Generator with continuous variable volume compression ratio

A volume compression and engine technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve problems such as few achievements, complex structure, and difficulty in mass production, so as to save fuel, reduce vehicle weight, and improve air intake The effect of charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the drawings and embodiments.

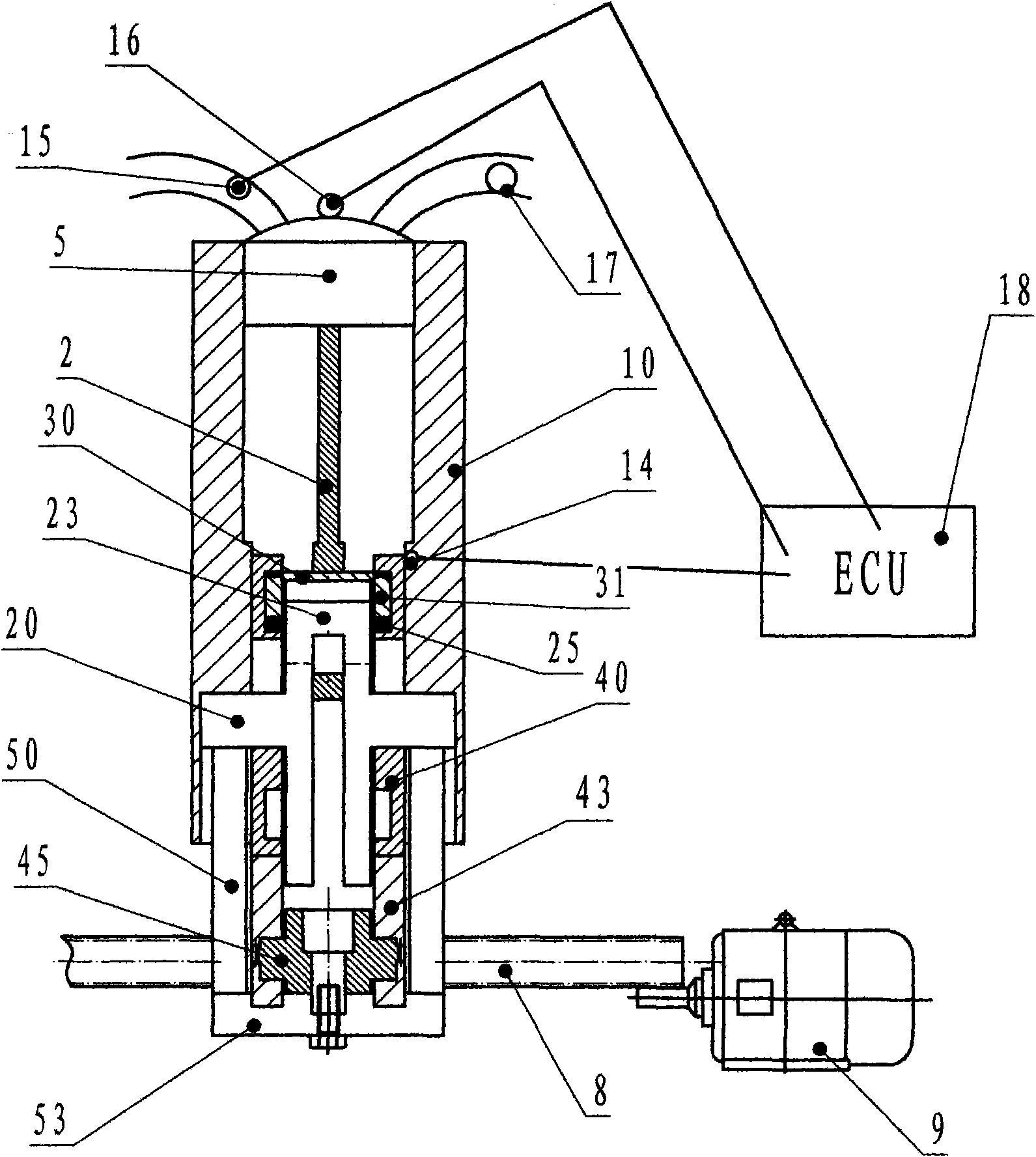

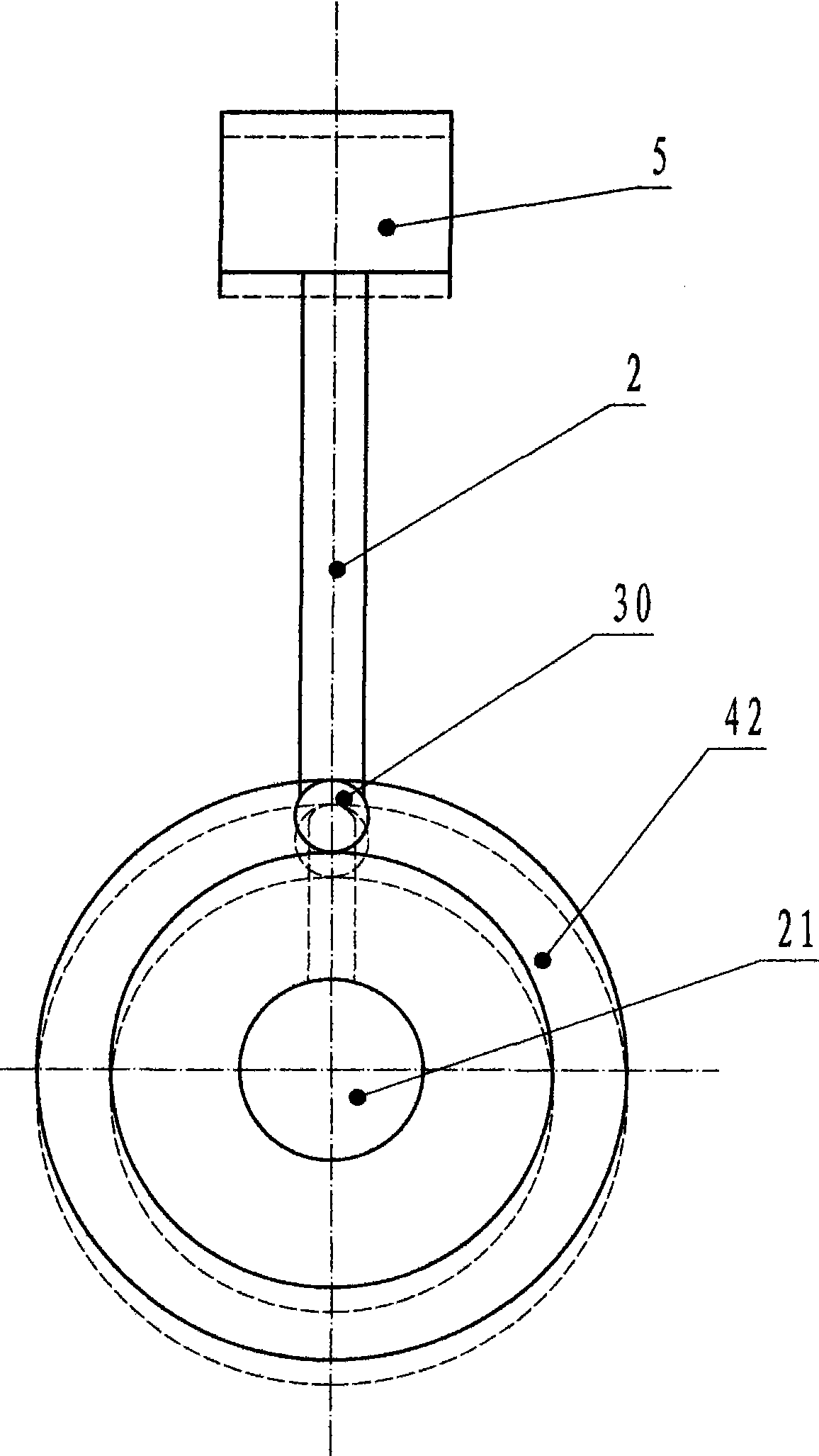

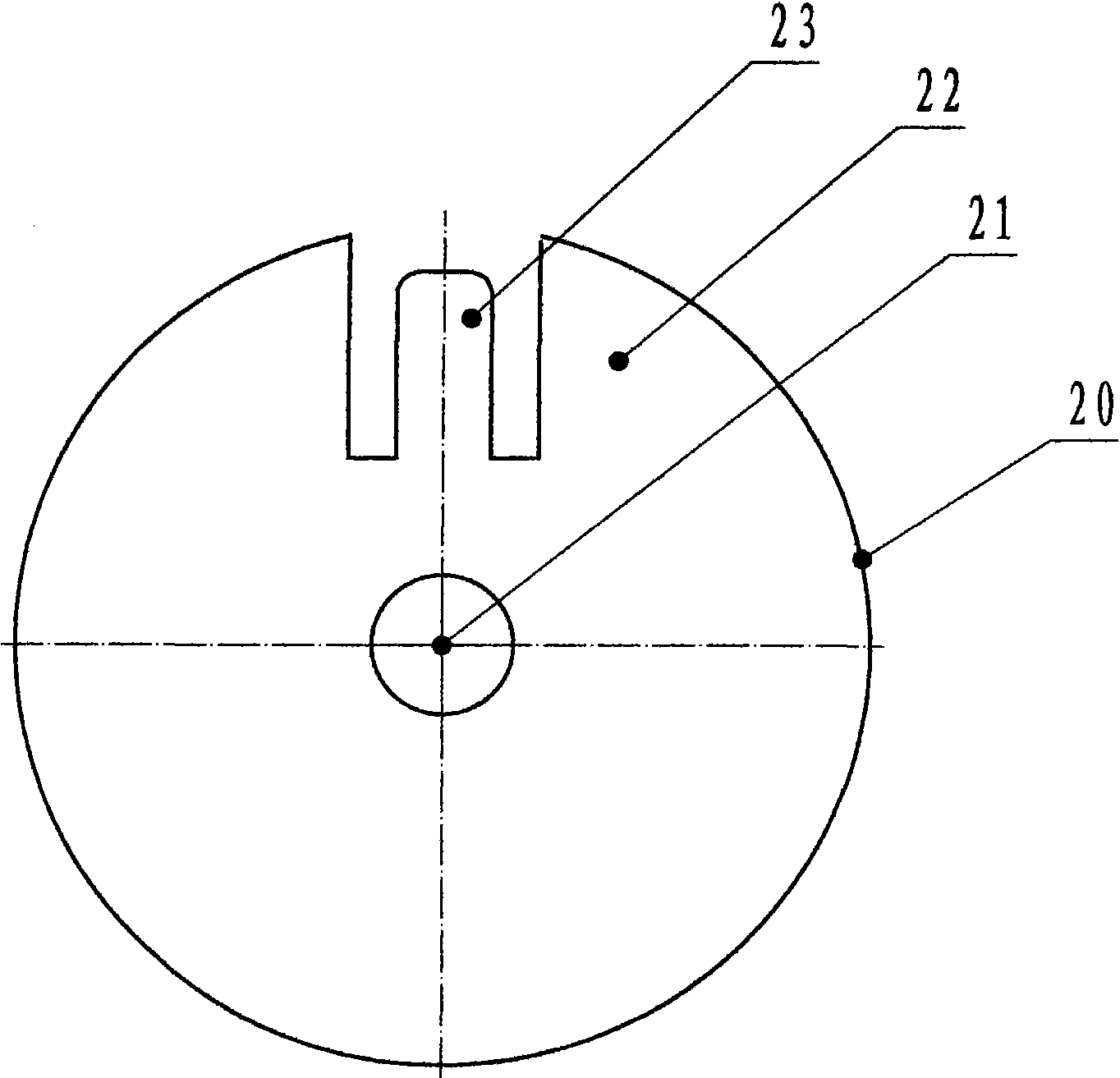

[0025] Reference figure 1 , The continuously variable volume compression ratio engine of the present invention includes a sensor, a box body 10, a crankshaft 20, and at least one connecting rod 2 and a piston 5 whose one end is rotatably connected with an outer journal sleeve 30 mounted on the journal 23 The journal 23 of the crankshaft 20 is provided with a continuously variable volume compression ratio mechanism; the variable compression ratio mechanism is controlled by the ring track body 40 installed in the box body 10; the box body 10 is provided with a fixing mechanism, The fixing mechanism is provided with a control mechanism for a continuously variable volume compression ratio engine. The ring orbit body 40 is controlled by the control mechanism to control the position of the outer journal sleeve 30 at the top dead center, thereby changing the position of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com