U-shaped ball valve for slurry mixing and ash discharging

A U-shaped, slurry mixing technology, applied to valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as valve damage and failure, particle inclusion, long-term erosion, etc., to achieve low operating failure rate, improve service life, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

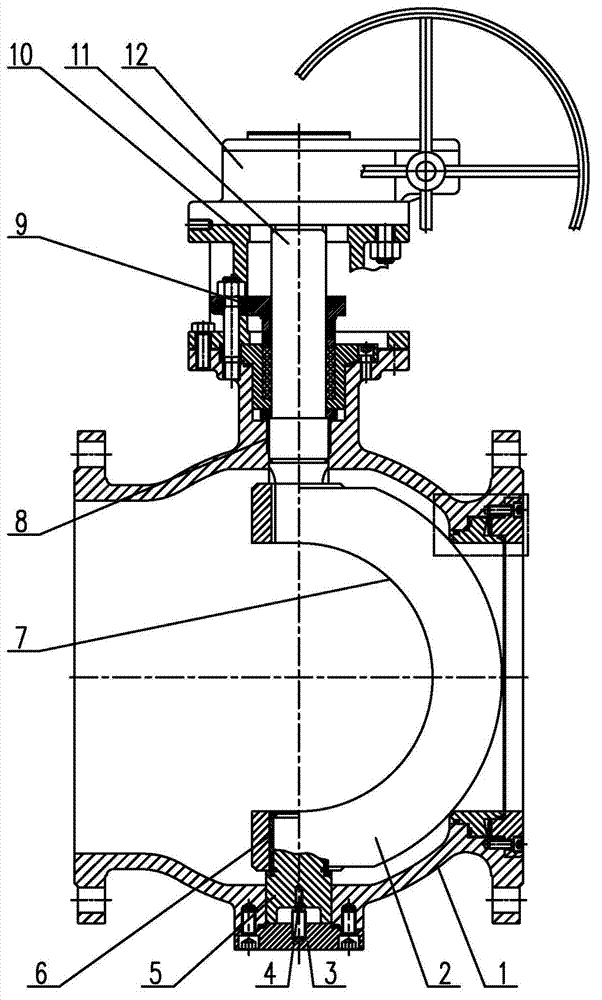

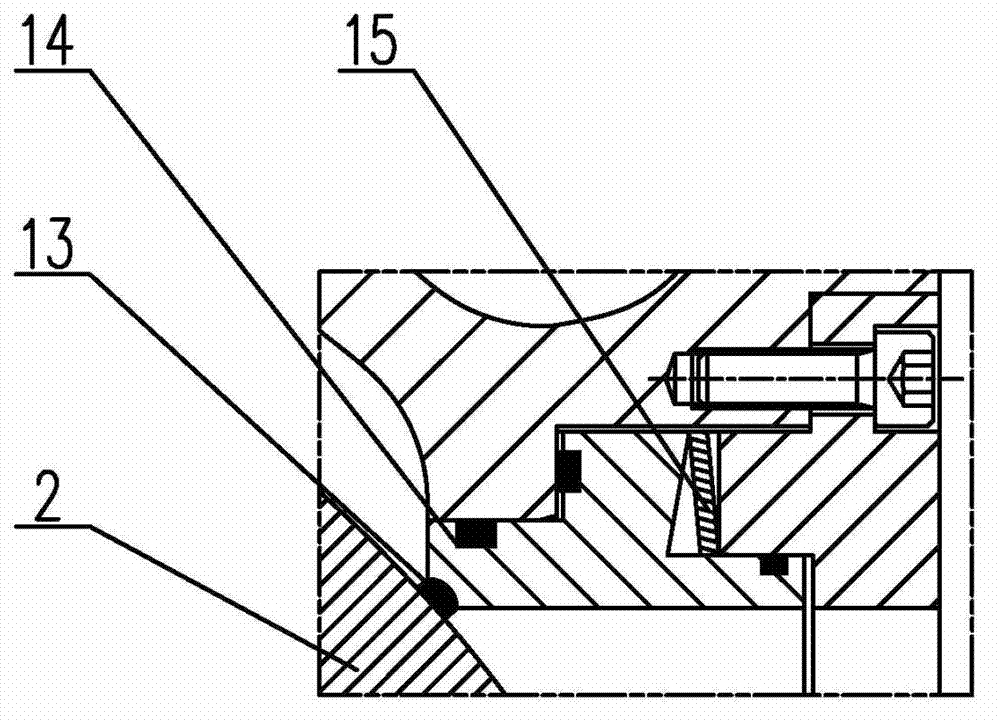

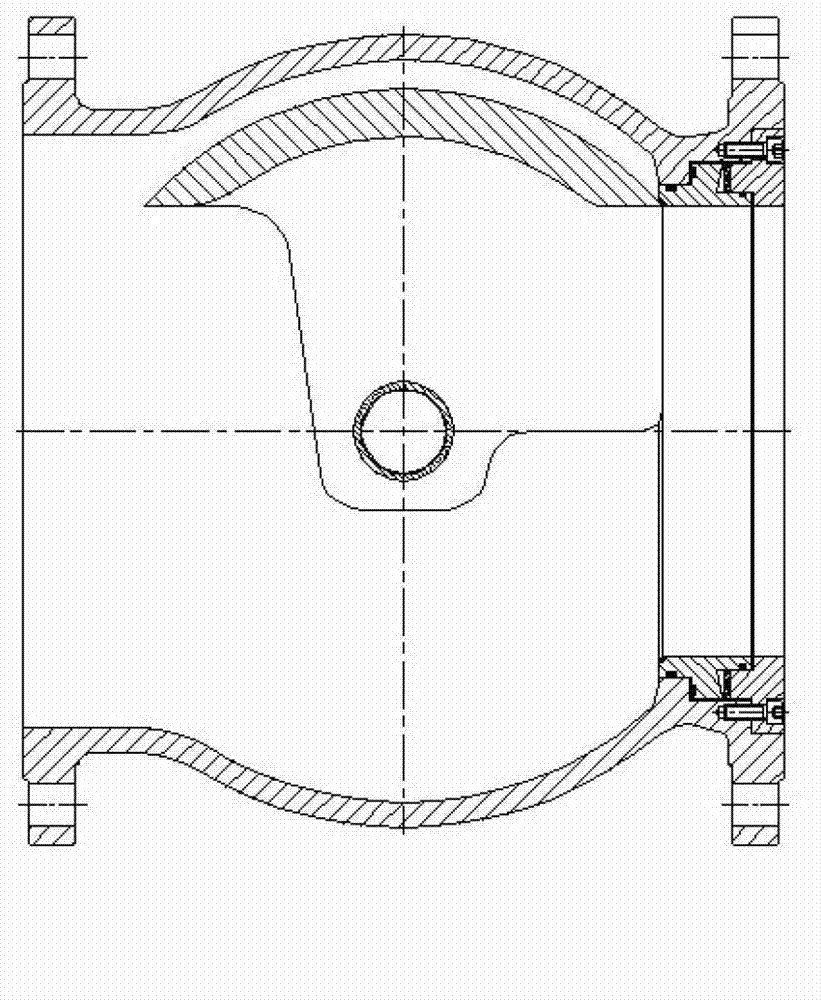

[0011] A U-shaped ball valve for slurry mixing and ash unloading, such as figure 1 As shown, it includes a valve body 1, a sphere 2, and a lower end cover 3. The lower end of the valve body 1 is provided with a lower end cover 3, and the lower end cover 3 is connected with the lower fixed shaft 5 through the adjusting screw 4; the lower fixed shaft 5 passes through the lower shaft sleeve 6 is movably connected with the rotating shaft at the bottom of the ball 2; the rotating shaft at the top of the ball 2 is connected with the bottom end of the valve stem 11 through the upper bushing 8; 12 is set on the bracket 10, and the bottom of the bracket 10 is connected to the top of the valve body 1 through the packing system structure 9; in the actual implementation process of the patent, the valve can complete stable and reliable opening and closing actions driven by the actuator 12, realizing Pipeline connection and disconnection. The valve is completely designed for working condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com