Dense medium beneficiation method for barites

A beneficiation method and heavy medium technology, which are applied in chemical instruments and methods, wet separation, magnetic separation, etc., can solve the problems of low production efficiency and large amount of waste of resources, and achieve a small footprint, low operating costs, and increased productivity. The effect of large total reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

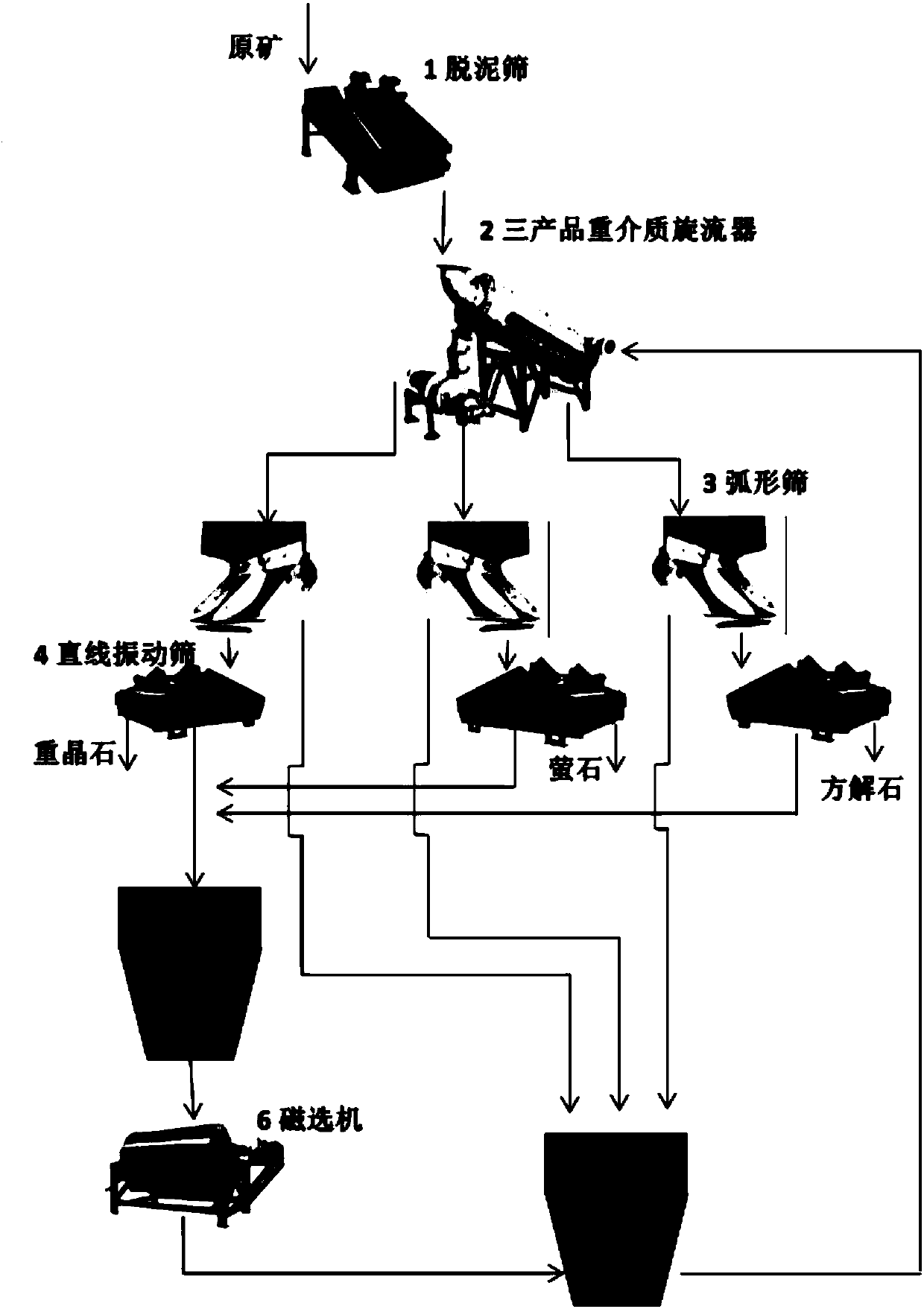

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] The raw ore first enters the 1st desliming screen, and the deslimed ore mixture enters the 2nd three-product dense medium cyclone. Add the dense medium suspension with the optimal concentration determined experimentally into the 2-three-product dense medium cyclone.

[0024] 2 The three-product dense medium cyclone is the most important part of the separation system. It consists of a cylinder and a cone. When rotating, the vortex separates. Taking advantage of the similar density of calcite and dense medium suspension, the calcite is first separated in the cylinder seperate. The rest of the ore enters the second section of the cone and continues to rotate. Due to the different specific gravity and centrifugal force of barite and fluorite during rotation, it is finally separated through different outlets.

[0025] The separated ore products enter different 3-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com