and stop heating when the acidity at the end point reaches 6.8mol / L. discharge. Wash 6-10 times with deionized water and drain. Incubate at 1000°C for 3 hours. to obtain yttrium oxide. Center particle size D 50 =27.31 microns, bulk density is 1.32g / cm 3 , the specific surface area is 26070 cm 2 / g, the total amount of rare earth is 99.02%, impurity content: Fe 2 o 3 is less than 2ppm, SiO 2 is less than 10ppm, and CaO is 8ppm...

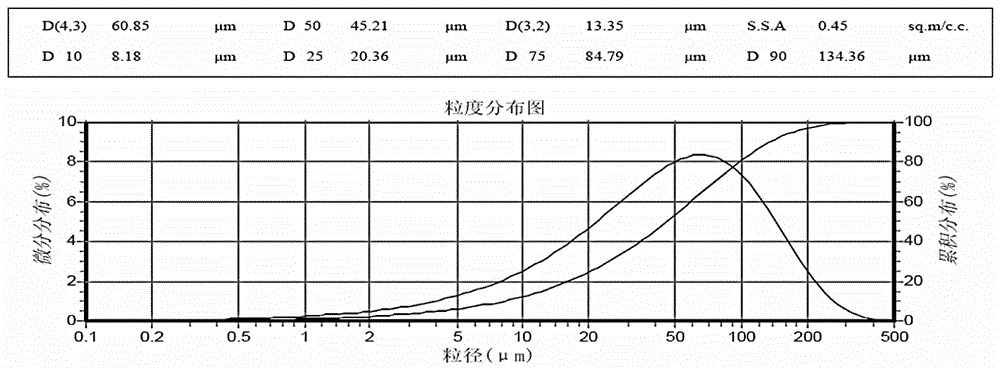

Embodiment 2

[0023] Add 40L of deionized water into the enamel pot, the temperature is 45°C, and start stirring. The concentration of yttrium chloride solution is 62g / L, the acidity is 3.5mol / L, and the concentration of oxalic acid solution is 108g / L. Add the yttrium chloride solution and the oxalic acid solution to the precipitation pot at a mass ratio of 1:2. After the addition, add oxalic acid to make the mass ratio reach 1:2.5. After the reaction was complete, stir for 10 minutes. Turn on the steam for heating, the temperature is controlled at 95-100°C, and stop heating when the acidity at the end point reaches 8mol / L. discharge. Wash 6-10 times with deionized water and drain. Incubate at 1000°C for 4 hours. to obtain yttrium oxide. Center particle size D 50 =45.21 microns, bulk density is 1.42g / cm 3 , with a specific surface area of 20000 cm 2 / g, the total amount of rare earth is 99.15%, impurity content: Fe 2 o 3 is less than 2ppm, SiO 2 is less than 10ppm, CaO is 10ppm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com