Deslagging filter

A filter and centrifugal filtration technology, which is applied in the direction of filtration separation, chemical instruments and methods, separation methods, etc., can solve the problems of high cost, short service life, expensive price, etc., and achieve low cost, long service life and long-lasting performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] like figure 1 As shown in the figure, the slag removal filter of the present invention (located between the beater and the raw material processing area) includes a slurry transmission channel 9, a centrifugal filter module and a drainage pipe 1 that are connected in sequence;

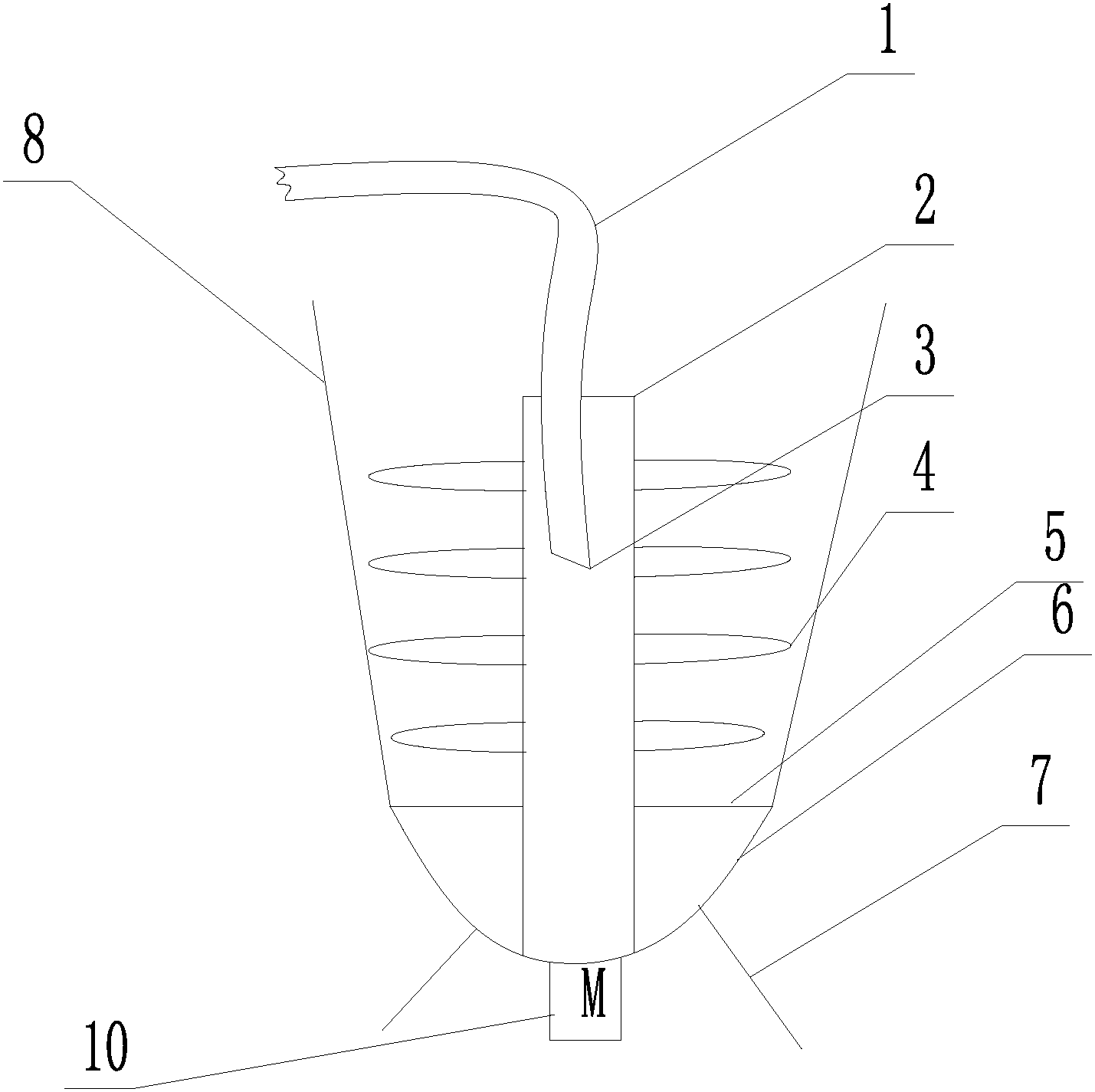

[0026] like figure 2 As shown, the centrifugal filter module includes a drum 8 with an open upper end and a stirring shaft 2 fixed on the bottom 6 of the drum, the stirring shaft 2 is provided with a stirring paddle 4, and the bottom 6 of the drum is a concave spherical shape. ; The stirring shaft 2 is in the shape of a hollow cylinder with an open upper end, and the stirring shaft 2 passes through the axial center axis of the drum 8 . A layer of metal mesh 5 is laid between the bottom 6 of the drum and the adjacent stirring paddle 4 .

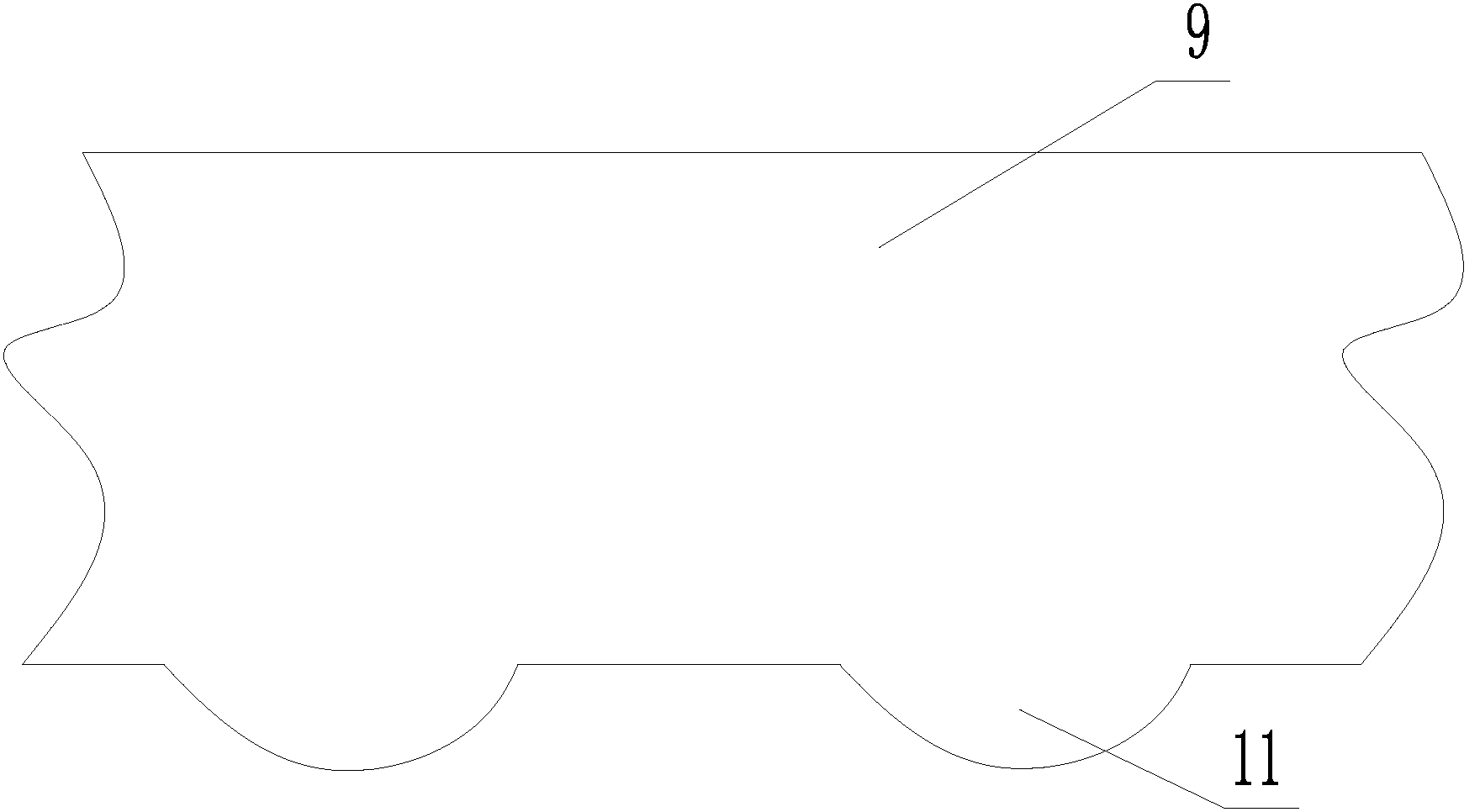

[0027] like image 3 As shown, along the length direction of the pulp conveying channel 9, that is, the pulp conveying direction, the pulp conveying channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com