3D (three-dimensional) printing bionic dental implant and manufacturing method thereof

A 3D printing and implant technology, applied in dental implants, dentistry, prostheses, etc., can solve the problems of immediate implantation, difficult to close wounds, poor initial stability of implantation, long healing time, etc., and achieve good biocompatibility and biodegradation. The effect of reducing the occurrence of peri-implantitis and inhibiting the ability of periodontal pathogens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

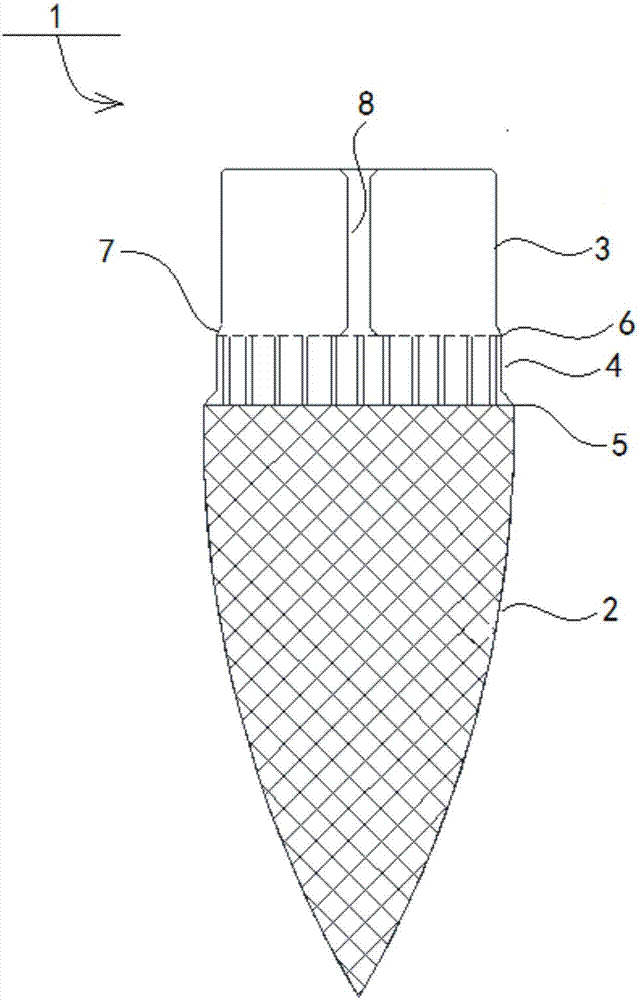

[0025] Such as figure 1 As shown, the present embodiment provides a 3D printing bionic dental implant, including an implant body 1, and also includes a chitosan nano-coating integrated with the outer surface of the implant body 1, and the implant body 1 includes a dental neck The root abutment and the tooth root 2 integrally connected with the tooth neck abutment located under the tooth neck abutment, wherein the tooth root 2 is a full-thickness three-dimensional network structure.

[0026] In the above structure, the tooth root 2 is a three-dimensional network structure. Compared with traditional dental implants, this three-dimensional network structure is similar to the structure of trabecular bone. The surface area of implant and osseointegration is conducive to the rapid attachment of blood and the promotion of blood metabolism, which is beneficial to osseointegration and shortens the osseointegration time. Moreover, in this structure, the outer surface of the implant b...

Embodiment 2

[0033]This embodiment also provides a method for manufacturing the above-mentioned 3D printed bionic dental implant, comprising the following steps:

[0034] Step 1: Obtain the 23D image of the patient's tooth root before surgery, extract the target subtraction tooth data through region growth, establish a 3D model of the bionic dental implant, and perform format conversion after smoothing, noise reduction, trimming, and optimization of the 3D model;

[0035] Step 2: Use the selective electron beam sintering equipment Q10 to make a 3D entity. The conditions are: use titanium alloy powder as the raw material, the layer thickness is 0.05mm, the production speed is 80cm3 / h, and helium is used as the inert protective gas; Clean up in the powder recovery system, recover the powder and perform ultrasonic cleaning for the first time, and then place it in acetone, ethanol and double distilled water for ultrasonic oscillation treatment for 15 minutes, repeat the cleaning twice, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com