System and method for calculating optimal heating curve of blank in heating furnace

A technology of heating curve and calculation system, applied in heat treatment furnaces, furnaces, furnace types, etc., can solve problems such as difficulty in achieving optimal control of heating furnaces, affecting the production efficiency of heating furnaces for metal heating quality, and difficulty in adapting to the needs of different billet heating processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

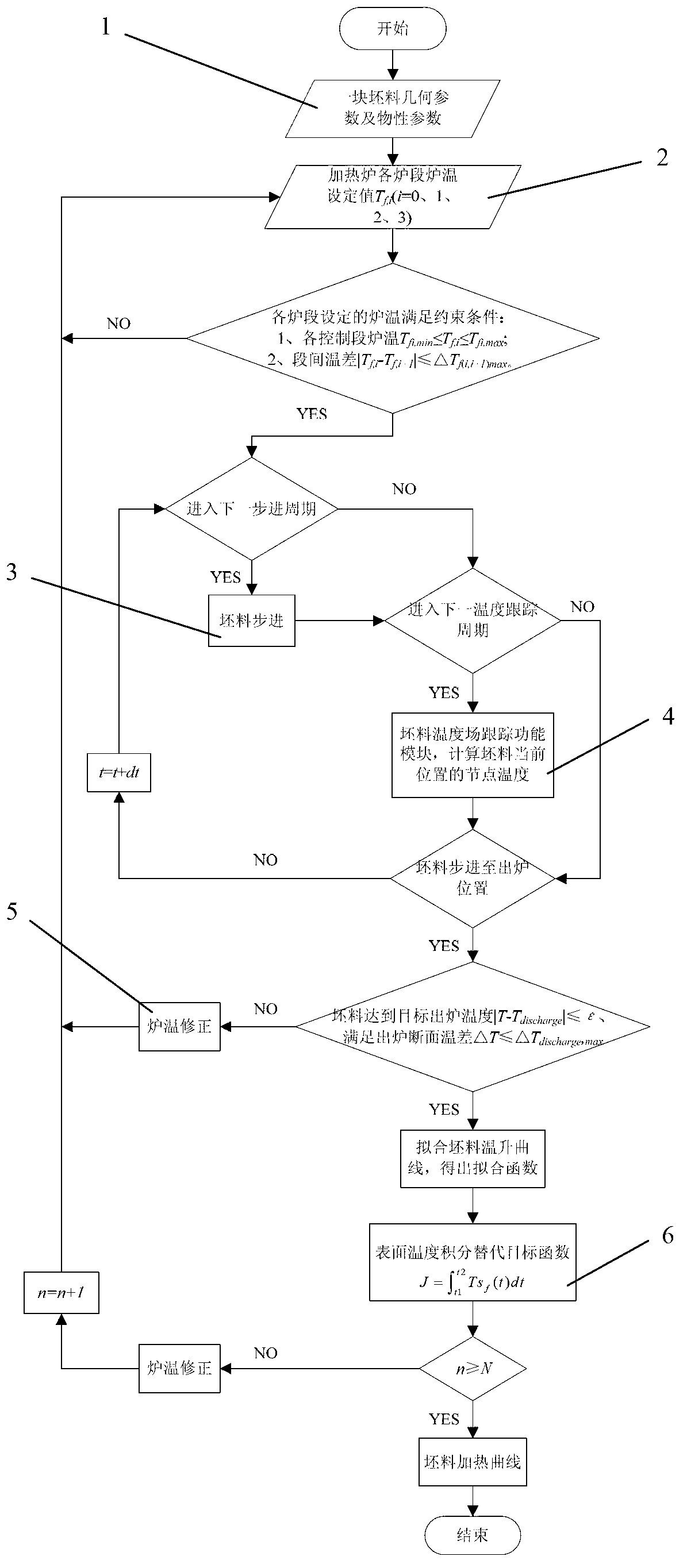

Method used

Image

Examples

Embodiment 1

[0130] For the hot charging blank, according to the method provided by the present invention, the initial internal node temperature is calculated and obtained, as shown in Table 2.

[0131] Table 2 Calculation of node temperature of hot charging billet

[0132]

Embodiment 2

[0134] For the hot charging blank, the initial internal node temperature is obtained through calculation according to the method provided by the present invention, as shown in Table 3.

[0135] Table 3 Calculation of node temperature of hot charging billet

[0136]

Embodiment 3

[0138] For the hot charging blank, the initial internal node temperature is obtained through calculation according to the method provided by the present invention, as shown in Table 4.

[0139] Table 4 Calculation of node temperature of hot charging billet

[0140]

[0141] Two. Embodiments of the invention

[0142] ● Example 1

[0143] Call the blank parameter initialization module 1 to initialize the calculation parameters. The initialization values of the main parameters of the blank are shown in Table 5, and the initialization values of the main parameters of the heating furnace are shown in Table 6.

[0144] Table 5 Blank parameters

[0145] parameter name

Width (m)

Thickness (m)

Density (kg / m 3 )

Blackness

Into the furnace temperature (℃)

parameter value

1.20

0.24

7850

0.8

300

[0146] Table 6 Heating furnace parameters

[0147]

[0148]

[0149] Using the method provided by the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com