Anti-clogging aerator

A technology of aerators and bubbles, applied in the field of anti-blocking aerators, to achieve the effects of increasing distance, small aeration resistance and preventing polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

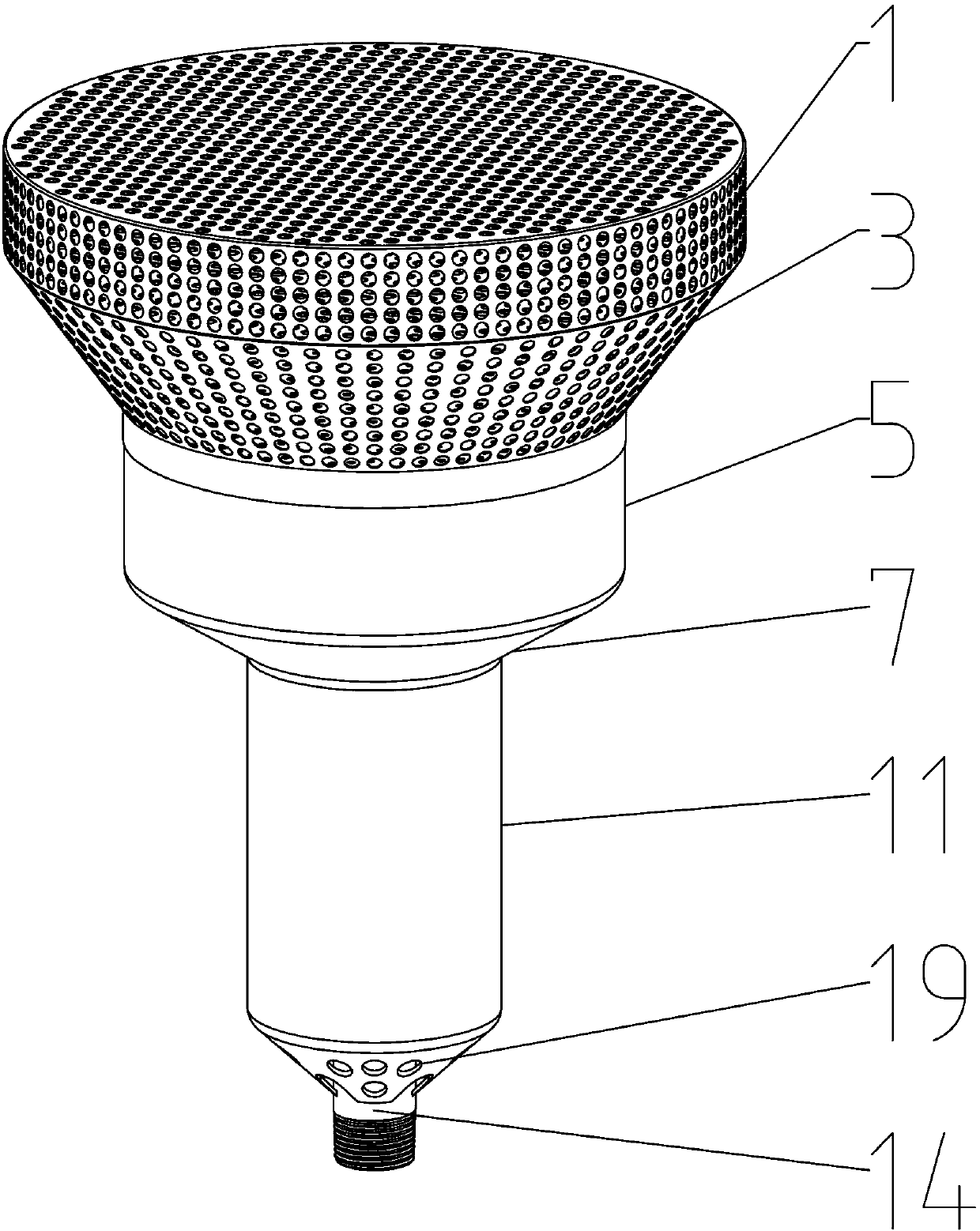

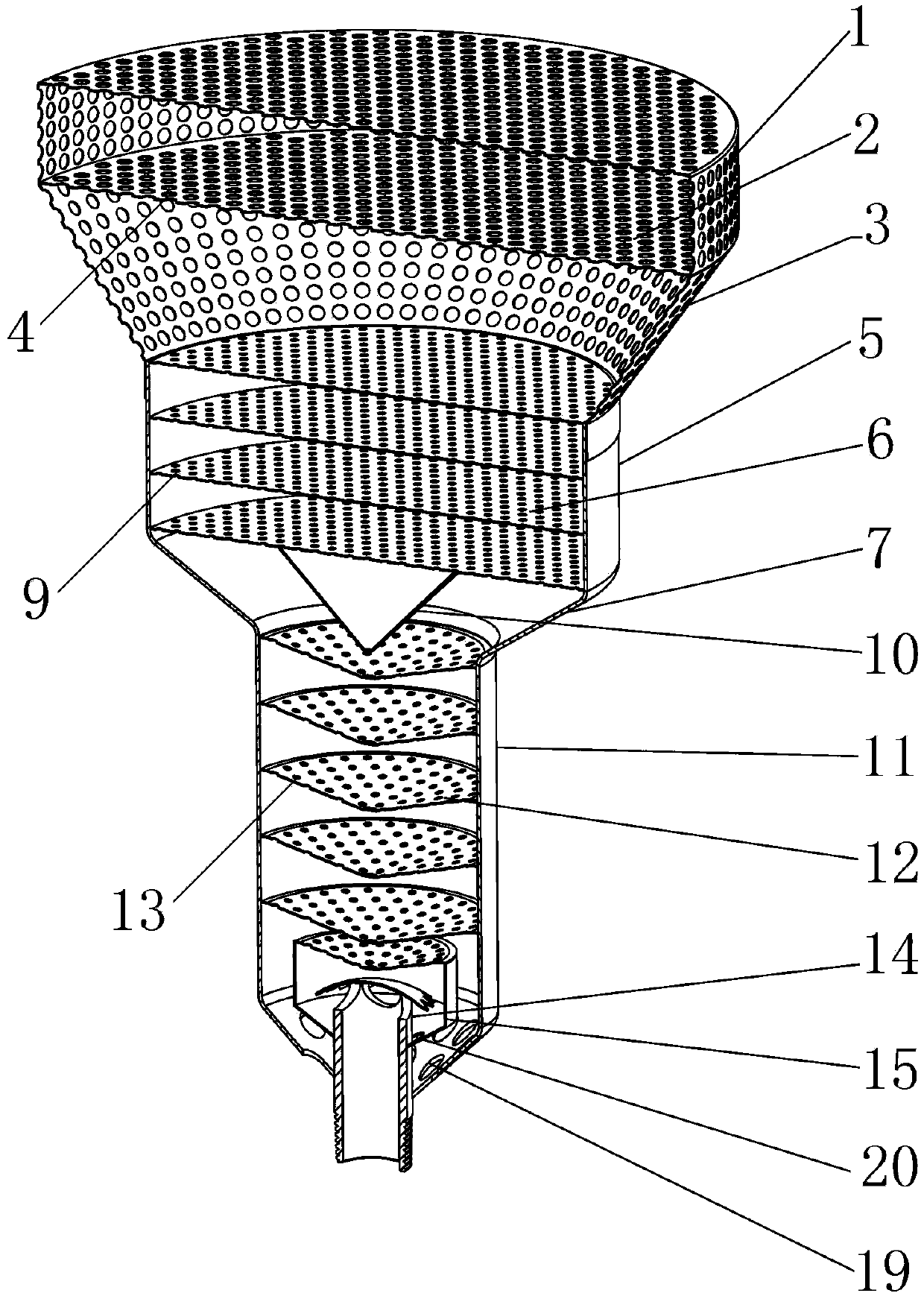

[0033] as attached figure 1 , 2 , 5, and 8, when the anti-blocking aerator of the present invention is a circular tube, the present invention includes an upper air bubble rectifying device, a middle air bubble cutting device, a lower air bubble cutting device and an air intake assembly arranged in the lower air bubble cutting device.

[0034] as attached figure 1 , 2 , 8, the upper air bubble rectifying device of the present invention includes a fairing 1, a rectifying plate 2 horizontally arranged in the fairing 1, and a funnel-shaped fairing transition connection shell arranged between the fairing 1 and the middle air bubble cutting device Body 3; the rectifying plate 2 is 1-3 layers, the best shown in the present embodiment is 2 layers, when the rectifying plate 2 is more than 2 layers, the distance between two adjacent layers of rectifying plates 2 is 30-50mm, the most Preferably 40mm; the fairing 1, the rectifying plate 2 and the funnel-shaped fairing transition connec...

Embodiment 2

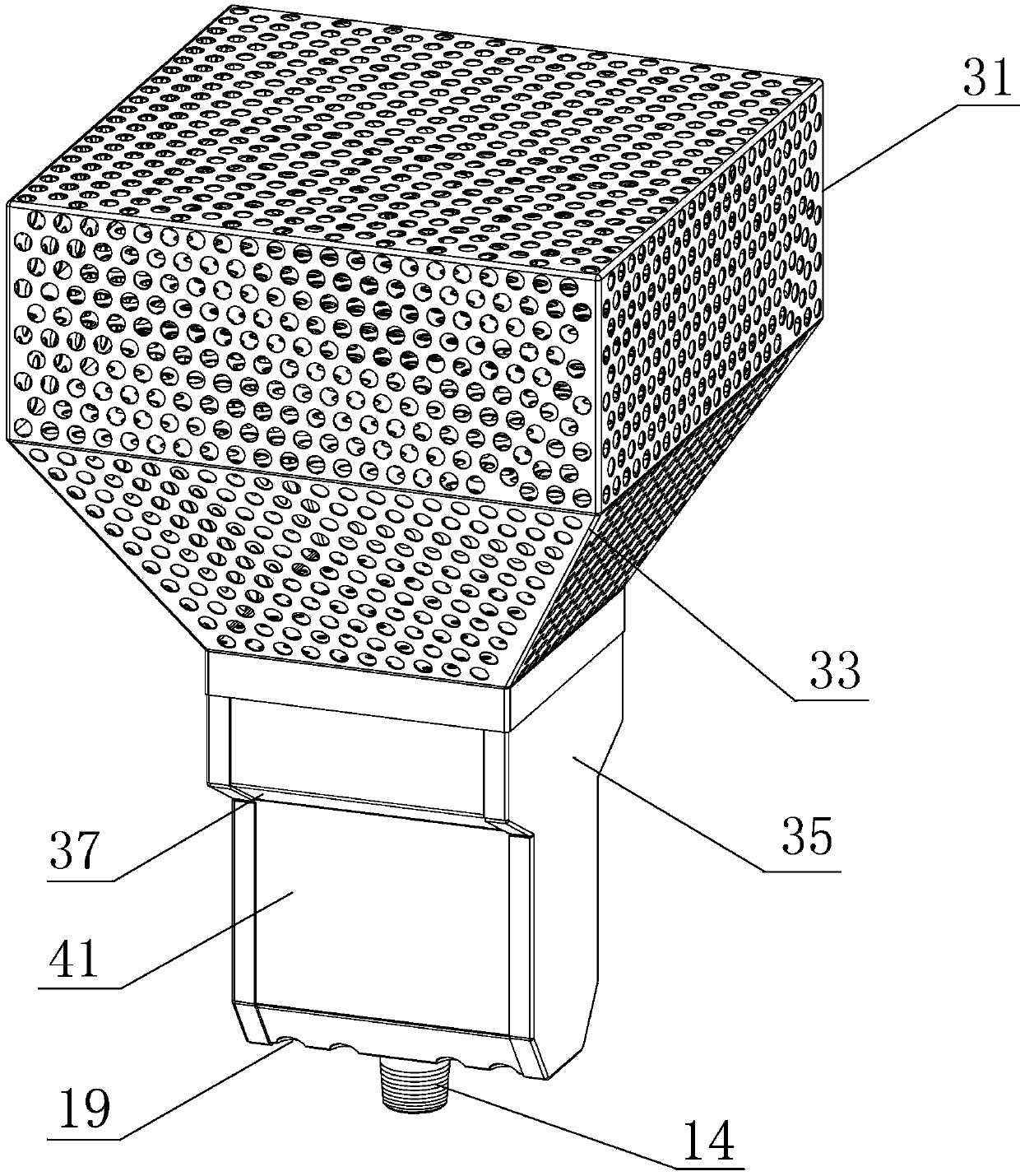

[0041] as attached image 3 , 4 , 6, and 9, when the anti-blocking aerator of the present invention is a square tube, it includes an upper air bubble rectifying device, a middle air bubble cutting device, a lower air bubble cutting device and an air intake assembly arranged in the lower air bubble cutting device.

[0042] as attached image 3 , 4 , 9, the upper air bubble rectifying device of the present invention includes a fairing 31, a rectifying plate 32 horizontally arranged in the fairing 31, and a funnel-shaped fairing transition connection shell arranged between the fairing 31 and the middle air bubble cutting device body 33; the rectifying plate 32 is 1-3 layers, preferably 2 layers, the rectifying plate 32 shown in the present embodiment is 3 layers, when the rectifying plate 32 is more than 2 layers, adjacent two layers of rectifying plates 32 The distance is 30-50mm, the best is 40mm; the fairing 31, the rectifying plate 32 and the funnel-shaped fairing transiti...

Embodiment 3

[0049] as attached Image 6 , 7 As shown, the difference between Embodiment 3 of the present invention and Embodiment 2 lies in the structure of the cover body:

[0050] as attached Figure 7As shown, the cover body of the present invention is an air intake horizontal tube 24 whose bottom end communicates with the top of the air intake pipe 14, and the two ends of the air intake horizontal tube 24 are provided with sealing end caps B25, and the lower part of the air intake horizontal tube 24 is a square groove Such a structure can make the nozzle of the intake pipe 14 and the intake cross tube 24 convenient to fix, and it is easy to combine during processing. 24 The arc surface of the upper semicircular tank body is provided with air bubble primary cutting holes 18, and the shielding plate is connected with two sealing end caps B25 through two support rods.

[0051] When working, when the present invention is installed in the working area, the gas enters the cover body thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com