Wall-mounted air intake fan

A kind of air inlet and wall-mounted technology, which is applied in heating mode, ventilation system, mechanical equipment, etc. It can solve the problems of closed structure, easy cleaning and replacement, and unsatisfactory noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

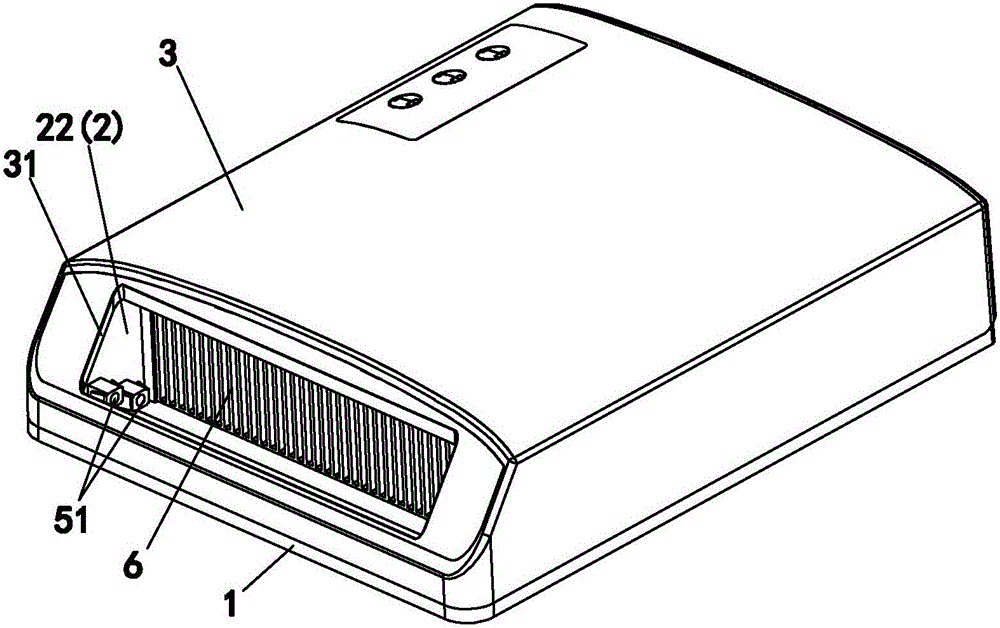

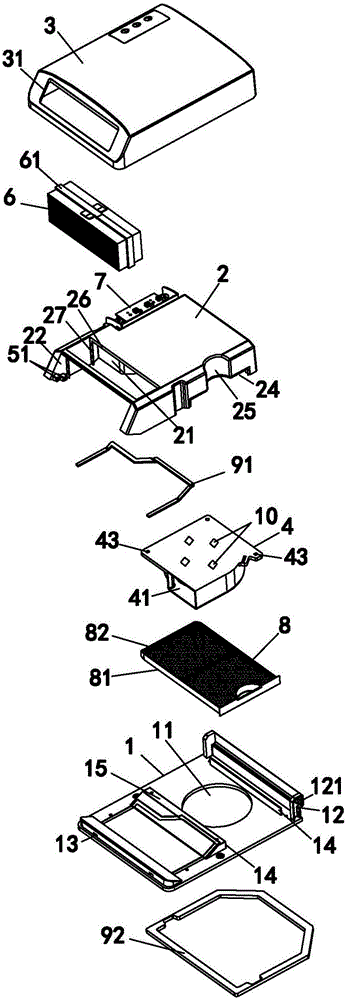

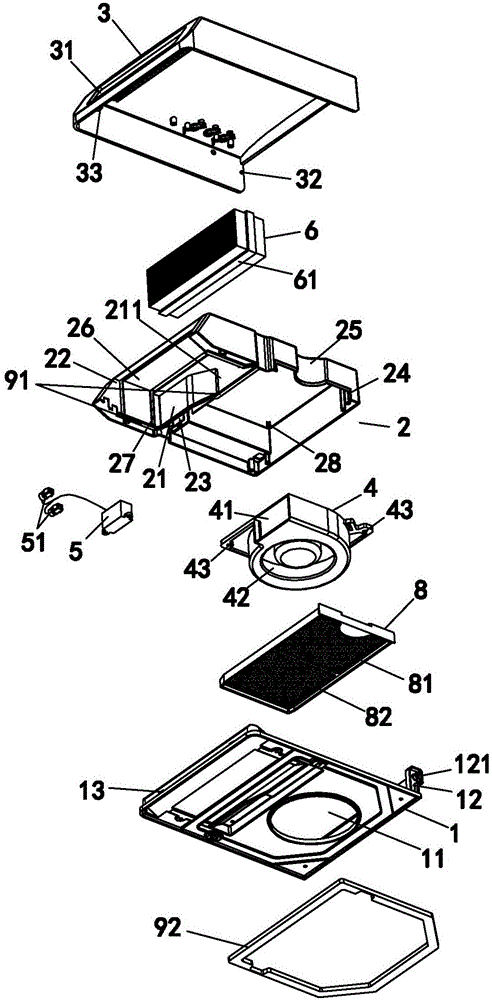

[0030] A wall-mounted air intake fan disclosed by the present invention includes a mounting base 1, an inner casing 2, an outer casing 3, an exhaust fan 4, an anion generator 5, an air outlet filter 6 and a control module 7; figure 1 , figure 2 and image 3 The shown details describe the positional connection relationship between the components.

[0031] As shown in the figure, the exhaust fan 4, the negative ion generator 5 and the air outlet filter 6 are arranged on the inner casing 2, and the inner casing 2 is provided with a partition 21, and the partition 21 divides the interior The casing 2 is divided into two areas respectively provided with an exhaust fan 3 and an air outlet filter 6, and the partition 21 is provided with a connecting port 211 for connecting with the air outlet 41 of the exhaust fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com