Cefixime side chain acid crystal form and preparation method thereof

A technology of cefixime side chain acid and crystal form, which is applied in the field of cefixime side chain acid crystal form and its preparation, can solve problems such as poor stability of cefixime side chain acid, achieve uniform primary particle size distribution, and process operation Simple and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

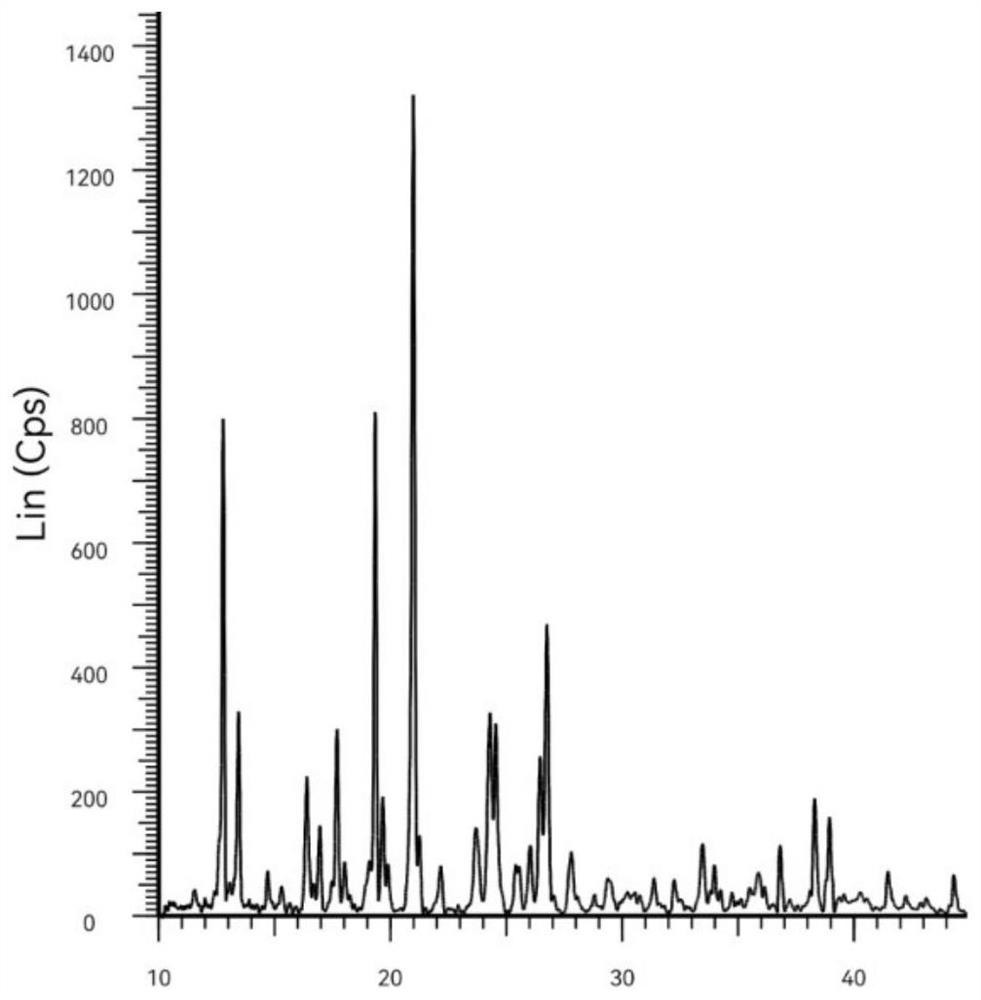

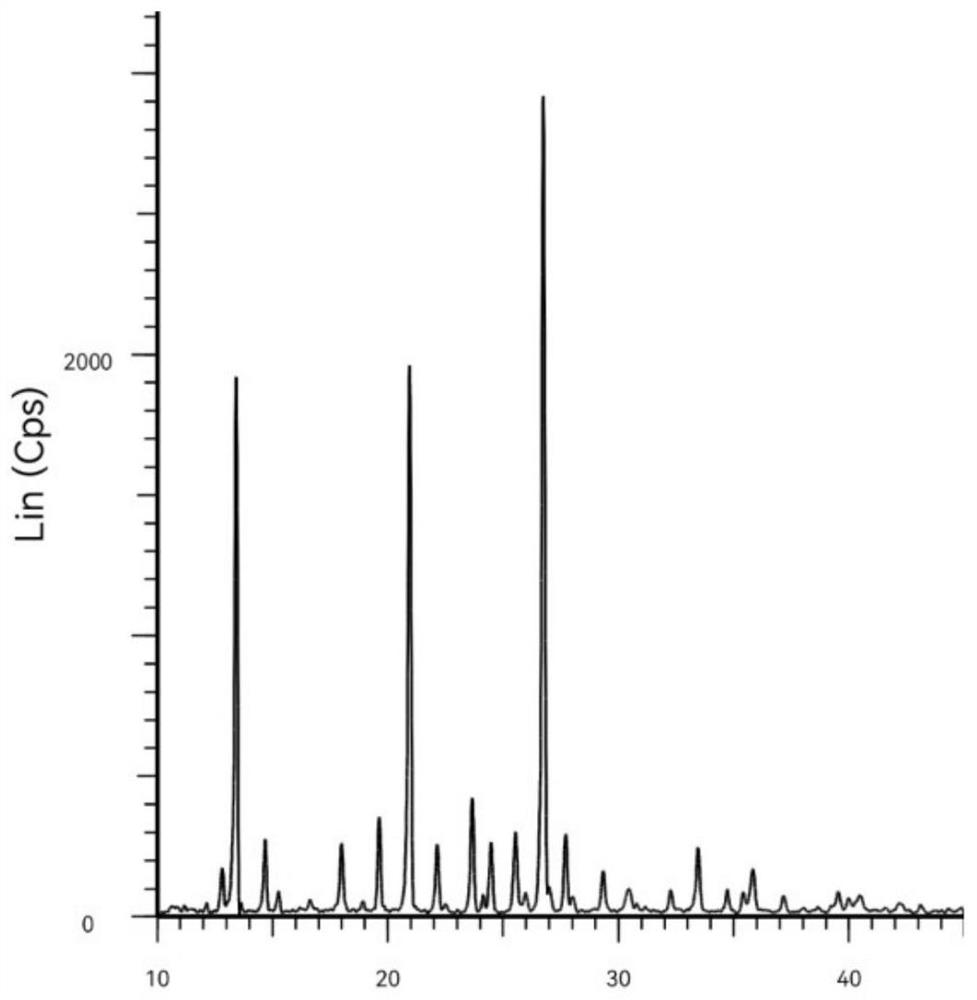

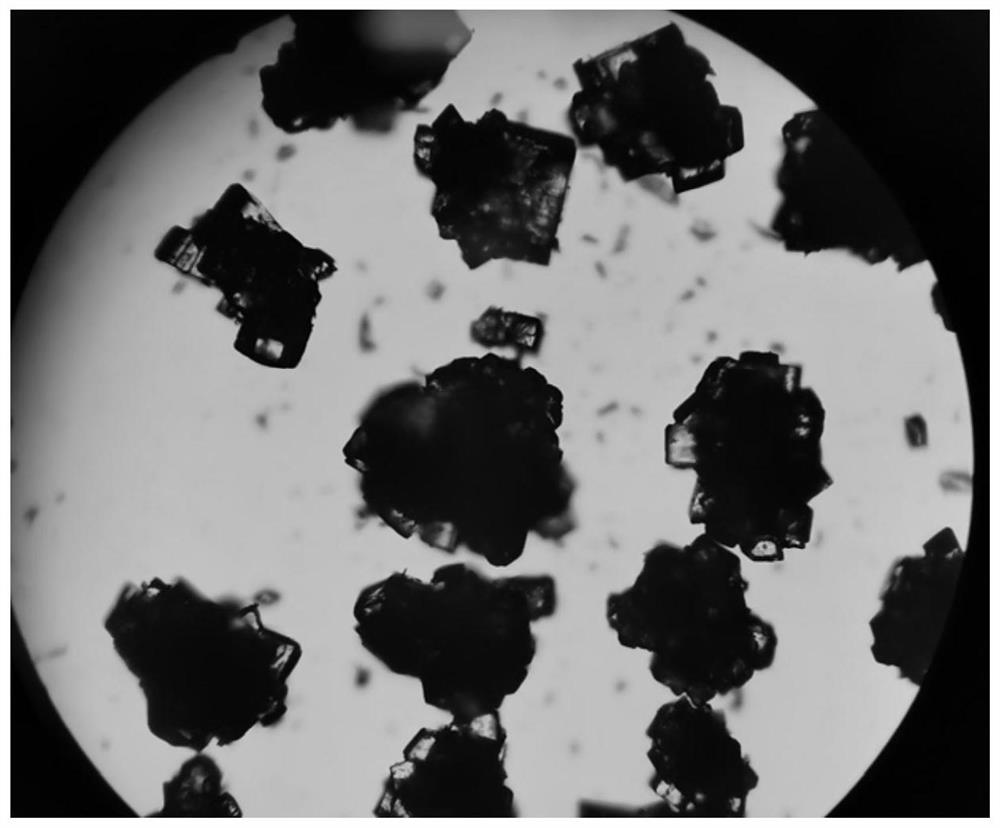

[0026] Dissolve 16g of cefixime side-chain acid in 800ml of 20wt.% methanol aqueous solution in a 1000ml silk bottle; ultrasonically treat for 80min at 40°C with an ultrasonic frequency of 60KHz, filter after dissolving; put the resulting filtrate into a jacket The temperature in the kettle was slowly lowered to -8°C in 120 minutes, the pressure in the jacketed kettle was -0.03MPa, and the crystallization was carried out at a stirring speed of 40r / min. After the crystals were precipitated, the crystallization was carried out for 120 minutes; when the system was obviously turbid, the stirring Slowly increase the speed to 150r / min, maintain the temperature at -8~-10°C, and continue to grow the crystal for 150min; filter and wash the filter cake with a solvent of 20wt.% methanol aqueous solution; then put the filter cake at a temperature of 40°C and a vacuum of 0.1MPa Under vacuum drying 120min, obtain white granular cefixime side-chain acid crystal 14.06g, yield is 87.87%, and HP...

Embodiment 2

[0031] Dissolve 13g of cefixime side-chain acid in 800ml of 40wt.% methanol aqueous solution in a 1000ml silk bottle, ultrasonically treat for 90min at 39°C, the ultrasonic frequency is 90KHz, filter after dissolving; put the gained filtrate into the jacket Slowly lower the temperature in the kettle to -7°C in 130min, the pressure in the jacketed kettle is -0.04MPa, and crystallize at a stirring speed of 50r / min. After the crystals are precipitated, crystallize for 120min; when the system is obviously turbid, stir Slowly increase the speed to 130r / min, maintain the temperature at -8~-10°C, and continue to grow the crystal for 180min; filter and wash the filter cake with a solvent of 40wt.% methanol aqueous solution; then put the filter cake at a temperature of 40°C and a vacuum of 0.08MPa Drying under vacuum for 120 min gave 11.08 g of white granular cefixime side-chain acid crystals with a yield of 85.23% and an HPLC purity of 99.85%, which was detected as crystal form B by X-...

Embodiment 3

[0033] Dissolve 15g of cefixime side-chain acid in 800ml of 60wt.% methanol aqueous solution in a 1000ml silk bottle, ultrasonically treat for 150min at 40°C, the ultrasonic frequency is 80KHz, filter after dissolving; put the obtained filtrate into the jacket The temperature in the kettle was slowly lowered to -10°C in 150 minutes, the pressure in the jacketed kettle was -0.03MPa, and the crystallization was carried out at a stirring speed of 50r / min. After the crystals were precipitated, the crystallization was carried out for 150 minutes; Slowly increase the speed to 150r / min, maintain the temperature at -8~-10°C, and continue to grow the crystal for 180min; filter and wash the filter cake with a solvent of 60wt.% methanol aqueous solution; then put the filter cake at a temperature of 40°C and a vacuum of 0.09MPa Dry under vacuum for 90 minutes to obtain 12.97 g of white granular cefixime side-chain acid crystals with a yield of 86.47% and an HPLC purity of 99.87%, which was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com