Electrostatic coating device of locomotive-mounted wheel rail friction control material

An electrostatic coating, vehicle-mounted technology, applied in electrostatic spray devices, spray discharge devices, spray devices, etc., can solve the problems of affecting the health of drivers and passengers, long insulation conveying pipelines, complicated installation, etc., and achieve scientific coating methods. and precision, improved material utilization, and compact device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

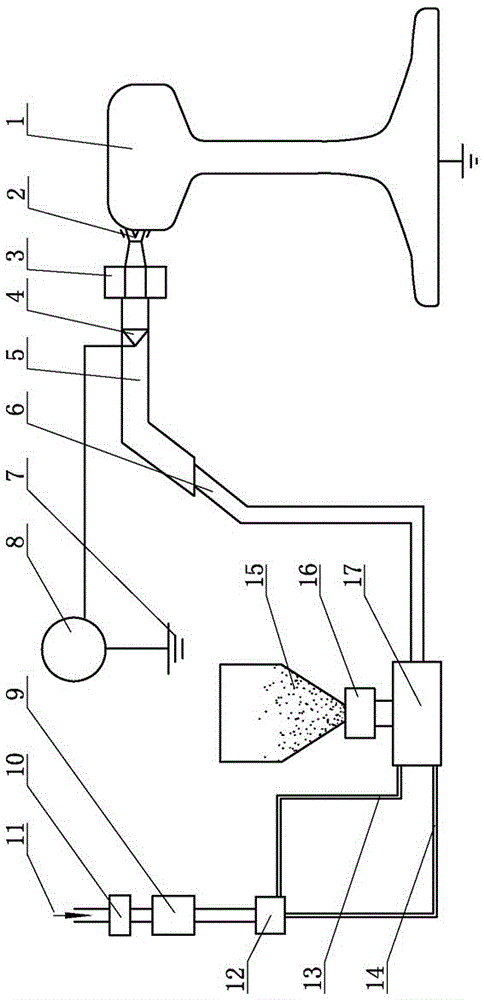

[0009] A locomotive vehicle-mounted wheel-rail friction control material electrostatic coating device according to the present invention, such as figure 1 As shown, a powder pump 17 is included, and the powder pump 17 is provided with a secondary air pressure pipe 13 and a primary air pressure pipe 14 . The feed port of the powder pump 17 is connected to the feeding solenoid valve 16, and the feeding solenoid valve 16 is connected to the storage tank 15. The outlet of powder pump 17 is connected to the powder air mixing tube 6, the powder air mixing tube 6 is connected to the nozzle 5, the nozzle 5 is equipped with a high voltage electrode 4, the high voltage electrode 4 is connected to the high voltage electrostatic generator 8, and the high voltage electrostatic generator (8) can be connected to locomotive circuit. The feeding solenoid valve 16 is an existing solenoid valve that can control powder flow or on-off. During installation, the nozzle 5 is suspended at a position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com