Method for determining master-slave control proportional factor of hot rolling heating furnace

A technology of proportional coefficient and determination method, which is applied in the direction of heat treatment process control, temperature control, heat treatment furnace, etc., can solve the problem of not being able to adapt well to different slab heating conditions, unable to meet complex and changeable production requirements, and lack of changing proportional relationship to overcome the inaccurate fuel ratio coefficient, optimize the master-slave control ratio coefficient, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

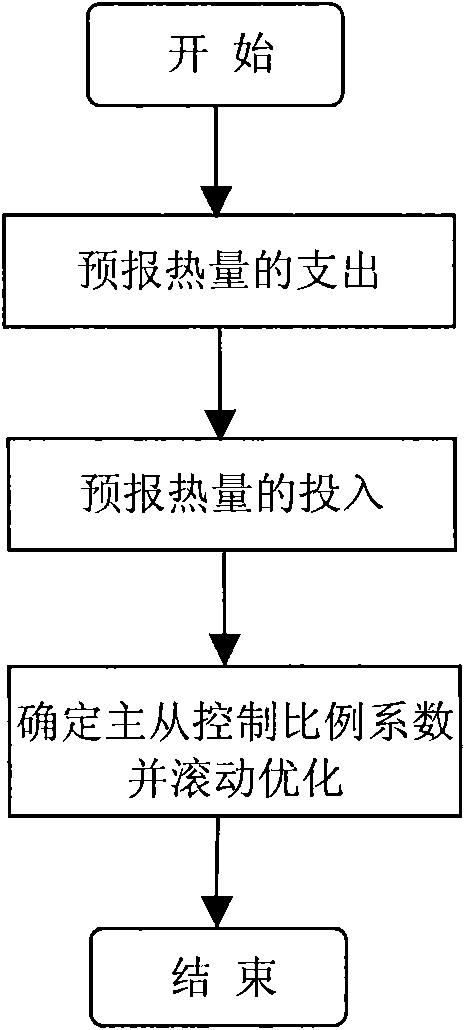

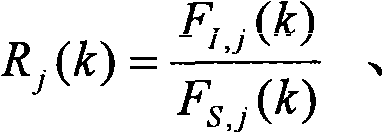

Method used

Image

Examples

Embodiment

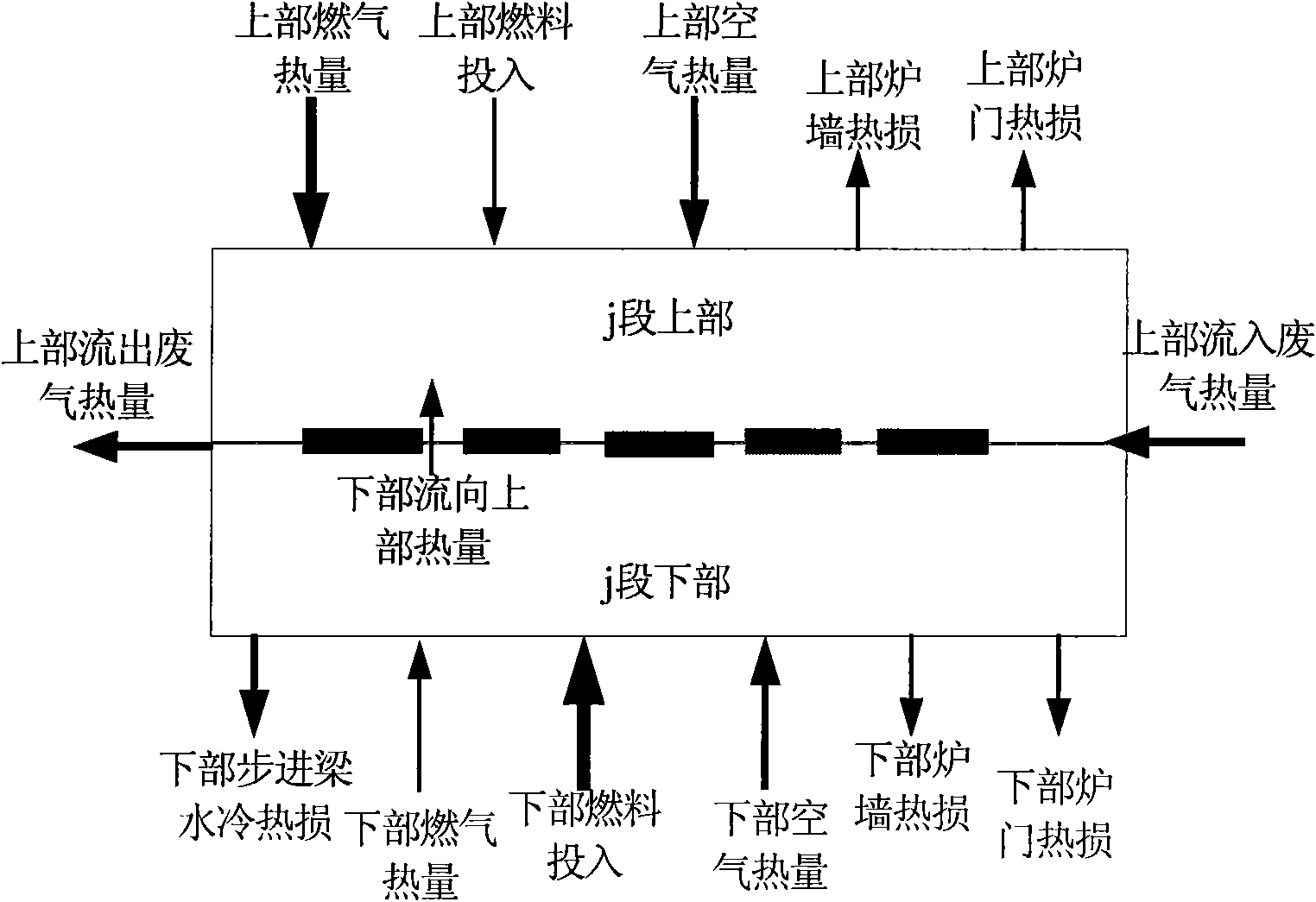

[0138] A four-section walking beam heating furnace is adopted, and the section lengths of the furnace tail section, preheating section, first heating section, second heating section, and soaking section are 11.0m, 7.4m, 7.0m, 7.0m, and 8.65m respectively; The outer width is 12.7m, the height of the upper and lower furnace walls is 2.5m and 1.5m respectively; the output per hour is 250 tons / hour, and the calorific value of gas is H f 2200kcal / mN 3 , combustion air temperature θ a is 600°C, the air-fuel ratio B is 2.2, and the specific heat of air is c a is 0.324, gas specific heat c f is 0.3785, and the physical parameters of the slab are those of low-carbon steel. The top temperatures of the furnace tail section, preheating section, first heating section, second heating section, and soaking section are: 60°C, 105°C, 110°C, 115°C, 110°C; the furnace wall temperature of each section is 40°C, 85°C, 90°C, 95°C, 90°C respectively, the furnace wall of the furnace tail section, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com