Pneumatic executor for driving valve

A pneumatic actuator and valve-driving technology, which is applied in the direction of valve operation/release devices, valve details, valve devices, etc., can solve the problems of the influence of air supply resistance, fast execution speed, and impossible proportional amplification, etc., and achieve the improvement of action speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

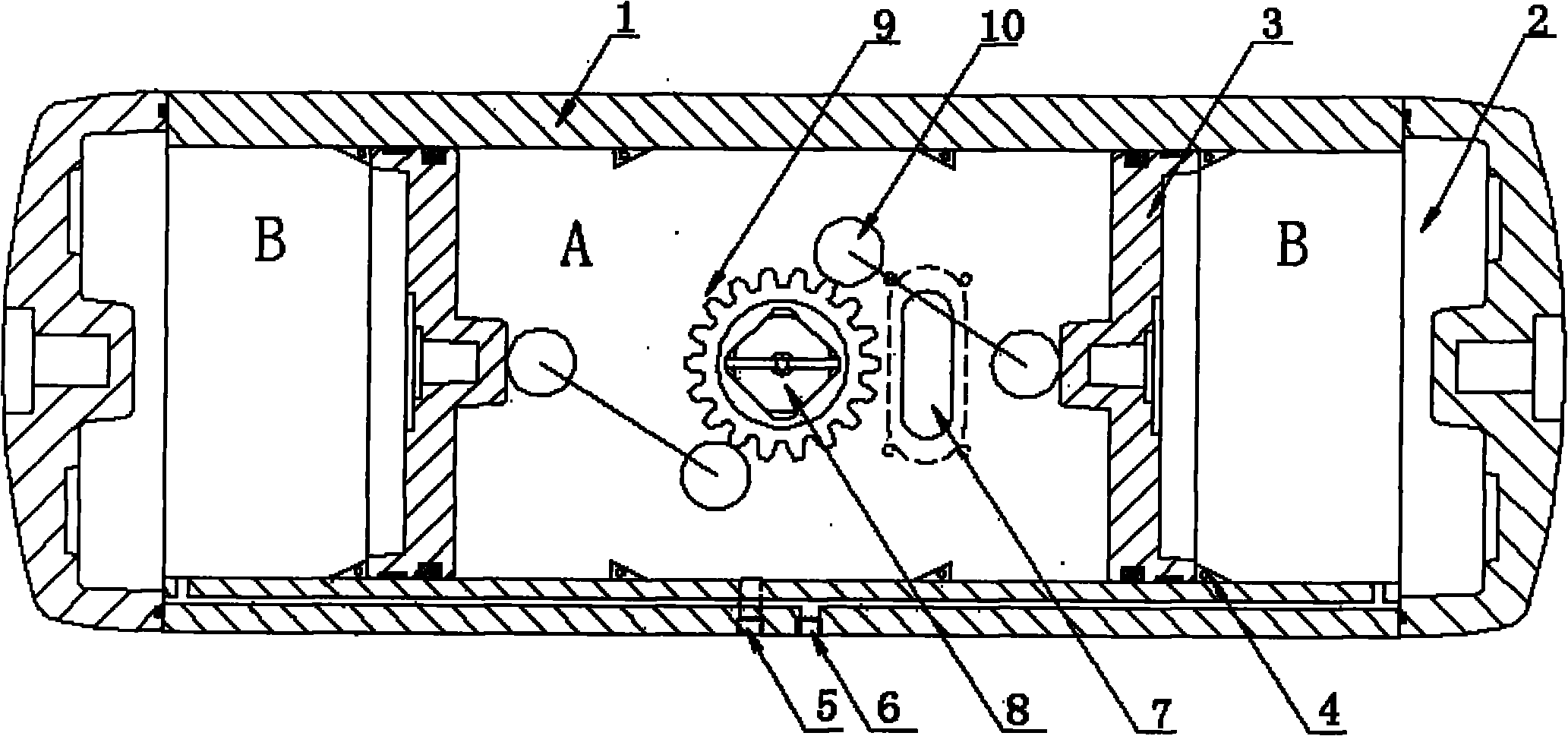

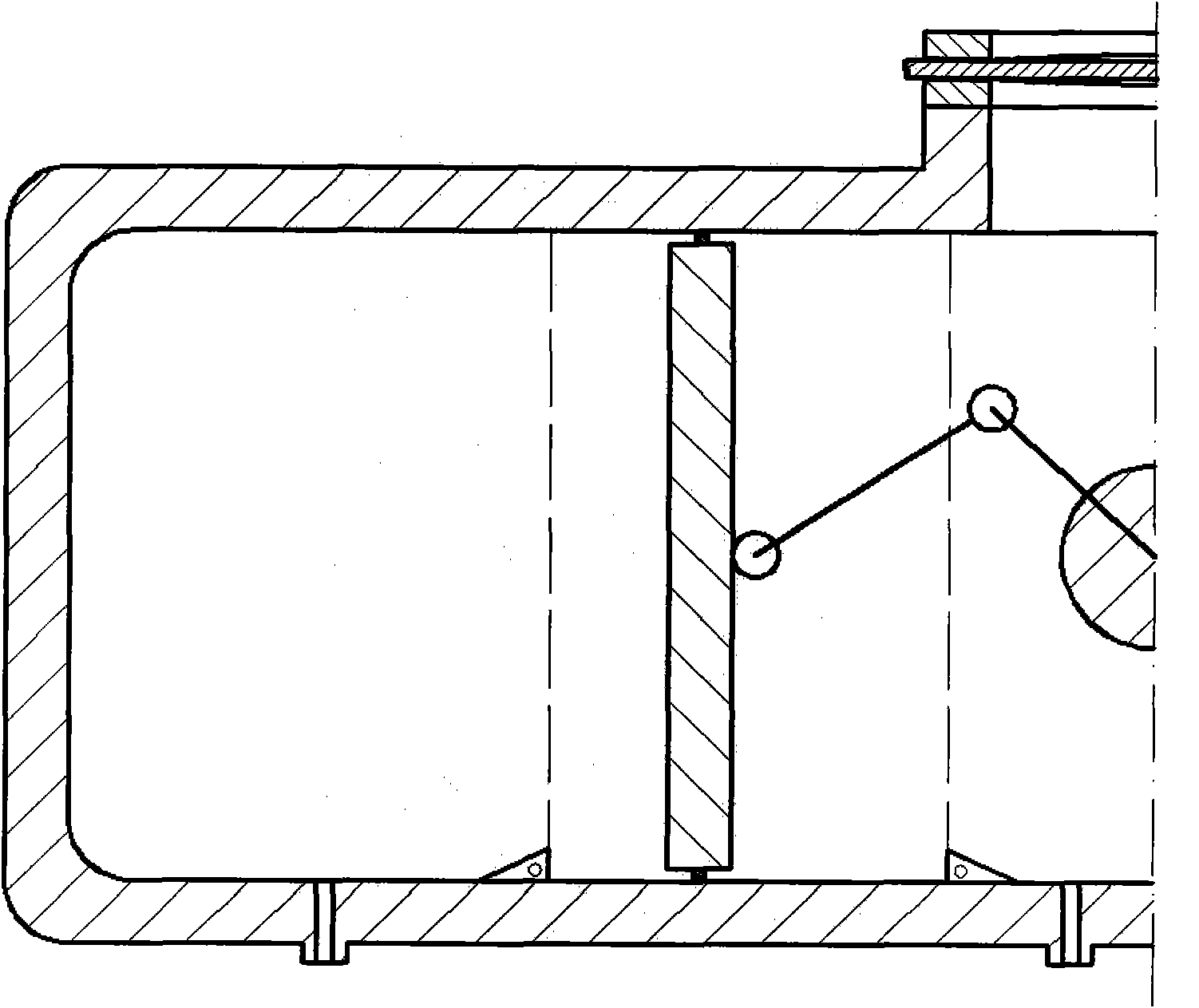

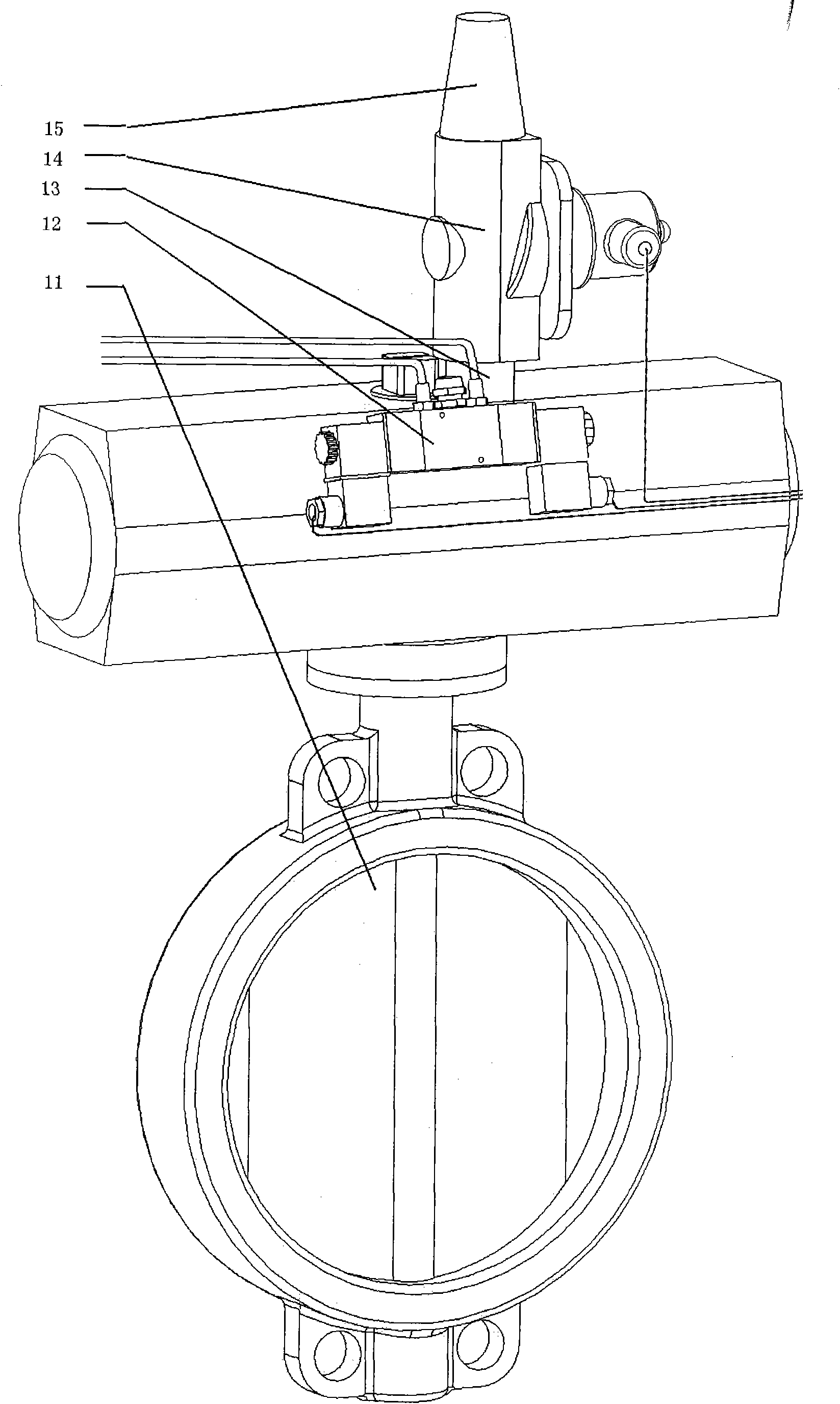

[0018] Such as figure 1 , figure 2 As shown, the present invention includes a cylinder block 1, the two ends of the cylinder block 1 are respectively fixedly connected with a sealing end cover 2, two pistons 3 and corresponding limit mechanisms 4 are arranged in the cylinder block 1, and the two pistons 3 connect the cylinder block 1 Divided into an inner chamber A and two outer chambers B. The cylinder body 1 is provided with two air passages 5, 6, and the inner chamber A and the outer chamber B are respectively provided with air passages 5, 6. There is a vent hole 7 on the wall of the inner cavity A, an actuator shaft 8 is arranged in the center of the cylinder block 1, a gear 9 is arranged on the outer edge of the actuator shaft 8, and two pistons 3 are symmetrically arranged on the inner ends. The rack 10 is meshed with two sides of the gear 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com