Mold and processing method for free-combination and suction-type building component processing

A kind of technology of building components and suction type, which is applied in the direction of molds, mold separation devices, etc., to achieve the effects of increased durability, convenient disassembly and assembly, and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

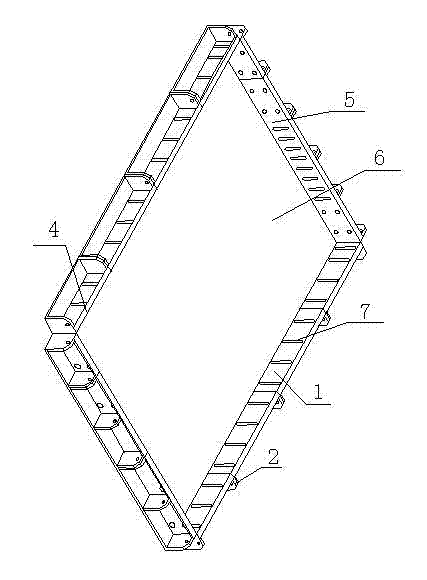

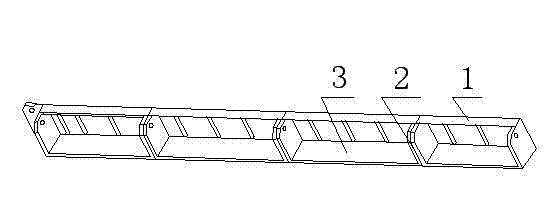

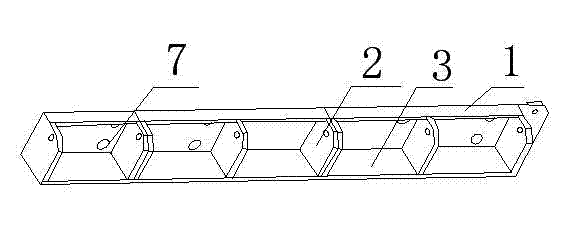

[0022] A mold used for the processing of building components of a free combination suction type, which consists of: a unit mold 1, a magnetic frame 2, the side of the unit mold 1 is attracted to the magnetic frame 2 to form a magnetic mold unit 3, and the set of magnetic molds The units 3 are attracted to each other to form a strong magnetic single-sided mold 4, and the strong magnetic single-sided molds 4 are attracted to each other to form an upper mold 5, and the upper mold 5 is attracted to a bottom formwork 6 to form a building component processing mold.

Embodiment 2

[0024] The mold used for the processing of the free combination suction type building components described in Example 1 has a connecting hole 7 on the strong magnetic single side mold.

Embodiment 3

[0026] A combination and processing method of moulds, which are used in the processing of free-combination and suction-type building components. Firstly, according to the design arrangement and combination, the unit molds with holes in the mold library are taken out and sucked on the magnetic frame, and the unit molds on the magnetic frame are sucked together. The strong magnetic single-side mold is formed by the mutual attraction of the magnetic frame, the strong magnetic single-side mold is attracted to each other to form the upper mold, the upper mold is attracted to the bottom formwork to form the component mold for construction processing, and the steel bar is installed through the hole of the single-side mold. The steel bars are exposed and the reserved holes for the connection are pre-buried, and the building components with the exposed steel bars and the reserved holes for the connection are finally formed through concrete pouring and curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com