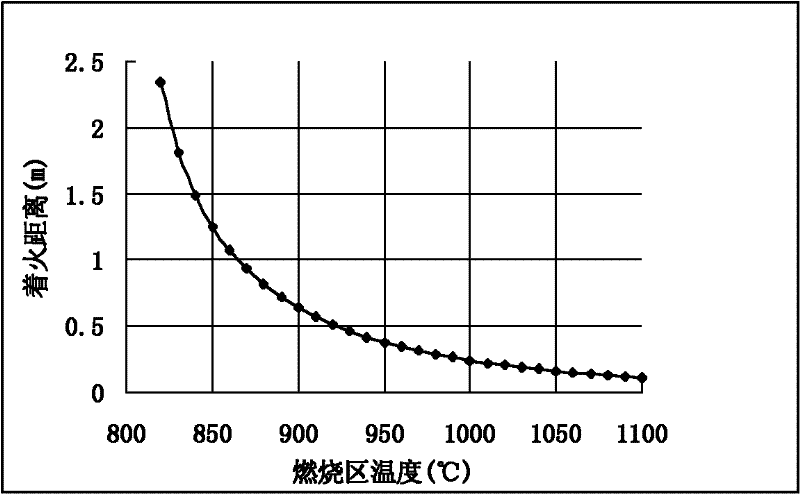

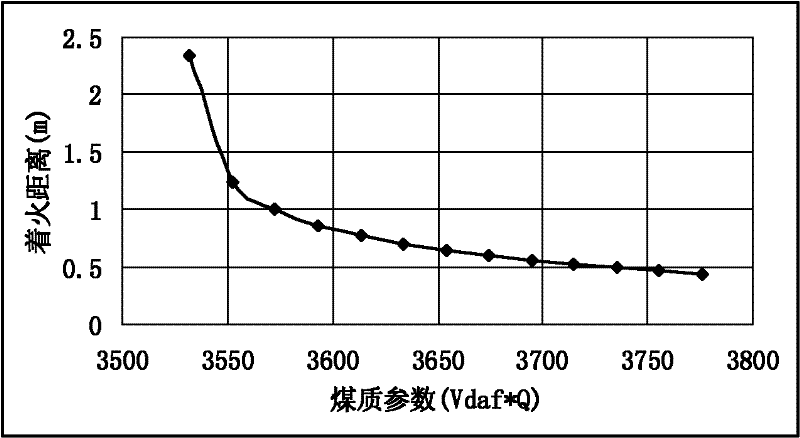

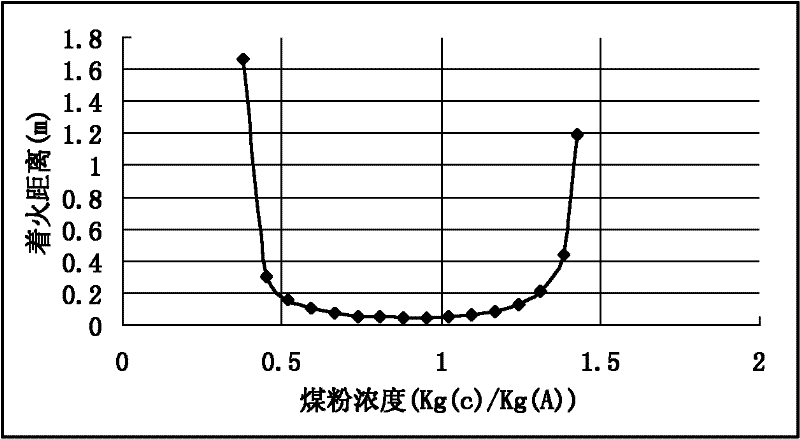

Method for measuring primary air-coal powder burning distance and coals for DC (direct current) burner of coal-fired boiler

A technology of ignition distance and coal-fired boilers, applied in measuring devices, fuel oil testing, instruments, etc., can solve problems such as affecting the design and safe operation of boilers in power plants, unreasonable air distribution, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0128] This embodiment is applied to a 200MW hot air powder feeding unit. The boiler of this unit adopts the HG-130 / 39-2 medium-temperature, medium-pressure and medium-storage pulverized coal boiler produced by Harbin Boiler Factory. Each boiler is equipped with 8 direct-flow Pulverized coal burner, the four corners of the hot air supply powder are tangentially burned, and the specific measurement steps are as follows:

[0129] 1. First divide the air duct once. For the determined units and burners that have not been modified, their constants and the primary air duct are fixed. The principle of division is to ensure that the measurement parameters of each part in each section of the primary air duct are consistent. The measurement parameters are: primary air temperature, Coal powder concentration, primary wind speed, coal powder fineness, oxygen content, coal quality parameters. The burner in this embodiment has not been transformed, so the primary air duct is divided into on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com