Biomass wood powder burning engine

A biomass and burner technology, applied in burners, combustion methods, combustion types, etc., can solve the problems of increasing the temperature of superheated steam, reducing the combustion efficiency of biomass wood powder, and reducing boiler output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

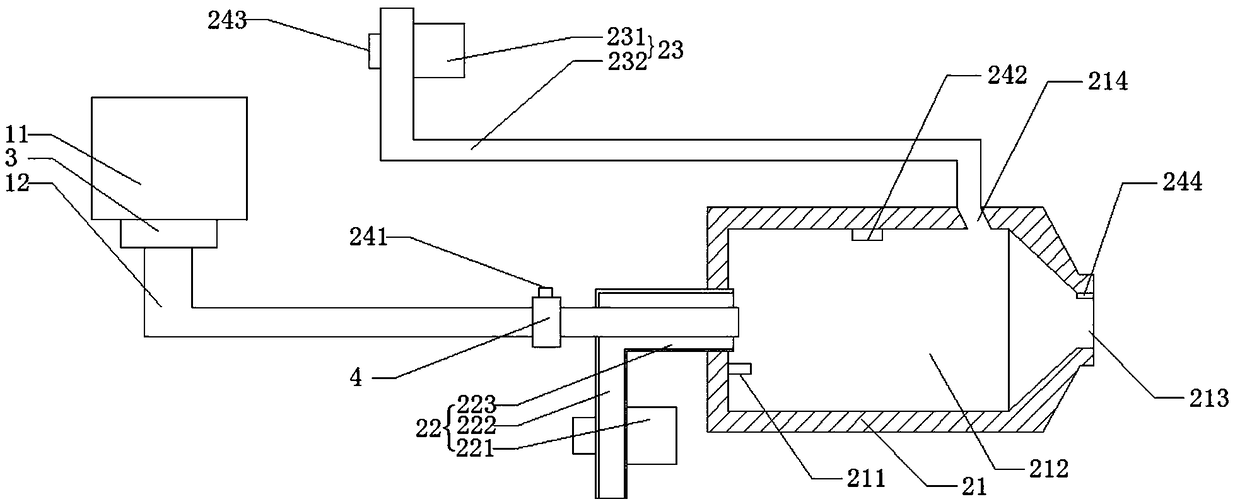

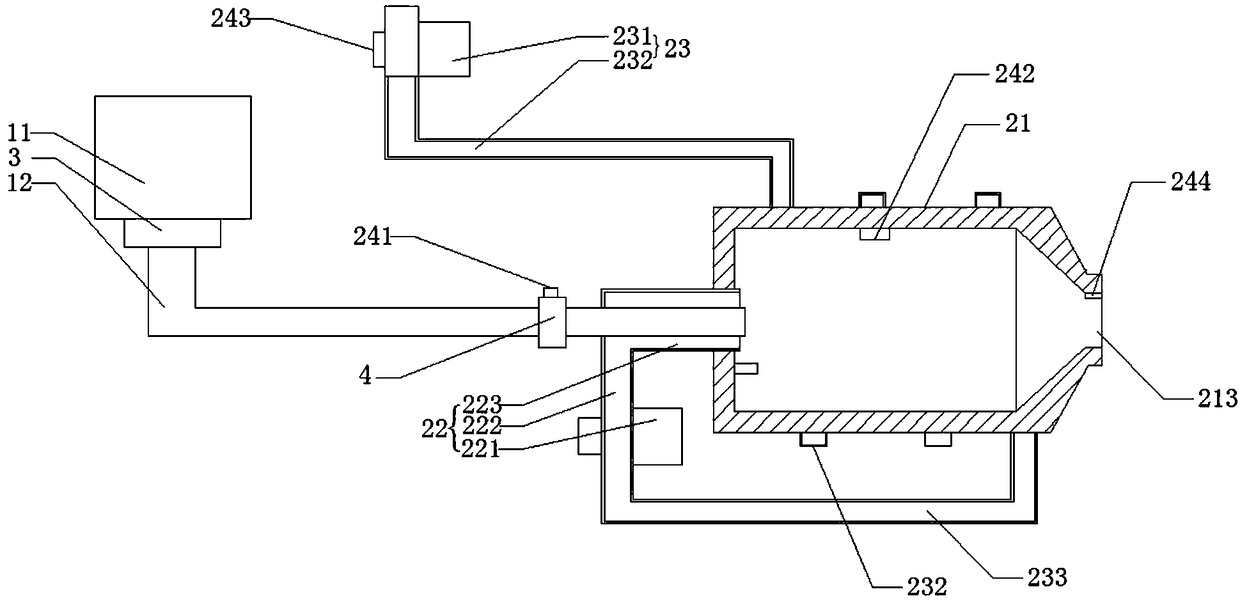

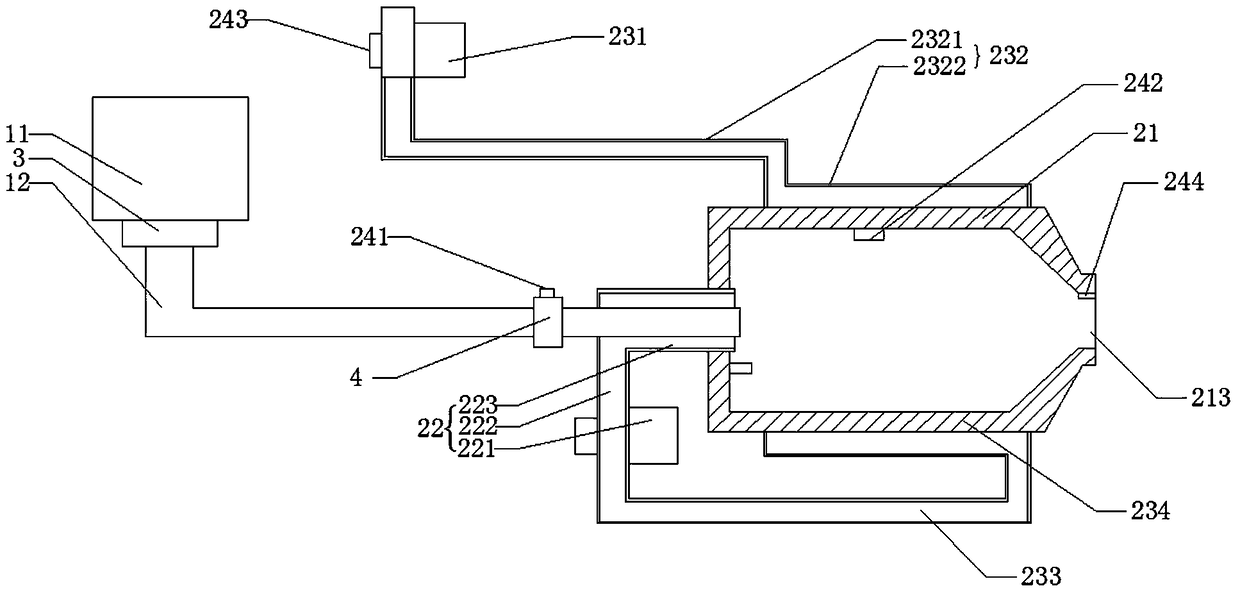

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] Such as figure 1 As shown, the embodiment of the present invention provides a biomass wood powder burner, including:

[0024] The feeding part, the feeding part includes a storage box 11 and a feeding pipe 12, and the storage box 11 is connected to the feeding pipe 12 for storing biomass wood powder;

[0025] Combustion section, the combustion section includes a burner 21, an oxygen supply part 22, a cooling part 23 and a detection part, the burner 21 is connected to the feeding pipe 12, and is used for burning biomass wood powder, and the oxygen supply part 22 is arranged at one end of the burner 21 , used to pass air into the burner 21, the cooling component 23 includes a cooling fan 231 and a cooling pipe 232, one end of the cooling pipe 232 is connected to the cooling fan 231, and the other end communicates with the burner 21, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com