Low NOX dry ash extraction coal powder burning method

A technology of slagging pulverized coal and combustion method, which is applied in the direction of combustion method, combustion using gaseous fuel and powder fuel, combustion using multiple fuels, etc., and can solve problems such as insufficient mixing, large q4 loss, and low burnout rate , to achieve the effect of avoiding coking, avoiding excessive temperature and sufficient combustion

Inactive Publication Date: 2010-11-10

郑雯平

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

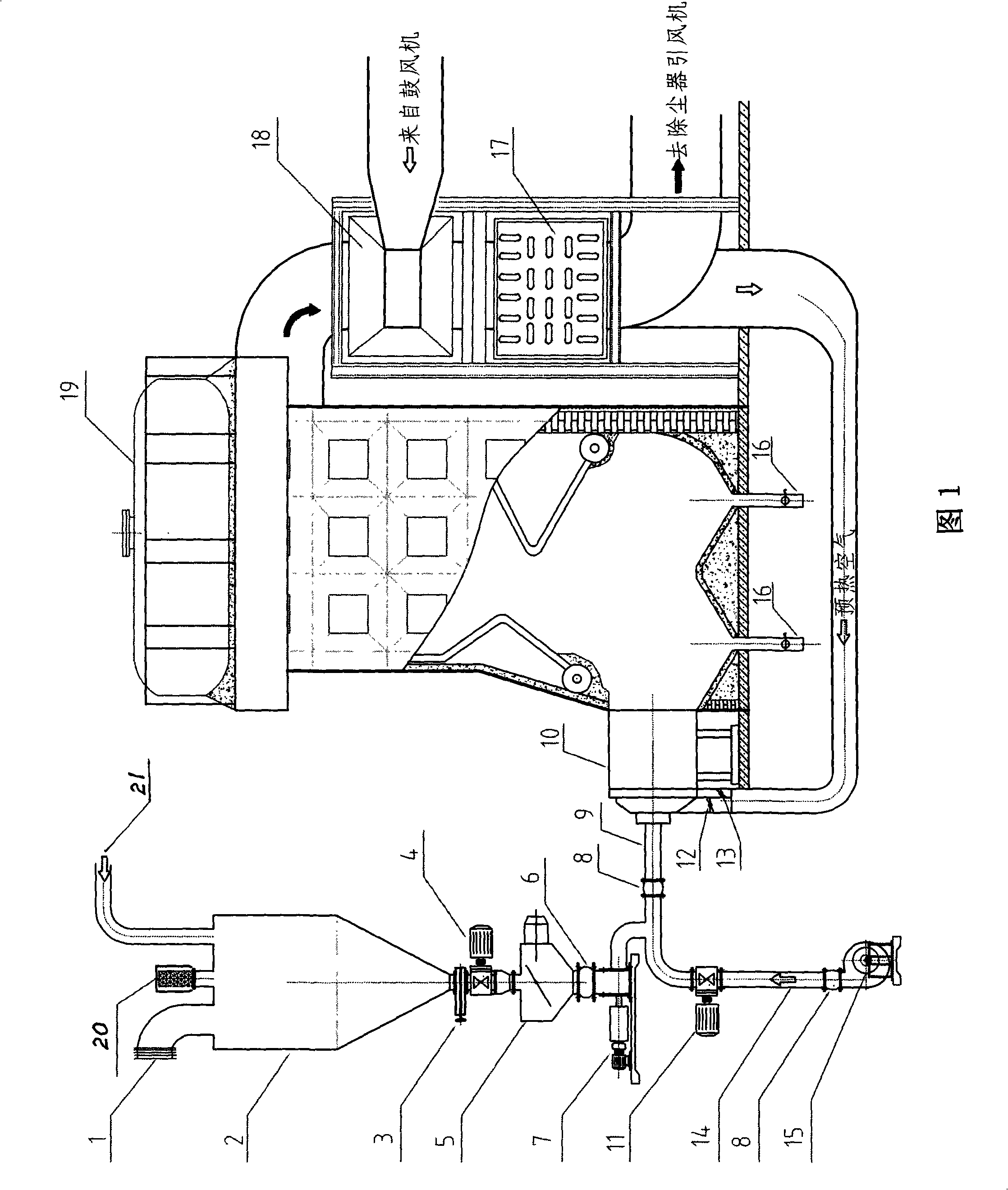

Chain boiler is a furnace type widely used in industrial boilers at present. As shown in Figure 1, it includes boiler furnace C and chain grate B. Fuel coal A enters the boiler and burns in layers on chain grate B. The combustion flue gas flows from The outlet D of the boiler furnace C is discharged. The disadvantage of this kind of boiler is that the mixture with the air is not sufficient during combustion, resulting in incomplete combustion, low burnout rate, large q4 loss, exhaust smoke containing NOx, SO2, high dust concentration, and polluting the environment. In order to solve these problems, people have improved the structure of industrial boilers, but they have not changed the traditional combustion method, and the effect is not ideal.

The applicant applied on July 28, 2008 for a utility model patent titled "Low NOx Liquid Slagging Double Swirling Pulverized Coal Burner", the application number is "200820151316.0"; the title is "A Combustion Method for Industrial Boilers" Patent for invention, application number is "200810041070.6", the secondary air chamber of the burner is set outside the combustion chamber shell, and a swirl duct is arranged in the secondary air chamber, the primary air is axially introduced, and the secondary air is Tangentially introduced, the combustion temperature can reach 1450°C-1600°C, so the liquid slag is discharged after combustion, and its disadvantage is that it can only burn coal with a low ash melting point

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

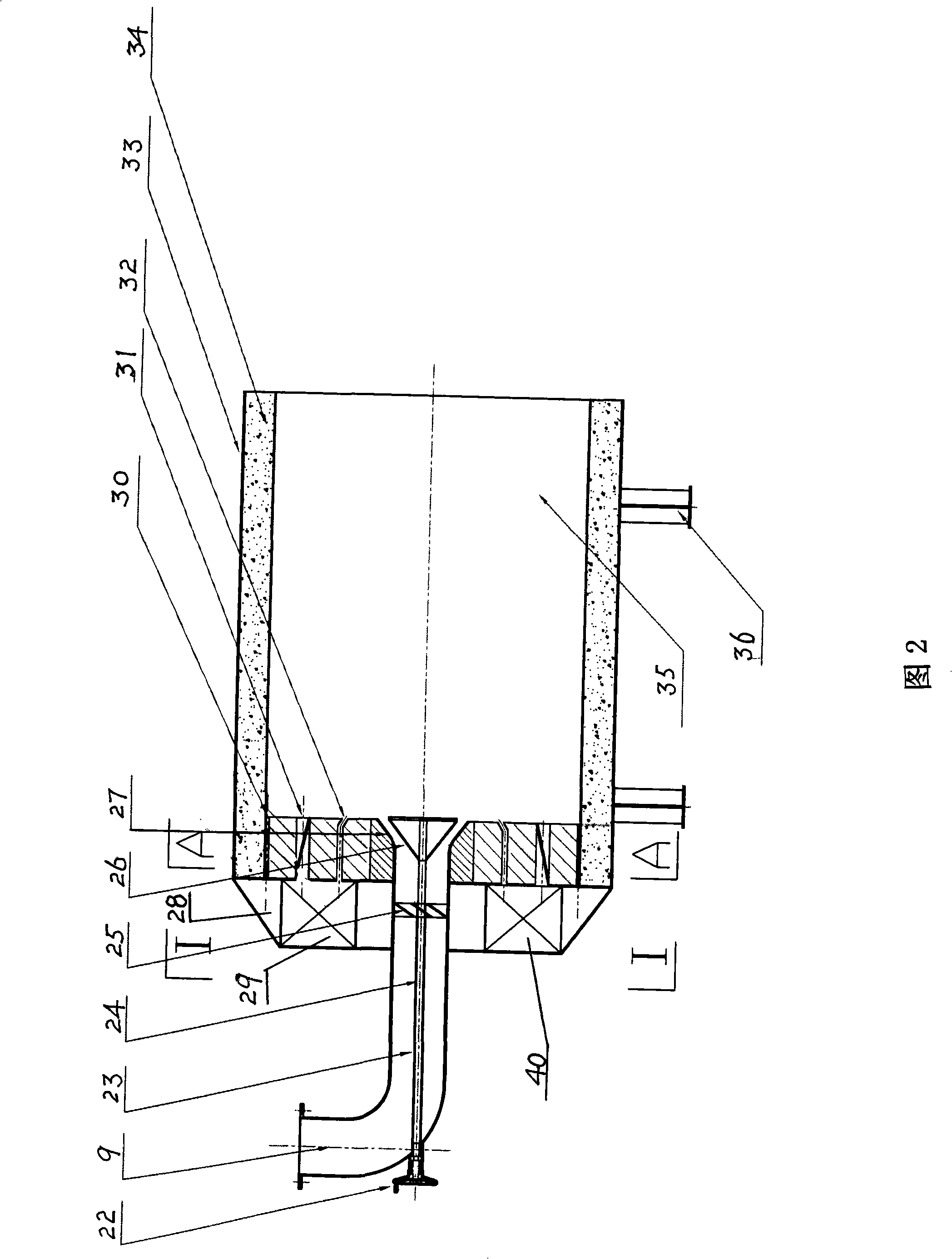

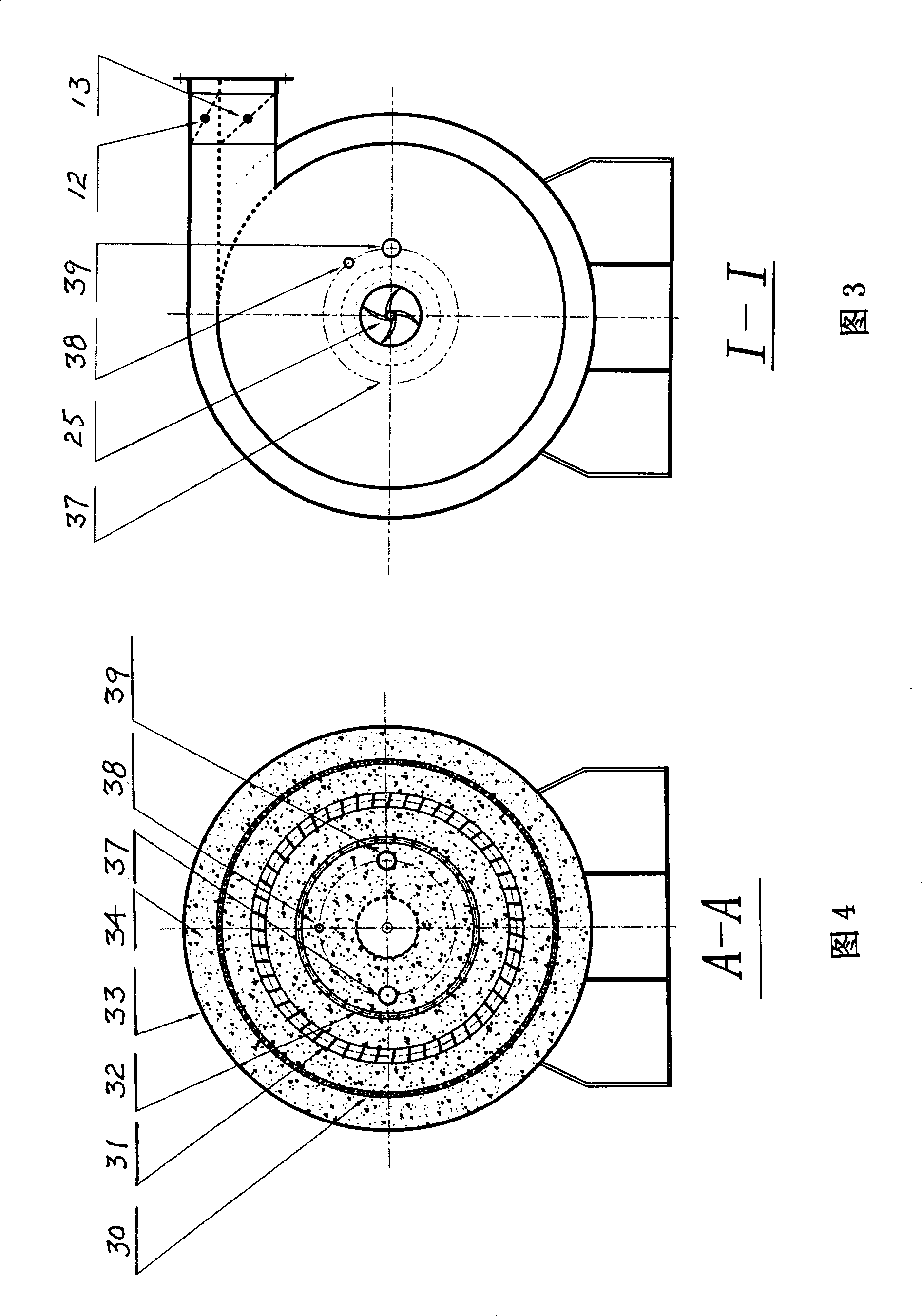

The invention relates to a low NOX solid residue discharge coal dust combustion method which is characterized in that a fire grate at the bottom of an old boiler is dismounted, so that a pure hearth is formed, or a boiler provided with the pure hearth is manufactured; at least one inflamer is arranged at the bottom or one side of the pure hearth; when a primary air fan is started, primary air andcoal dust enter the inflamer through a primary air / coal dust pipe, so that the primary air and the coal dust can burn sufficiently after entering a combustion chamber; meanwhile, a flame detector automatically enters a crust block prevention tertiary air curtain regulating valve which can monitor and has the function of linkage protection and regulation and a secondary air regulating valve, an air curtain is formed on the inner wall of a high temperature fire resistant layer by the wind sprayed out of a crust block prevention tertiary air curtain spray pipe, the secondary air enters the combustion chamber through a secondary air rotational flow guider and a secondary air flame stabilizing rotational flow guider, the rotational flow direction of the secondary air is consistent with that ofan axial flow generator, and the secondary air is mixed with the coal dust burnt by the primary air again to be burnt, thus leading the coal dust to be burnt more fully. The invention has the advantage of burning the coals with low ash fusion point and high ash fusion point.

Description

Combustion method of low NOX solid slagging pulverized coal technical field The invention relates to a low NOX solid slagging pulverized coal combustion method, suitable for 2-35 tons of steam, hot water boilers, kilns, forging, steelmaking, road and bridge mixing stations, heating of cold aggregates, ignition of power plant boilers and other industries The field produces a combustion device that requires heat energy, and belongs to the technical field of pulverized coal burners. Background technique Chain boiler is a furnace type widely used in industrial boilers at present. As shown in Figure 1, it includes boiler furnace C and chain grate B. Fuel coal A enters the boiler and burns in layers on chain grate B. The combustion flue gas flows from The outlet D of the boiler furnace C is discharged. The disadvantage of this kind of boiler is that the mixture with the air is not sufficient during combustion, resulting in incomplete combustion, low burnout rate, large q4 loss, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F23C5/00F23D1/00F23N1/02F23N5/00F23L1/00F23L9/00

Inventor 郑雯平潘玉明

Owner 郑雯平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com