Heat recovery device of controllable vehicle exhaust

A technology of heat recovery device and automobile exhaust, which is applied in exhaust devices, mufflers, mechanical equipment, etc., can solve problems such as consumption, large fuel oil, and increase air pollution, and achieve good controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

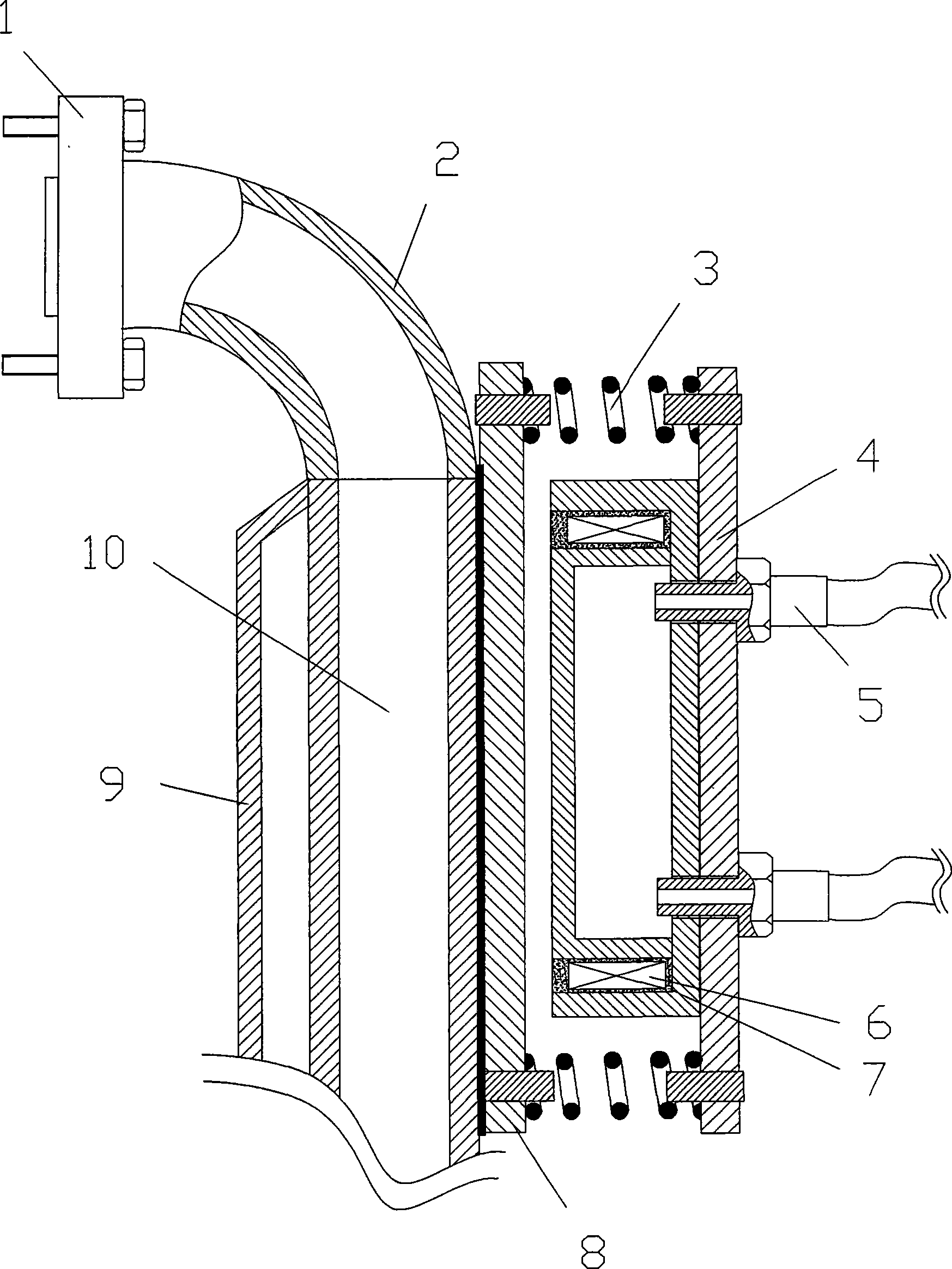

[0011] In conjunction with the accompanying drawings, the embodiment of the controllable automobile exhaust heat recovery device is to connect the waste gas box 10 in series near the exhaust pipe mouth 1 at the front of the exhaust pipe. An outer wall of the waste gas box 10 is a flat iron plate 8, and the Iron plate 8 is welded on exhaust gas box 10, and water tank 4 supports and hangs on plane iron plate 8 with spring 3, and water tank 4 and plane iron plate 8 are set up in parallel, leave the gap of 2-3mm therebetween.

[0012] The fronts of the waste gas box 10 and the water tank 4 are square, and there are four springs 3 for supporting the suspension of the water tank 4, which are distributed at the four corners of the water tank 4.

[0013] The water tank 4 is made of iron, and the circumference is slotted, and the notch faces the plane iron plate 8, and the coil 7 is embedded in the slot, and is encapsulated with the encapsulating resin 7, and the encapsulating resin ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com