Technological process and apparatus for drinking water treatment by film method

A drinking water treatment and membrane technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc. Problems such as troublesome operation and maintenance, to achieve the effects of excellent effluent quality, prolonged coagulation residence time, and difficult floc breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

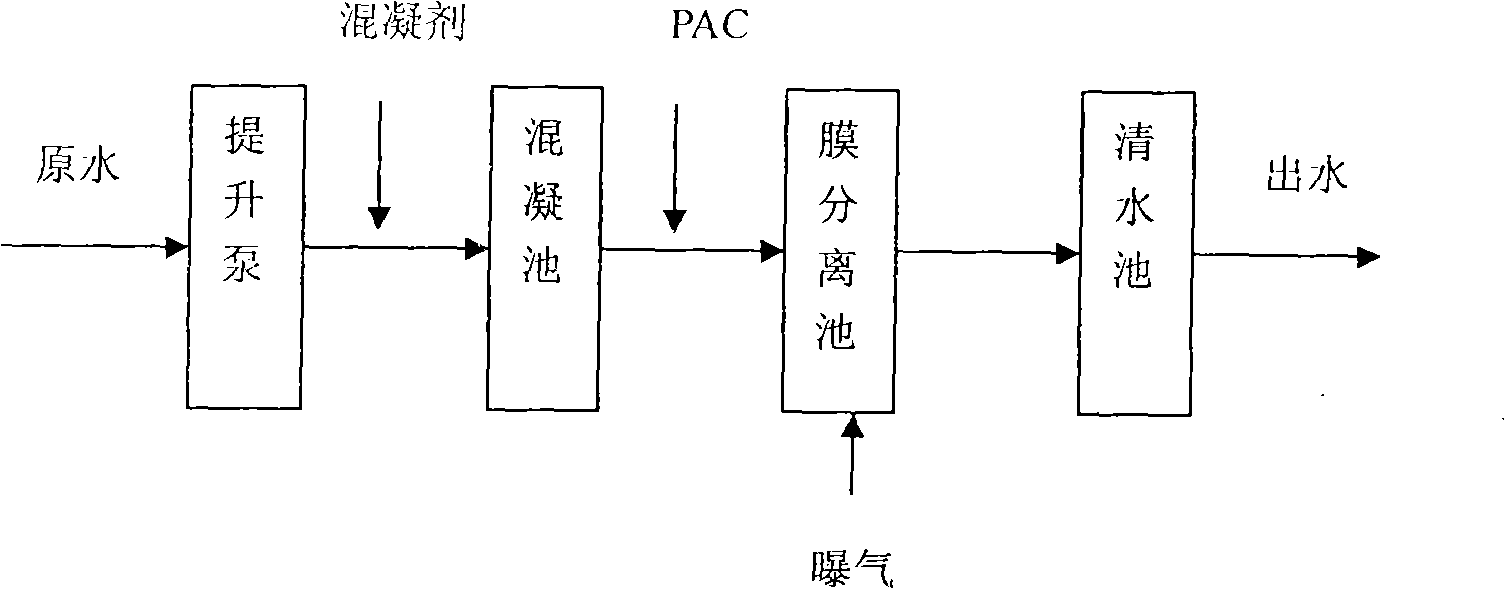

[0047] Membrane drinking water treatment process equipment of the present invention is roughly as figure 1 shown, including:

[0048] Lift pump, coagulation tank, membrane separation tank, clear water tank. The raw water to be treated is pumped by the lift pump and passed through the coagulation tank. Before entering the coagulation tank, add coagulant. The water after coagulation treatment enters the membrane separation tank for aeration treatment, and the treated water passes through the clear water tank before exiting.

[0049] The general structure and treatment method of the water treatment equipment of the present invention described above, the structure of the membrane method drinking water treatment equipment is described in detail below, which includes

[0050] (1) Preprocessing unit:

[0051] Coarse grids and Y-shaped pipe filters are set up as pretreatment to prevent impurities in the raw water from clogging the inlet pump and inlet water meter.

[0052] (2) Mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com