Wind powder mixing temperature and flow speed secondary adjusting system

A secondary adjustment and air-powder mixing technology, which is applied in the direction of adjusting fuel supply, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., can solve the problem of many restrictions on combustion adjustment means, unfavorable stable combustion, and reduced pulverized coal burnout To achieve the effect of improving the combustion reaction rate and the stable combustion ability of the boiler under low load, reducing the exhaust gas temperature and the content of fly ash combustibles, and improving the operating flexibility of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

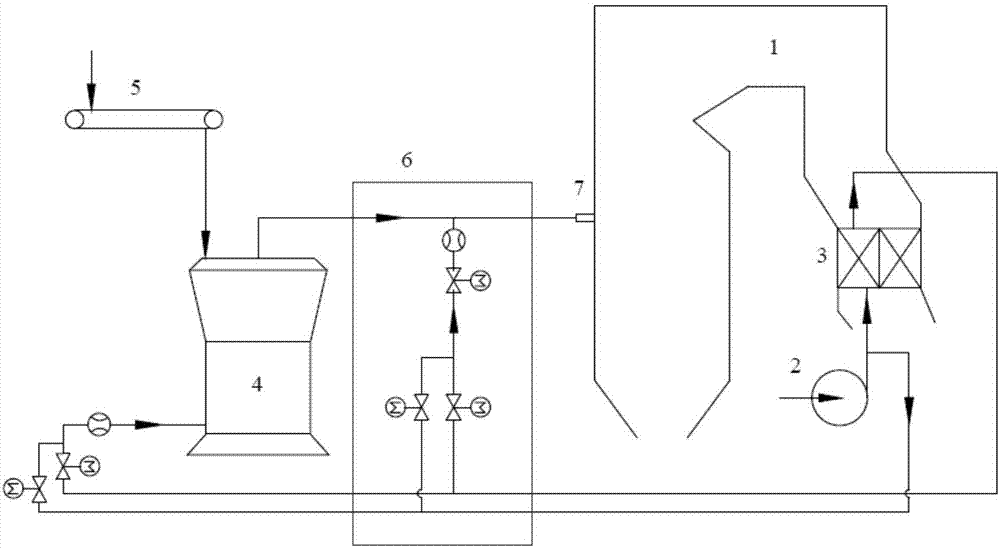

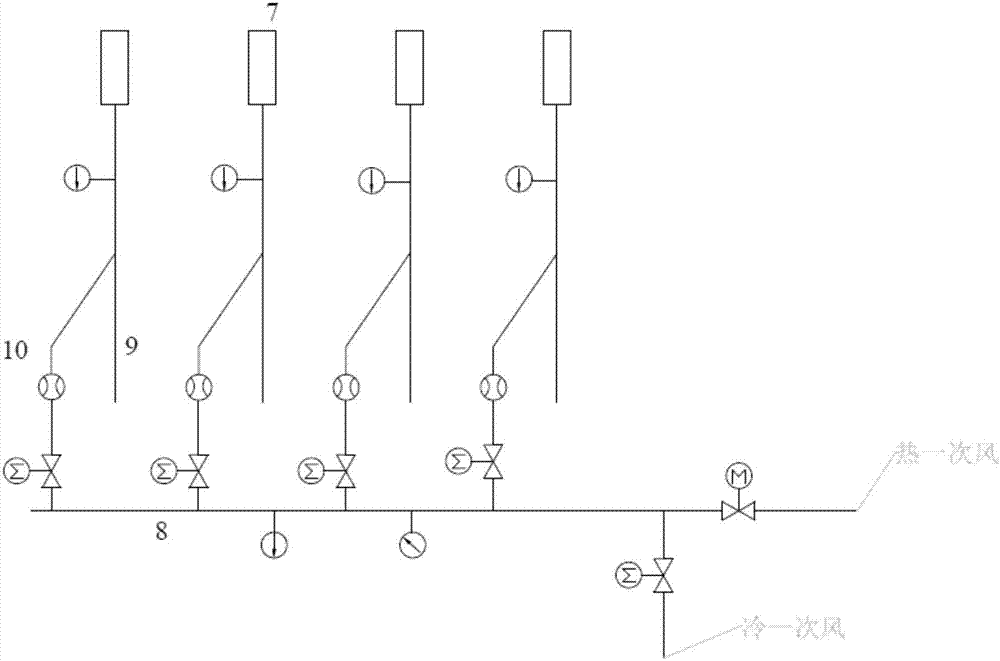

[0023] refer to figure 1 The air-powder mixing temperature and flow velocity secondary adjustment system of the present invention includes a primary fan 2, an air preheater 3, an air-powder gas-solid two-phase temperature and flow velocity adjustment system 6, a first valve, a second valve, and a coal feeder. Machine 5, coal mill 4 and boiler 1; the air outlet of the primary fan 2 is divided into two paths, one of which passes through the air preheater 3 and the hot air inlet and the first valve of the air powder gas-solid two-phase temperature and flow rate adjustment system 6 The outlet of the first valve is connected with the air inlet of the coal mill 4, and the other is connected with the cold air inlet of the air-powder gas-solid two-phase temperature and flow rate adjustment system 6 and the inlet of the second valve. The outlet of the valve is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com