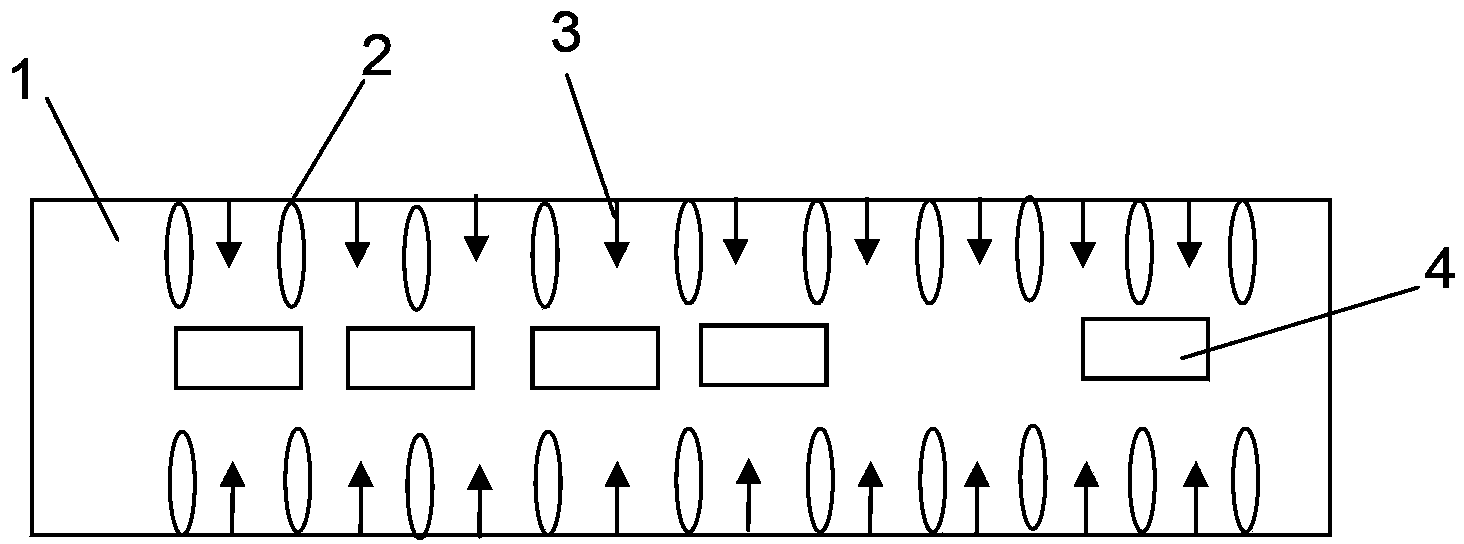

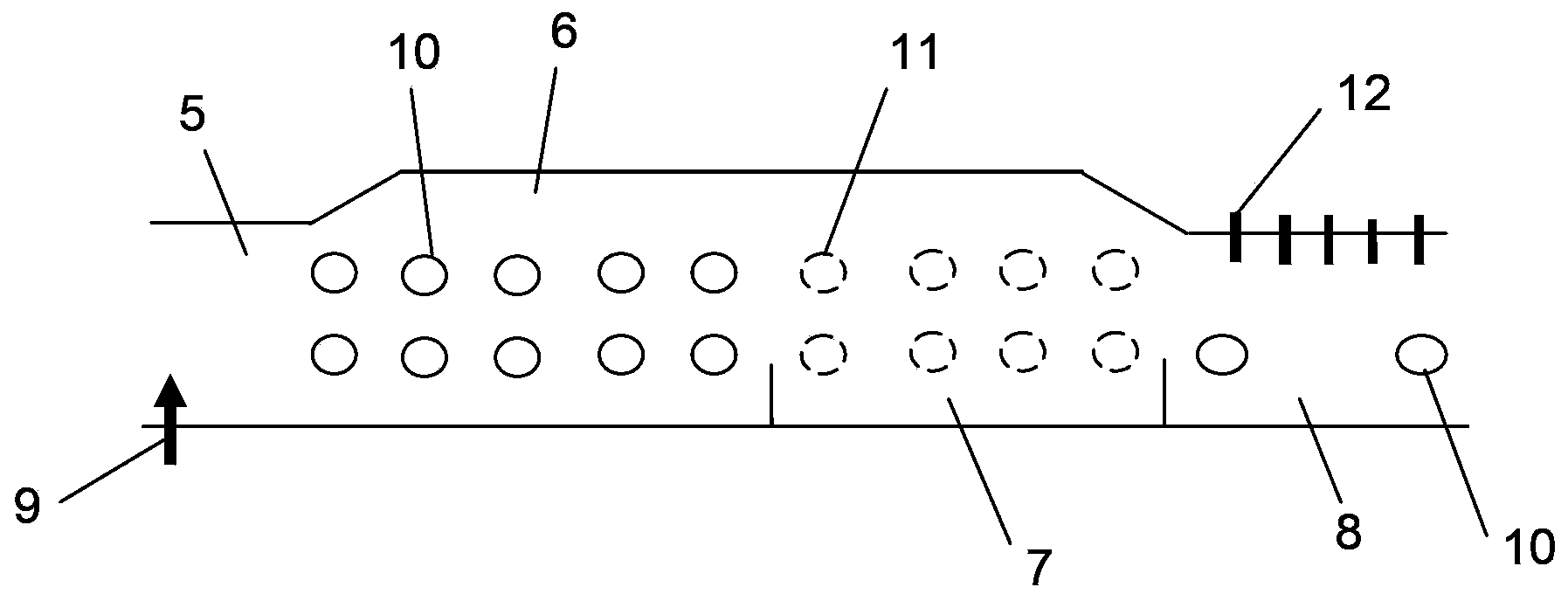

Hot rolling heating furnace and local strengthening heating control method thereof

A local strengthening and heating control technology, applied in the field of hot rolling heating, can solve the problems of not being able to greatly reduce energy consumption, meet the high requirements of hot rolling heating quality and energy saving, and achieve the effect of improving uniformity and ensuring heating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

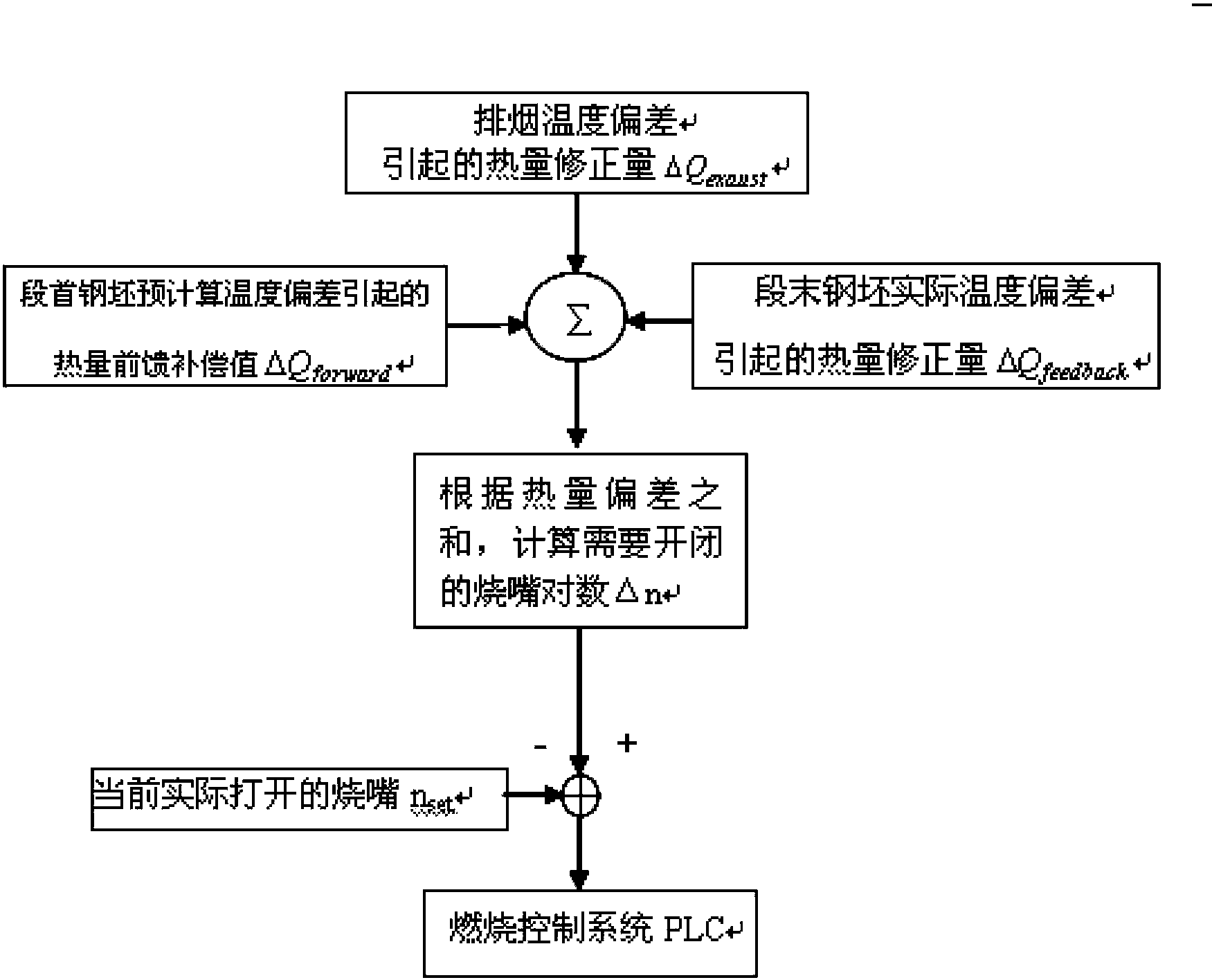

Method used

Image

Examples

Embodiment 1

[0061] Carbon steel standard slab: 230×1400×10000mm, cold charging, hourly output 320t / h, target temperature of slab at the end of preheating section 900℃, target temperature of unloading 1200℃, target temperature of smoke exhaust in heat recovery section 600℃. In the current control state, the total fuel input is 48626Nm 3 , of which the preheating section is 16153N m 3 , heating section 21549N m 3 , soaking section 10924N m 3 , the actual exhaust gas temperature is 551 degrees, the predicted end temperature of the preheating section is 850 degrees, the actual temperature at the end of the preheating section is 836 degrees, and the actual temperature of the furnace is 1198 degrees.

[0062] The heat feed-forward compensation weight δ is 0.5, and the heating efficiency λ is 0.9. The heating furnace provided by the present invention is used for heating, the heating section adopts the heat storage pulse control method, the soaking section adopts the conventional control metho...

Embodiment 2

[0080] Carbon steel standard slab: 230×1400×10000mm, hot charging at 400 degrees, hourly output 350t / h, target temperature of billet at the end of preheating section 900 degrees, furnace target temperature 1200 degrees, heat recovery section smoke target temperature 600 degrees. In the current control state, the total fuel input is 43128Nm 3 , of which the preheating section is 16047Nm 3 , heating section 18184Nm 3 , soaking section 8897Nm 3 , the actual exhaust gas temperature is 612 degrees, the predicted end temperature of the preheating section is 950 degrees, the actual temperature at the end of the preheating section is 933 degrees, and the actual furnace temperature is 1208 degrees.

[0081] The heat feed-forward compensation weight δ is 0.5, and the heating efficiency λ is 0.9. The heating furnace given in this patent is used for heating. The heating section adopts the heat storage pulse control method, the soaking section adopts the conventional control method, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com