In-furnace time control method for thick steel plate heat treatment

A technology of time control and control method, which is applied in the direction of heat treatment process control, heat treatment furnace, heat treatment equipment, etc., and can solve problems such as lag and low heat treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

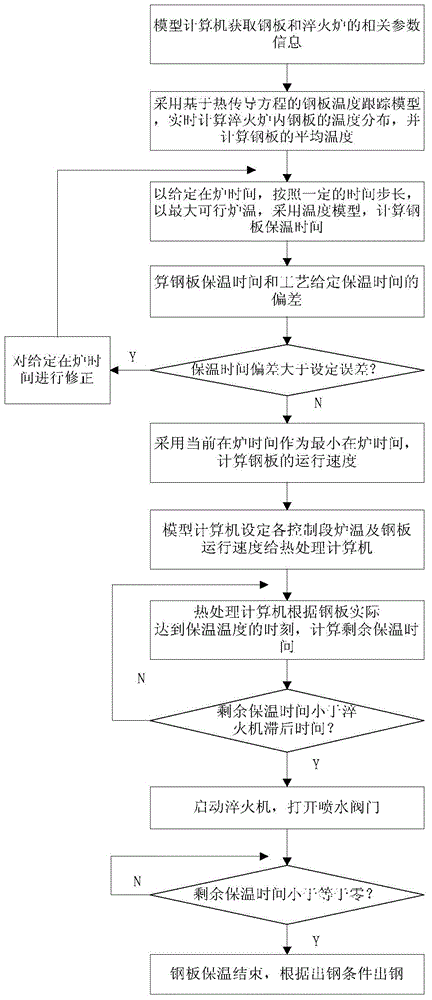

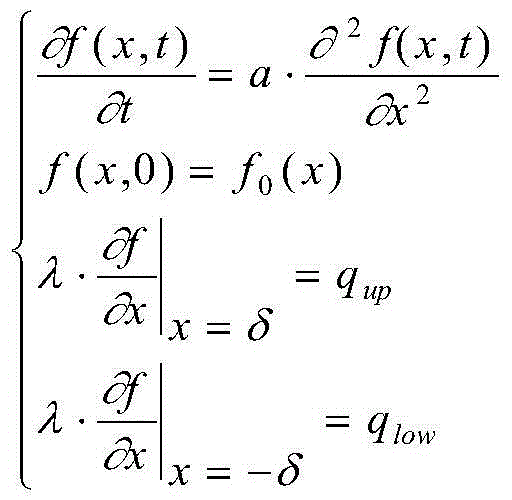

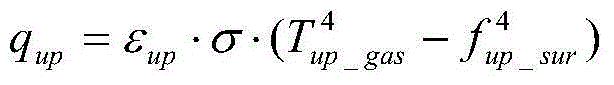

Method used

Image

Examples

Embodiment

[0070] The following is an example of a low-carbon steel plate with a thickness of 40 mm and a length of 5000 mm to further describe the present invention in detail. In this embodiment, the roller hearth quenching furnace used for heating the above-mentioned steel plate is divided into 10 control sections along the length direction , each control section has two upper and lower furnace temperature control areas.

[0071] 1. Obtain relevant parameter information required for forecast calculation through the model computer.

[0072] The length of each control section and the standard process are shown in Table 1 below. The heating time of the standard heating process is 43 minutes, and the holding time is 14 minutes. The physical parameters of the steel grades of the examples are shown in Table 2.

[0073] Table 1 The length of the control section of the quenching furnace and the standard process furnace temperature corresponding to the target steel plate temperature of 910 °C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com