Inertial electrode low-temperature aluminium electrolytic cell

A technology of aluminum electrolytic cell and inert electrode, which is applied in the field of aluminum electrolysis, can solve problems such as high energy consumption and environmental pollution, and achieve the effects of low energy consumption, low corrosion and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

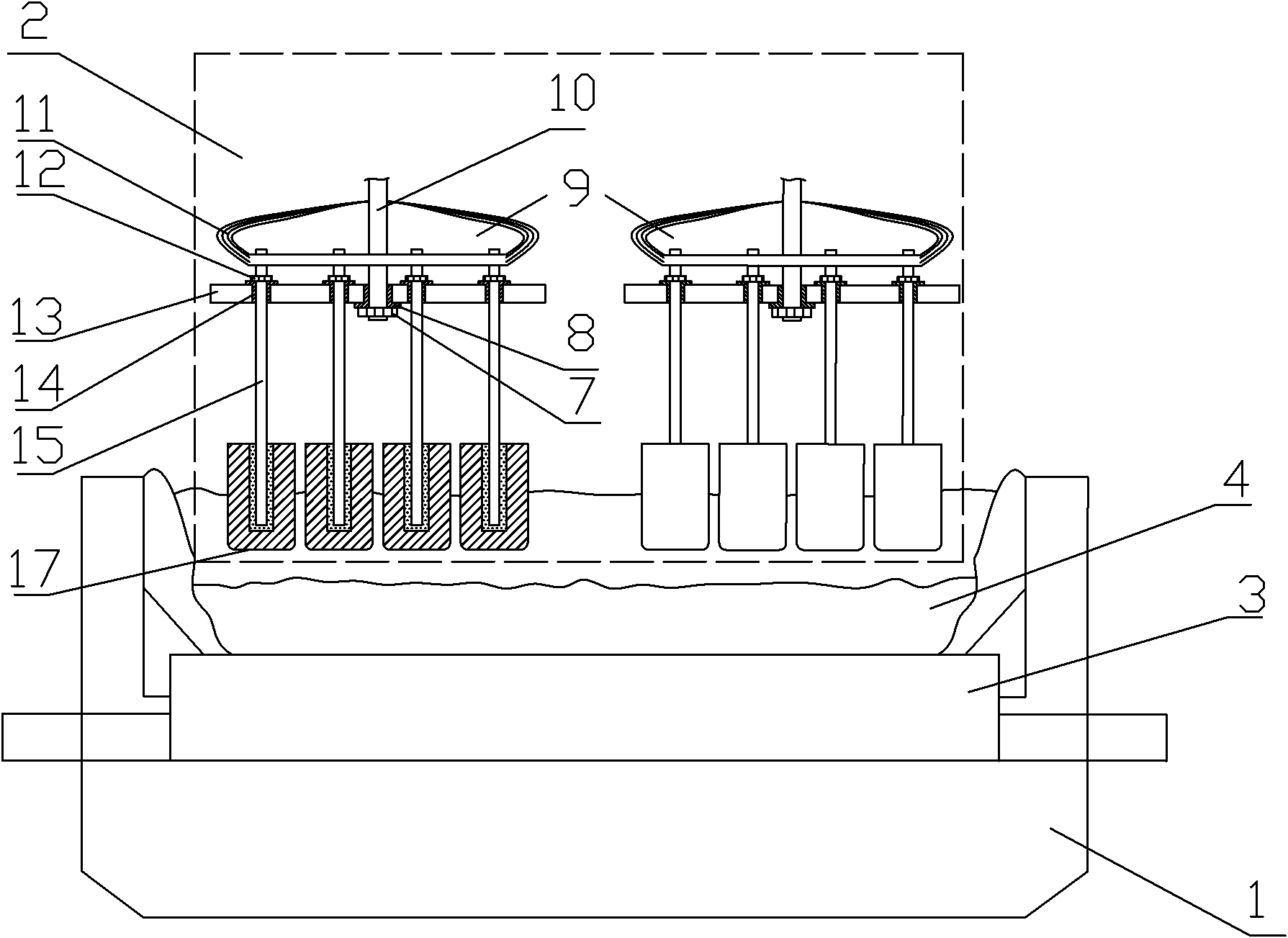

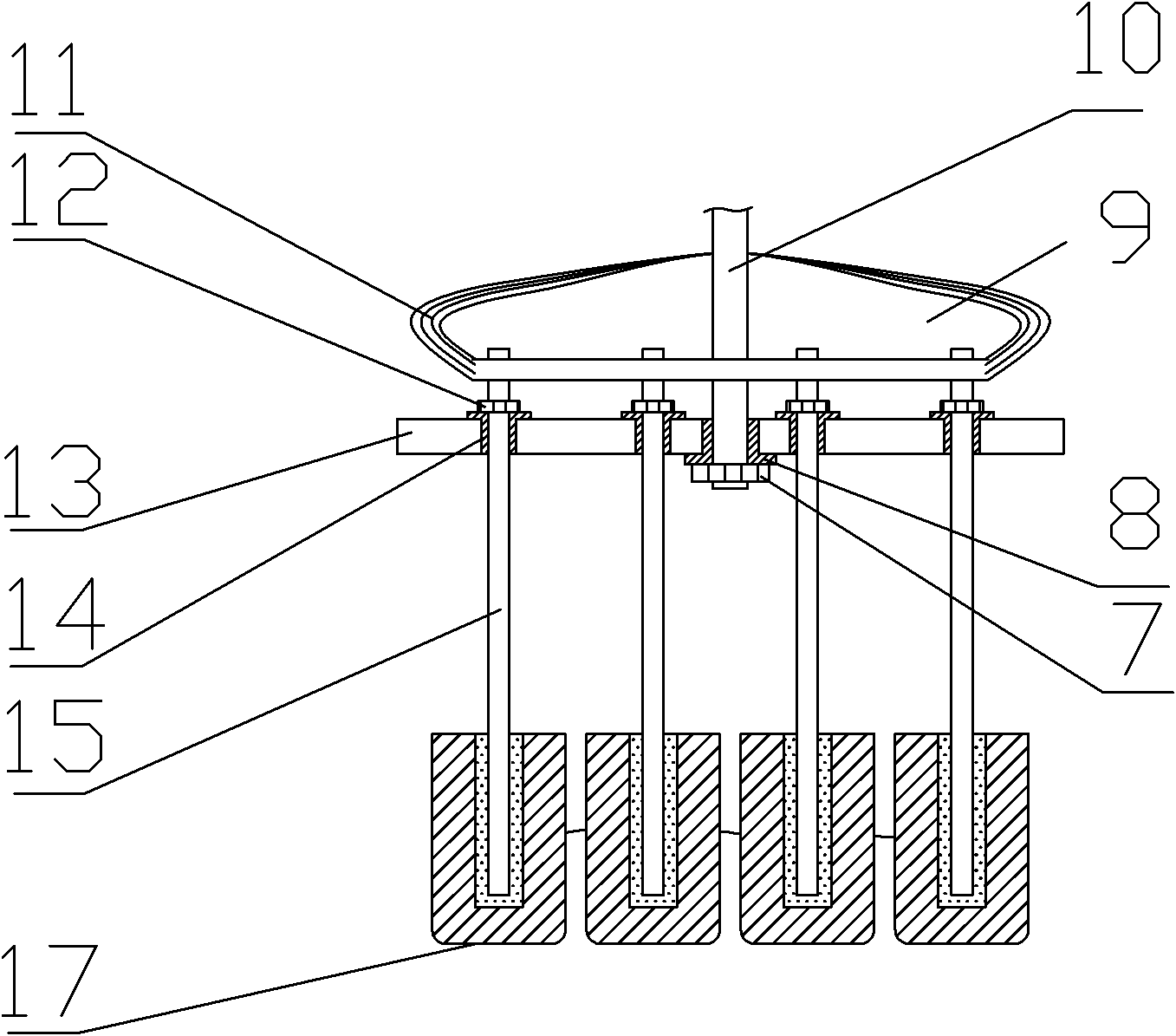

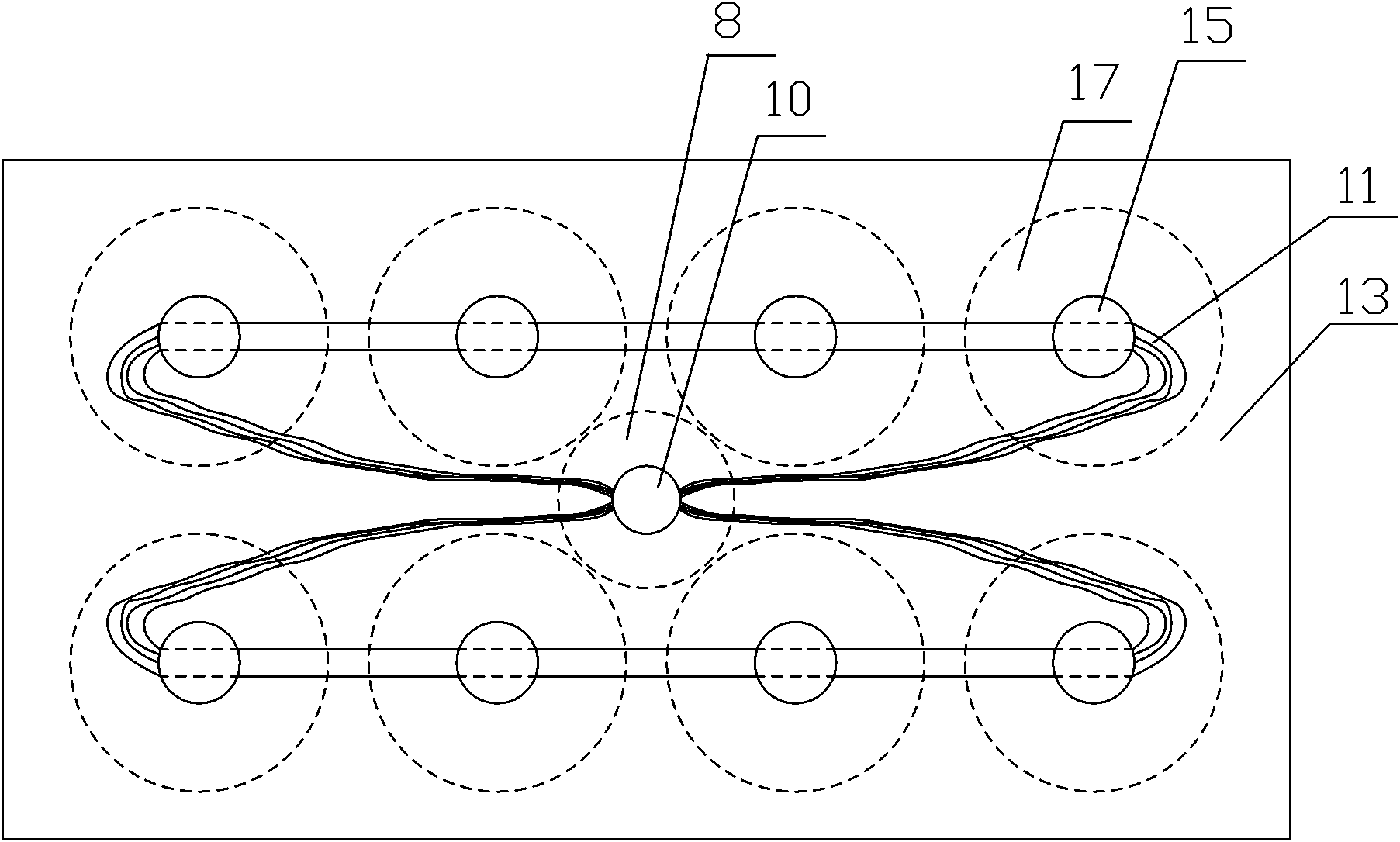

[0032] See attached figure 1 , 2 , 3. A low-temperature aluminum electrolytic cell, comprising a cell body 1, a cermet inert anode 2, a wettable cathode 3, and a low-temperature electrolyte 4; the wettable cathode 3 is arranged at the bottom of the cell body 1; the low-temperature The electrolyte 4 is arranged in the cell body 1; the cermet inert anode 2 is arranged on the upper part of the cell body 1, and its end extends into the low-temperature electrolyte 4;

[0033]The cermet inert anode 2 is composed of 2 groups of cermet inert anode groups 9, and each cermet inert anode group 9 is composed of 8 cermet inert anode monomers 17; between the cermet inert anode groups 9 And the cermet inert anode monomers 17 in the same cermet inert anode group 9 are electrically parallel structures;

[0034] The wettable cathode 3 is composed of multi-block size-graded functionally graded TiB 2 / C compound cathode composition;

[0035] The low temperature electrolyte consists of Na 3 A...

Embodiment 2

[0044] The structure of the electrolytic cell of the present embodiment is the same as that of embodiment 1, except that the specific components of the cermet inert anode monomer 17 are: CaO-Ni-NiFe 2 o 4 Cermet inert anode.

[0045] In the actual use of this embodiment, the cell voltage can be controlled at 3.8V-3.9V, the electrolysis temperature is 890-920°C, and the power consumption is less than 13500kWh / t-Al, CF n The emission of compounds is reduced by 70%, which has a great impetus for the development of the environment-friendly aluminum electrolysis industry.

Embodiment 3

[0047] The structure of the electrolytic cell of the present embodiment is the same as that of the embodiment 1, except that the specific components of the cermet inert anode monomer 17 are: CaO-BaO-Ni-NiO-NiFe 2 o 4 Cermet inert anode.

[0048] In the actual use of this embodiment, the cell voltage can be controlled at 3.8V-3.9V, the electrolysis temperature is 890-920°C, and the power consumption is less than 13500kWh / t-Al, CF n The emission of compounds is reduced by 70%, which has a great impetus for the development of the environment-friendly aluminum electrolysis industry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com