Hot rolling titanium plate production method and system

A production method and technology for titanium plates, which are applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of unstable quality, high cost, and low yield of titanium plates, and achieve simple methods and improved finished products. rate, the effect of reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

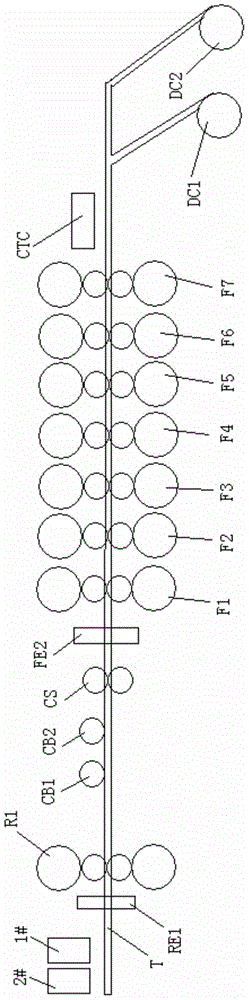

[0026] see figure 1 , a production method of hot-rolled titanium plate, the method comprises the following steps:

[0027] Step 1: The titanium slab is heated by heating furnaces #1 and #2, and then the furnace-grown iron oxide formed on the titanium slab due to heating is removed, and then the titanium slab is sent into the rough rolling device by the roller table. Among them, the temperature of the titanium slab out of the furnace is controlled at 878°C to 882°C.

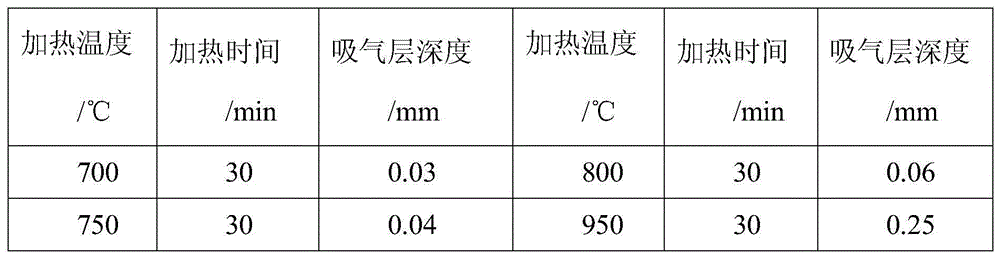

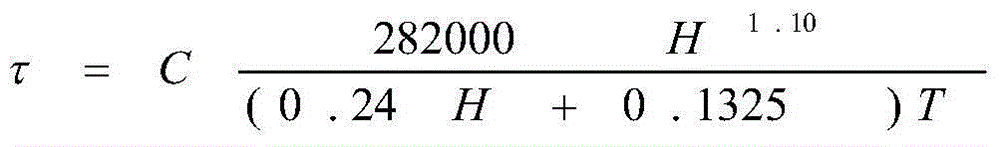

[0028] Titanium is a metal with very active chemical properties. At high temperature, the affinity between titanium and oxygen is extremely strong. At the initial stage of heating, oxygen enters the lattice on the surface of titanium to form a dense oxide film, which can prevent further diffusion of oxygen to the substrate. When heated above 500°C, the oxide film of titanium becomes porous, thickened and easily peeled off. Oxygen diffuses continuously to the substrate through the pores in the film, forming a hard...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com