Distribution diameter automatic pitch-control five-axle wheel screwing equipment

A circle diameter and wheel technology, which is applied in the field of five-axis wheel nut tightening equipment with distributed circle diameter automatic variable distance, can solve the inability to meet the requirements of multi-variety collinearity, low precision of tightening torque of pneumatic wrench, and inability to meet the production cycle requirements To achieve the effect of providing production efficiency and torque accuracy, meeting production tact, and avoiding occupational diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

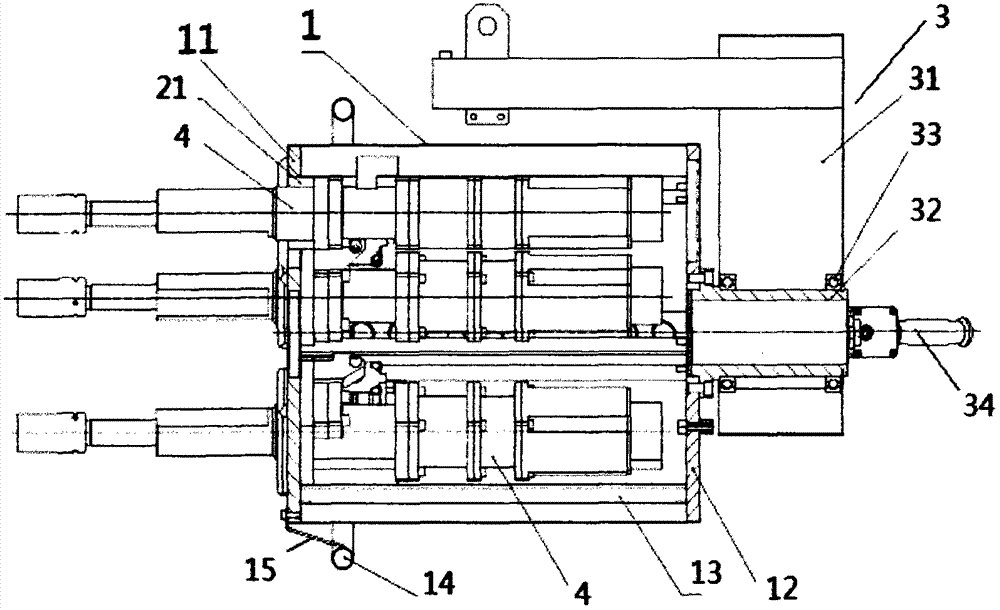

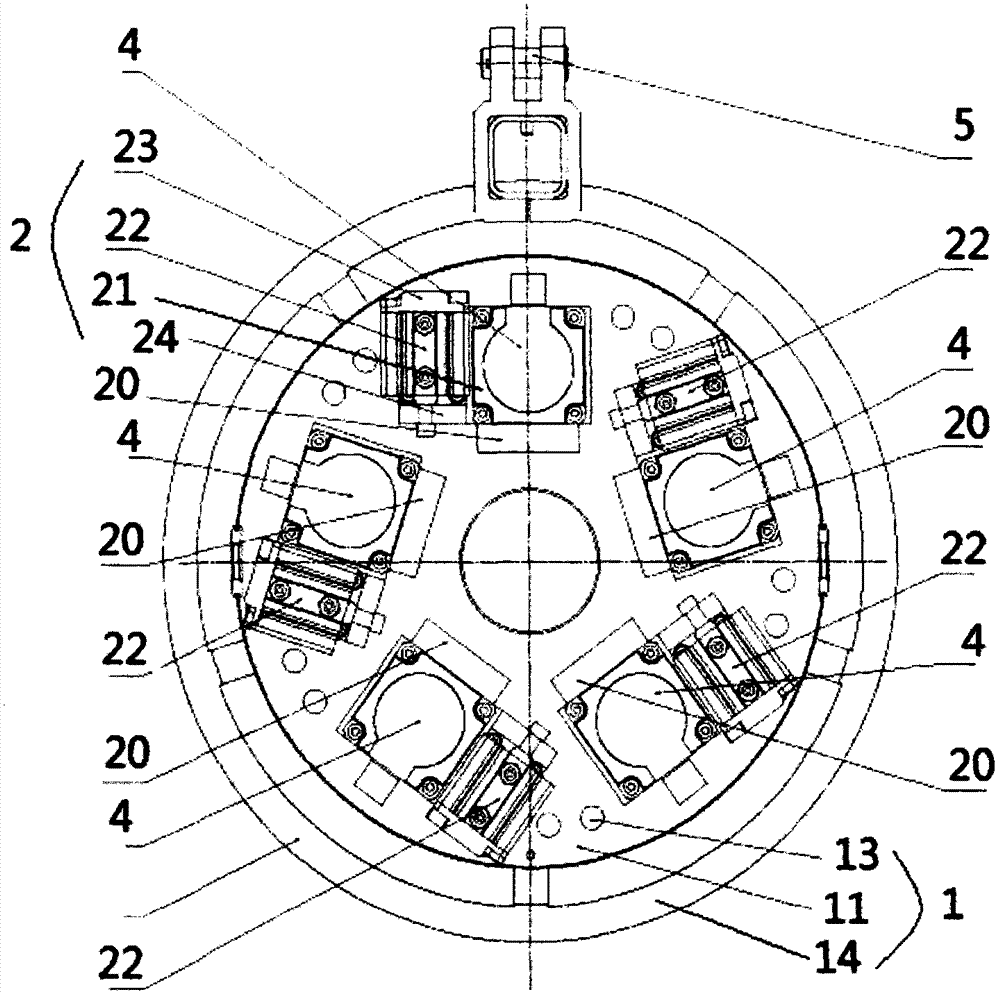

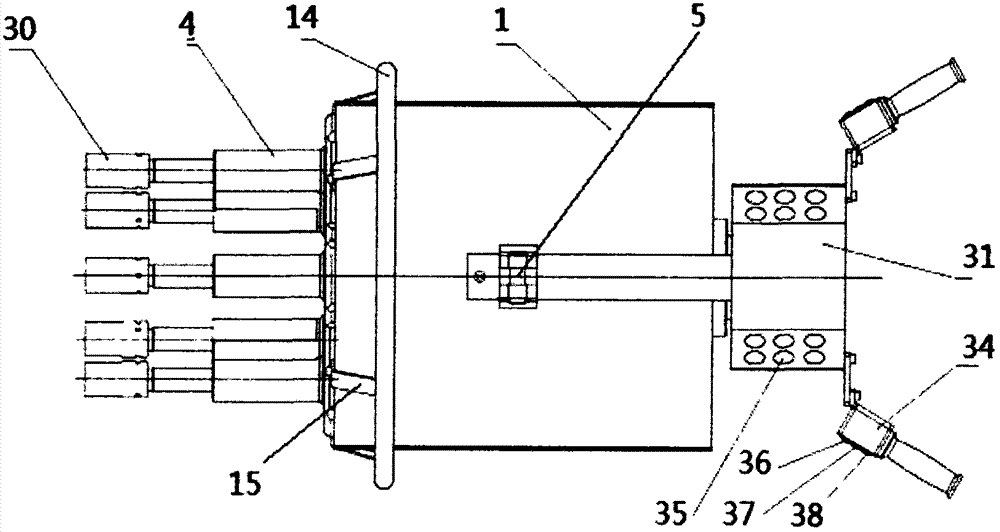

[0026] like figure 1 , figure 2 and image 3 As shown, a five-axis wheel nut tightening device with a distribution circle diameter automatically variable pitch provided by the present invention includes a tightening bracket 1, a hoisting mechanism 3 and five tightening shafts 4 fixed in the tightening bracket 1, and the tightening bracket 1 One end is fixed with a tightening shaft fixing plate 11, five through holes 20 located on the same circumference are distributed on the tightening shaft fixing plate 11, the tightening shaft 4 penetrates through the through holes and is fixed on the tightening shaft fixing plate 1, and the hoisting mechanism 3 is fixed on the tightening shaft On the other end of the bracket 10, a plurality of radial pitch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com