Phase-change energy storage box

A technology of phase change energy storage and solid-liquid phase change, which is applied in the field of heat exchange, can solve the problems of low heat exchange effect of heat exchanger, unstable water supply temperature, and large water tank volume, so as to facilitate assembly production and ensure continuous Constant temperature operation, simple and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

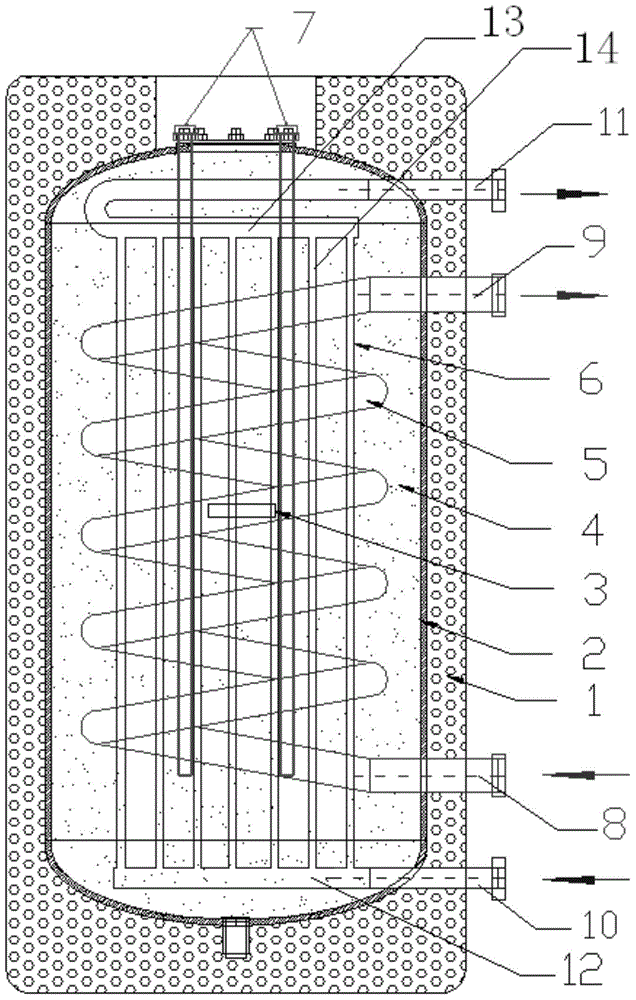

[0024] The schematic diagram of the phase change energy storage tank using copper heat exchange coil as the heat medium heat exchanger in the present invention is as follows figure 1 As shown, it includes a box body 2, a refrigerant heat exchanger 6, a heat medium heat exchanger 5, and an electric auxiliary heater 7. In order to ensure the strength of the box body, the box body 2 is made of steel. The compartment 2 is filled with a solid-liquid phase change energy storage material 4, and an insulation layer 1 is installed outside the compartment 2. The insulation layer 1 can use various insulation materials. The insulation layer in this embodiment is polyurethane foam layer. The refrigerant heat exchanger 6 , heat medium heat exchanger 5 and electric auxiliary heater 7 are placed in the solid-liquid phase change energy storage material 4 inside the box body 2 . The car body 2 is provided with maintenance holes. The refrigerant inlet of the refrigerant heat exchanger 6 is con...

Embodiment 2

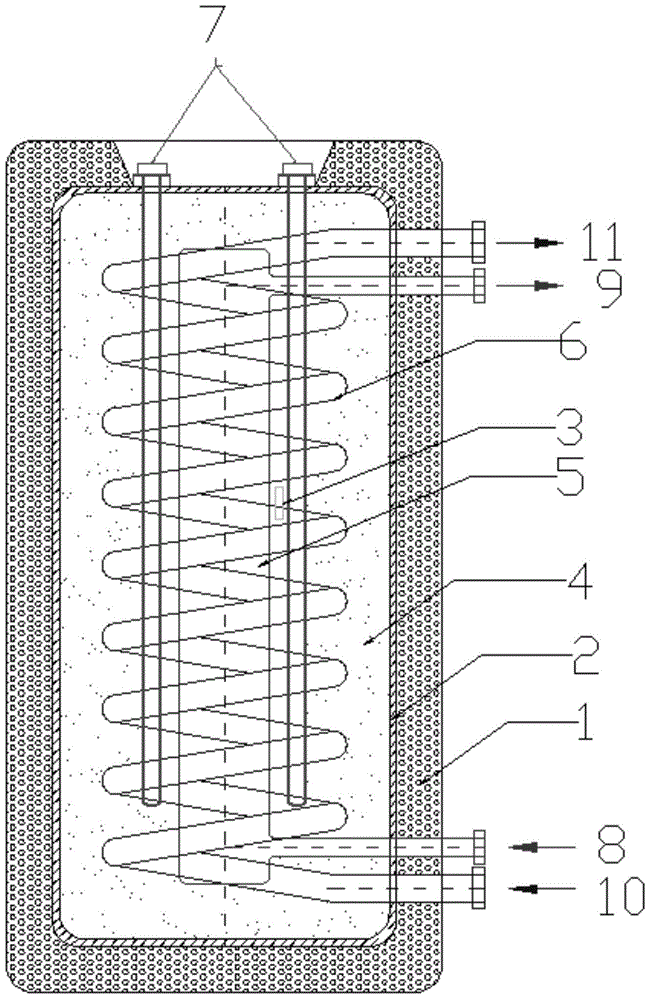

[0029] The schematic diagram of the phase change energy storage tank using copper heat exchange coil as the refrigerant heat exchanger in the present invention is as follows figure 2 As shown, it includes a box body 2, a refrigerant heat exchanger 6, a heat medium heat exchanger 5, and an electric auxiliary heater 7. In order to ensure the strength of the box body, the box body 2 is made of steel. The compartment 2 is filled with a solid-liquid phase change energy storage material 4, and an insulation layer 1 is installed outside the compartment 2. The insulation layer 1 can use various insulation materials. The insulation layer in this embodiment is polyurethane foam layer. The refrigerant heat exchanger 6 , heat medium heat exchanger 5 and electric auxiliary heater 7 are placed in the solid-liquid phase change energy storage material 4 inside the box body 2 . The car body 2 is provided with maintenance holes. The refrigerant inlet of the refrigerant heat exchanger 6 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com