Cooling device for powder burned by saggar

A cooling device and powder technology, applied in inorganic chemistry, phosphorus compounds, non-metallic elements, etc., to achieve the effects of energy-saving powder cooling, simplified structure, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

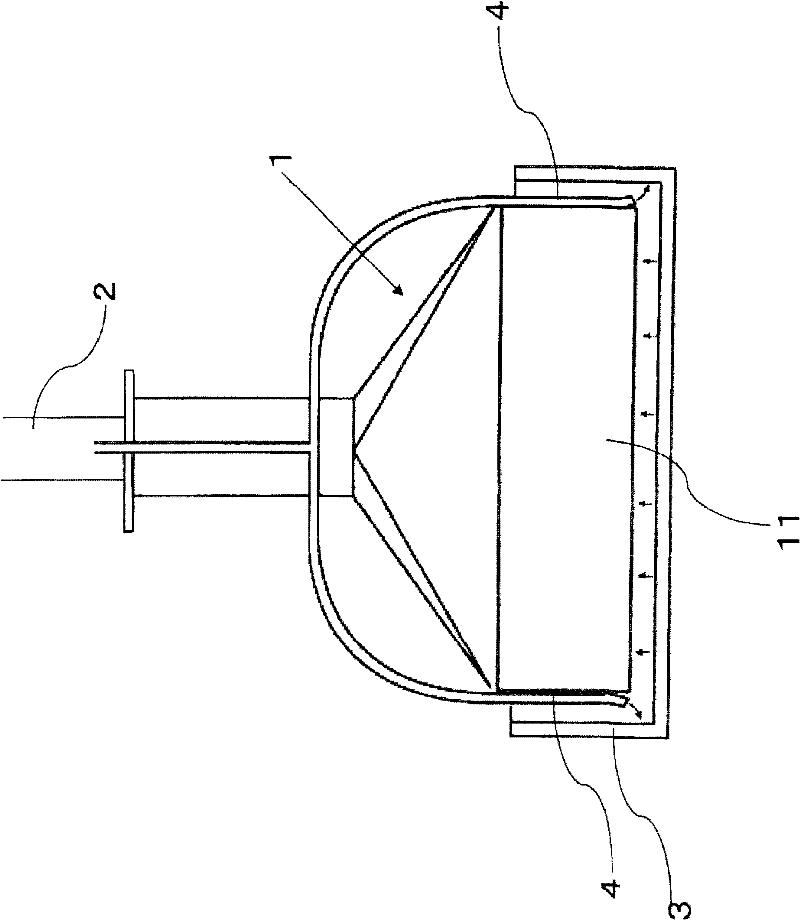

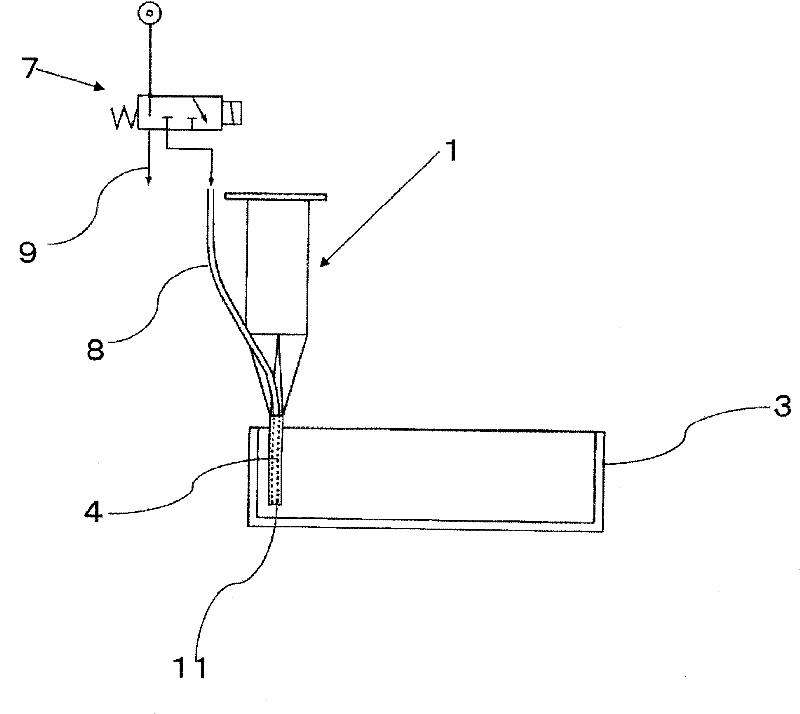

[0031] Next, preferred embodiments of the present invention are shown. figure 1 is the front view of the powder cooling device, figure 2 Yes figure 1 The side view of the cooling device is shown, and, in each drawing, 1 denotes a powder suction nozzle, 2 denotes a transport line, 3 denotes a sagger, and 4 denotes a gas nozzle.

[0032] The powder suction nozzle 1 has a scraper-shaped suction port 11 whose long side is approximately equal to the length of one side of the sagger, and has a gas nozzle 4 on the outer surface of the short side of the suction port.

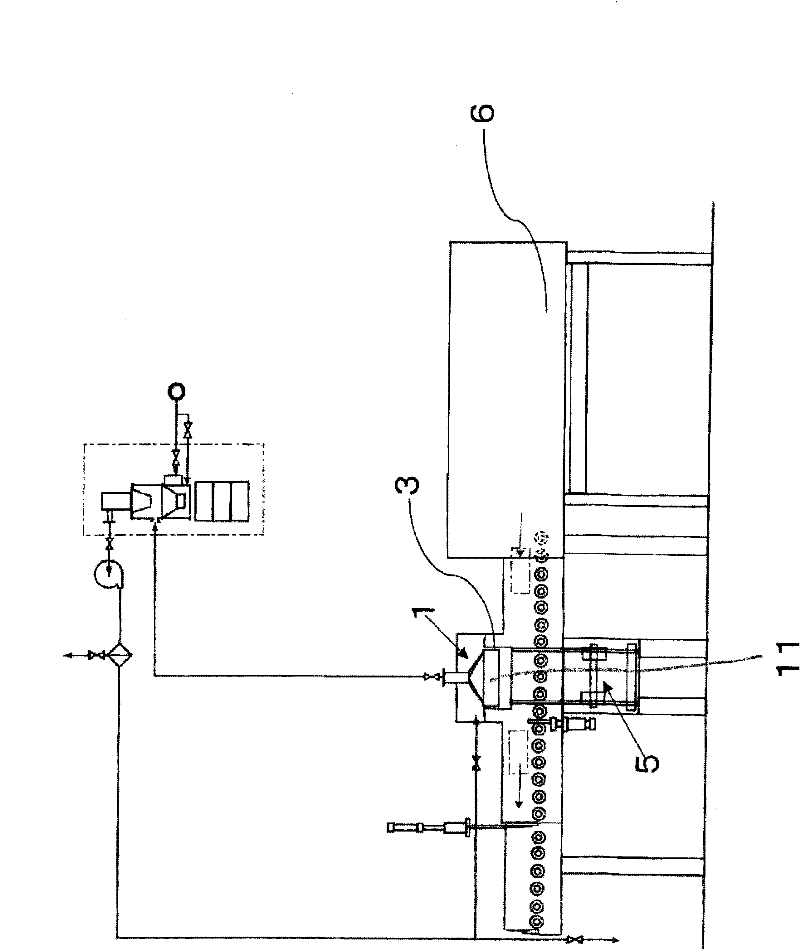

[0033] image 3 It is a figure for demonstrating the cooling device of the powder arrange|positioned at the exit of the continuous firing furnace 6. In this embodiment, if image 3 As shown, there is a sagger moving unit 5 for moving the sagger under the fixedly arranged powder suction nozzle 1 .

[0034] In this embodiment, the powder suction nozzle 1 is fixedly arranged, and if the sagger 3 taken out from the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com