Low-consumption environment-friendly biochar production equipment

A production equipment and environment-friendly technology, applied in the fields of biofuels, carbonization furnaces, special forms of dry distillation, etc., can solve the problems of incomplete carbonization, single processing materials, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings. The exhaust gas purification device used in this example is a self-developed product and the induced draft fan is a commercially available product.

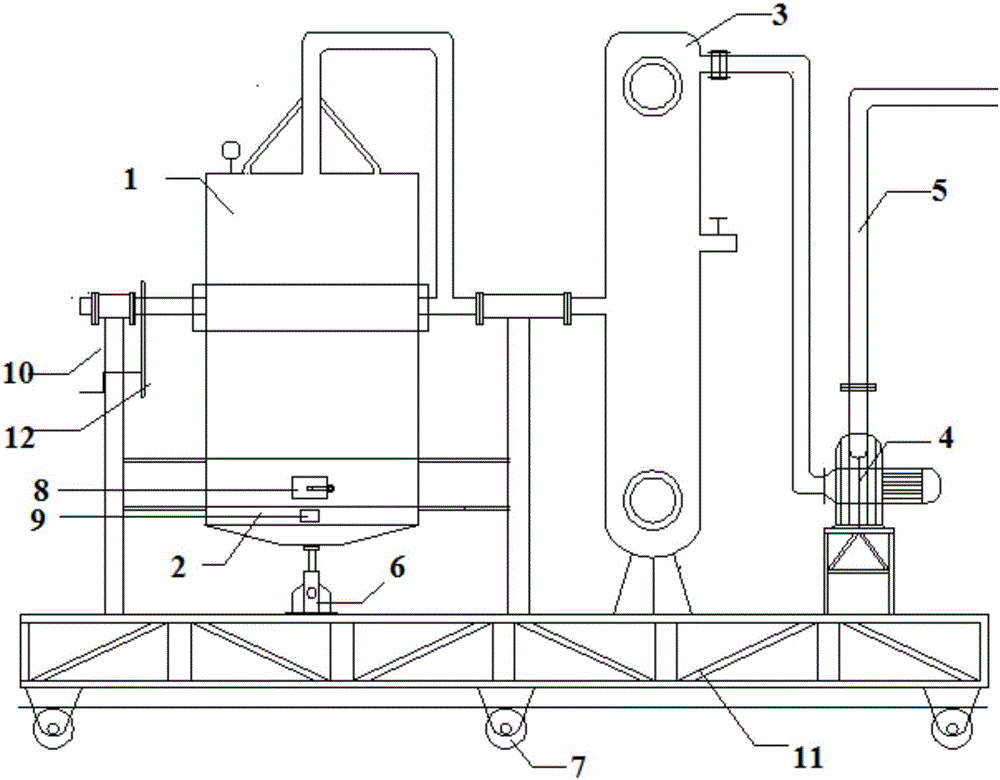

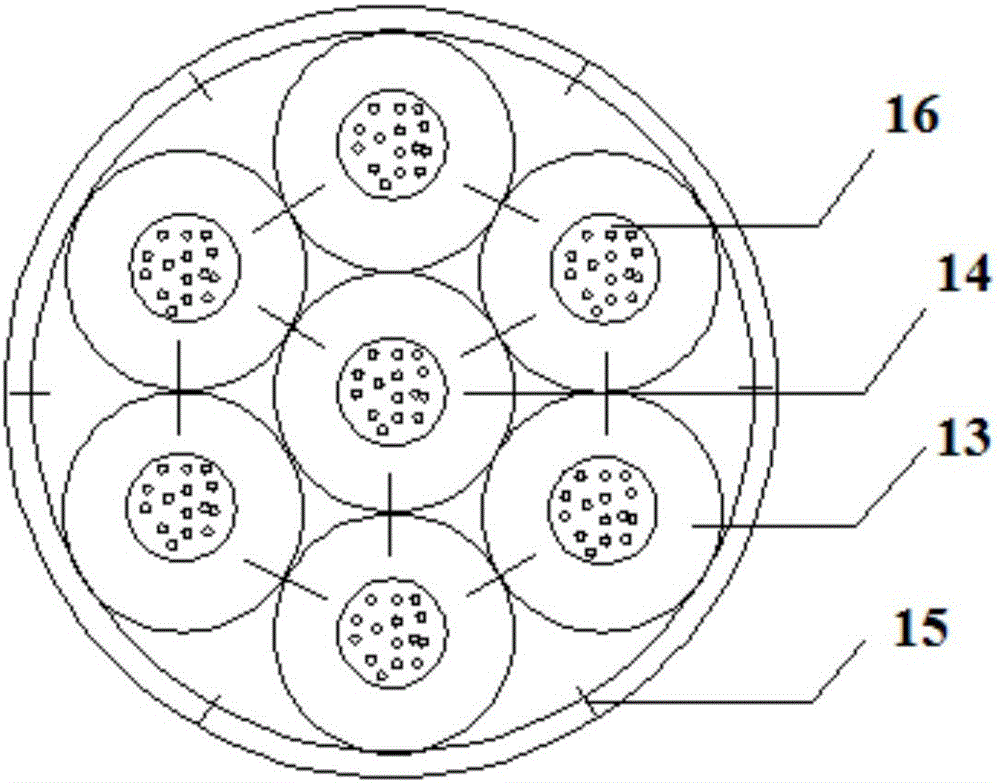

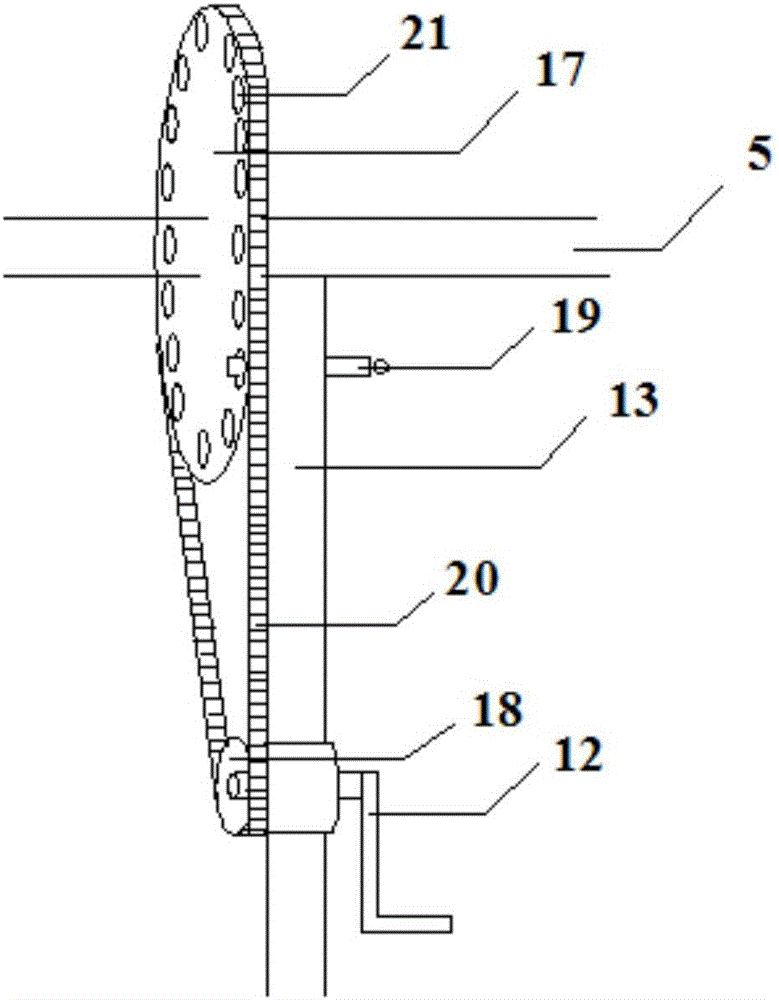

[0024] A low-consumption and environment-friendly biochar production equipment, which consists of a carbonization chamber 1, a combustion chamber 2, an exhaust gas purification device 3, an induced draft fan 4, an exhaust pipe 5, a combustion chamber bracket 6, a universal wheel 7, and a carbonization furnace support 10, Rotary handle 12, base 11 etc. are formed. The carbonization chamber 1 is placed on the combustion chamber 3, the combustion chamber 3 is supported by the combustion chamber bracket 6, the carbonization chamber 1 is fixed to the carbonization chamber support 10 by the pipe in the beam, and is supported by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com