Linear compressor or refrigerating unit comprising a discharge device for fluid condensate

A technology for linear compressors and discharge devices, which is applied in liquid variable capacity machinery, mechanical equipment, machines/engines, etc., and can solve the problems of expensive surface coating and reduced performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

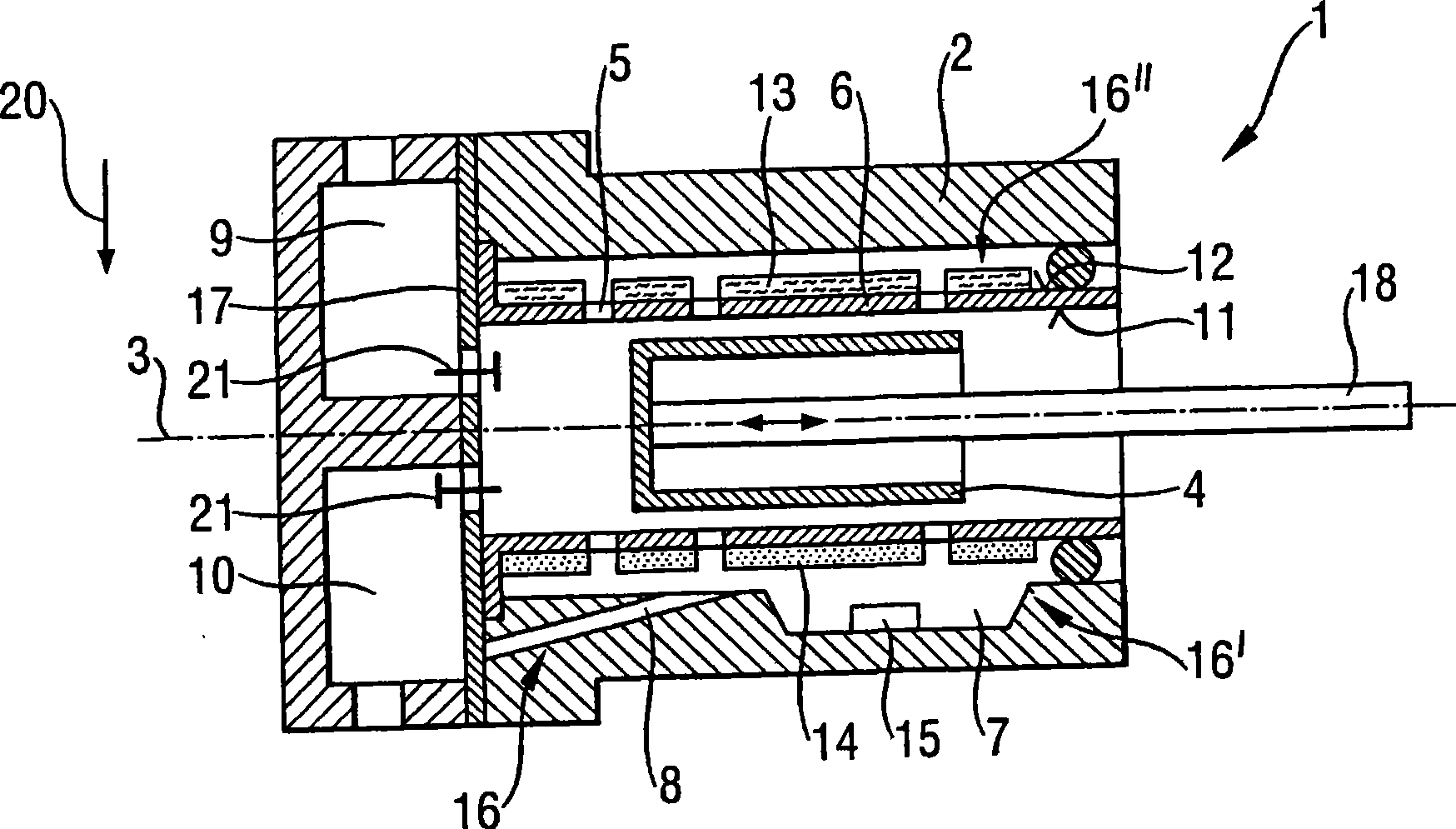

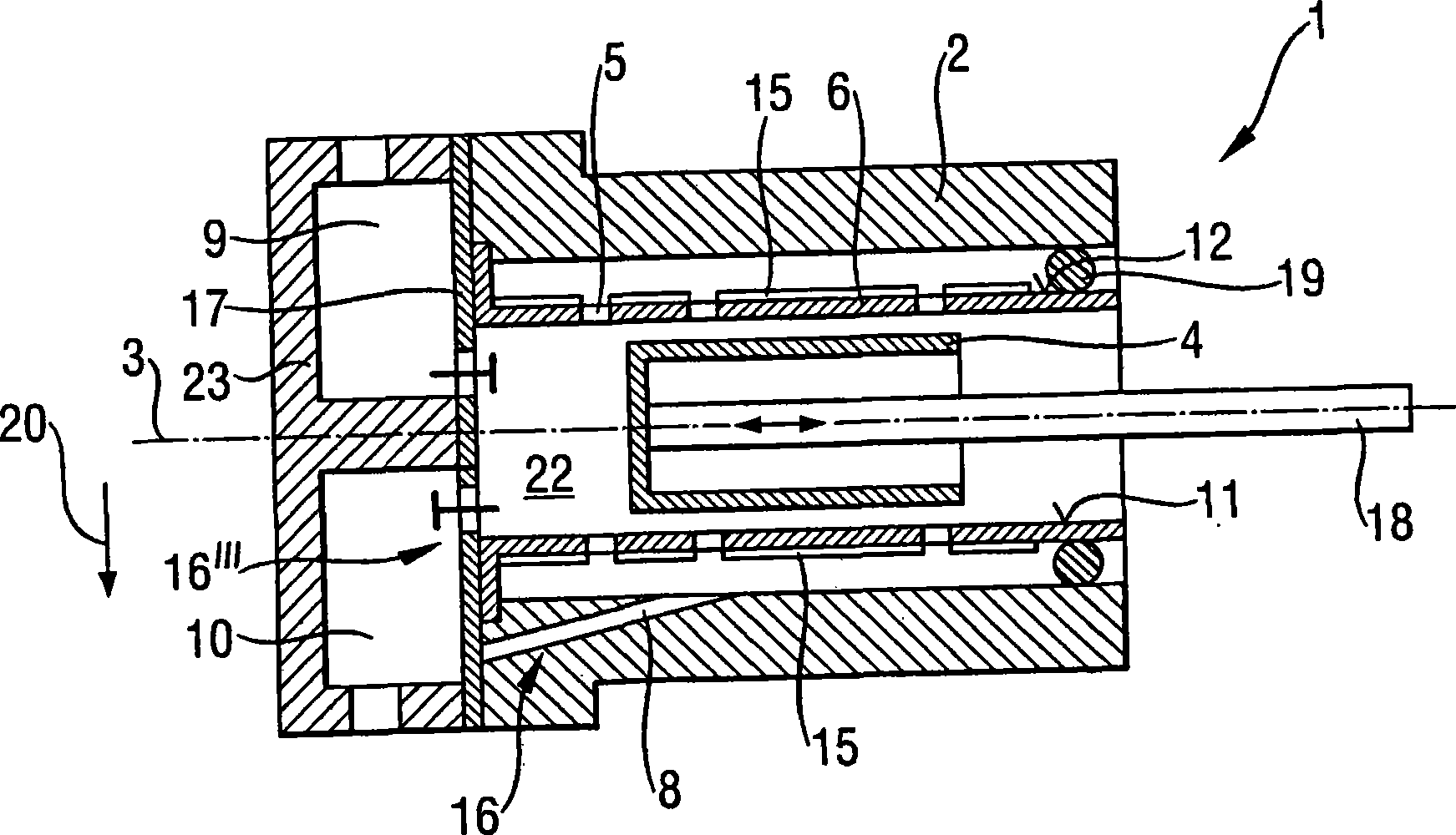

[0034] figure 1 A first embodiment of a linear compressor 1 with a piston housing 2 is shown in longitudinal section, wherein the compressor piston 4 is moved back and forth along the axis 3 by means of a piston rod 18 . The compressor piston 4 is supported by means of a housing wall 6 which has an opening 5 through which a fluid flows so that an air cushion is created between the housing wall 6 and the compressor piston 4 . Through the continuous flow of gas through the opening 5 , the compressor piston 4 is guided in a contactless manner in the housing wall 6 , which is formed as a cylinder liner. The linear compressor 1 has a suction connection 9 and a pressure connection 10 which are switched on and off in a suitable phase sequence by means of a valve plate 17 . The piston housing 2 has a recess 7 which acts as a drain 16' for fluid condensate. Any fluid condensate that forms flows from the housing wall 6 configured as a cylinder jacket into the recess 7 and collects the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com