Intelligent water-cooling permanent magnet frequency conversion direct-driving system for scraper conveyor

A scraper conveyor and water-cooling technology, applied in conveyors, transportation and packaging, single motor speed/torque control, etc., can solve the problems of insufficient cooling of the variable frequency drive system, insufficient starting of heavy loads, poor driving characteristics, etc., to achieve Improve reliability and service life, strong anti-overload ability, and reduce failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

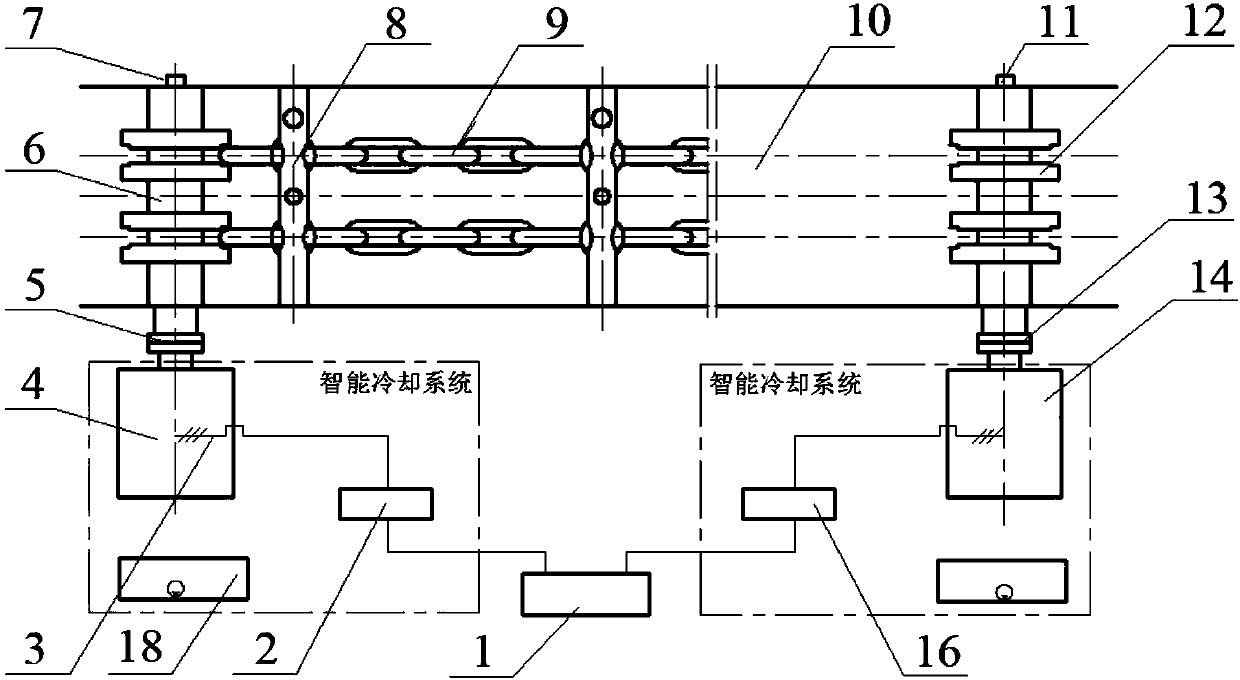

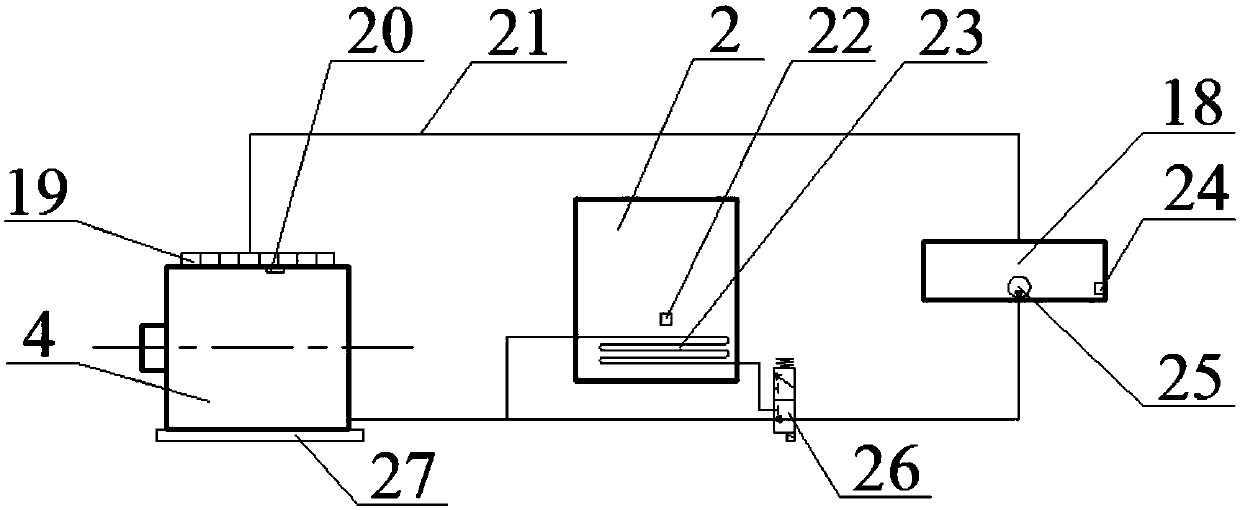

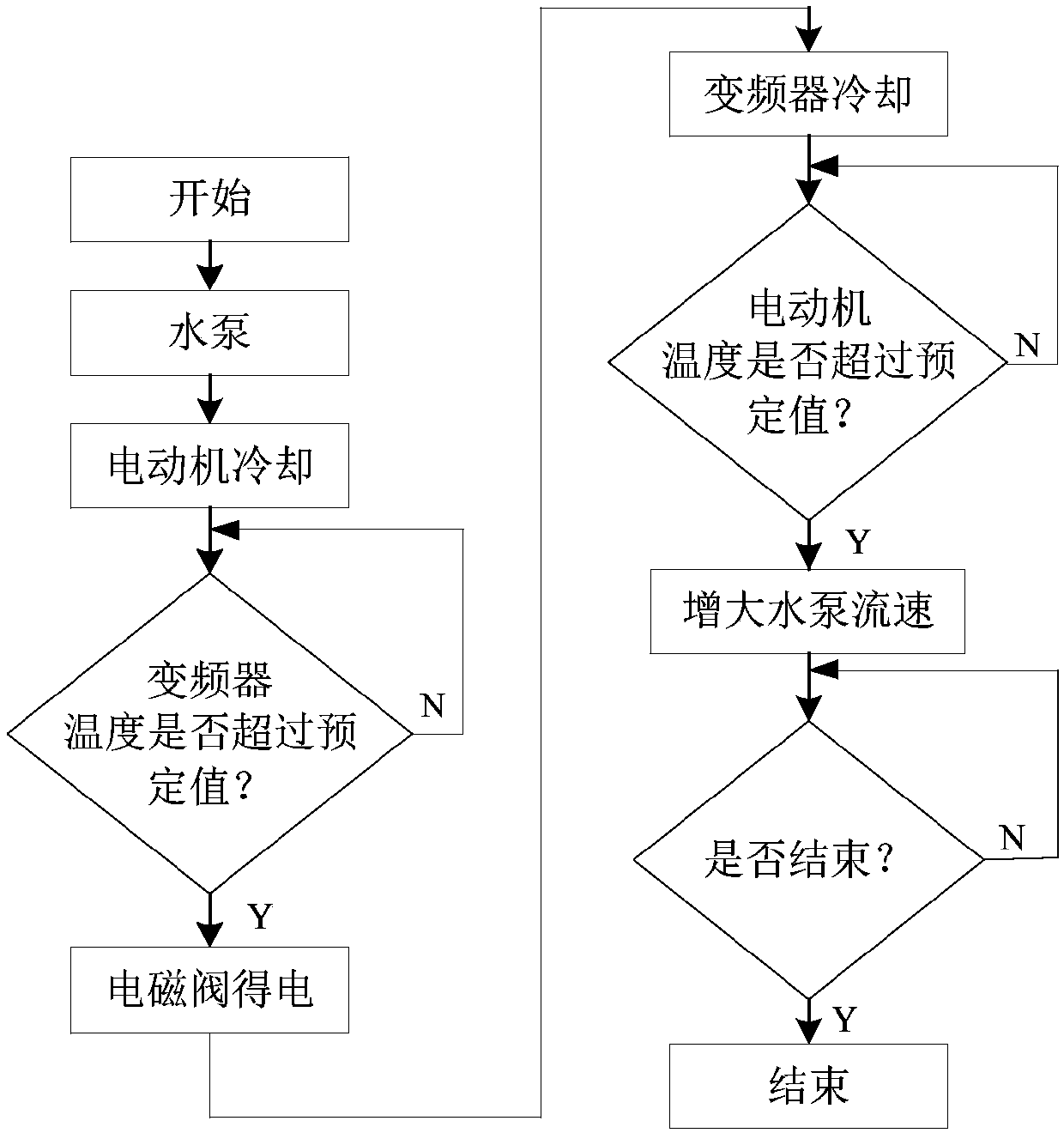

[0018] combined with Figure 1-3 , the present invention will be described in further detail.

[0019] like figure 1 As shown, the intelligent water-cooled scraper conveyor permanent magnet frequency conversion direct drive system of the present invention mainly includes a controller 1, a frequency converter I 2, a frequency converter II 16, a low-speed high-torque permanent magnet synchronous motor I 4, a low-speed high-torque permanent magnet Synchronous motor II 14, coupling I 5, coupling II 13, scraper conveyor sprocket I 6, scraper conveyor sprocket II 12, scraper 8, scraper chain 9, middle slot 10, and connection The three-phase wire 3 of the low-speed high-torque permanent magnet synchronous motor I 4 and the frequency converter I 2. The low-speed high-torque permanent magnet synchronous motor I 4 is connected to one end of the scraper conveyor sprocket I 6 through the coupling I 5, and drives the scraper conveyor sprocket I 6 to rotate; the low-speed high-torque perm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com