Method for producing beryllium-bronze flat ingot by natural-gas walking beam furnace

A walking heating furnace and technology for producing beryllium, which is applied in the field of non-ferrous metals, can solve the problems of increasing the oxidation degree of the surface of beryllium bronze slabs, reducing the utilization rate of beryllium copper slabs, and poor control effects, etc., to achieve uniform ingot temperature, Fire prevention, good uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

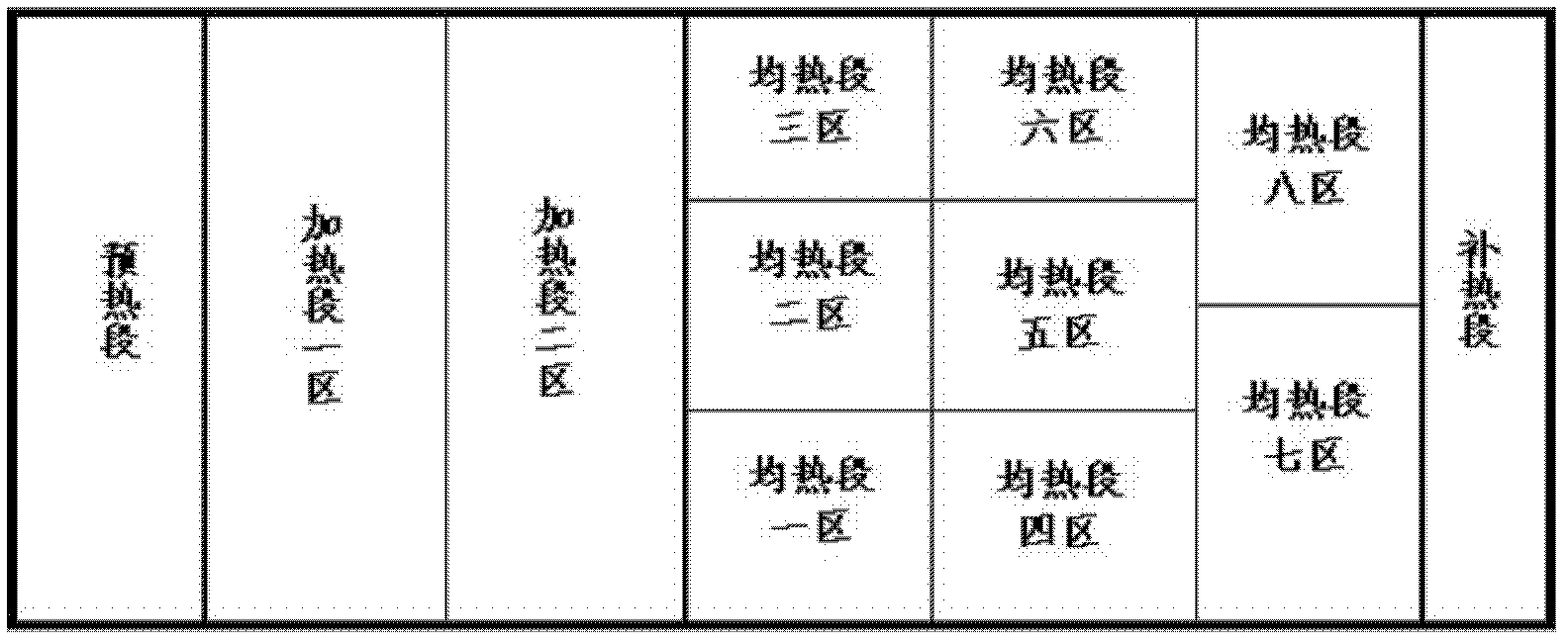

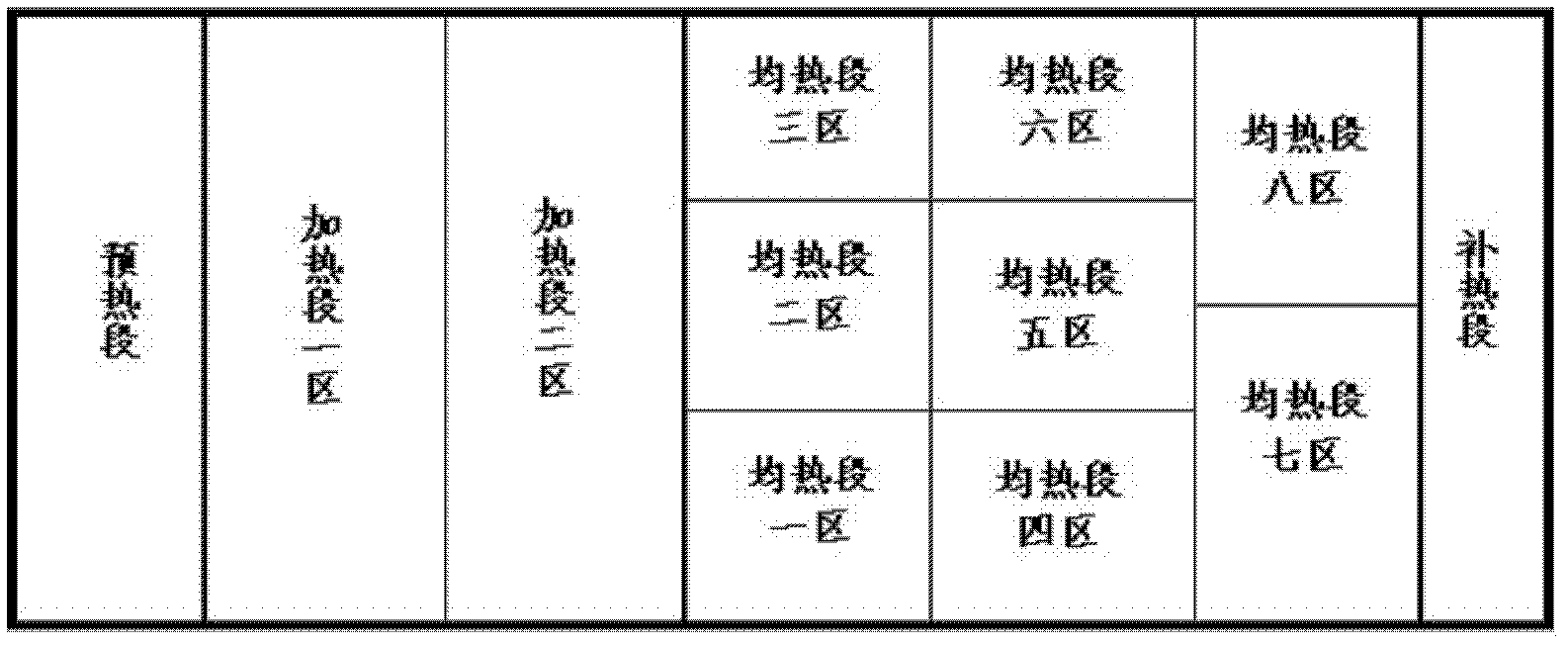

[0025] This walking heating furnace is heated by natural gas, and the calorific value of natural gas: Q 低 = 34.91MJ / Nm 3 ;Contact pressure in front of furnace: 8~10 kPa; Low calorific value: 34.91 MJ / Nm 3 . The beryllium bronze slab furnace goes through the preheating section, heating section, and soaking section to complete the heating and heat preservation process of the billet, and realize the heating temperature and ingot temperature uniformity required by the rolling process.

[0026] 1. Oven: Baking the furnace at 600°C for 4 hours before loading the furnace. In order to ensure safety, a safety interlock device is installed between the heating equipment and the fan to strictly prevent gas backflow and explosion accidents. When the outlet pressure of the blower or the pressure of the gas main pipe is too low, the quick shut-off valve on the gas main pipe will be automatically closed, and the nitrogen purge system will be opened. At the same time, an audible and visual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com