Low-pressure steam generating device

A low-pressure steam generation device technology, applied in the field of low-pressure steam generation devices, can solve the problem that the heating temperature of the reaction vessel is difficult to control accurately, and achieve the effects of high cost performance, industrial steam saving, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

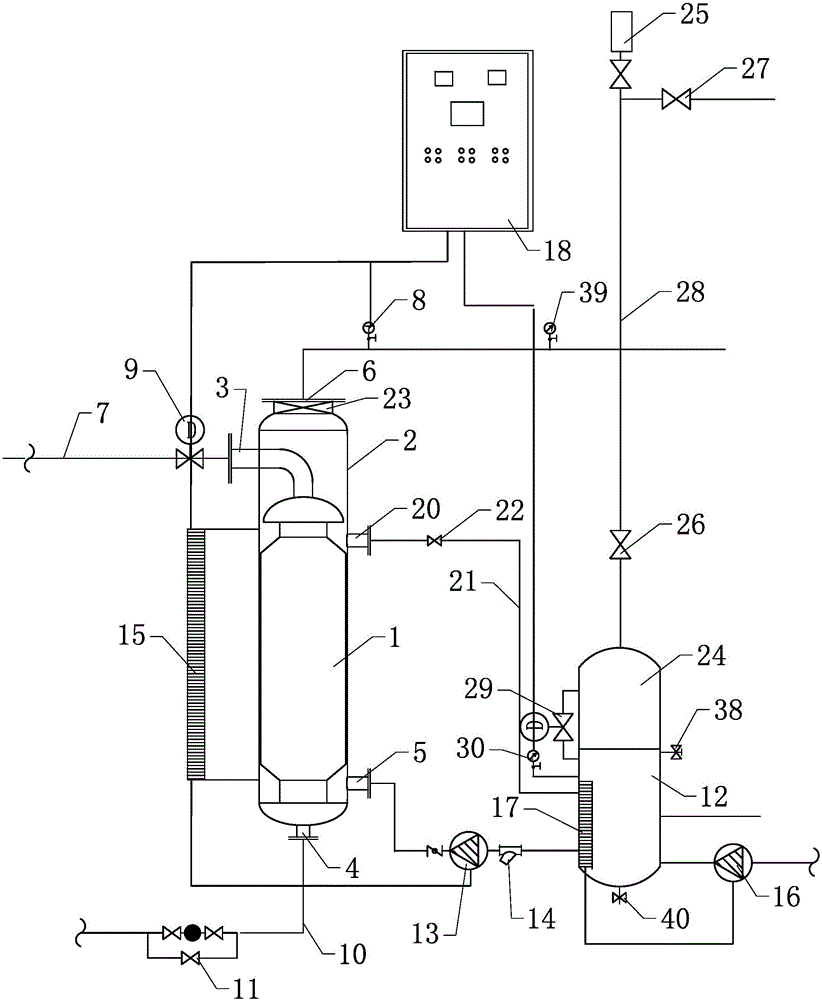

[0071] This embodiment is a specific embodiment of the low-pressure steam generating device.

[0072] A low-pressure steam generating device, comprising a heat exchanger core 1 and a shell 2, the heat exchanger core 1 has a first inlet 3 leading to a high-temperature medium and a first outlet 4 for discharging a condensing medium; the shell The body 2 surrounds the heat exchanger tube core 1, and the shell 2 is provided with a second inlet 5 and a low-pressure steam outlet 6 at the top of the shell. Medium (easily vaporized medium is the medium that can be evaporated to form low-pressure steam under the heating action of the heat exchanger tube core). The easy-to-vaporize medium is a liquid whose boiling point is lower than the temperature of high-temperature steam, including but not limited to water and ethanol. By passing high temperature into the heat exchanger tube core 1, the easy-to-vaporize medium in the shell 2 is heated, and the easy-to-vaporize medium will generate ...

Embodiment 2

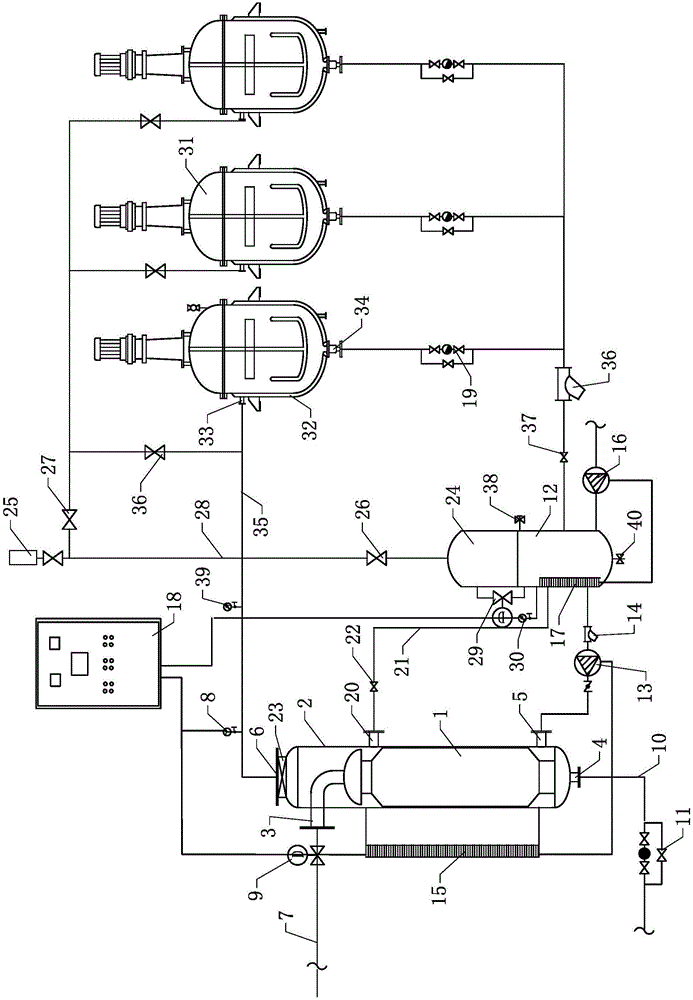

[0084] This embodiment is a specific embodiment of the high-efficiency temperature control system. In the high-efficiency temperature control system, a low-pressure steam generator is used.

[0085] The high-efficiency temperature control system with the device comprises the above-mentioned low-pressure steam generating device and at least one reaction vessel 31, the reaction vessel 31 is provided with a jacket 32, and the jacket 32 has a low-pressure steam inlet 33 and a condensate outlet 34, the low-pressure steam inlet 33 communicates with the low-pressure steam outlet 6 of the low-pressure steam generating device through a low-pressure steam delivery pipeline 35, and the low-pressure steam generated by the low-pressure steam generating device enters the jacket 32, and the The reaction vessel 31 is heated. This device has high heating efficiency and high cost performance. The low-temperature steam used as the heating medium of the reaction vessel has a heating efficienc...

Embodiment 3

[0090] This embodiment provides a temperature control method, the temperature control method is carried out by using the high-efficiency temperature control system as in Embodiment 2, and the low-pressure steam generated by the low-pressure steam generating device enters the jacket of the reaction vessel through the low-pressure steam delivery pipeline Inside, the temperature-controlled heating of the heating container is realized.

[0091] The method comprises the steps of:

[0092] (1) Open the vent valve 38 at the top of the liquid storage tank 12, close the drain valve 40, and simultaneously open the replenishment pump 16 and the circulation pump 13 to replenish the easy-to-vaporize medium in the liquid storage tank 12 until the liquid storage tank 12 and the liquid in the housing 2 The easily vaporized medium reaches the maximum liquid level;

[0093] (2) the second steam trap 19 of the reaction vessel, the intake valve 36 of the low-pressure steam delivery pipeline, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com