Patents

Literature

89results about How to "Guaranteed heating quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

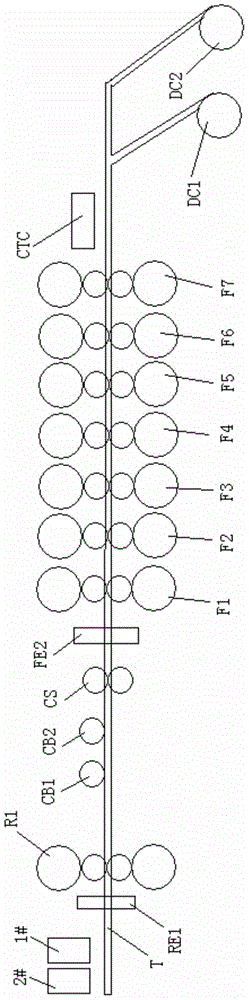

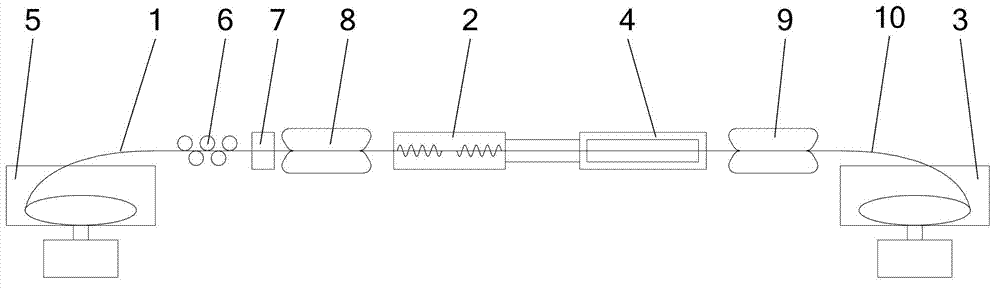

Hot rolling titanium plate production method and system

InactiveCN103599927AImprove yieldSimple methodWork treatment devicesMetal rolling arrangementsLaminar coolingStrip mill

The invention provides a hot rolling titanium plate production method and system. The method includes the steps of firstly, heating a titanium plate blank, and feeding the same to a coarse rolling device after iron oxide generated by a furnace is removed; secondly, by the coarse rolling device, coarsely rolling the titanium plate blank to allow the thickness of the middle of the blank to 25-40mm, and then feeding the same to a hot coil box; thirdly, uncoiling with an uncoiling arm, using a head cutting flying shear to cut the irregular head into an arc shape when the head of the titanium plate blank is guided out, and then feeding the same to a fine rolling machine set for fine rolling; fourthly, continuously rolling the titanium plate blank into finished titanium strips through the fine rolling machine set which comprises seven total hydraulic four-roll rolling machines, and feeding the strips to a laminar cooling device for cooling; fifthly, coiling the titanium strips in a coiling machine to form titanium strip coils. The method has outstanding advantages that the method is simple and high in automation level, and yield and production efficiency of the titanium strip coils can be increased by accurate control of each link.

Owner:SICHUAN SOUTHWEST STAINLESS STEEL

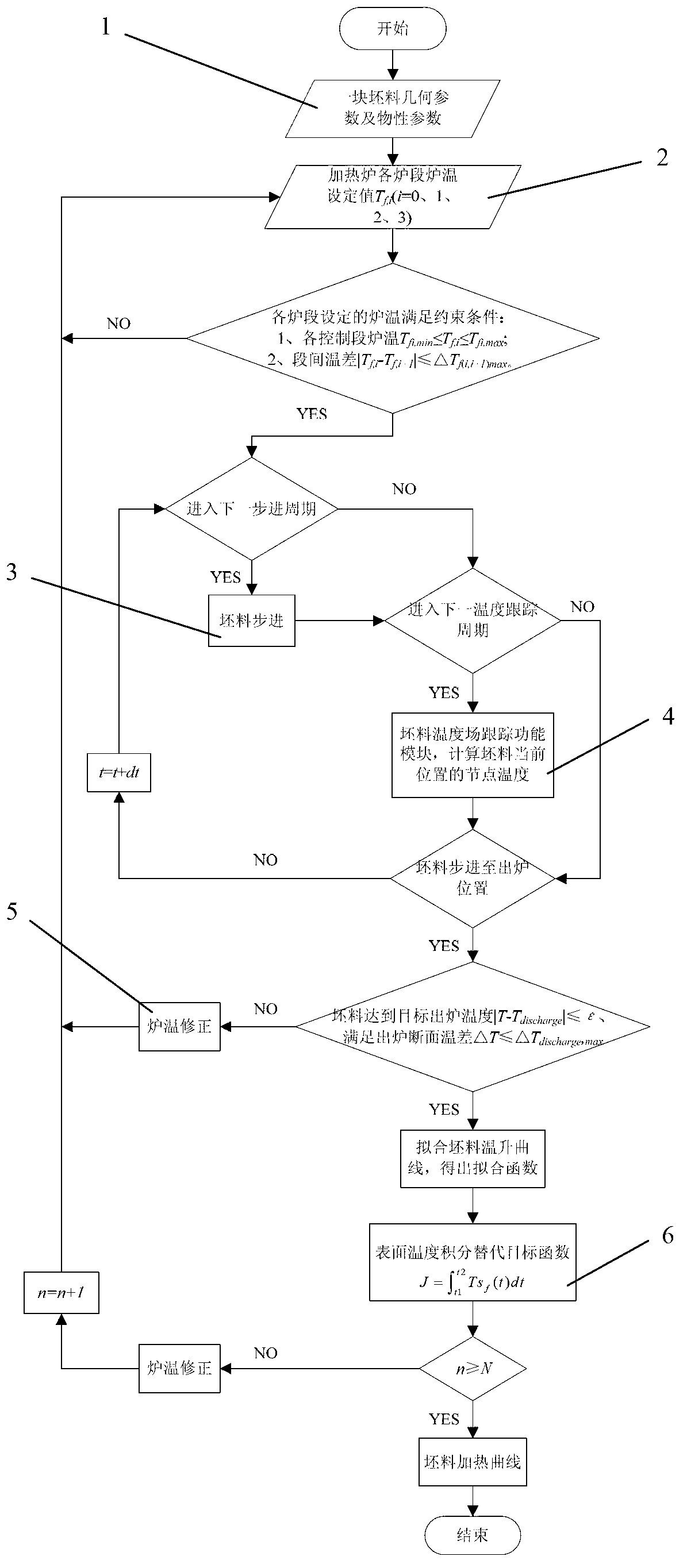

System and method for calculating optimal heating curve of blank in heating furnace

ActiveCN102994731AReduce labor intensityComputational flexibilityFurnace typesHeat treatment furnacesFurnace temperatureMathematical model

The invention relates to a method for calculating an optimal heating curve of a blank in a heating furnace and stepping and heating of the blank in the heating furnace can be realized mainly by position tracking and temperature tracking. The original furnace temperature schedule is revised by comprehensive considering of a difference between the tapping temperature and the target temperature of the blank and a heating rate of the blank, and the blank is reheated by the revised furnace temperature schedule; for the blank satisfying the tapping temperature, the fuel consumption used for the heating in the time is represented by an integral-replaced objective function; and after the optimizing calculation can be carried out for specified number of times, one integral-replaced objective function having the least value is selected out, and a heating curve corresponding to the integral-replaced objective function having the least value is taken as the optimal heating curve of the blank with the size. According to the method for calculating the optimal heating curve of the blank in the heating furnace, the calculations of the optimal heating curves of a plurality of blanks before the blanks are sent into the furnace can be finished, and the calculating efficiencies are high; and a heating schedule is beneficially revised by the calculated optimal heating curve of the blank by a heating furnace mathematical model, the heating quality of metal and the production efficiency of the heating furnace are improved, and the optimal control of the heating furnace is beneficially realized.

Owner:WISDRI WUHAN WIS IND FURNACE

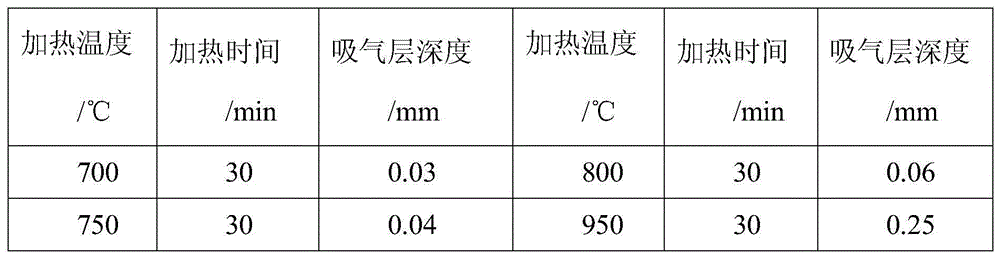

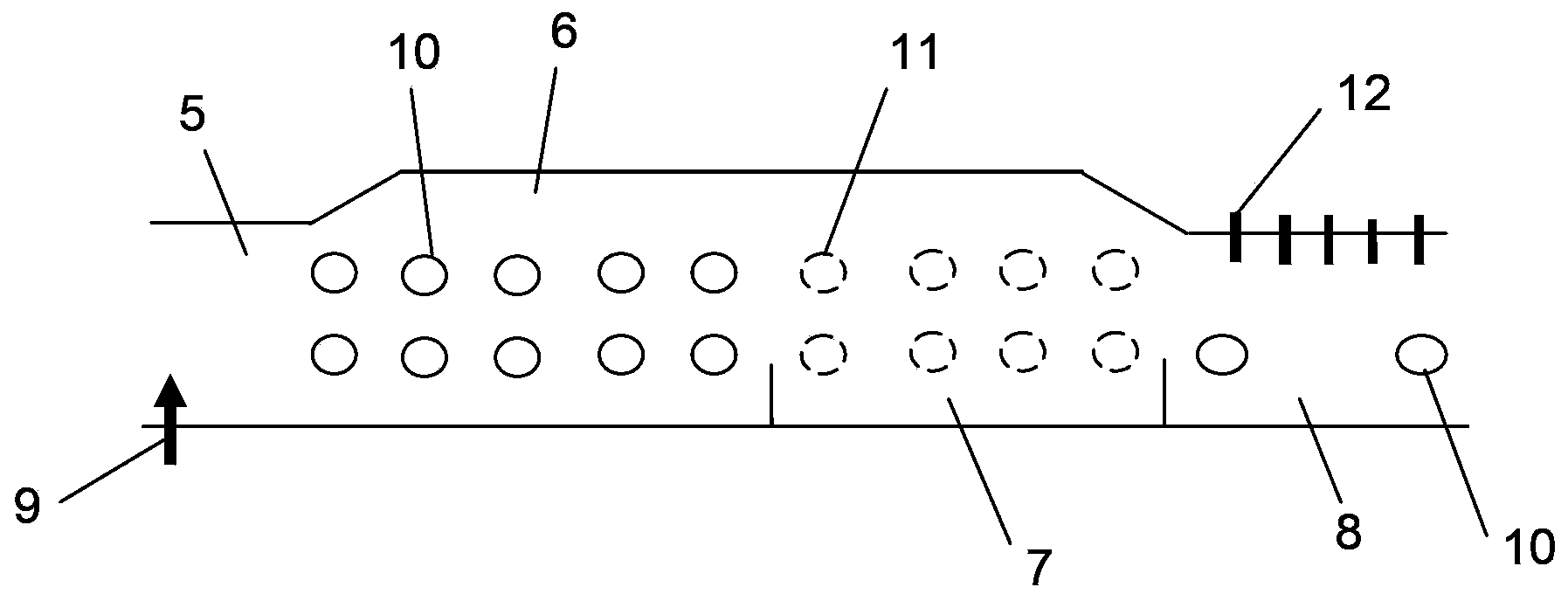

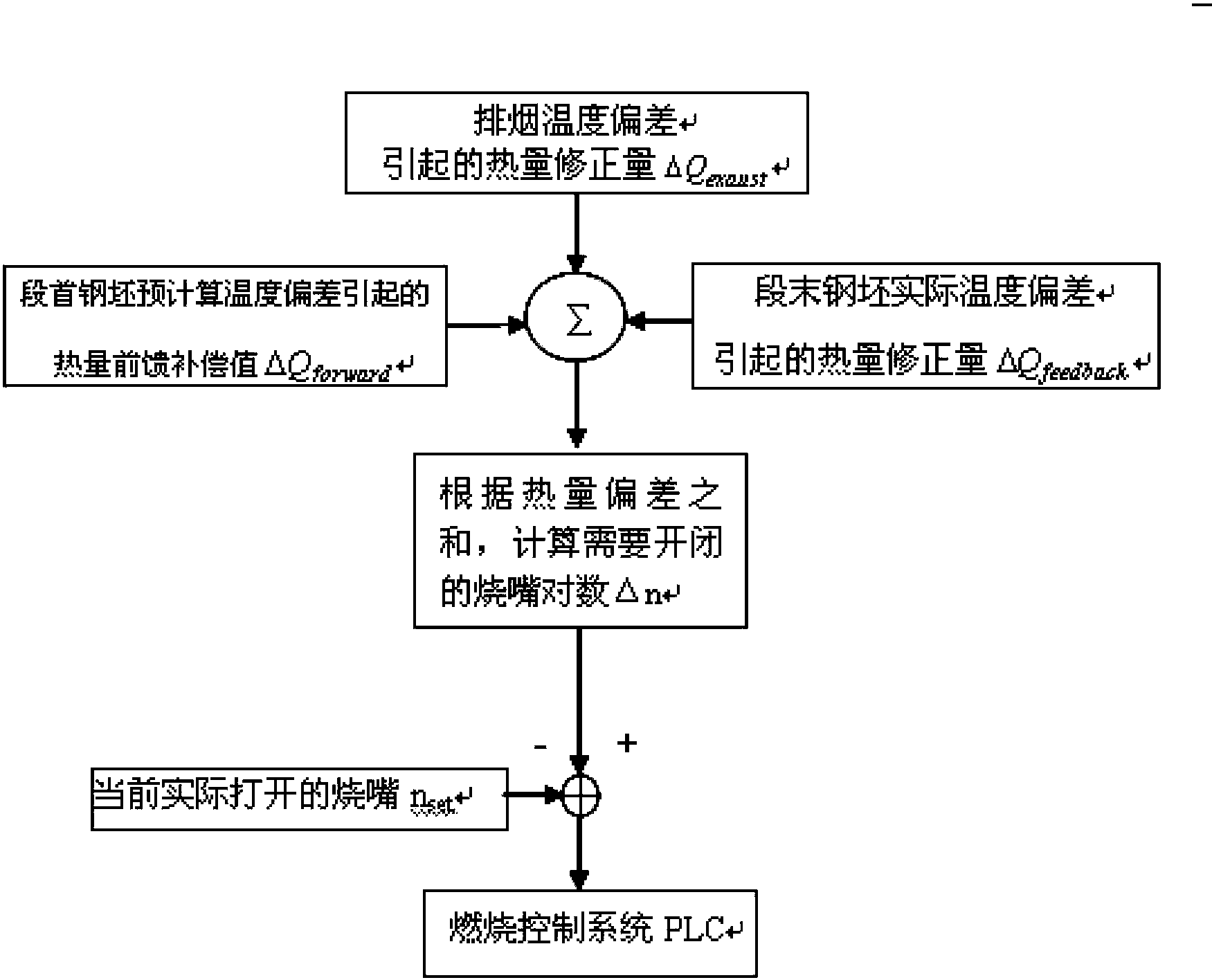

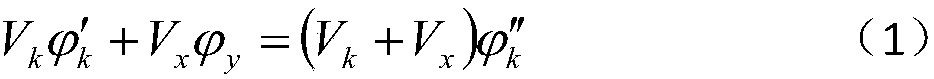

Method for heating industrial pure titanium plate blank by common step-by-step heating furnace

InactiveCN101974727AGuaranteed heating qualityLow investment costTemperature control deviceCombustionHeating furnace

The invention discloses a method for heating an industrial pure titanium plate blank, in particular to a method for heating an industrial pure titanium plate blank by a common step-by-step heating furnace. The invention provides a method for heating an industrial pure titanium plate blank by adopting a common step-by-step heating furnace for heating a steel billet. The heating method keeps the temperature of all heating sections below the temperature needed for generating chemical reaction on the industrial pure titanium plate blank by adjusting the combustion capacities of burning nozzles of all heating sections of the heating furnace, ensures that a front furnace temperature adjusting steel billet enters the heating furnace for adjusting furnace temperature before the pure titanium plate blank enters the heating furnace and ensures that a rear furnace temperature adjusting steel billet is discharged out of the heating furnace after all pure titanium plate blanks are discharged out of the heating furnace, thereby ensuring the heating quality of the whole heating process.

Owner:PANZHIHUA IRON AND STEEL +3

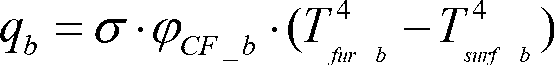

Hot rolling heating furnace and local strengthening heating control method thereof

ActiveCN103388071ABest burning stateTo achieve the purpose of local strengthening heatingFurnace typesMetal rolling arrangementsCombustionProcess engineering

The invention discloses a hot rolling heating furnace; and the hot rolling heating furnace is designed by comprising a furnace tail section, a preheating section, a heating section and a heat average section. The invention also discloses a local strengthening heating control method of the hot rolling heating furnace; an impulse burner is arranged at the preheating section, a constant combustion mode is adopted, the input amount of the impulse burner can be controlled according to the heat demand of the preheating section to make the burner to maintain an optimal combustion state, and the purpose of local strengthening heating can be achieved, so that temperature uniformity of the furnace width direction can be improved, the heating quality can be ensured and the energy saving purpose can be achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

Temperature control rolling method for Q345 steel plate

InactiveCN102151696AGuaranteed total deformationIncrease production capacityTemperature control deviceMetal rolling arrangementsMaterials scienceCrystallite

The invention discloses a temperature control rolling method for a Q345 steel plate. The method comprises the following steps of: after the Q345 steel plate blank passes through a preheating section, a heating section and a soaking section in a steel pushing heating furnace, discharging and removing oxide skin; performing first-stage rolling at the temperature of between 1,000 and 1,050 DEG C, wherein the total deformation is 50 to 60 percent, and then performing air cooling or water cooling for temperature reduction; and when the temperature is reduced to 900 to 950 DEG C, performing secondary-stage rolling, wherein the total deformation is 20 to 40 percent, and the rolling temperature is 800 to 850 DEG C, and then performing water-cooling or air-cooling quickly. In the method, the first-stage and second-stage control rolling is adopted, namely recrystallization area rolling and non-recrystallization area rolling are combined; large processing deformation is performed on an austenite recrystallization area at high temperature, and austenite recrystallization grains are refined by the repeated deformation and recrystallization of austenite grains; and in rolling process after the temperature is reduced, the full deformation is performed on a non-recrystallization area, and on the premise of guaranteeing the total deformation of the austenite recrystallization area, single-pass large deformation rolling is realized.

Owner:WESTERN TITANIUM TECH

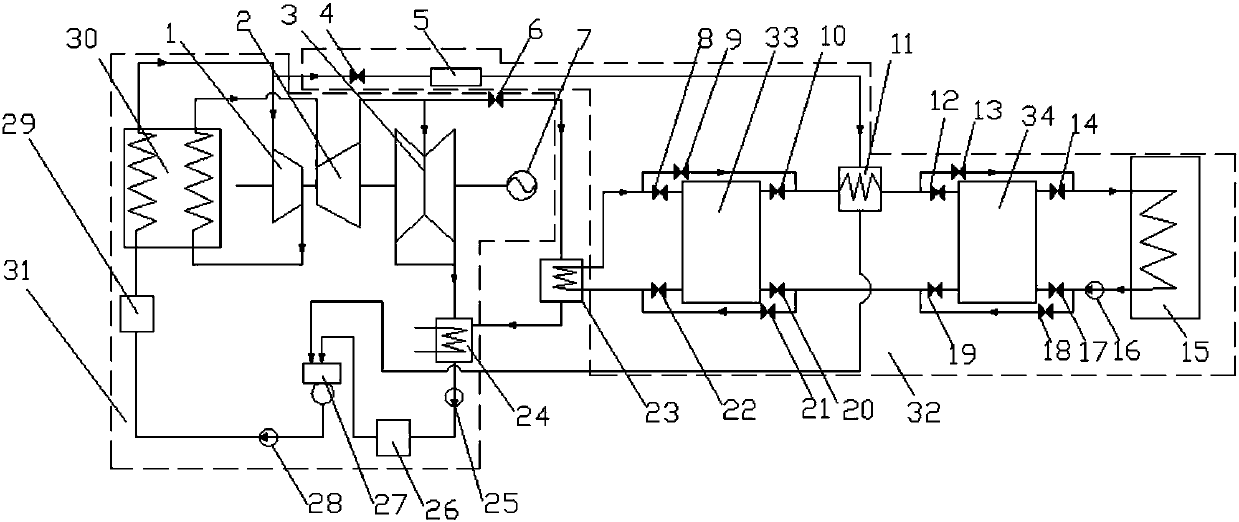

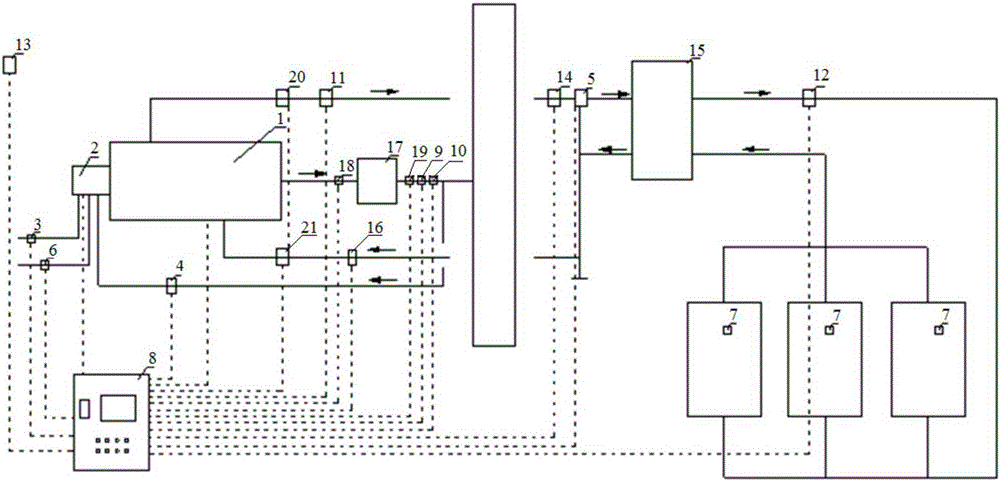

Graded heat storage system for cogeneration unit and peak shaving method thereof

PendingCN107940538AGuaranteed not to changeGuaranteed heating qualityCentral heating with accumulated heatLighting and heating apparatusThermal energyCogeneration

The invention discloses a graded heat storage system for a cogeneration unit and a peak shaving method thereof. The graded heat storage system comprises a power plant system and a heat storage system.The power plant system comprises a boiler, a steam turbine high-pressure cylinder, a steam turbine intermediate-pressure cylinder, a steam turbine low-pressure cylinder, an electric generator, a condenser, a condensate pump, a low-pressure heater, a deaerator, a water-feeding pump and a high-pressure heater. The heat storage system comprises a first heat network heat exchanger, a second heat network heat exchanger, a first control valve, a first heat storage water tank, a second heat storage water tank, a steam expander, a heat user part and a heat network circulating water pump. When the power grid load quantity demand is large and the heat production quantity is sufficient, the first heat storage water tank and the second heat storage water tank store heat, and when power grid peak shaving is conducted, the electric load is decreased and the heat production quantity is decreased, the first heat storage water tank and the second heat storage water tank release the heat, so that the heat supply quality is unchanged. The graded heat storage mode is utilized, the graded heat storage system is more suitable for deep peak shaving of the cogeneration unit, the heat supply quality can be better guaranteed, and the heat energy utilization rate is increased.

Owner:HUANENG POWER INTERNATIONAL +1

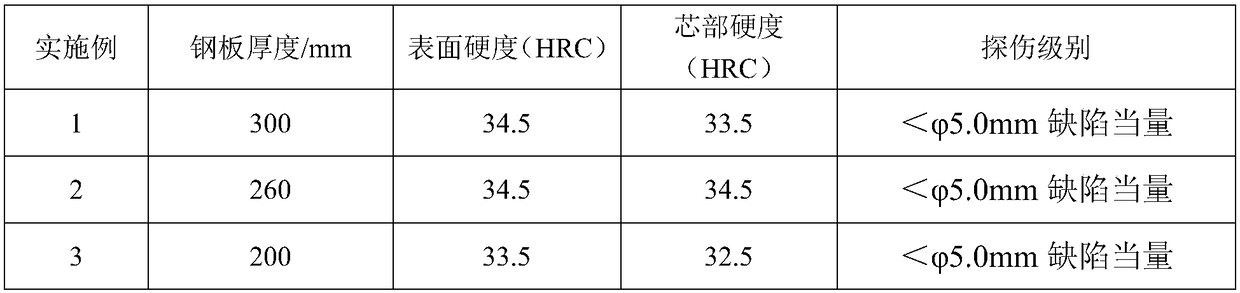

100-260 mm-thick tempering-state prehardened plastic mold steel plate and manufacturing method thereof

ActiveCN107177796AImprove organizationImprove the quality of flaw detectionSheet steelChemical composition

The invention relates to a 100-260 mm-thick tempering-state prehardened plastic mold steel plate. The steel plate has the following chemical components in percentage by mass: 0.35-0.45 of C, 0.20-0.50 of Si, 0.60-1.00 of Mn, 1.00-2.50 of Cr, 0.20-0.50 of Mo, 0.04-0.15 of V+Ti, 0.01-0.04 of Als, 0.015 or less of P, 0.005 or less of S, and the balance of Fe and inevitable impurities; the steel plate is uniform in performance; the overall hardness difference is not more than 2.0 HRC; and the steel plate reaches NB / T47013.3 plate part I grade requirements by ultrasonic detection. The overall hardness difference is not more than 2.0 HRC; the steel plate reaches NB / T47013.3 plate part I grade requirements by ultrasonic detection; and the total inclusion grade is not higher than 2.5. The chemical components of the mold steel plate are simplified; the improvement is performed from the production process angle; the difference of the steel plate in the thickness direction is reduced; and in particular, the section hardness uniformity is improved.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

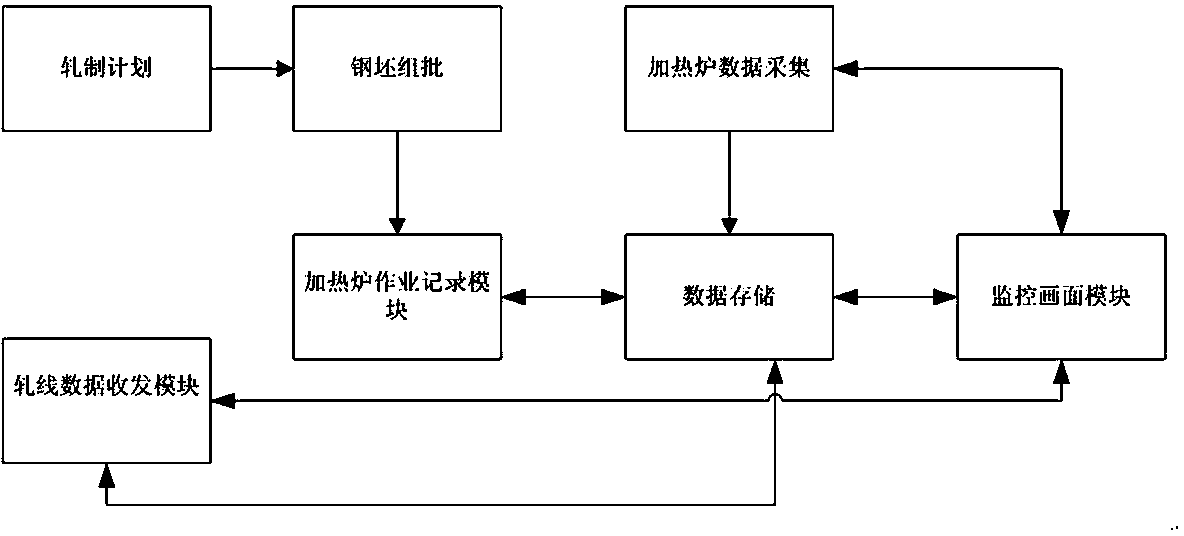

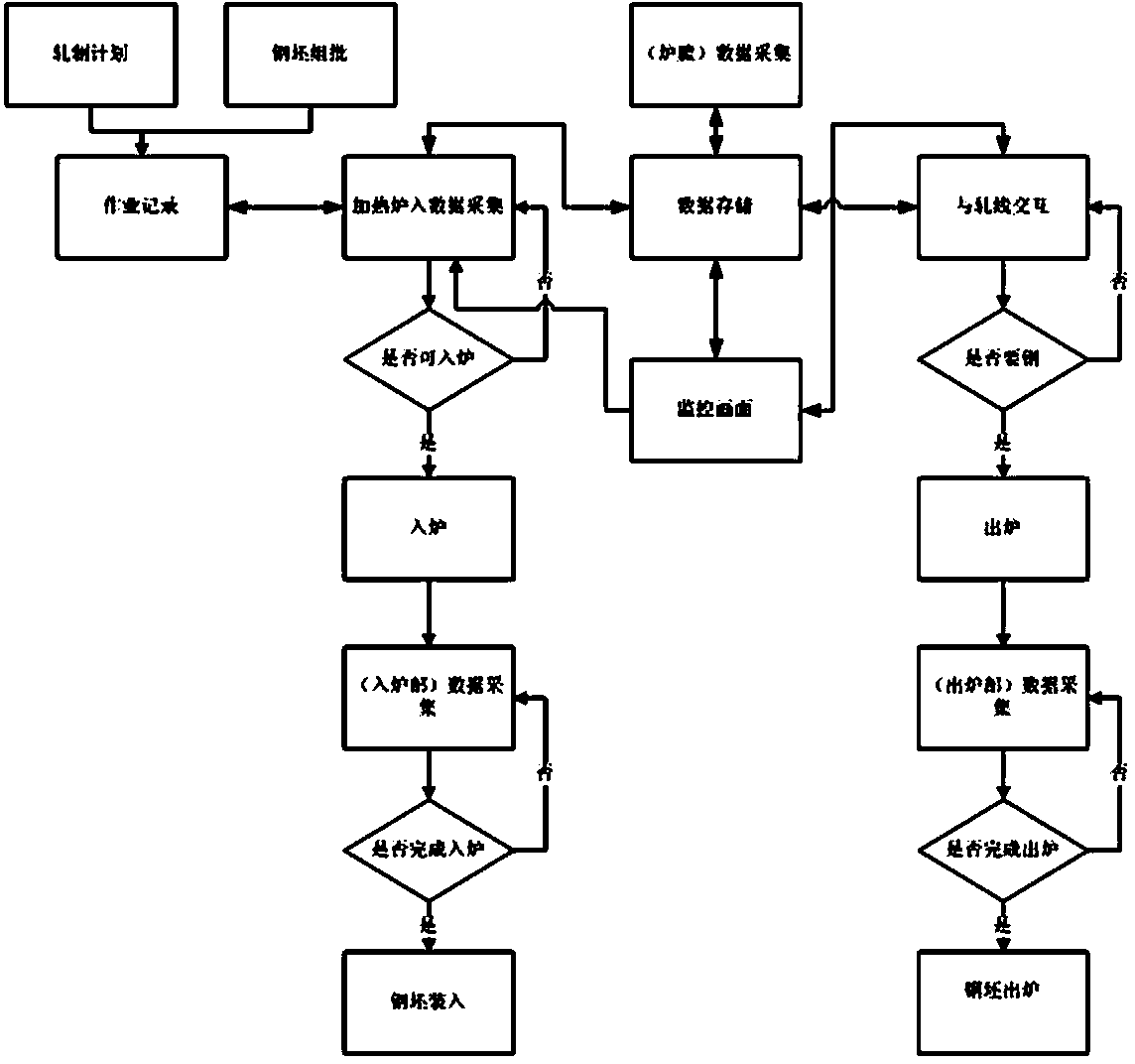

System and method for managing steel billets in heating furnace

The invention discloses a system and a method for managing steel billets in a heating furnace. The system for managing the steel billets in the heating furnace comprises a plan module, a lot grouping module, a data acquisition module, a data memory module, an image generation module, a data logging module, and a data transceiving module. The method for managing the steel billets in the heating furnace includes the following steps of compilation of a rolling plan, rolling and lot grouping of the steel billets, steel billet feeding into the furnace, and steel billet discharging from the furnace; during a heating process, if conditions of steel billet shortage, waste elimination, and returning are encountered, the conditions are recorded in a heating abnormal data table; during shift changing, shift information of shift changing operation staff is recorded, and rolling conditions of the steel billets are updated. According to the system and the method for managing the steel billets in the heating furnace, steel billet feeding into the furnace and steel billet discharging from the furnace are automatically judged, automatic interaction with rolling lines is achieved, and most of data of an operation hearth of the heating furnace and steel billet heating processes are automatically recorded by the data memory module; centralized control of steel billet lot grouping to steel billet heating of heating furnace operation is achieved, efficiency of steel billet feeding into the furnace and steel billet discharging from the furnace is high, the steel billet heating process is monitored, heating qualities can be guaranteed, and energy consumption is saved.

Owner:WUKUN STEEL

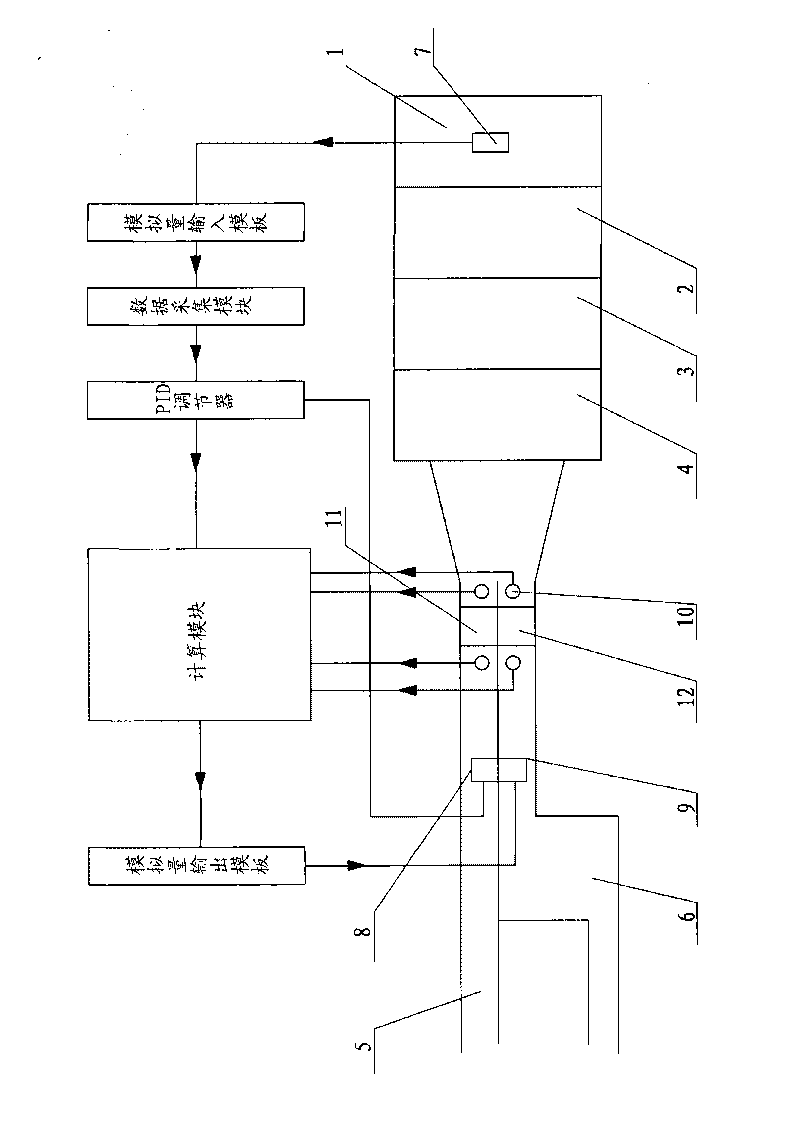

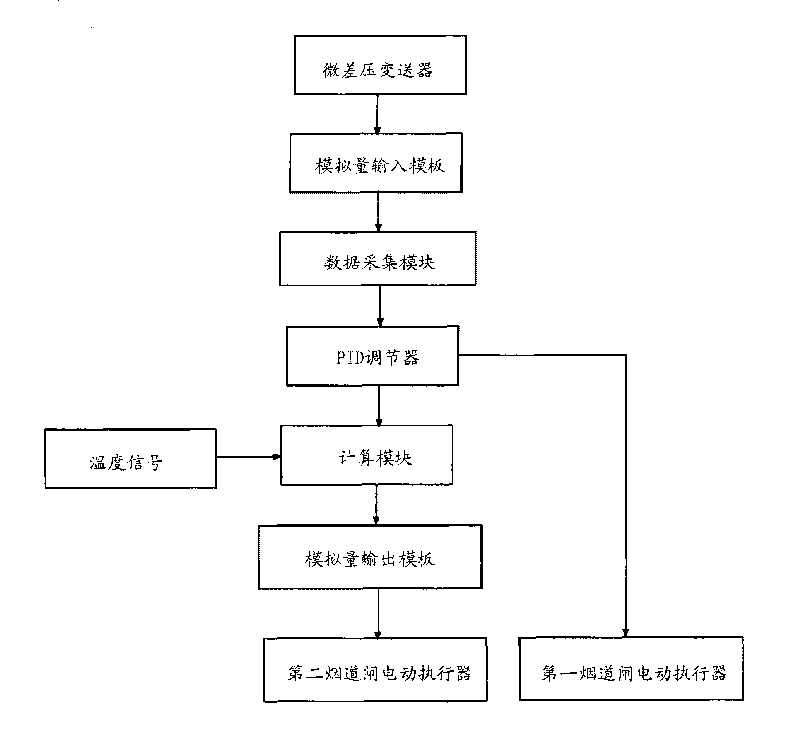

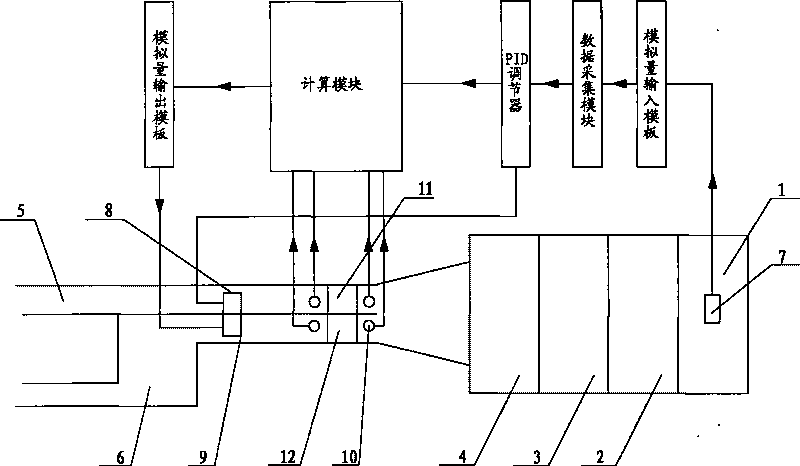

Method for controlling furnace pressure of heating furnace with dual flues

InactiveCN101760607AControl furnace pressureReduce heat consumptionFurnace typesHeat treatment process controlEngineeringTemperature difference

The invention discloses a method for controlling the furnace pressure of a heating furnace with dual flues. In the method, a flue damper electric executer on one side of the heating furnace is controlled according to a furnace pressure signal to control the opening of a flue shutter on one side of the heating furnace, and the flue damper electric executer on the other side of the heating furnace is controlled according to the furnace pressure signal obtained by compensating the furnace pressure signal with temperature difference signals of heat exchangers in the flues on the two sides of the heating furnace to control the opening of the flue shutter on the other side of the heating furnace, so that differential control over the opening of the flue shutters on the two sides of the heating furnace is realized to further effectively control the furnace pressure and ensure the heating quality of billets.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM +1

Preparation method of black tomato freeze-dried powder

PendingCN105053873AAvoid it happening againConducive to sublimationFood preservationFood shapingChlorine dioxideAutomatic control

The invention discloses a preparation method of a black tomato freeze-dried powder. The method adopting black tomatoes as a raw material comprises the following steps: choosing black tomatoes, removing impurities, disinfecting by using an aqueous solution of chlorine dioxide, cutting, pre-cooling, carrying out vacuum freeze-drying until the water content of the obtained material is 3.0-5.0%, and taking out the black tomatoes, wherein computer automatic control temperature programming is adopted in the vacuum freeze-drying process, the heating process is carried out according to a function of F=F1+(t / t1)3*(F2-F1), F is the heating medium temperature at the t moment after heating, t is 0 ~ t1, the unit of t is min, the total time t1 = 1020~1200min, an initial temperature F1 is 30~35DEG C, and a final temperature F2 is 50~55DEG C; and carrying out refrigeration crushing at a low temperature being smaller than -50DEG C to obtain the black tomato freeze-dried powder with the granularity being greater than 200 meshes. The black tomato freeze-dried powder is packaged by a silver paper bag, so the shelf life at normal temperature exceeds 1.5 years. The black tomato powder reserves nutritional substances and taste of fresh black tomatoes, and the above whole process is suitable for industrial production.

Owner:GUANGZHOU HUISHENGSENFENG AGRI SCI ANDTECH DEV CO LTD

Intelligent heat-supply system based on indoor temperature

InactiveCN105318393ASafe and stable operationMeet heat demandLighting and heating apparatusSpace heating and ventilation detailsShielded cableAutomatic control

The invention relates to an intelligent heat-supply system based on an indoor temperature. The heat-supply system is composed of a boiler, a burner, a gas meter, a first electric control valve, a system electric control valve, a draught fan, indoor temperature transmitters, an intelligent control device, an oxygen content sensor, a nitrogen oxide sensor, a boiler outlet thermal flowmeter, a secondary thermal flowmeter, an outdoor temperature transmitter, a primary system water supply temperature transmitter, a plate-type heat exchanger, a second electric control valve, a waste heat recovery device, a waste heat recovery device inlet pressure transmitter, a waste heat recovery device outlet pressure transmitter, a boiler outlet pressure transmitter and a boiler inlet pressure transmitter. The intelligent control device is communicated with the other components of the heat-supply system through shielded cables. The intelligent heat-supply system based on the indoor temperature has the advantages that automatic control and adjustment of heating output loads can be achieved according to real-time heat using requirements and the heat using requirements of users are met on the premise of ensuring the heating quality, ensuring the safe and stable operation of the boiler and reducing the operating cost.

Owner:BEIJING ZHICHENGHONGYE INTELLIGENT CONTROL TECH

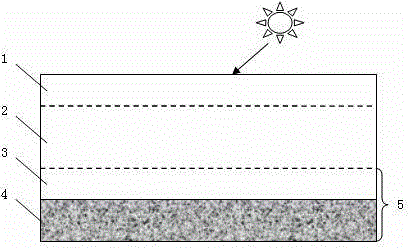

Salt gradient solar pond technology for accumulating heat by using latent heat

InactiveCN105588345AImprove heat storage capacityGuaranteed stabilitySolar heat devicesHeat storage plantsSaline waterInter layer

The invention provides a method for adding a latent heat accumulating layer at the bottom of a heat storage layer of a salt gradient solar pond, provides the salt gradient solar pond for continuously supplying a lot of heat supply quantities in an effective heat exchange temperature range, and achieves the purposes of guaranteeing stability of a gradient layer and greatly increasing the heat accumulating quantity of the heat storage layer. The salt gradient solar pond consists of three layers from top to bottom: the uppermost layer is an upper convection layer consisting of fresh water; the middle layer is a salt gradient layer with gradually increased salinity from top to bottom; and the lowermost layer is the heat storage layer mainly consisting of strong brine; the lower half part of the heat storage layer is the latent heat accumulating layer; the latent heat accumulating layer is a heat accumulating layer with a phase change material, is positioned in the heat storage layer, and is horizontally spread at the bottom of the heat storage layer; and the phase change material in the latent heat accumulating layer generates solid-liquid phase change in use.

Owner:HENAN POLYTECHNIC UNIV

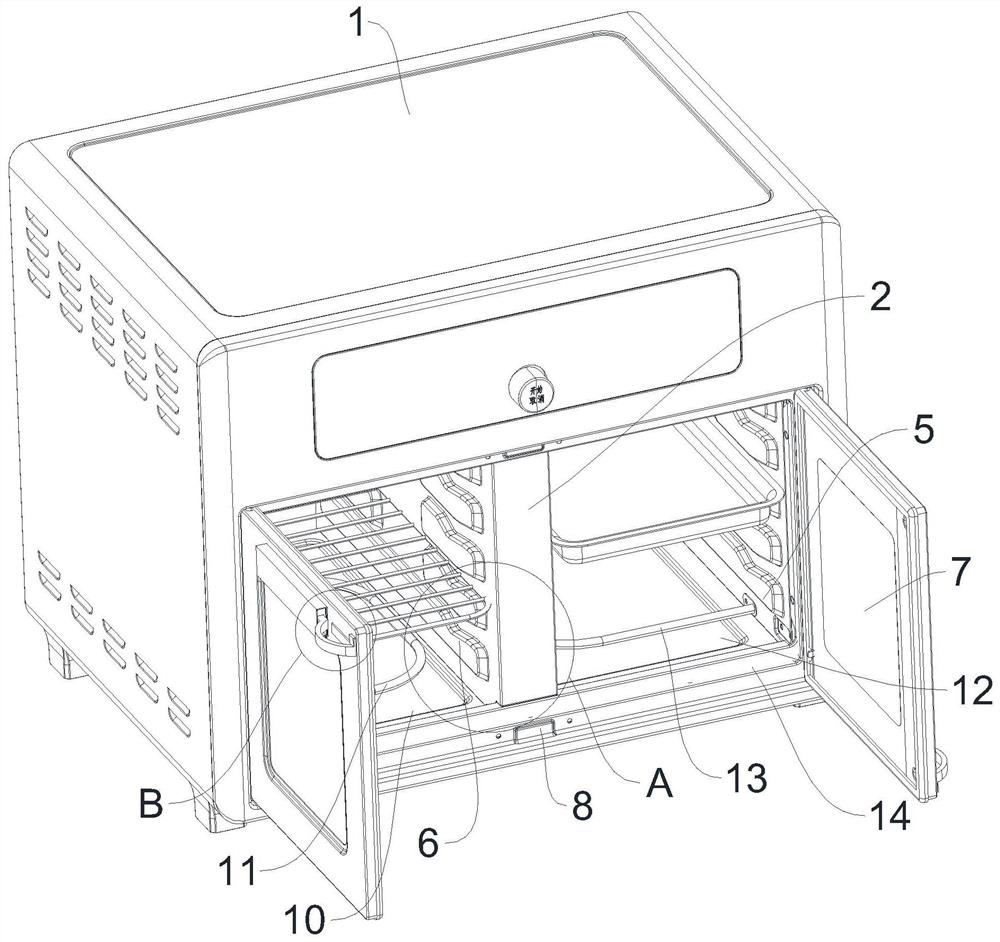

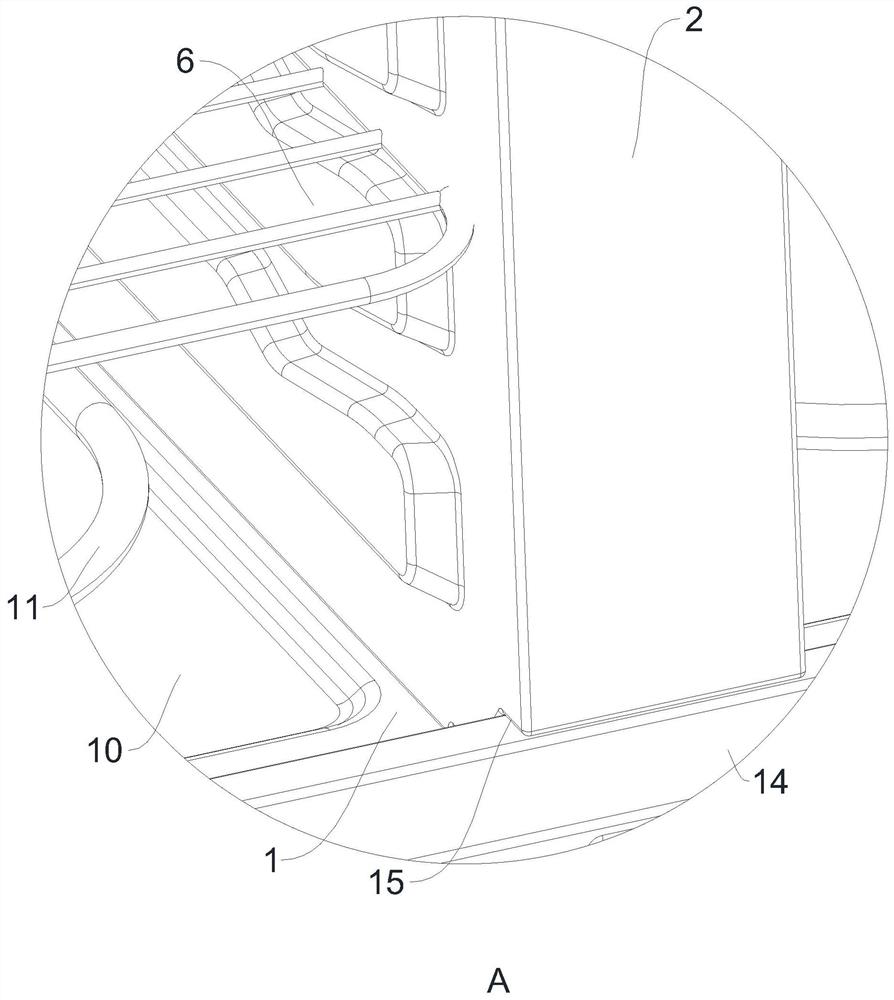

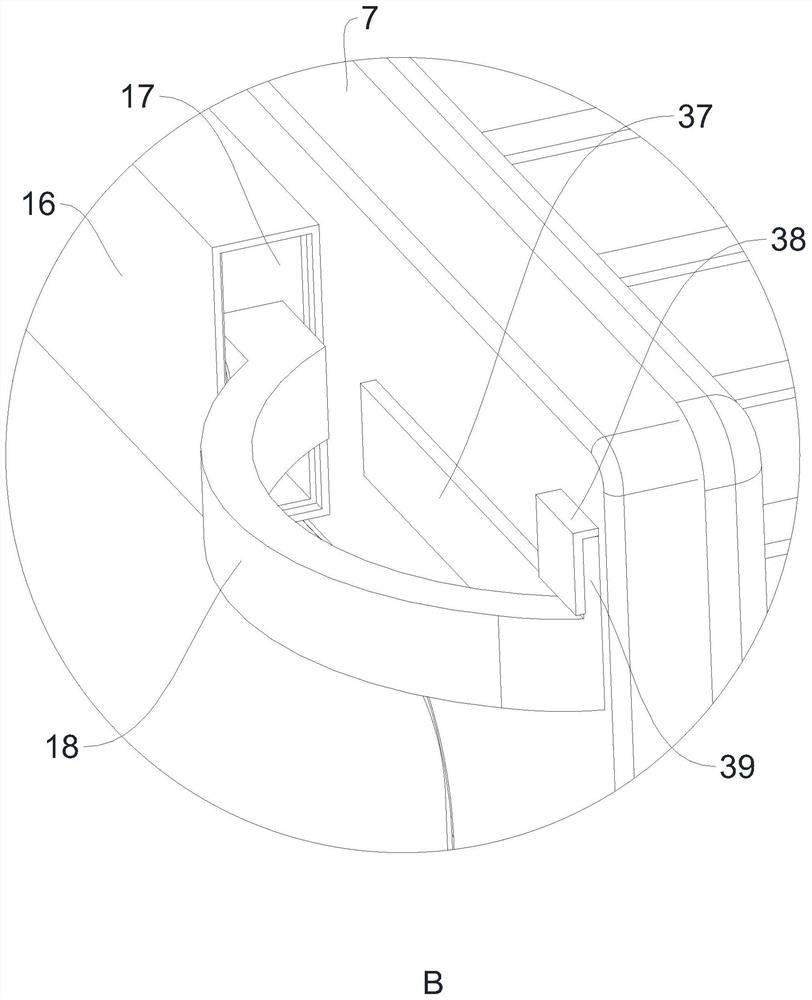

Electric oven easy to clean and with balanced temperature field

The invention discloses an electric oven easy to clean and with a balanced temperature field. The electric oven comprises an inner container and an outer cavity. A microcrystal type infrared radiation heating device is installed on the top of the inner container and comprises an infrared radiation quartz heating pipe and a microcrystal plate; a temperature sensor is fixedly arranged on the top of the inner container; a back metal tubular heating pipe is installed on the back of the inner container; a bottom face metal tubular heating pipe is installed at the bottom of the inner container; air blowers are arranged on the two sides of the inner container respectively, and ventilation grid nets are movably and fixedly arranged on the outer sides of the air blowers; the portions between the inner container and the outer cavity are filled with heat insulation filler. The interior of the inner container is conveniently cleaned, the balanced temperature difference inside the inner container is ensured, the temperature is made to be uniform, and the cooked food quality and the service life of the electric oven are ensured.

Owner:成都前锋电子有限责任公司

Stepping beam lifting synchronous control method of stepping plate blank heating furnace

InactiveCN101726189AControl running speedReal-time adjustment of lifting speedCharge manipulationControllers with particular characteristicsFailure rateSynchronous control

The invention discloses a stepping beam lifting synchronous control method of a stepping plate blank heating furnace, comprising the following steps of: adjusting the set value of a speed by mainly using a molten steel side beam to ensure that the molten steel side beam completes the corresponding stroke with the set time according to the set speed; using the molten steel side beam as the reference datum for the lifting of a finished steel side beam, obtaining the position differential of the two beams according to the measuring valve of a displacement sensor, and then calculating the speed compensating value of the finished steel side beam; using the speed compensating value outputted by a PID controller as the output of a PLC and correcting the lifting speed of the finished steel side beam in real time so that the finished steel side beam follows the molten steel side beam in real time, and then realizing the synchronous running of the lifting. In the invention, the position differential of the two beams is controlled within 10 millimeters so that the heating quality of the plate blank is ensured, and then the stepping beam is protected. Meanwhile, the invention reduces the failure rate, reduces the maintenance time of equipment, enhances the heating efficiency, lowers the cost and increases the benefits.

Owner:NANJING IRON & STEEL CO LTD

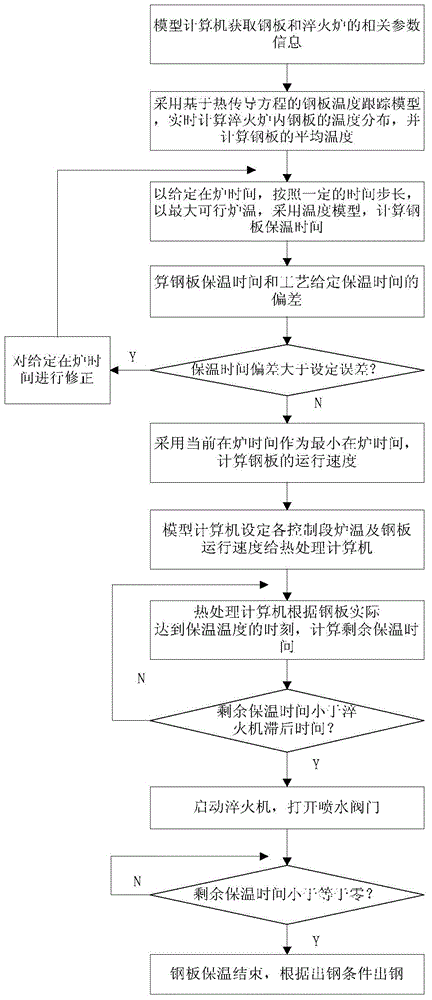

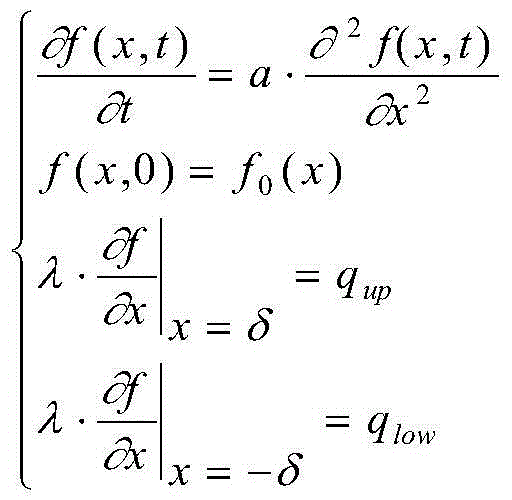

In-furnace time control method for thick steel plate heat treatment

ActiveCN106191411AIncrease productionReduce oven timeFurnace typesHeat treatment process controlSheet steelTime control

The invention relates to an in-furnace time control method for thick steel plate heat treatment. According to the control method, a modeling computer is used for tracking a model through the given temperature, a quenching furnace is operated at the highest feasible temperature, and the shortest in-furnace time of steel plates is estimated and computed; and before the steel plate heat preservation temperature is reached, the steel plate heat preservation time is computed through an estimating method, a quenching machine is started in advance so that the delay time of steel plate tapping can be shortened, and the steel plates are discharged out of the furnace in the shortest time on the premise that the requirements for the heat preservation temperature and the heat preservation time are met. The problems that in the traditional thick steel plate heat treatment process, steel plate tapping is delayed and the heat treatment efficiency is low are solved.

Owner:BAOSHAN IRON & STEEL CO LTD

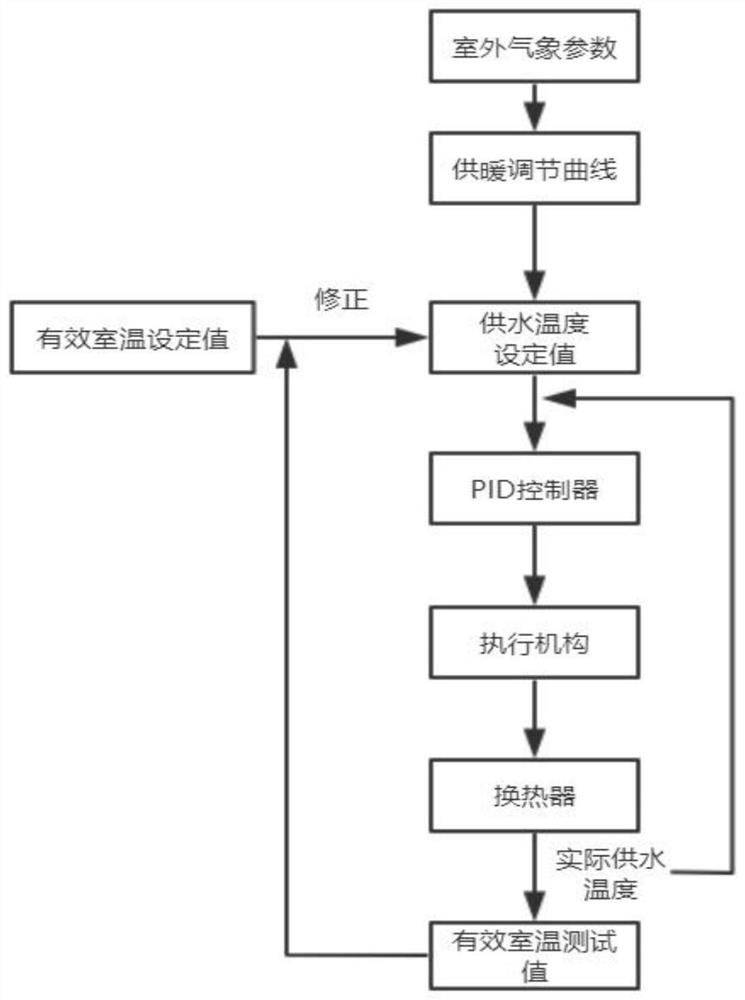

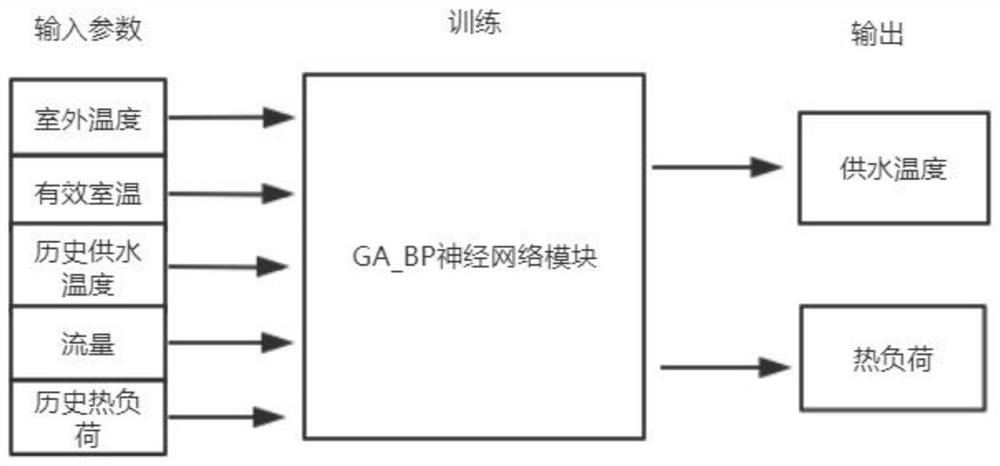

Heat exchange station predictive control method based on effective room temperature detection

ActiveCN113623719AImprove thermal comfortGuaranteed heating qualityLighting and heating apparatusEfficient regulation technologiesThermodynamicsRoom temperature

The invention discloses a heat exchange station predictive control method based on effective room temperature detection, and relates to the technical field of heat exchange station heating control. A heating stage is divided into an initial heating period, a stable heating period and a final heating period, and effective room temperature feedback control is adopted in the initial heating period and the final heating period. In the stable heating period, heating adjustment parameters calculated according to outdoor meteorological parameters are combined with effective room temperature feedback control for operation, operation data in the stable heating period serve as basic data of neural network training to train a neural network, and the trained neural network predicts the secondary network water supply temperature and the heat load in the next time period; and according to the characteristics of a heat exchange station in the whole heating period, a method of applying feedback control in the newly-built heat exchange station and the initial and final periods of heating operation and combining feedback control and predictive control in the stable heating period is adopted, so that the room temperature is controlled within a reasonable range in the whole heating period, the fluctuation of the heating room temperature is reduced, and on-demand heating is achieved.

Owner:CPI NORTHEAST POWER

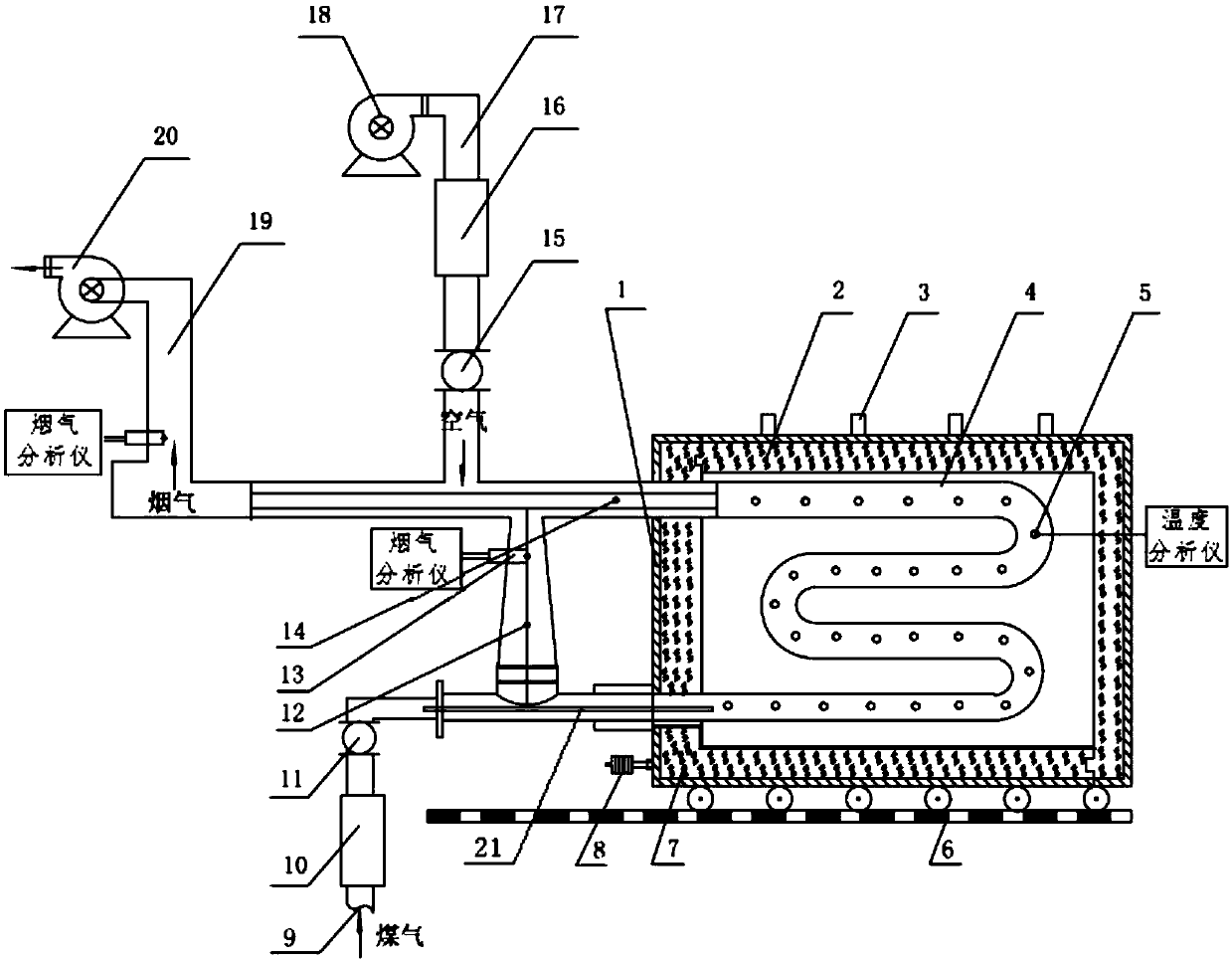

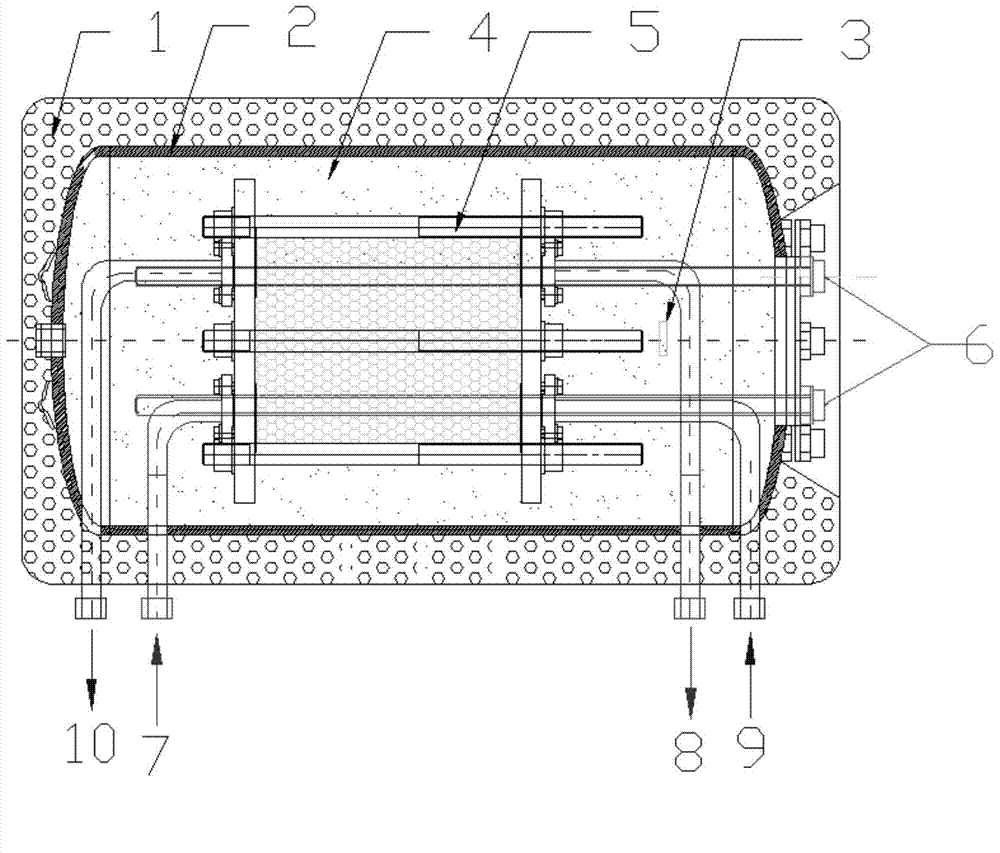

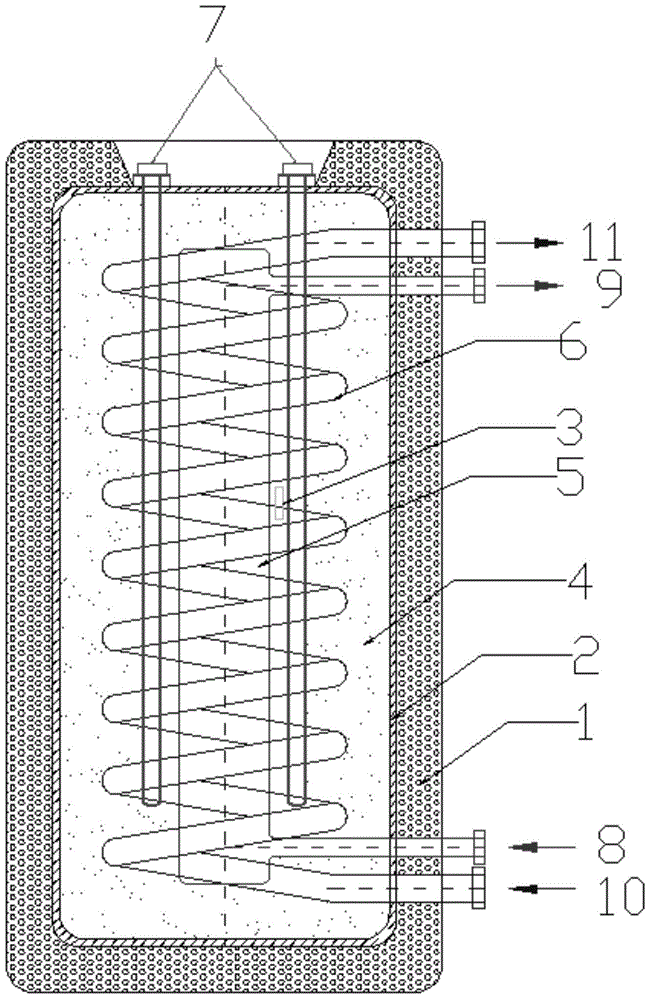

Radiant pipe combustion performance thermal simulation test furnace and method

ActiveCN108826989AImprove combustion efficiencyLower fuel consumptionStructural/machines measurementCharge manipulationPollutantControl models

The invention relates to a radiant pipe combustion performance thermal simulation test furnace and a method. The test furnace comprises a furnace body, a movable end wall, a radiant pipe, a slideway,a trolley bottom, a heat exchanger, a preheating air pipe and a radiation pipe burner. Compared with the prior art, the radiant pipe combustion performance thermal simulation test furnace and the method has the beneficial effects that the combustion performance of the radiant pipe of a continuous annealing furnace in actual production can be detected, the detection result can be used for optimizing combustion parameters of the continuous annealing furnace combustion control model, the combustion efficiency of the radiant pipe is improved, the efficiency of the heat exchanger is improved, the fuel consumption is reduced, the emission amount of NOx pollutants is reduced, and energy conservation and environmental protection are facilitated; and in addition, in a new product development designprocess of a radiant pipe complete device, the selection of thermal parameters is also a very important experiment method, the heating effect of the new product is improved, and the heating quality of thin strip steels is ensured.

Owner:ANGANG STEEL CO LTD

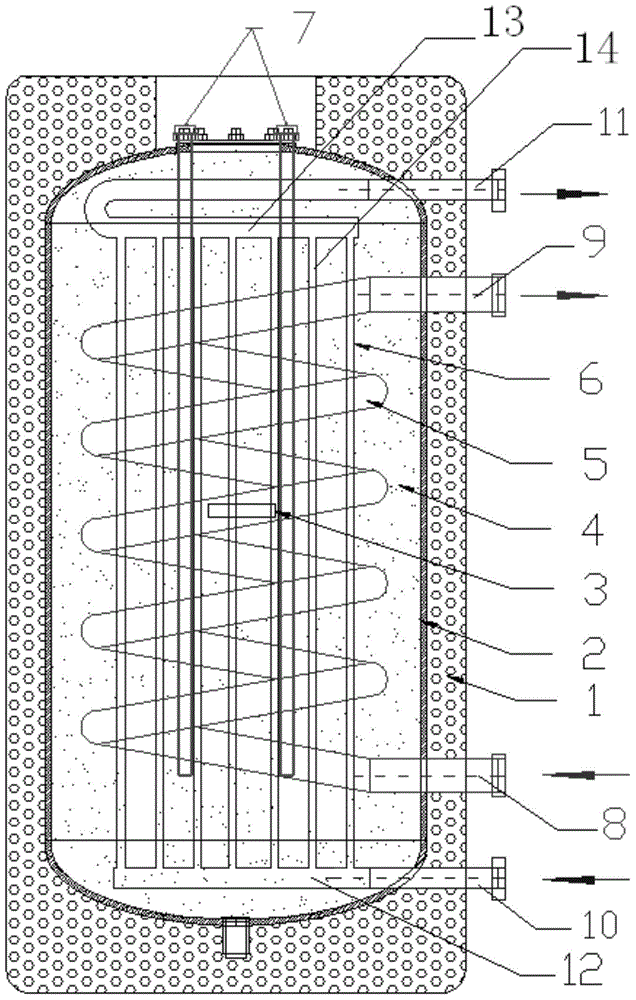

Phase change material and plate type heat exchanger combined phase change energy storage tank

InactiveCN104776743AGuarantee continuous constant temperature operationReduce volumeCentral heating with accumulated heatHeat storage plantsElectricityEngineering

The invention discloses a phase change material and plate type heat exchanger combined phase change energy storage tank. Heat is absorbed by the phase change of a phase change energy storage material, and is stored in the phase change energy storage material, so that the energy storage tank forms a heat-preservation tank for ensuring the heat utilization of a user at any time. The energy storage tank comprises a tank body, plate type heat exchangers and electric auxiliary heaters, wherein a solid-liquid phase change energy storage material is filled in the tank body; the plate type heat exchangers and the electric auxiliary heaters are arranged in the solid-liquid phase change energy storage material in the tank body; a maintenance hole is formed in the tank body; a heat-preservation layer is arranged outside the tank body. According to the energy storage tank, heat can be absorbed by the heat exchange of the energy storage material, and is stored in the phase change energy storage material, so that the energy storage tank forms the heat-preservation tank for ensuring the heat utilization of the user at any time; the continuous and constant temperature running of a heating system can be ensured, and heating quality is ensured; on the basis of providing the same heat, the size of the tank body can be reduced.

Owner:TIANJIN UNIV OF COMMERCE

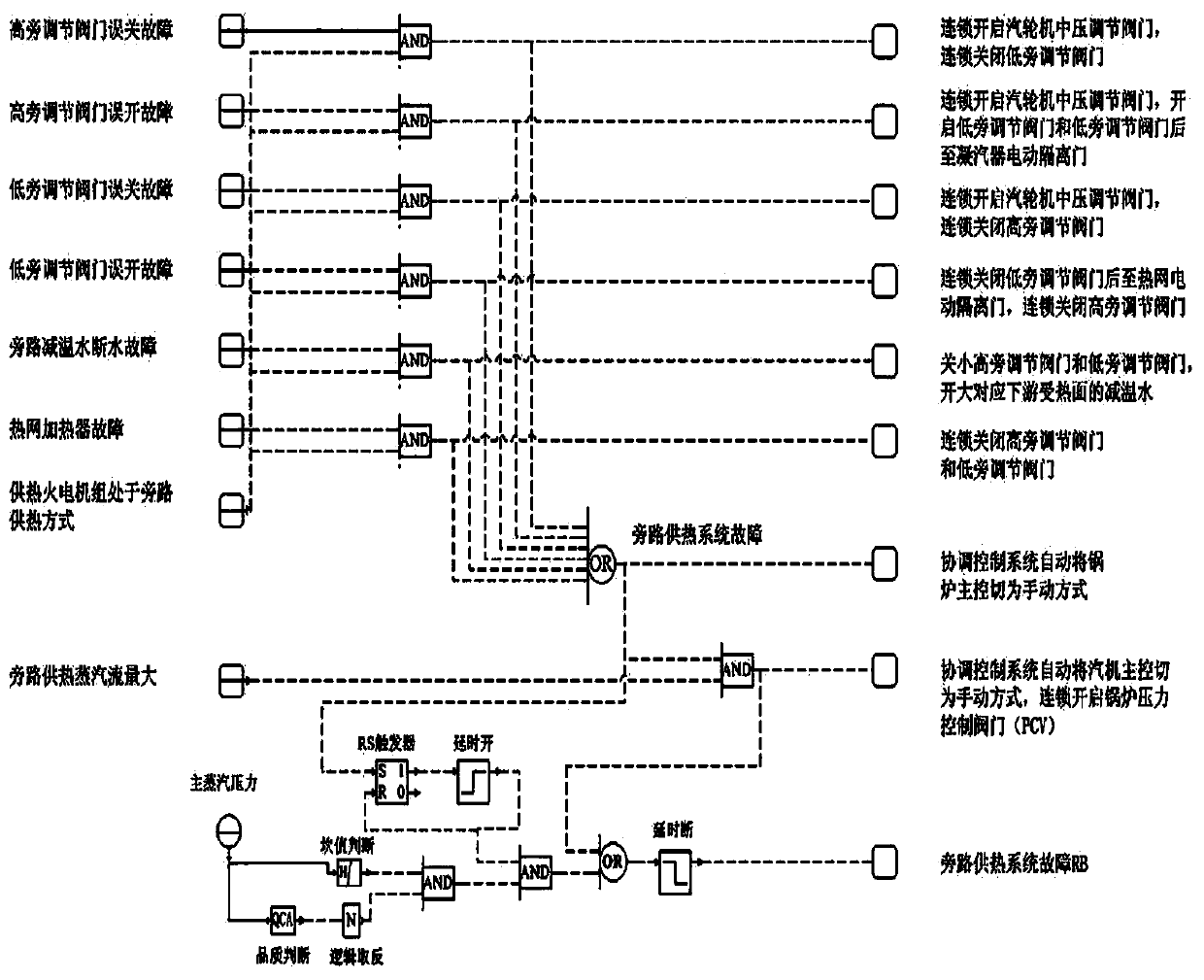

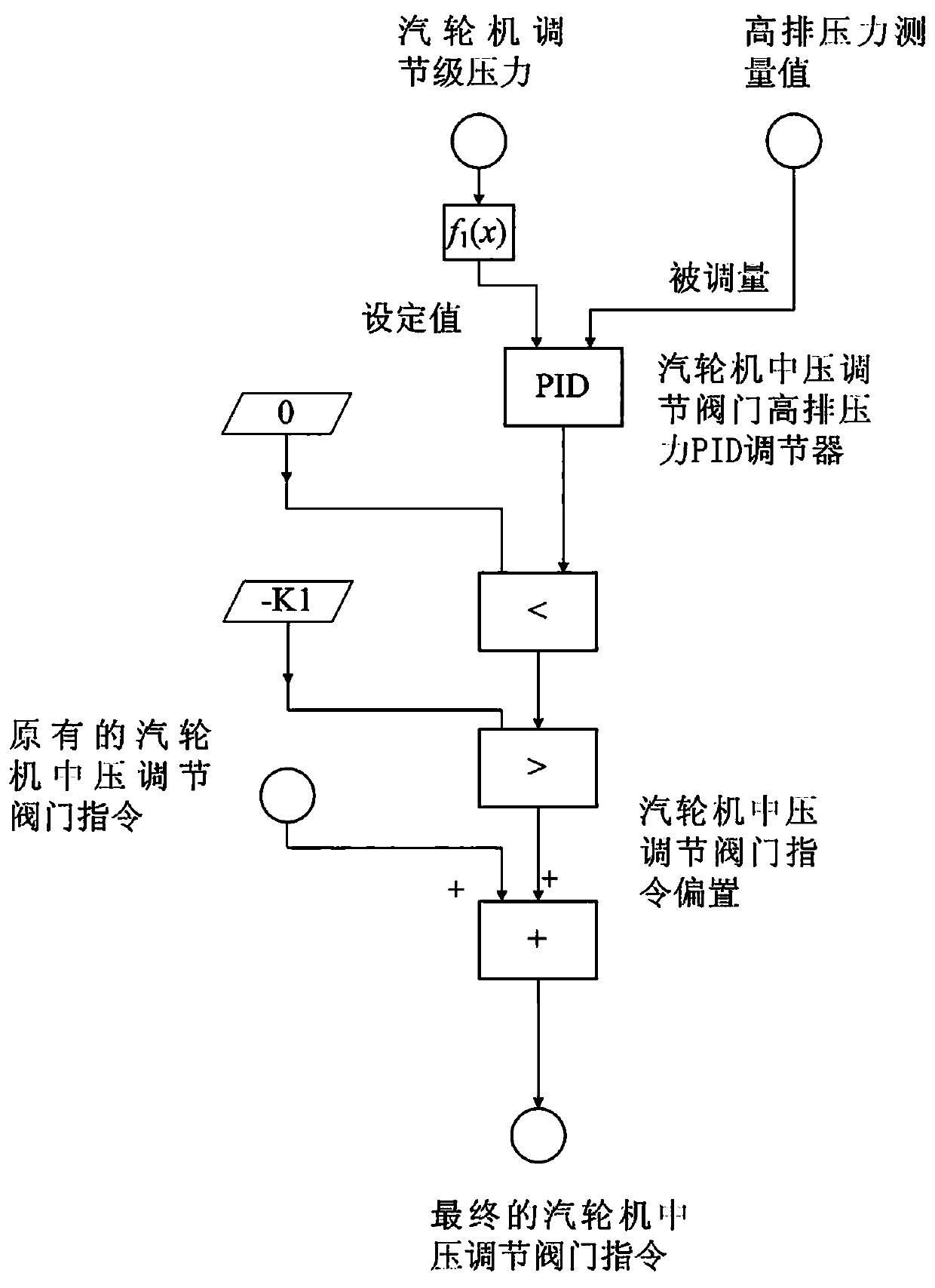

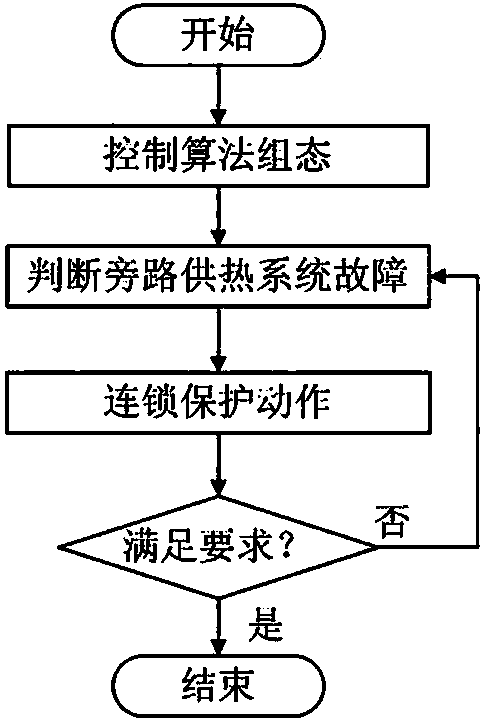

Optimization control method for improving reliability of unit bypass heat supply operation

ActiveCN110500645ASafe and stable operationSafe and Stable Operating ParametersLighting and heating apparatusSpace heating and ventilation detailsAutomatic controlSystem failure

The invention relates to the technical field of automatic control of thermal power units, in particular to an optimization control method for improving the reliability of unit bypass heat supply operation. The method comprises the following steps that when a heat supply thermal power generating unit is in a bypass heat supply mode, the fault of the unit bypass heat supply system is judged throughconfiguration of a control logic of a DCS of the heat supply thermal power generating unit; the size of bypass heat supply steam flow is judged, and interlocking protection action is performed in combination with fault of unit bypass heat supply system, so that the safety and stable operation of the unit is ensured; an automatic control logic is added, and the stability of operation parameters ofthe unit bypass heat supply system is controlled; and historical operation data and design data of the DCS of the heat supply thermal power generating unit are inquired, and all automatic control logic parameters are set. According to the method, the safety of equipment can be guaranteed under the working condition that the heat supply quality is ensured by the heat supply unit, the labor intensity of operators is effectively reduced, the control effect is not dependent on the technical level of operators, the real-time performance is good, the field debugging process is simple, and the engineering is convenient to realize.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

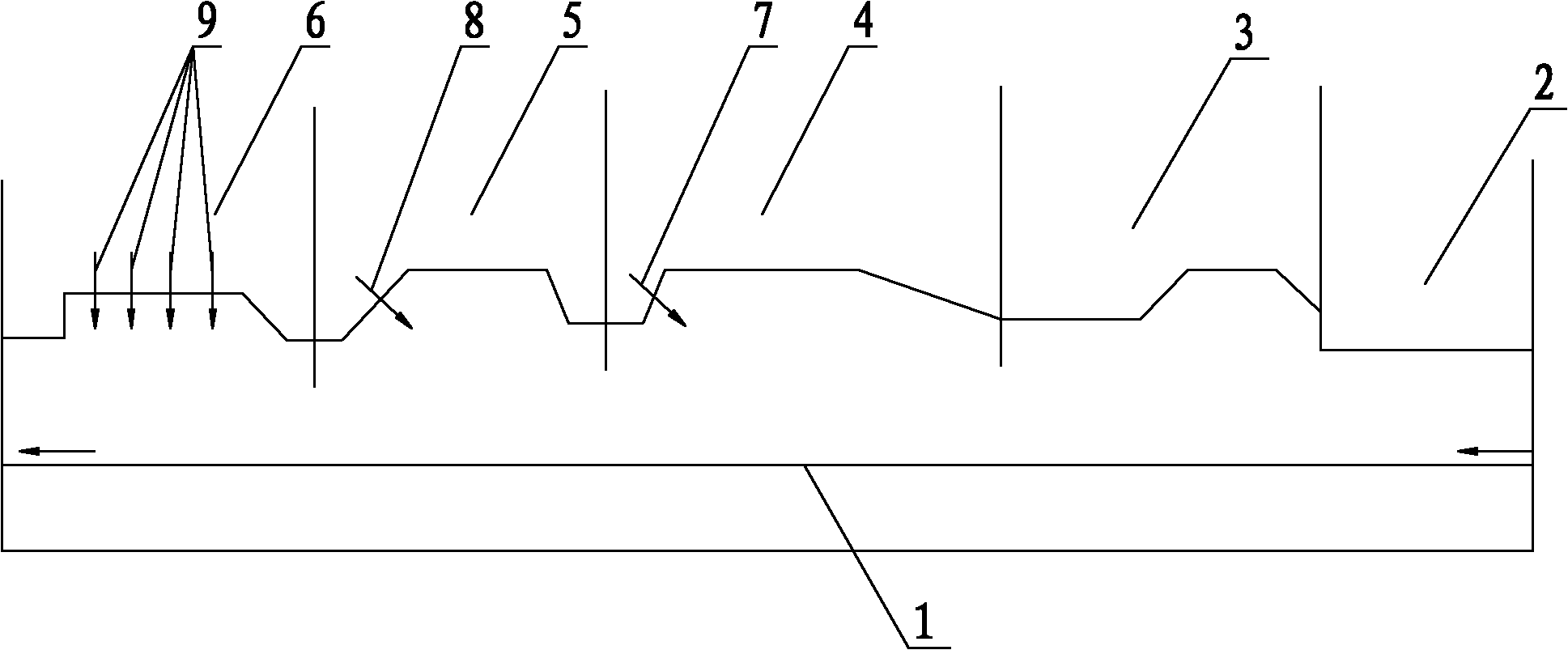

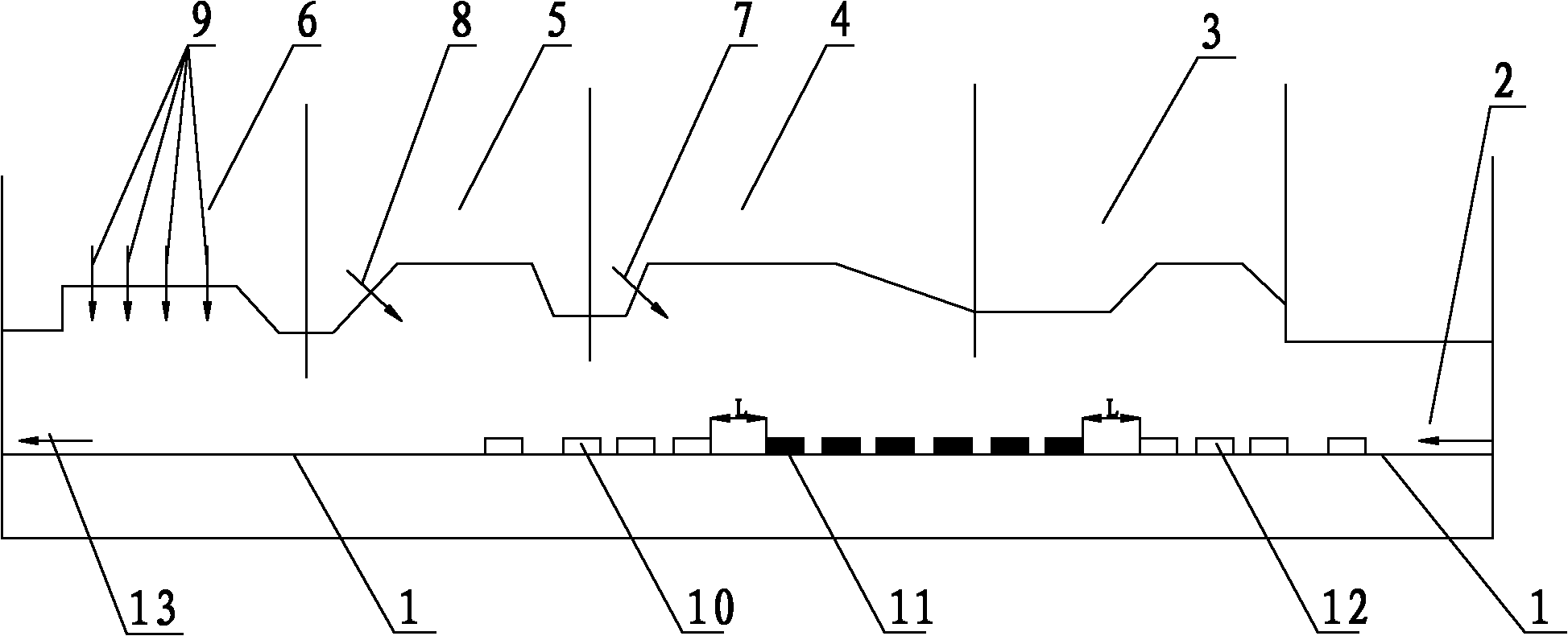

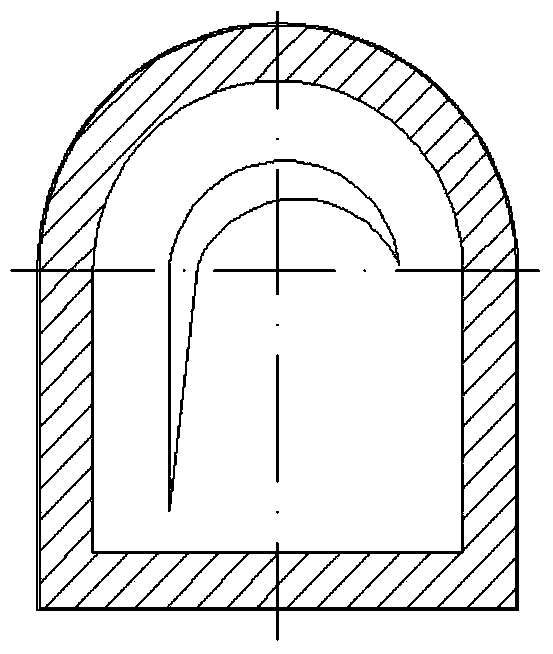

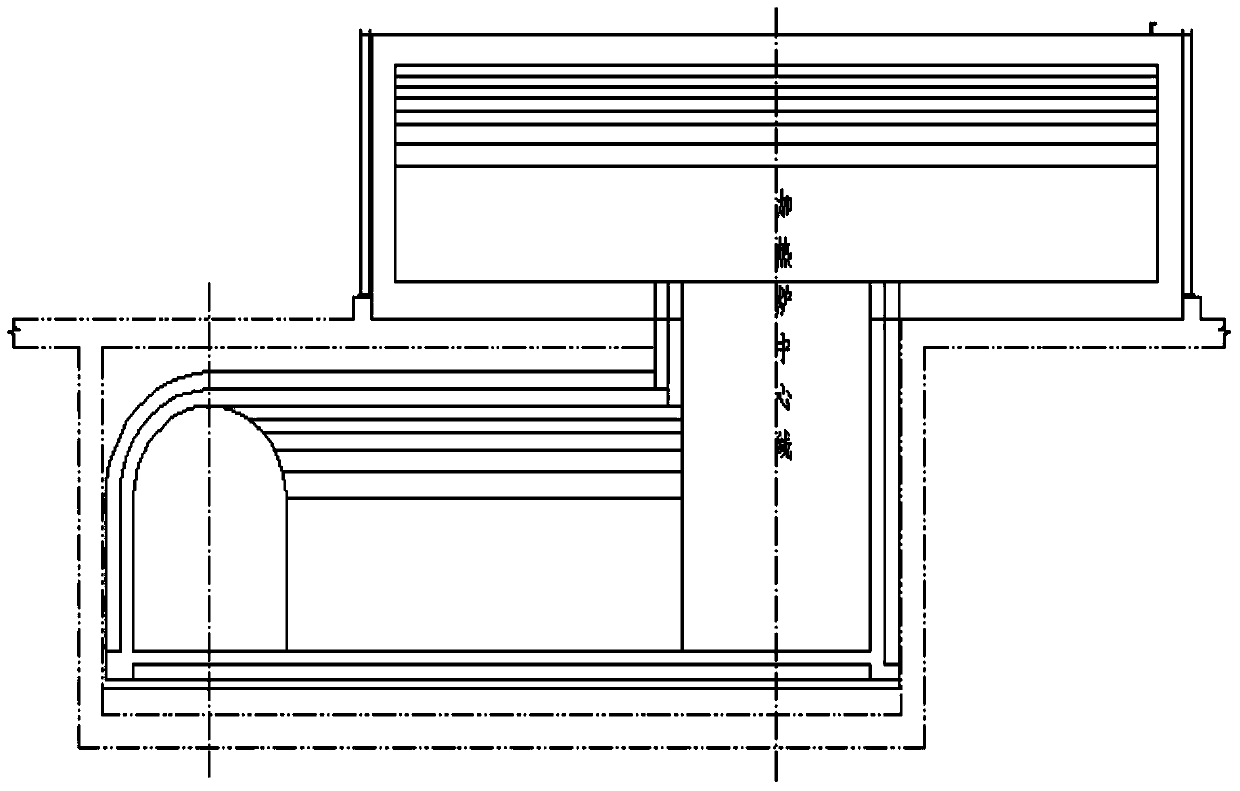

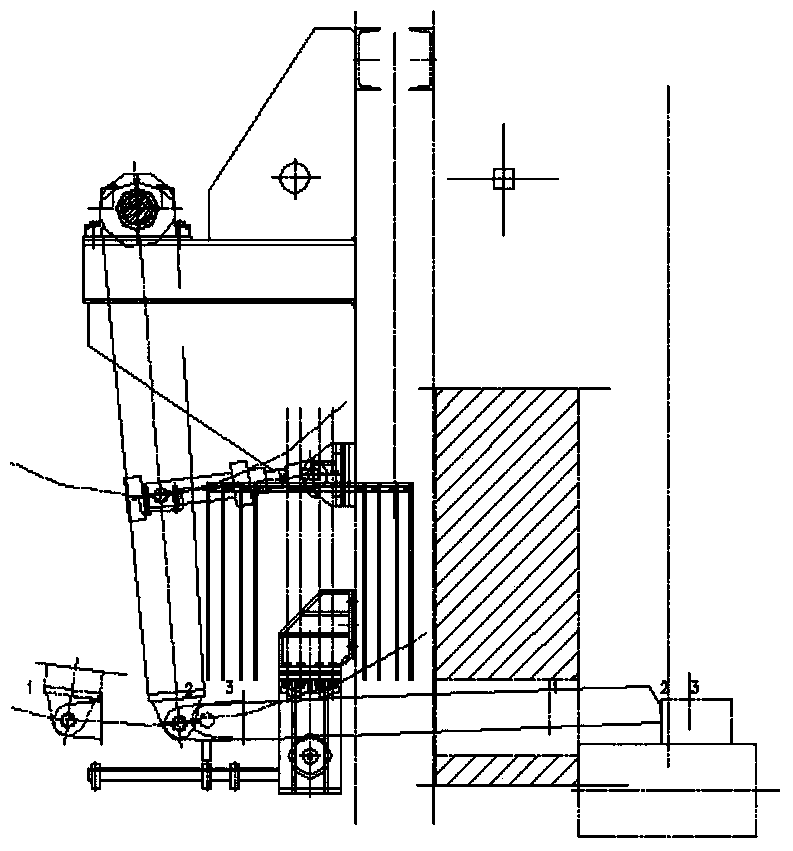

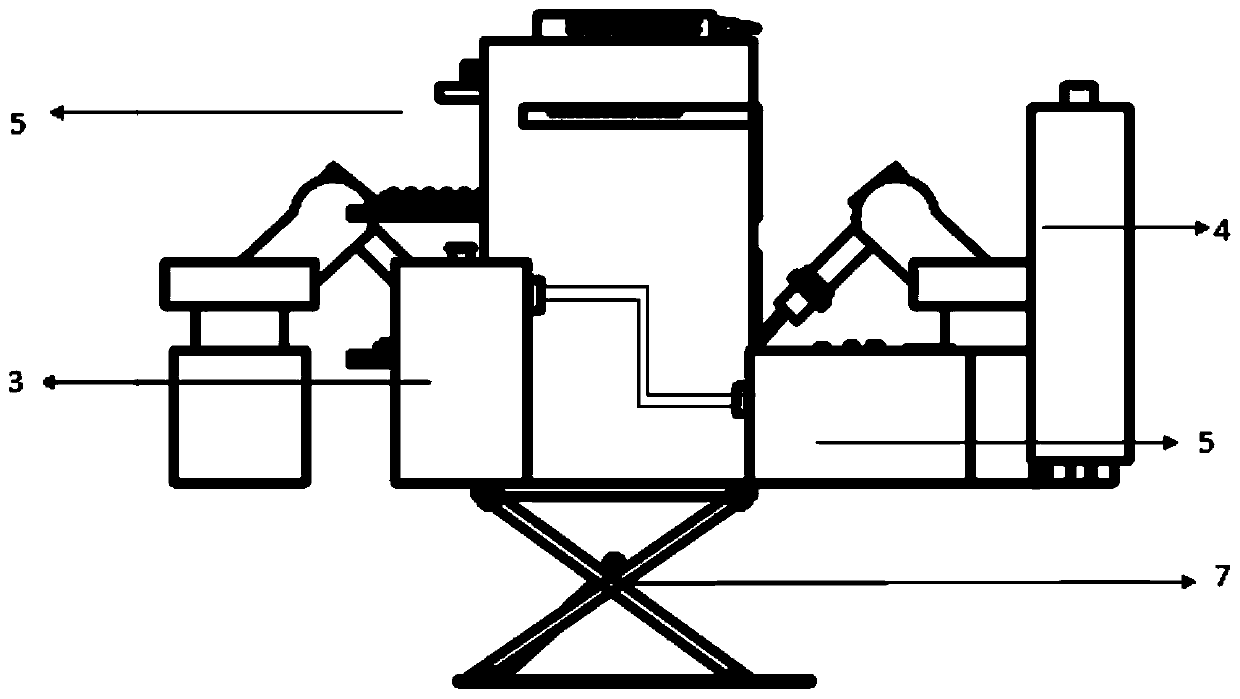

Rod and wire heating furnace achieving flexible matching direct hot loading of casting machine and rolling mill

ActiveCN103808150AIncrease hot delivery and hot charging rate and furnace entry temperatureIncrease productionCharge manipulationWaste heat treatmentFlueCharge type

The invention provides a rod and wire heating furnace achieving flexible matching direct hot loading of a casting machine and a rolling mill, and belongs to the technical field of industrial furnaces. The rod and wire heating furnace comprises a cantilever roller bed side-inlet and side-outlet step-type heating furnace body, accessory equipment, a loading end lower smoke exhausting tube, a smoke exhausting flue, a flexible matching loading machine and a suspension furnace-charging type pusher. The flexible matching loading machine is arranged at the end of the cantilever roller bed side-inlet and side-outlet step-type heating furnace body and the end of the accessory equipment, the suspension furnace-charging type pusher is arranged on the end of the cantilever roller bed side-inlet and side-outlet step-type heating furnace body, the end of the accessory equipment and the upper portion of the flexible matching loading machine, and the exhausting tube and the smoke exhausting flue are arranged at the end of the cantilever roller bed side-inlet and side-outlet step-type heating furnace body, the end of the accessory equipment and the lower portion of the flexible matching loading machine. The rod and wire heating furnace has the advantages that the problem that the steel making continuous casting machine and the steel rolling mill are not matched in production speed and production and maintaining system is solved, the hot conveying and hot loading furnace charging rate and hot conveying billet furnace charging temperature can be improved, and energy consumption of the heating furnace is reduced.

Owner:BEIJING SHOUGANG INT ENG TECH

Phase-change energy storage box

InactiveCN104792207AGuarantee continuous constant temperature operationReduce volumeHeat storage plantsStorage heatersElectricityEngineering

The invention discloses a phase-change energy storage box. Heat is absorbed through phase change of energy storage materials and is accumulated in the phase-change materials, the phase-change energy storage box becomes a heat preservation box, and a guarantee is provided for a user for using heat at any time. The phase-change energy storage box comprises a box body, a refrigerant heat exchanger, a heating medium heat exchanger and an electric auxiliary heater. The box body is internally filled with the solid-liquid phase-changer energy storage materials, a heat preserving layer is installed outside the box body, and the refrigerant heat exchanger, the heating medium heat exchanger and the electric auxiliary heater are arranged in the solid-liquid phase-change energy storage materials in the box body; the box body is provided with a maintenance hole; a refrigerant inlet of the refrigerant heat exchanger is connected with a refrigerant inlet connecting pipe penetrating through the box body and the heat preserving layer, and a refrigerant outlet of the refrigerant heat exchanger is connected with a refrigerant outlet connecting pipe penetrating through the box body and the heat preserving layer; a heating medium inlet of the heating medium heat exchanger is connected with a heating medium inlet connecting pipe penetrating through the box body and the heat preserving layer, and a heating medium outlet of the heating medium heat exchanger is connected with a heating medium outlet connecting pipe penetrating through the box body and the heat preserving layer.

Owner:TIANJIN UNIV OF COMMERCE

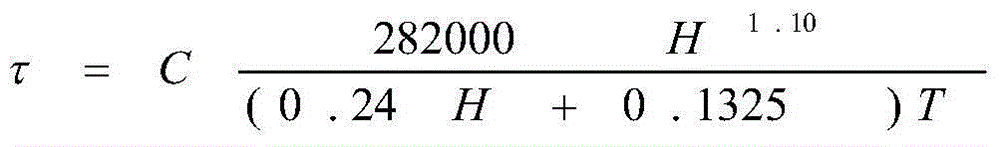

Method or accurately controlling slab in-furnace time of stepping heating furnace

InactiveCN110983024APrecise furnace timeGuaranteed heating qualityFurnace typesHeat treatment process controlControl systemEngineering

The invention discloses a method for accurately controlling slab in-furnace time of a stepping heating furnace, and belongs to the technical field of metallurgical steel rolling heating furnace process control. According to the technical scheme, the method comprises the steps of determining slab thickness, steel grade and width according to production requirements, and determining in-furnace timeby comprehensively considering the slab thickness, steel grade and width according to a combination of a Tyzs formula and an empirical formula; determining the furnace length of the heating furnace and the tapping number of steel blocks per hour, calculating the loading number of steel blocks in a single furnace to obtain the distance between slabs, and writing the distance between the slabs intoa control system of the steel-making furnace, thereby accurately adjusting the gap between the slabs, realizing the purpose of accurately controlling the in-furnace time of the slabs, ensuring the heating quality of the slabs finally, avoiding the temperature under-burning, and also ensuring the steel passing rhythm and the lowest oxidation burning loss.

Owner:HANDAN IRON & STEEL GROUP +1

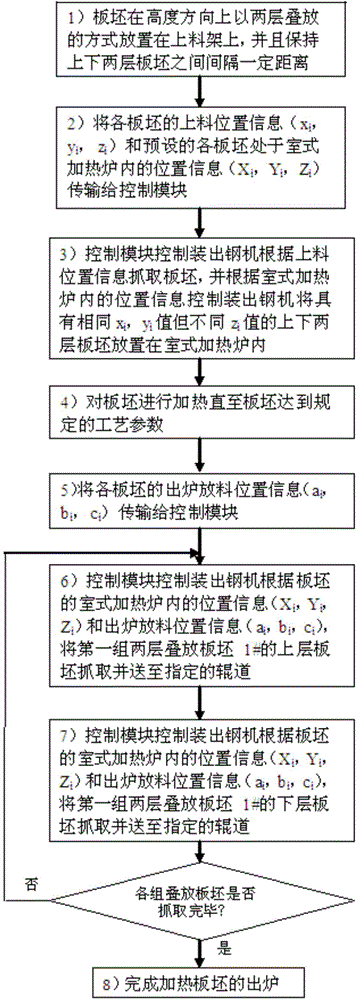

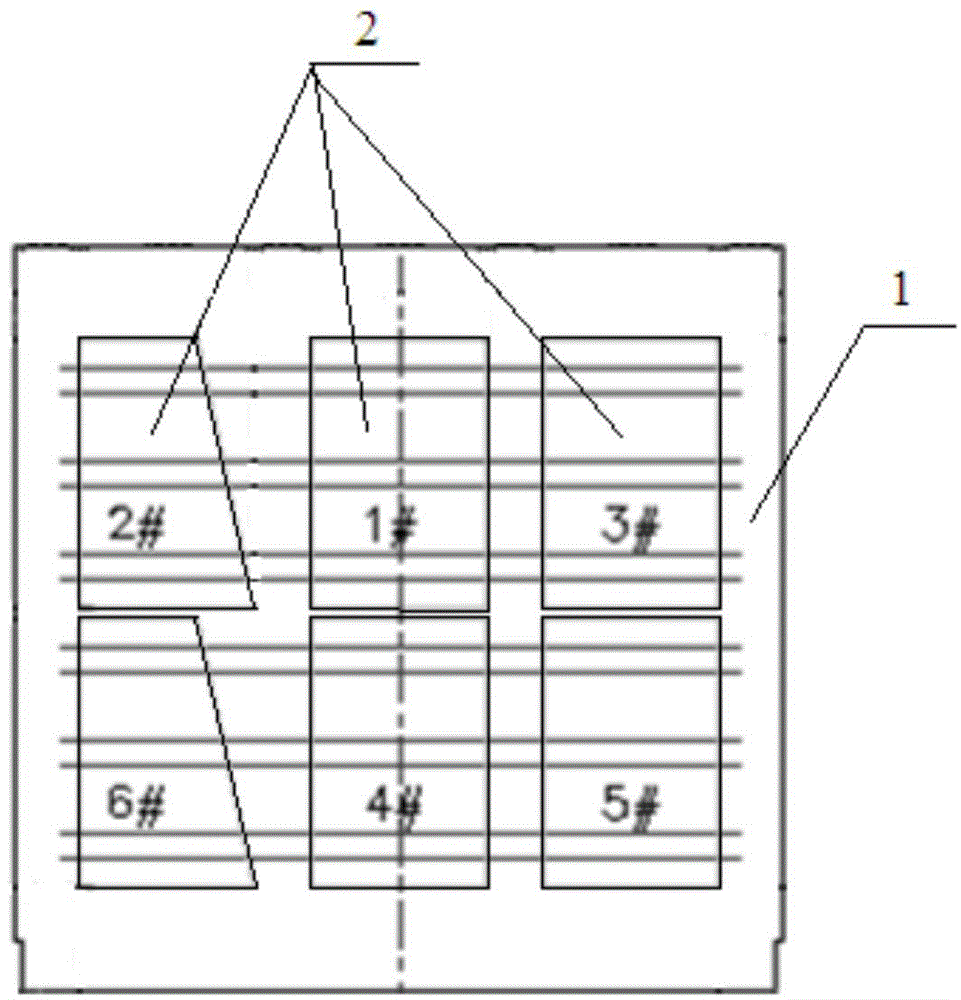

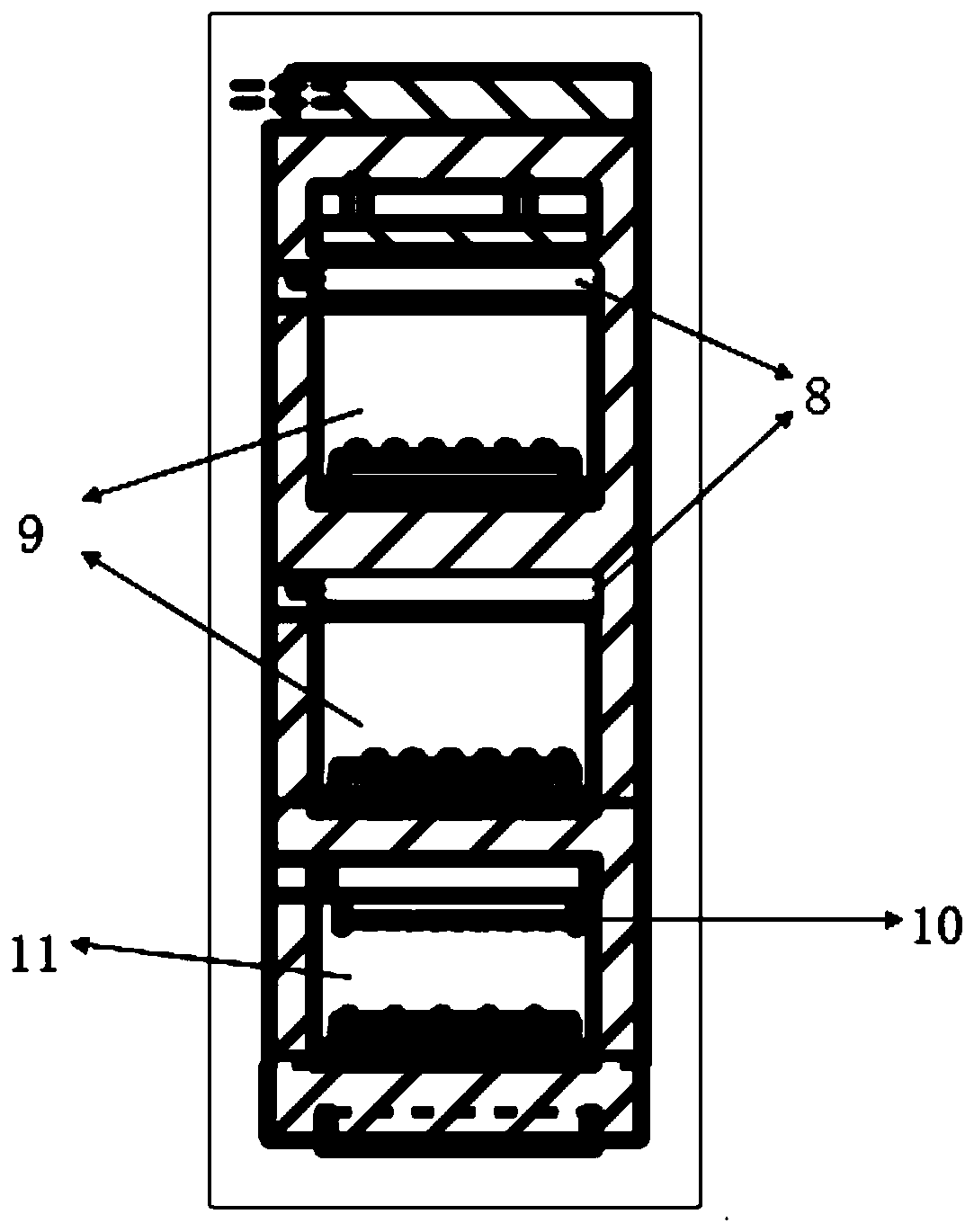

Steel charging/discharging control method for chamber-type heating furnace multilayer material distribution

InactiveCN105316468AAvoid situations where positioning accuracy is not highCompactFurnace typesHeat treatment process controlComputer moduleHeating furnace

The invention discloses a steel charging / discharging control method for chamber-type heating furnace multilayer material distribution, which includes the following steps: (a) stacking billet materials on a material loading frame in height direction in a multilayer stacking manner with each layer arranged at intervals, wherein each billet material has corresponding material loading position information (x, y, z), wherein the z expresses height information; (b) sending the loading position information of each billet material and preset position information of each billet material in a chamber-type heating furnace to a control module; (c) controlling a steel charging / discharging machine to grasp the billets according to the material loading position information by the control module and controlling the steel charging / discharging machine to arrange the billets being same in x and y but different in z in the layers into the chamber-type heating furnace according to the position information in the chamber-type heating furnace in a stacking manner; (d) sending material discharging position information of each billet to the control module; and (e) after heating is completed, successively grasping and discharging the billets which have been heated from an upper layer to a lower layer by the steel charging / discharging machine according to the position information in the chamber-type heating furnace and the material discharging position information of each billet.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

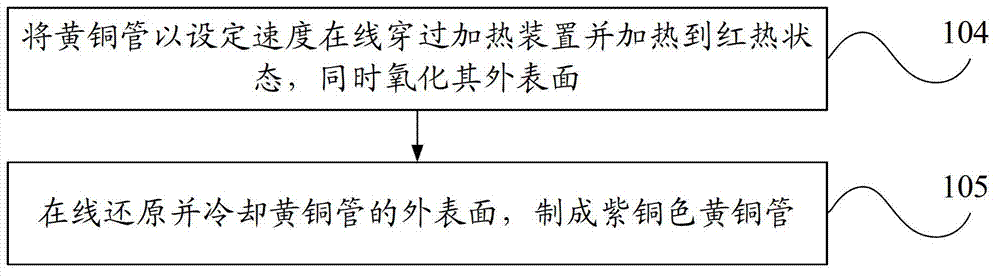

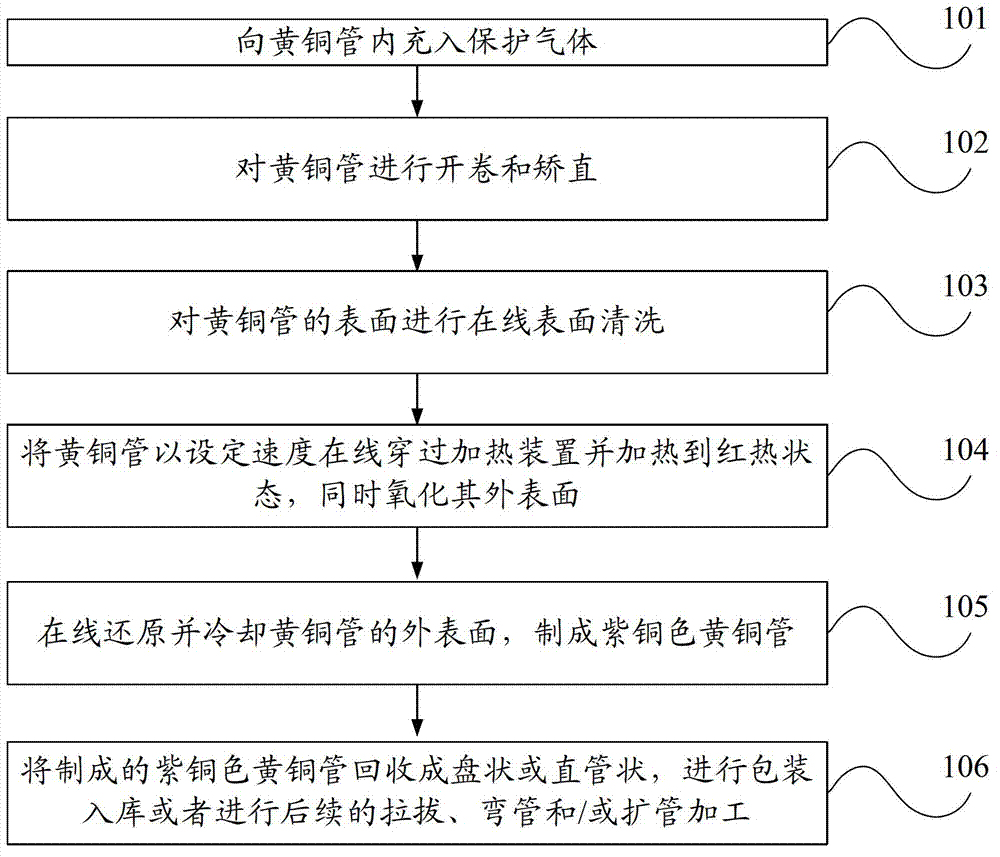

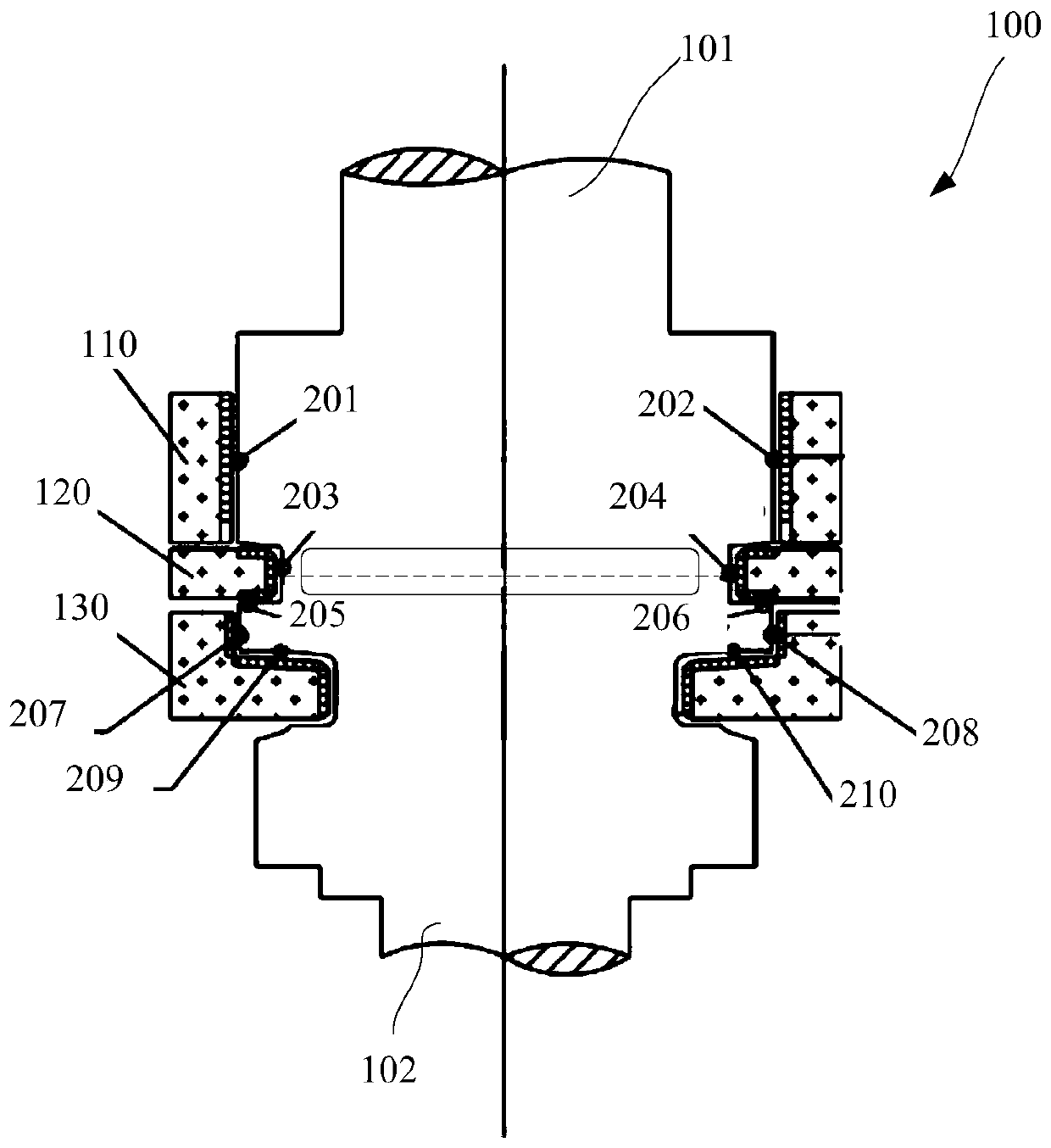

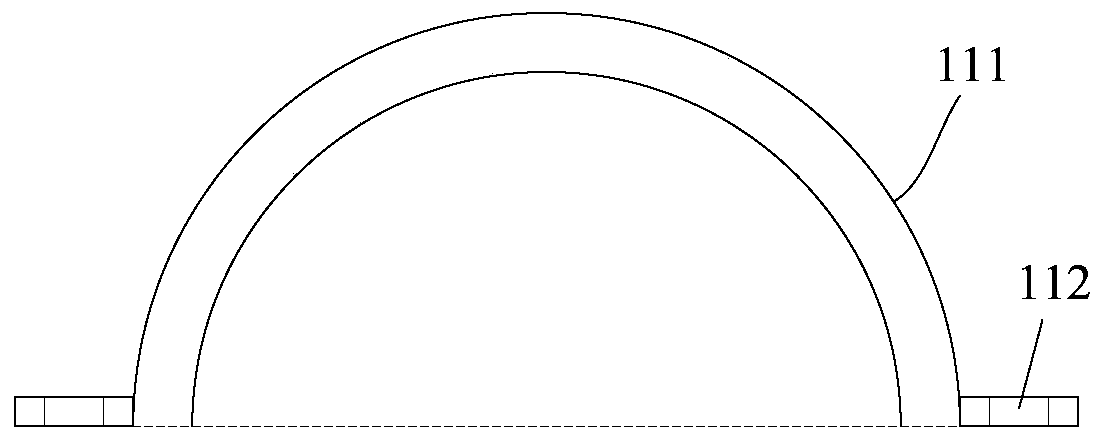

Purple bronze brass tube and manufacturing method and production line thereof

InactiveCN103243291ADense outer surfaceUniform outer surfaceSolid state diffusion coatingProduction lineShielding gas

The invention provides a purple bronze brass tube and a manufacturing method and production line of the purple bronze brass tube. The manufacturing method of the purple bronze brass tube comprises the following steps: allowing the brass tube to penetrate through the heating device on line at a set speed and heating to a red hot state, and oxidizing the outer surface; and reducing and cooling the outer surface of the brass tube on line, and manufacturing the purple bronze brass tube. The purple bronze brass tube production line comprises a heating device and a reduction tank, wherein reducing and cooling liquid is filled in the reduction tank. Compared with the prior art, the manufacturing method of the purple bronze brass tube has the advantages that process steps are less, yield is high, production efficiency of the purple bronze brass tube is high, lots of brass tube pickling process are eliminated in the related technology, the outer protective gas of the brass tube is canceled, the manufacturing cost is obviously reduced, the brass tube is energy-saving and environment-friendly, the manufactured purple bronze brass tube is dense and uniform in outer surface and can serve as a finished tube, drawing, bending, tube expanding and other subsequent treatment can be performed, and the color layer does not drop.

Owner:JIANGSU XINGRONG HI TECH

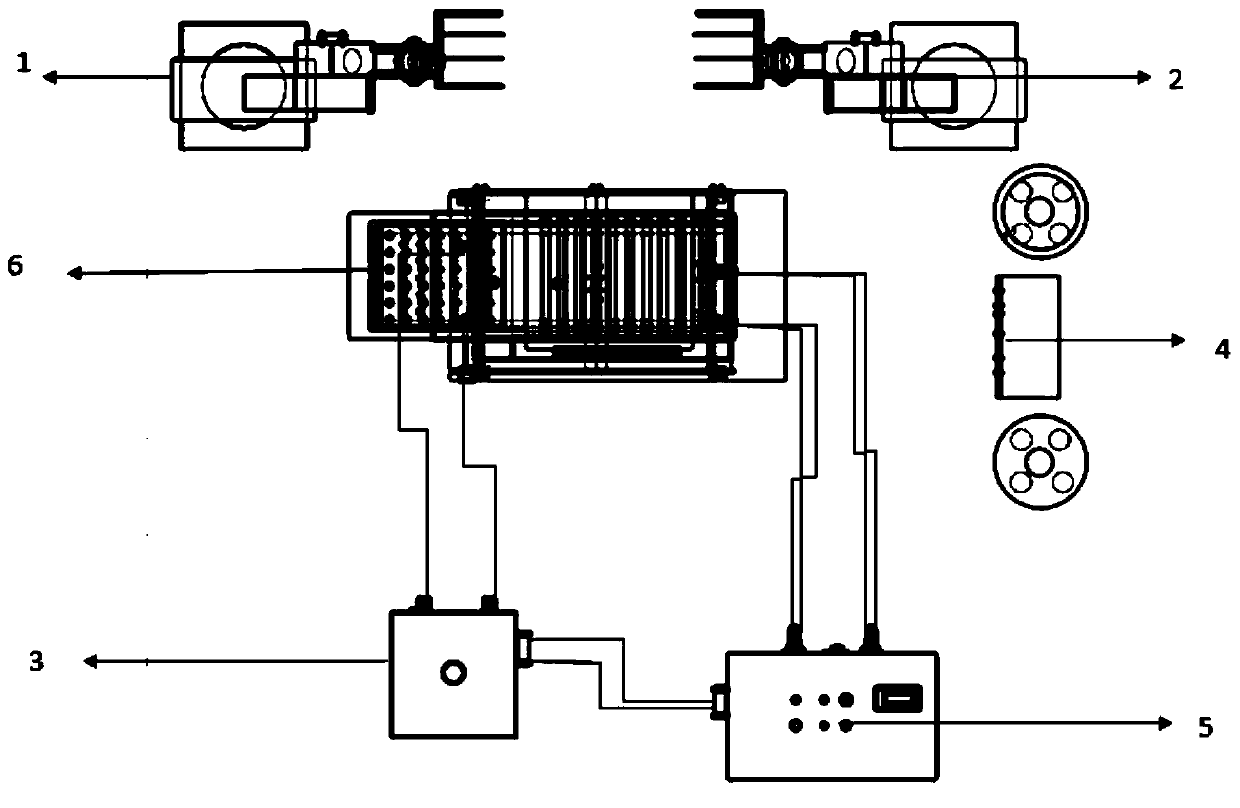

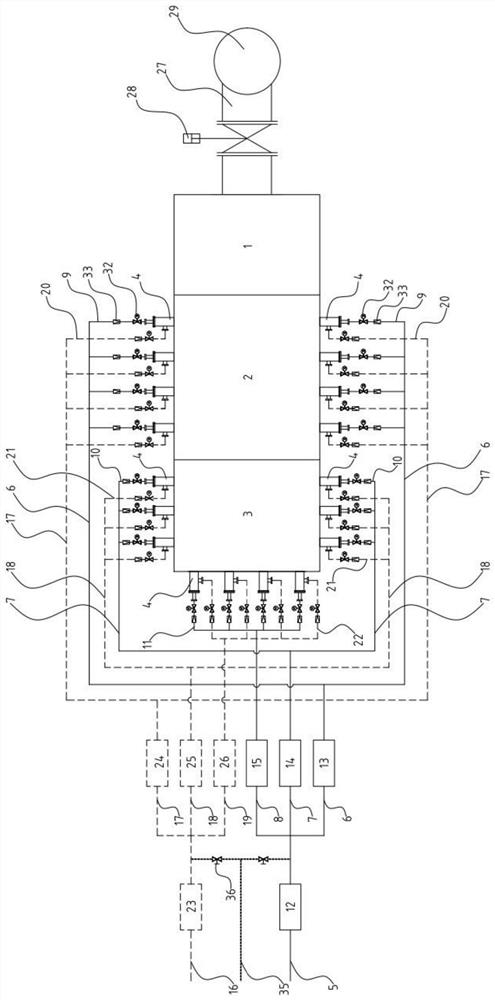

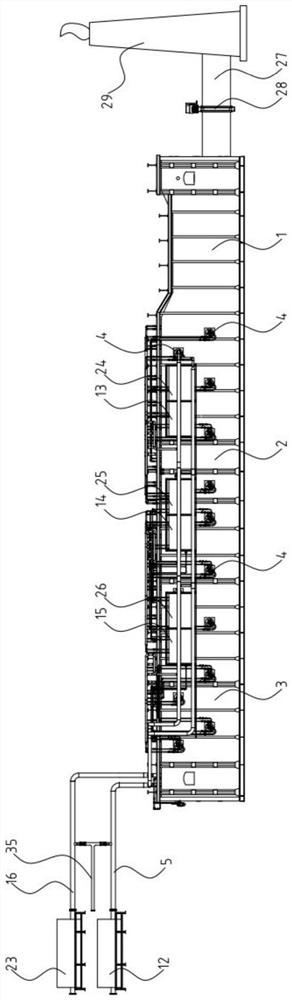

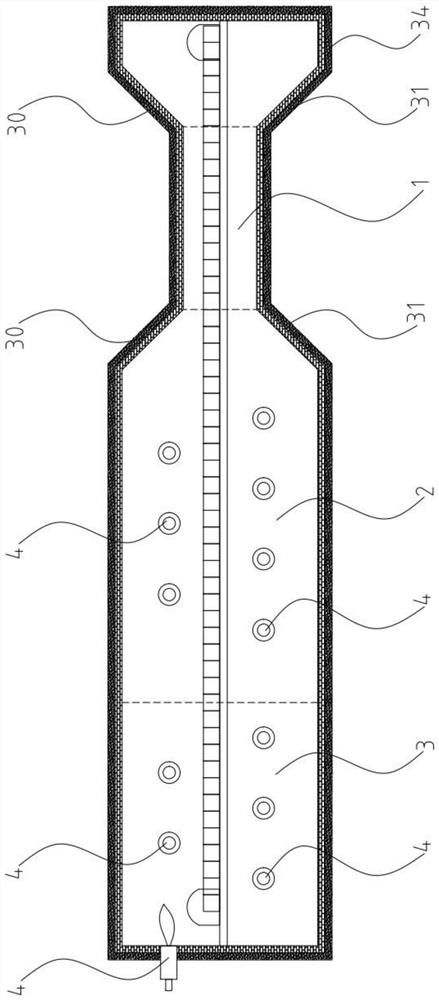

Annealing system and method for welded rotors

ActiveCN111020164AReduce local internal stressGuaranteed heating qualityFurnace typesHeat treatment process controlMechanical engineeringMaterials science

The invention puts forward an annealing system and method for welded rotors. The annealing system comprises multiple heating devices and multiple temperature measuring devices; the multiple heating devices are arranged on multiple heating zones of the welded rotors; the multiple temperature measuring devices are arranged on the multiple heating zones of the welded rotors and are connected with themultiple heating devices; and the annealing temperatures of the multiple heating zones are different. By the aid of the annealing system for the welded rotors, manual operations can be reduced, and the heating quality is stable.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

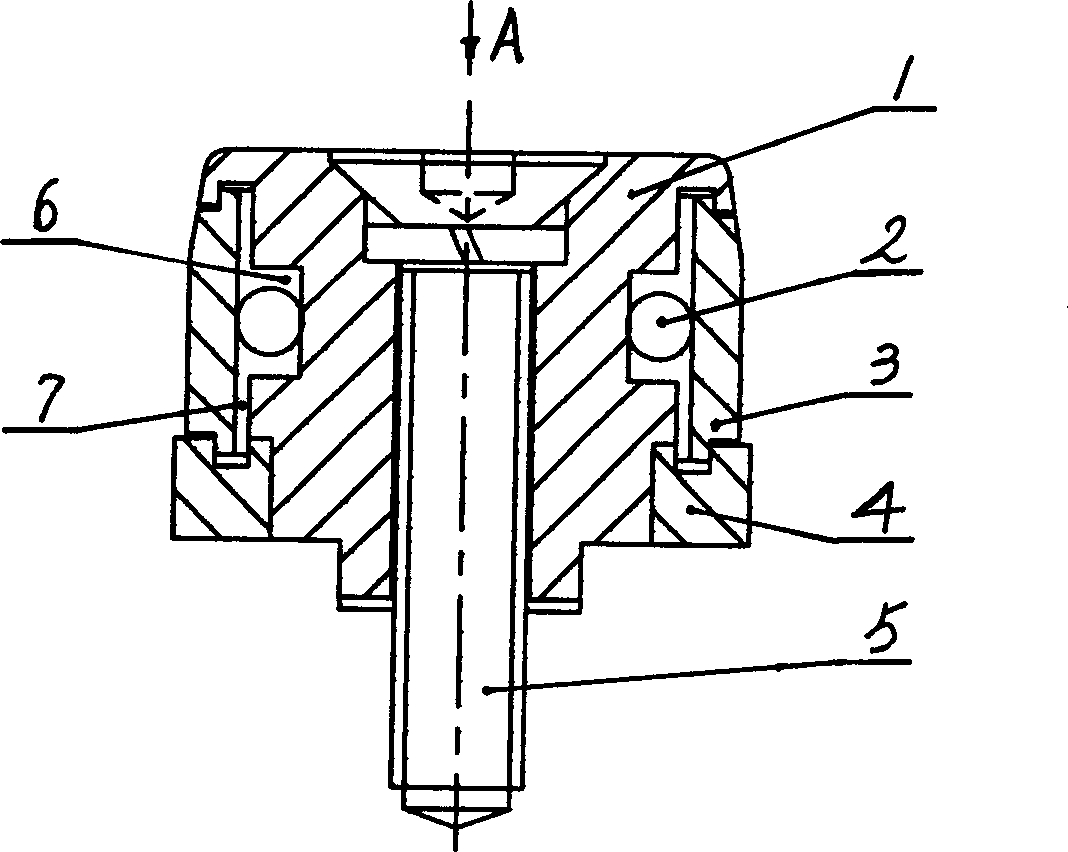

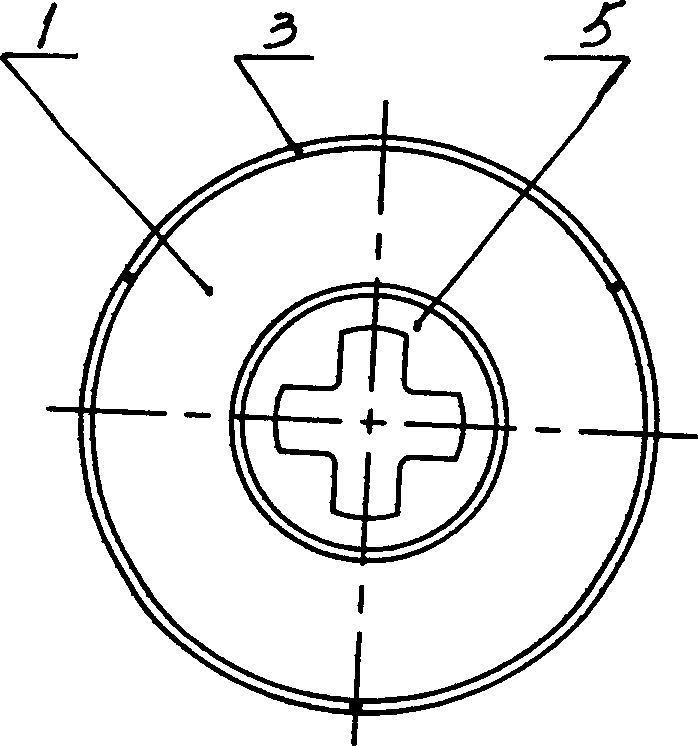

Bottle blank plug of heater of plastic bottle blank

A plug of the plastic bottle blank heater for inserting it in the mouth of plastic bottle blank has a main body connected to the bottle blank delivering mechanism and with a slot on its external surface. A movable ring is installed in said slot and is fixed by a limiting pad. An elastic ring is installed at inside of said movable for fastening the bottle blank.

Owner:汪祥建

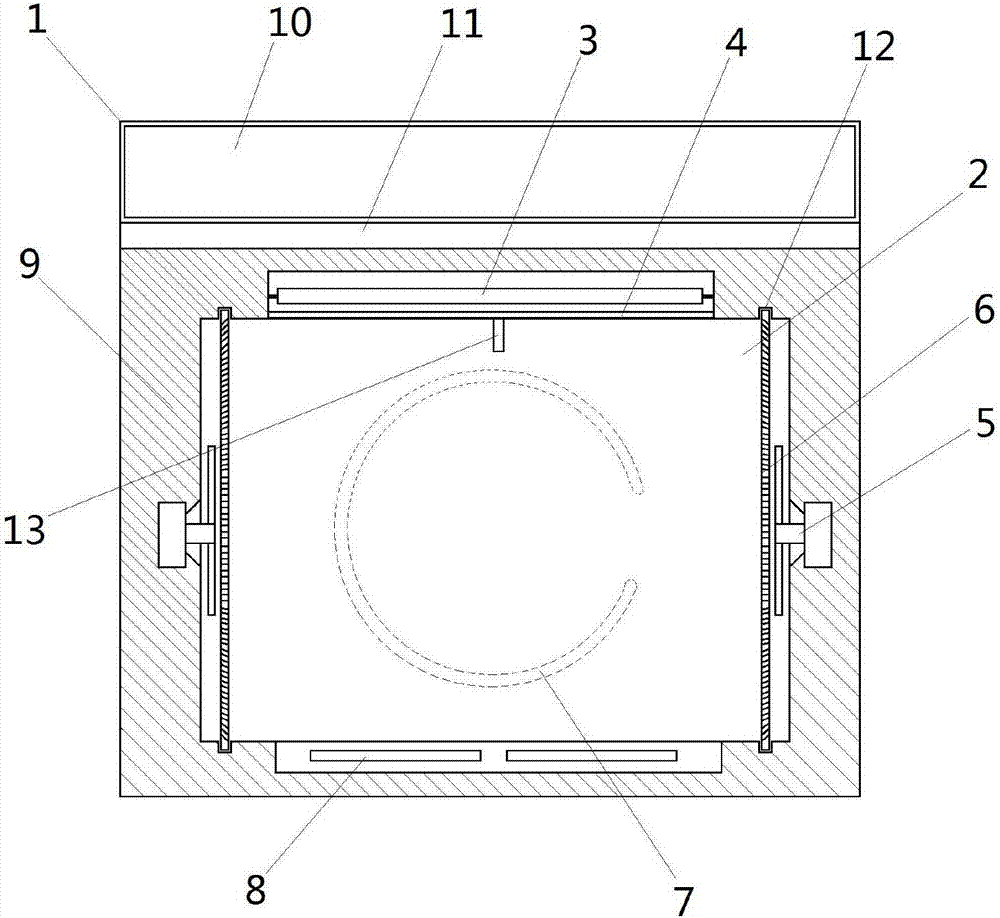

Sheet heating multifunctional and small infrared composite box type heating furnace and method

PendingCN110118486ASmall footprintLow costFurnace typesFurnace heating elementsField uniformityPunching

The invention belongs to the technical field of hot punching forming, and discloses a sheet heating multifunctional and small infrared composite box type heating furnace and a method. An upper arrangement manner or a lower arrangement manner is adopted in an infrared heating layer; meanwhile, lifting regulation and control can be conducted on the height of a heating furnace body; and the output power, the radiation distance and the modulator tube distance of an infrared heating pipe can be collaboratively regulated and controlled, and real-time adjustment on the blank heating temperature, theheating speed and temperature field uniformity is achieved. The composite heating box type furnace combines many advantages of small occupied space, low cost, good technology flexibility, high energyefficiency and the like, and a heating manner extremely has application prospects for future sheet heating.

Owner:山东威奥智能装备有限公司

Production process of large-thickness high-performance pre-hardened SM4Cr2Mn plastic mold steel plates

InactiveCN109433824AEfficient adjustment of heating rateGuaranteed heating qualityMetal rolling arrangementsLow speedTemperature difference

The invention relates to a production process of large-thickness high-performance pre-hardened SM4Cr2Mn plastic mold steel plates. The production process comprises the technological steps of continuous casting, hot feeding, soaking pit furnace heating, rolling, heat treatment, flaw detection, finishing, check and warehousing of elliptical billets with the diameter of 900*1450 mm. The temperature rising rate of a soaking pit furnace is set according to characteristics of the steel type during rolling and heating and includes the low-temperature section, the medium-temperature section and the high-temperature section. The heating rate is set in a sectioned mode. Thermal stress formed by the internal and external temperature difference to the elliptical billets can be effectively retarded. The full-longitudinal low-speed high-reduction rolling process is adopted during rolling, and the widths of the steel plates are invariant finally. Scale removing is conducted through high-pressure water for 1-3 times in the rolling process, the quality of the steel plates is ensured, vertical roll rolling is conducted after completion of the high-reduction pass, the edges of the steel plates are protected against bulges, and the yield is increased. The offline quenching and tempering heat treatment process is adopted during heat treatment. The stability of the core performance of this types ofsteel plates can be substantially improved, the hardness difference of the whole plates can be reduced, and the comprehensive performance of the steel plates can be improved.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

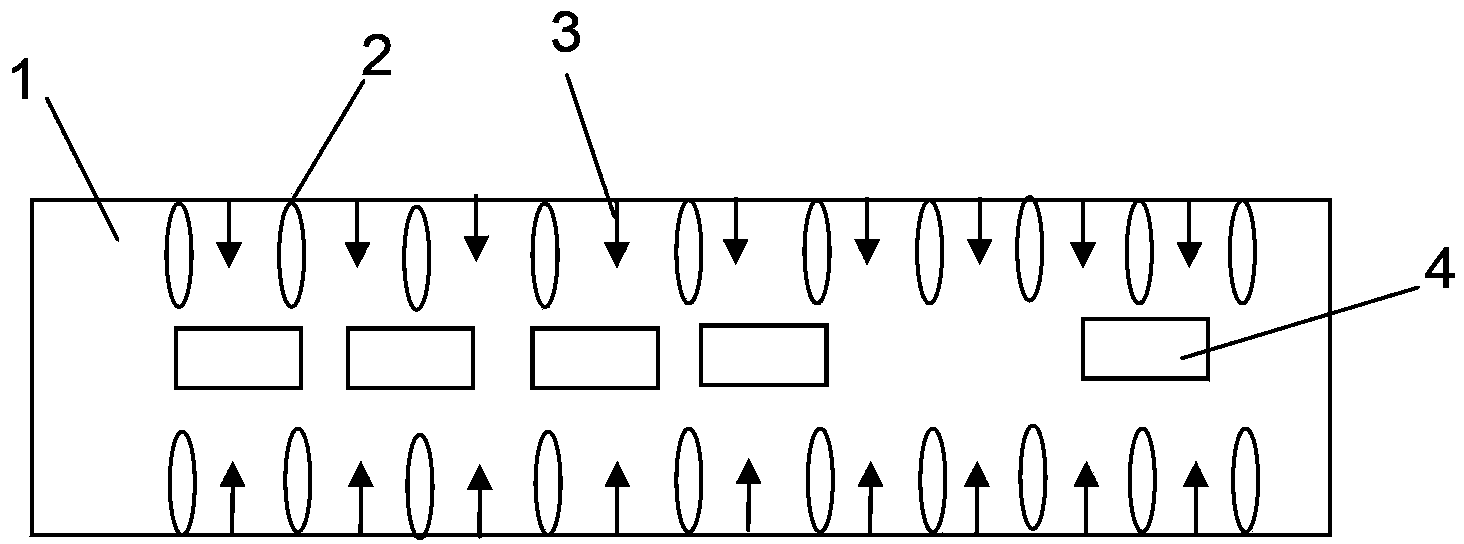

Oxy-fuel combustion system for steel rolling heating furnace

PendingCN114688868AImprove combustion efficiencyImprove heat transfer efficiencyFurnace typesHeat treatment furnacesCombustion systemTemperature control

The invention provides an oxygen-fuel combustion system for a steel rolling heating furnace. The oxygen-fuel combustion system comprises the heating furnace, a fuel system, a combustion-supporting system, a nitrogen purging system, a smoke exhaust system and a control system. The heating furnace comprises a preheating section, a heating section and a soaking section. Total-oxygen flameless combustors are arranged on the side walls of the upper heating area and the lower heating area of the heating section, and the total-oxygen flameless combustors are arranged in an up-and-down layered and left-and-right staggered mode. Total-oxygen flameless combustors are arranged on the side walls of the upper heating area and the lower heating area of the soaking section, and the total-oxygen flameless combustors are arranged in an up-and-down layered and left-and-right staggered mode. Total-oxygen flameless combustors are arranged on the end wall of the heating area on the upper portion of the soaking section and are horizontally arranged in a single-layer mode. The control system comprises a blank tracking system, an intelligent temperature control system, a hearth pressure control system, a linkage alarm protection system and a blank heat preservation rolling waiting system. The combustion efficiency and the heat transfer efficiency of the steel rolling heating furnace are improved, and the purposes of improving productivity, saving fuel, reducing emission and improving product quality are achieved.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

Double-door double-cavity oven

PendingCN113017439AImprove heating efficiencyGuaranteed heating qualityRoasters/grillsWarming devicesPhysicsEngineering

The invention provides a double-door double-cavity oven which comprises an oven body and a slidable baffle vertically arranged in the middle of an inner cavity of the oven body, the baffle divides the inner cavity of the oven body into a first heating cavity and a second heating cavity, a first heating structure is arranged at the top of the first heating cavity, and a second heating structure is arranged at the top of the second heating cavity; a plurality of first supporting pieces are horizontally arranged on the inner walls of the two sides of the oven body, and a plurality of second supporting pieces matched with the first supporting pieces are arranged on the two sides of the baffle; and the oven also comprises two oven doors, the two oven doors are hinged to the two horizontal sides of the oven body respectively, and the two oven doors are matched with the opening of the oven body. The double-door double-cavity oven has better using effect.

Owner:广东家好美电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com