Oxy-fuel combustion system for steel rolling heating furnace

An all-oxygen combustion and heating furnace technology, applied in the field of heating furnaces, can solve problems such as combustion processes and methods that do not involve all-oxygen heating furnaces, and achieve the effects of ensuring heating quality and performance, saving construction investment, and reliable sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

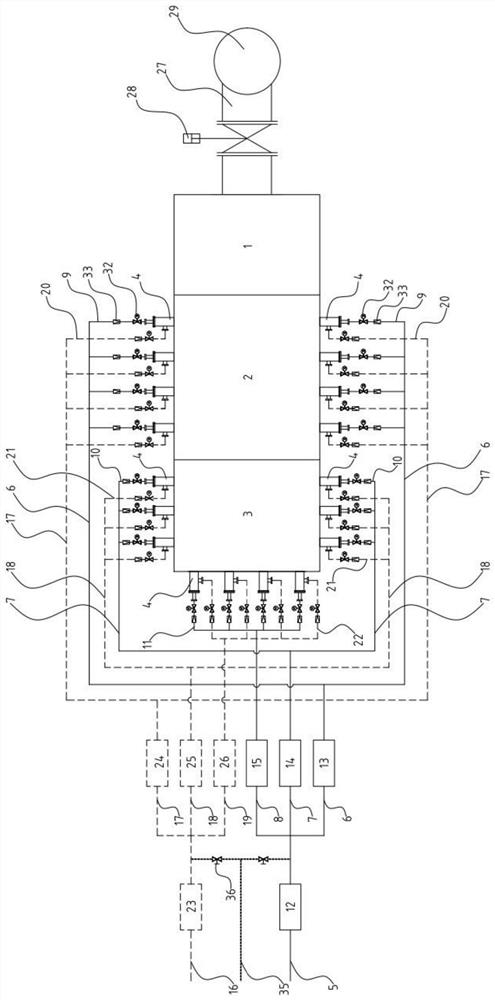

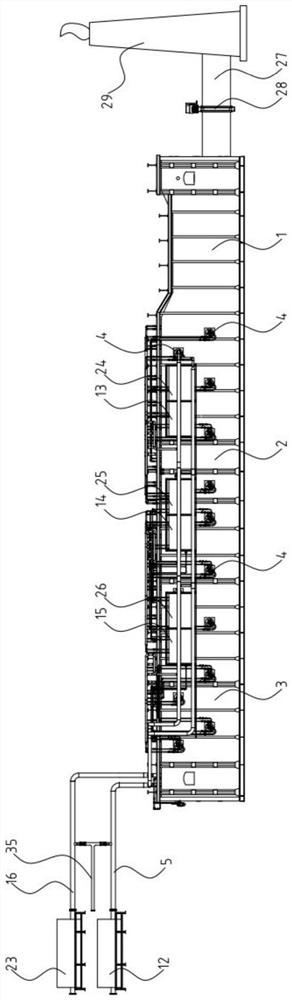

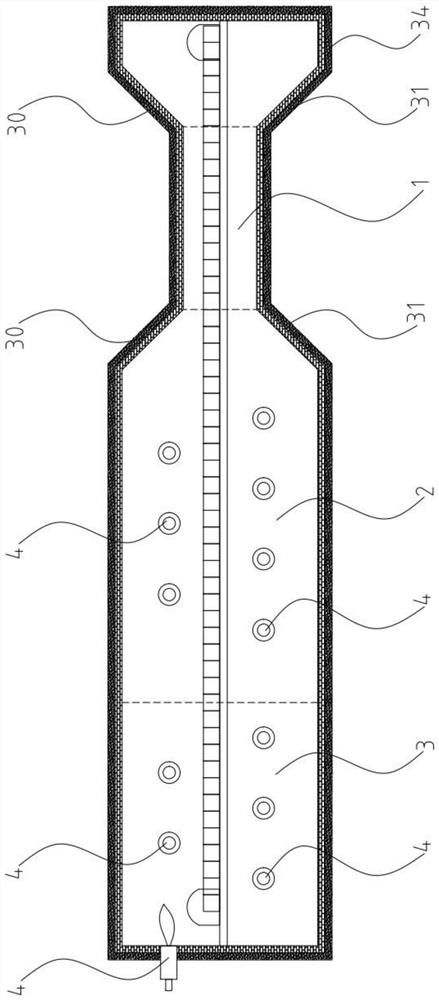

[0042] The specific embodiments provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0043] like figure 1 As shown, an all-oxygen combustion system for a steel rolling heating furnace includes a heating furnace, a fuel system, a combustion-supporting system, a nitrogen purging system, a smoke exhaust system, and a control system. The heating furnace includes a preheating section 1, a heating section 2, and a soaking section 3. The heating section 2 and the soaking section 3 are divided into an upper heating zone and a lower heating zone. Preheating section 1 does not have a heating zone. The fuel system includes fuel pipelines and fuel valve groups. Combustion-supporting system includes oxygen pipeline and oxygen valve group. The nitrogen purge system includes nitrogen line 35 and nitrogen valve 36 . The smoke exhaust system includes an exhaust flue 27 , a smoke exhaust valve 28 and a chimney 29 . The control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com