Electromagnetic valve

A solenoid valve and valve body technology, applied in the field of solenoid valves, can solve problems such as increasing the leakage rate of equipment systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

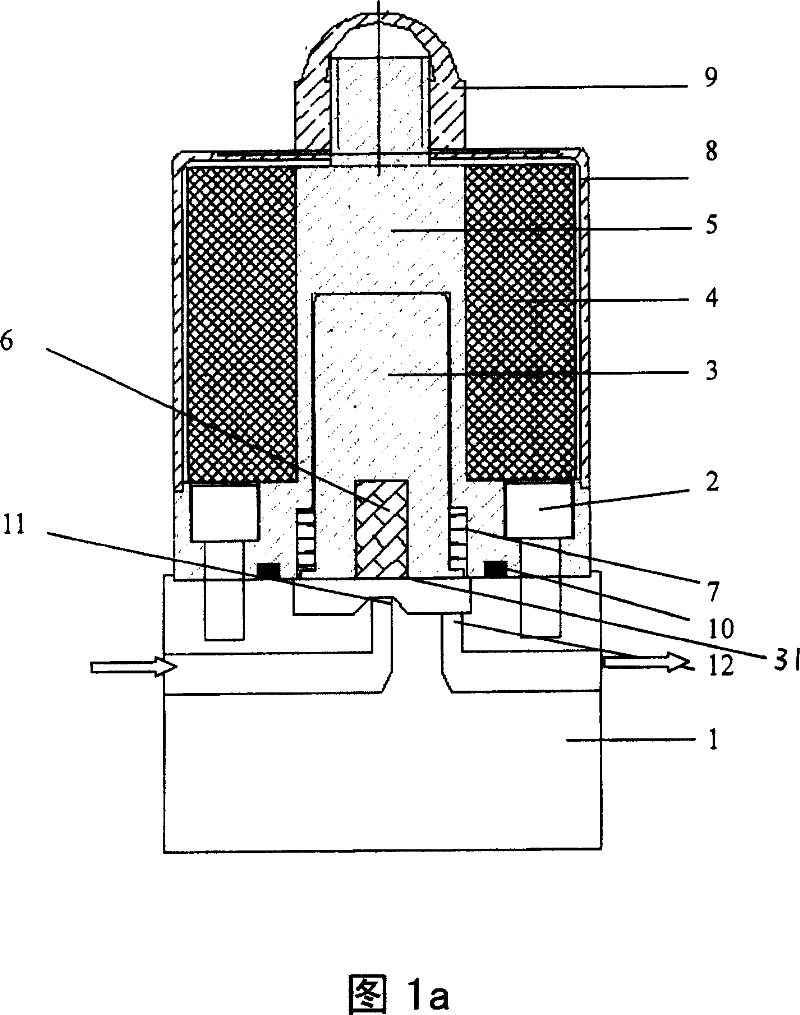

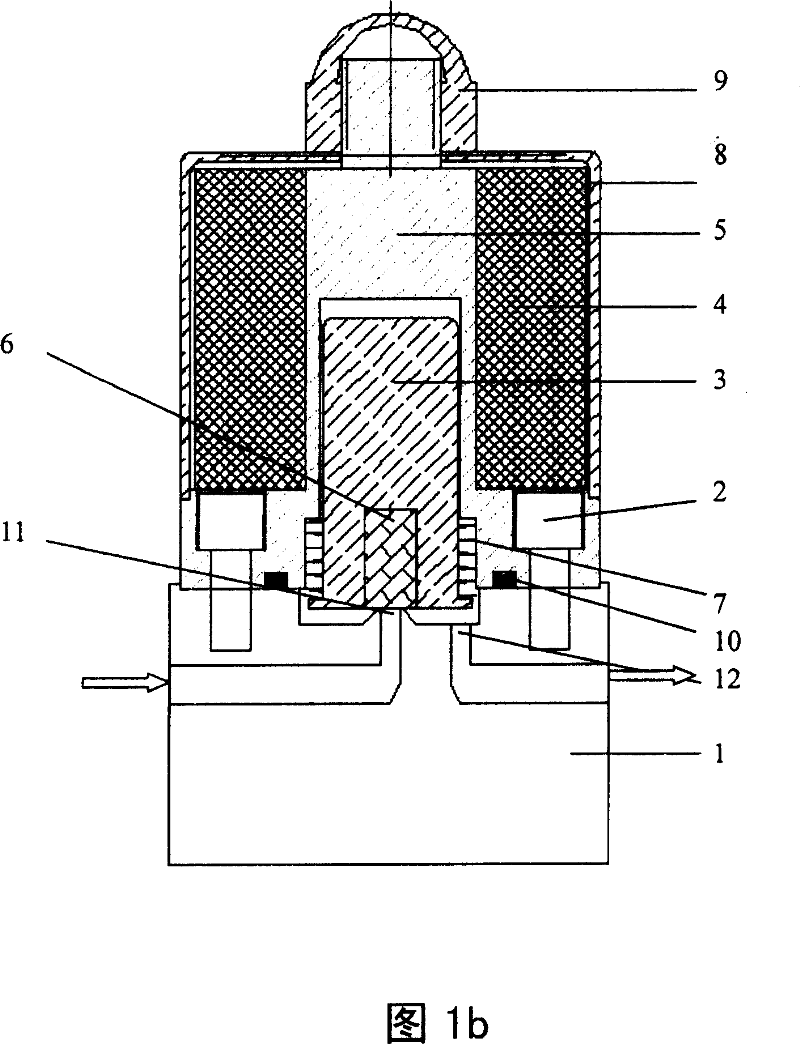

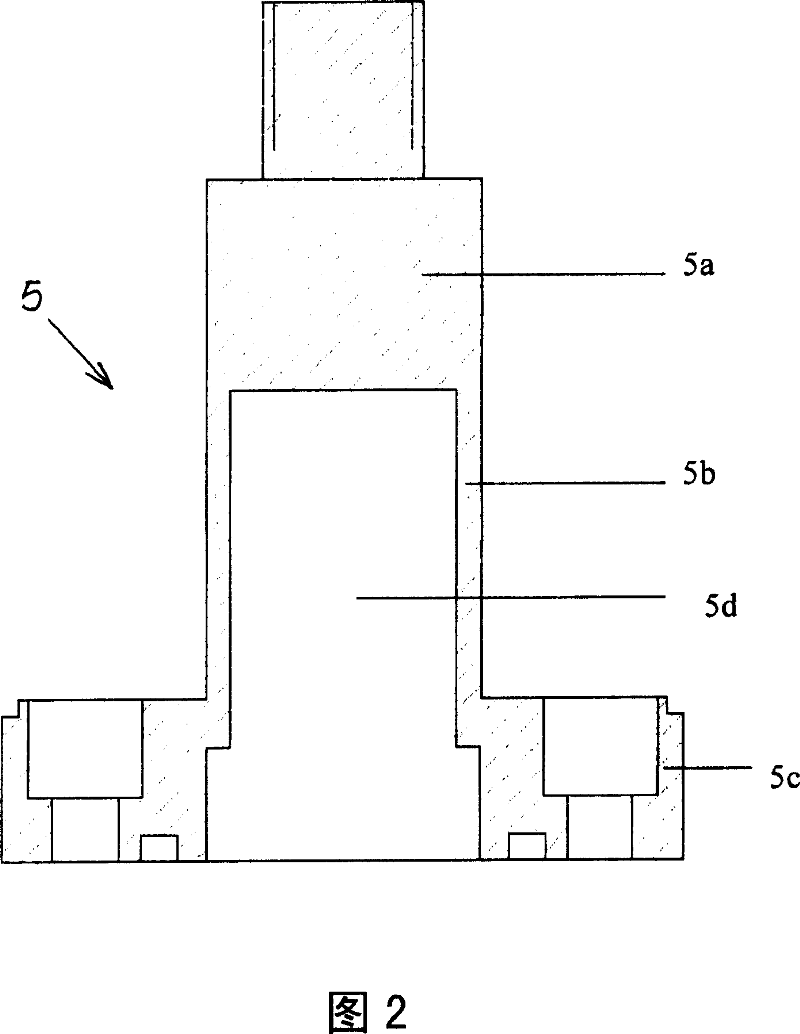

[0048] The solenoid valve of the present invention mainly includes a magnetic valve casing 8, a non-magnetic stainless steel valve seat 1, a stainless steel valve body 5, a magnetic stainless steel valve core 3, an electromagnetic coil 4, a spring 7 and a fluorine rubber strip 6, etc., and its structure is shown in Figure 1a and Figure 1. 1b, wherein Figure 1a is the valve open state, and Figure 1b is the valve closed state. The stainless steel valve body 5 is connected with the non-magnetic stainless steel valve seat 1 with stainless steel screws 2 and sealed with a sealing ring 10 . The upper half 5a and the lower half 5c of the stainless steel valve body 5 are made of magnetic stainless steel, the middle part 5b is made of non-magnetic stainless steel, the uppermost part of the stainless steel valve body 5 is threaded, and a stainless steel nut is used between the shell 8 9. Tighten it so that the magnetic path can be better formed when the electricity is turned on. There i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com