Patents

Literature

30results about How to "Improve coal adaptability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

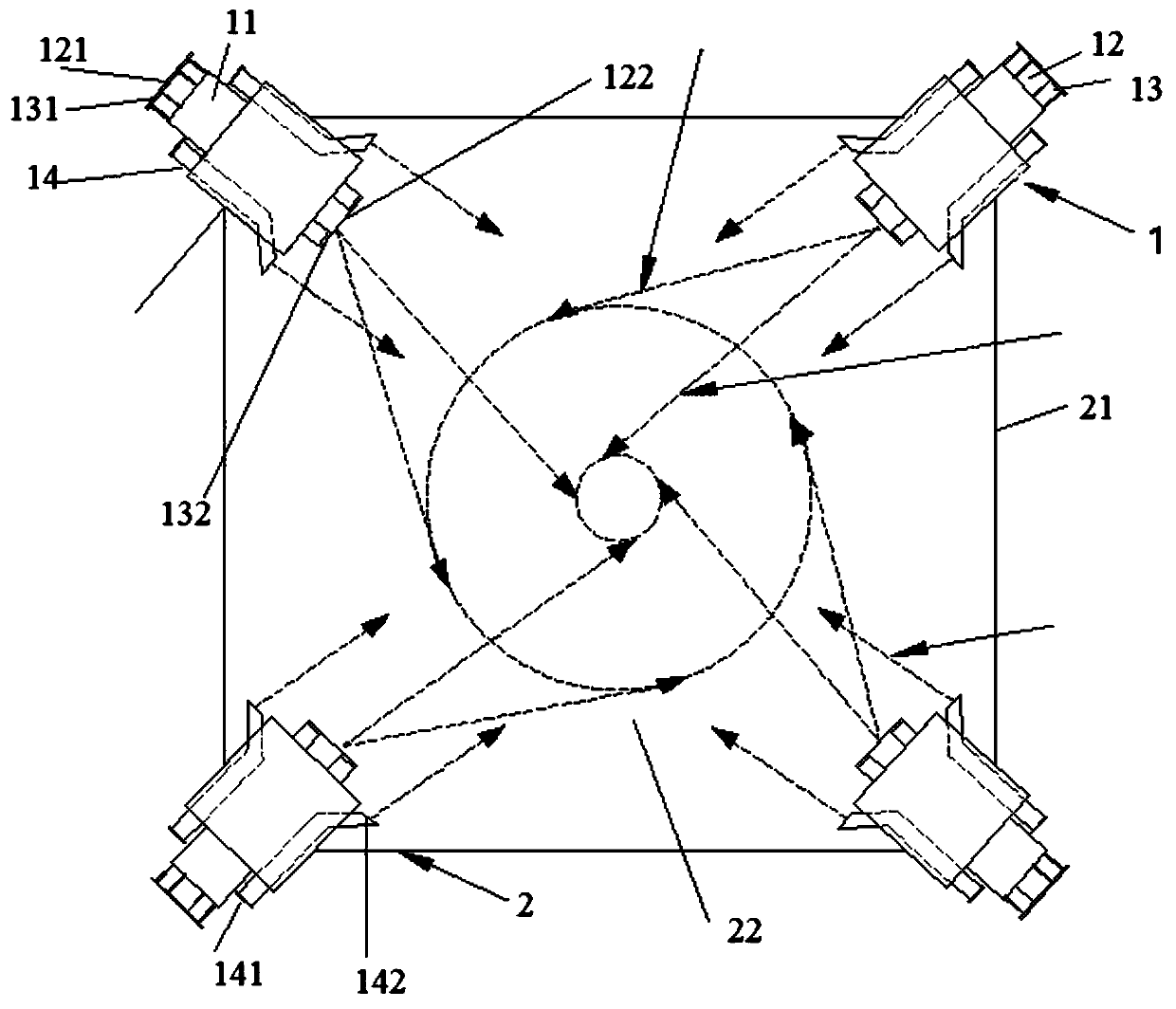

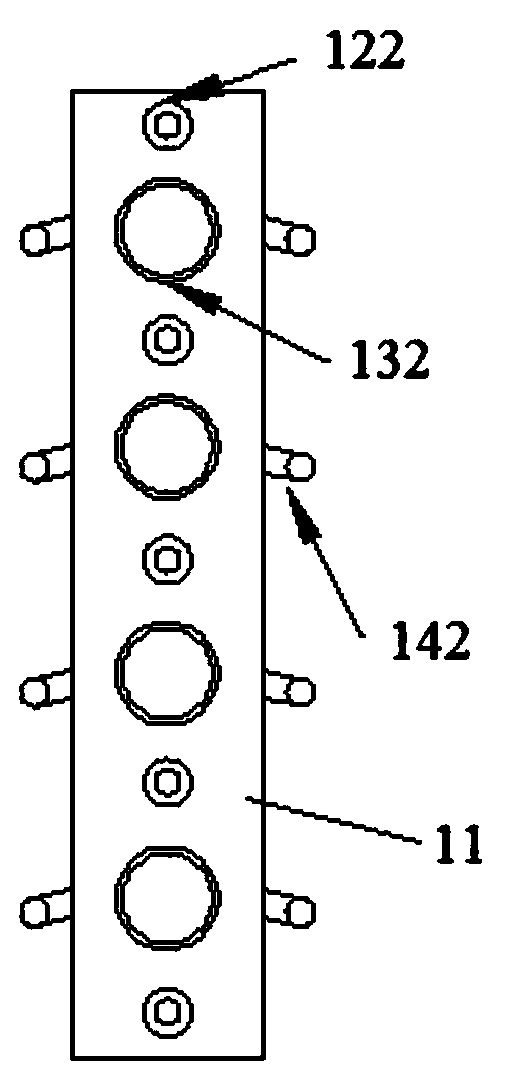

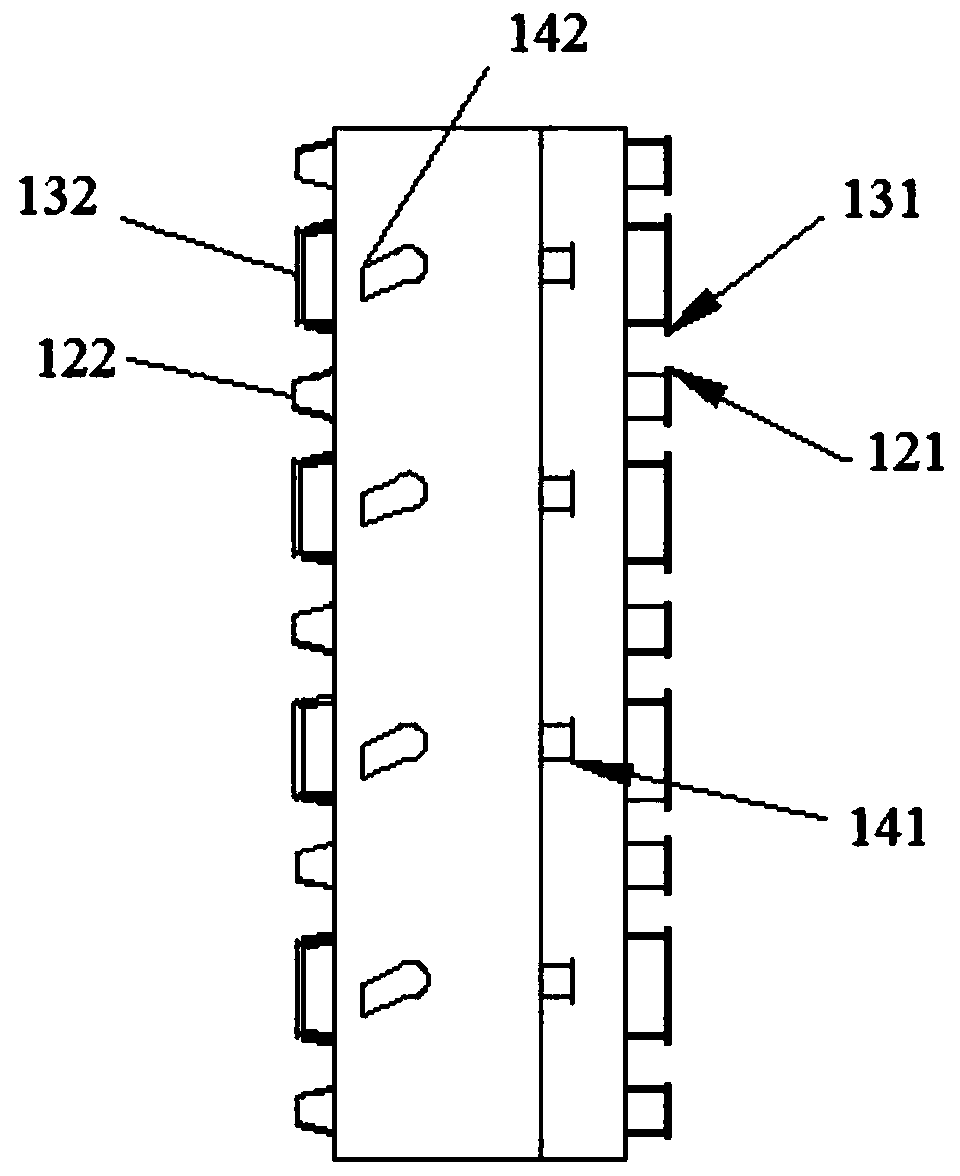

Low-load stable-combustion boiler combustor and combustion method and application thereof

ActiveCN109812803AGood heatCoal type adaptability and load regulation are goodCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSlagAutomotive engineering

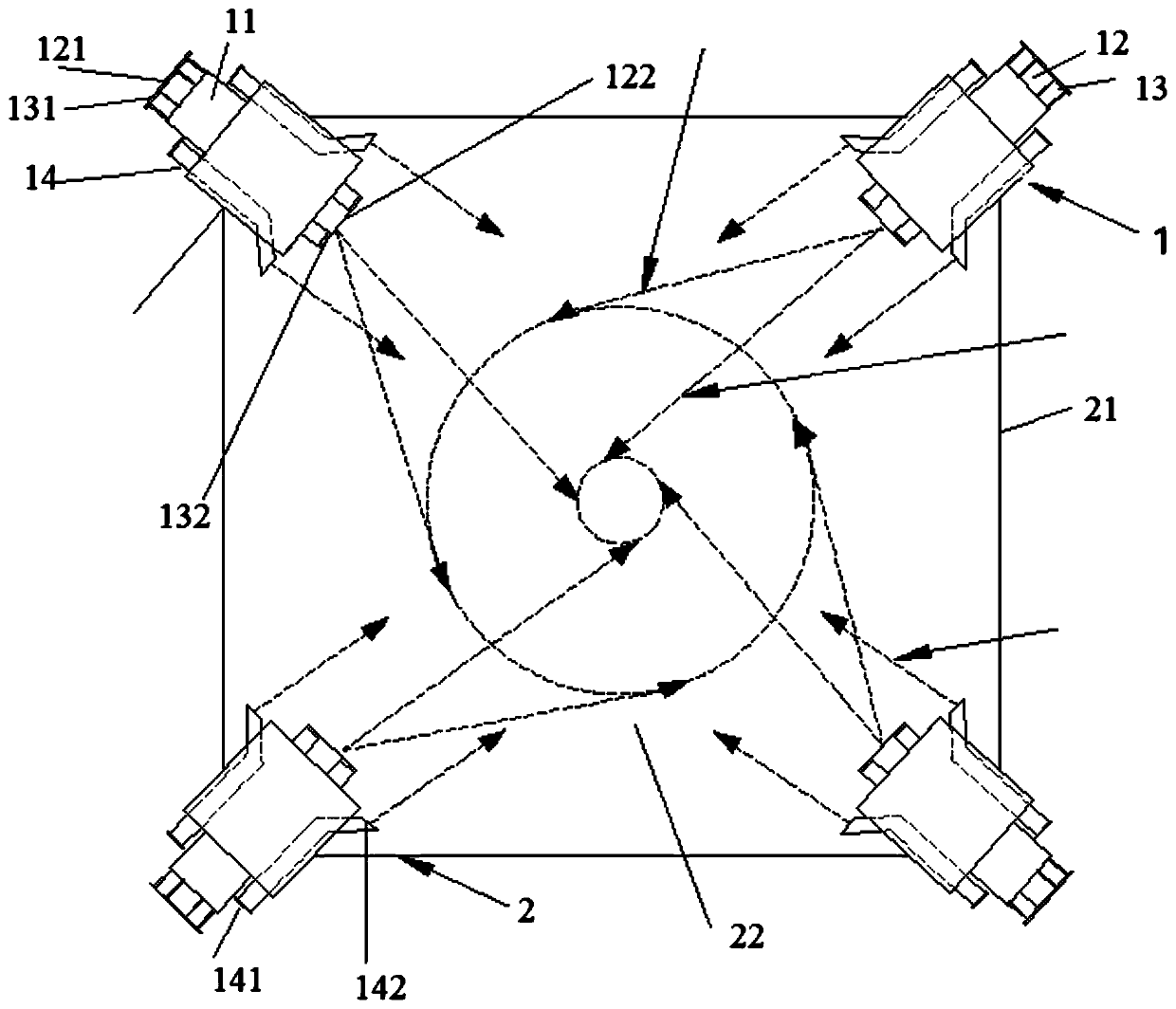

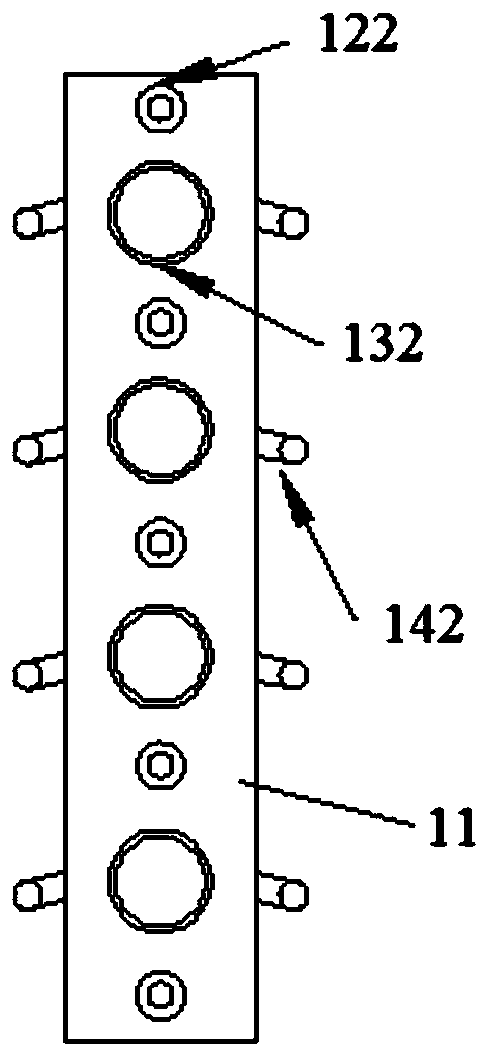

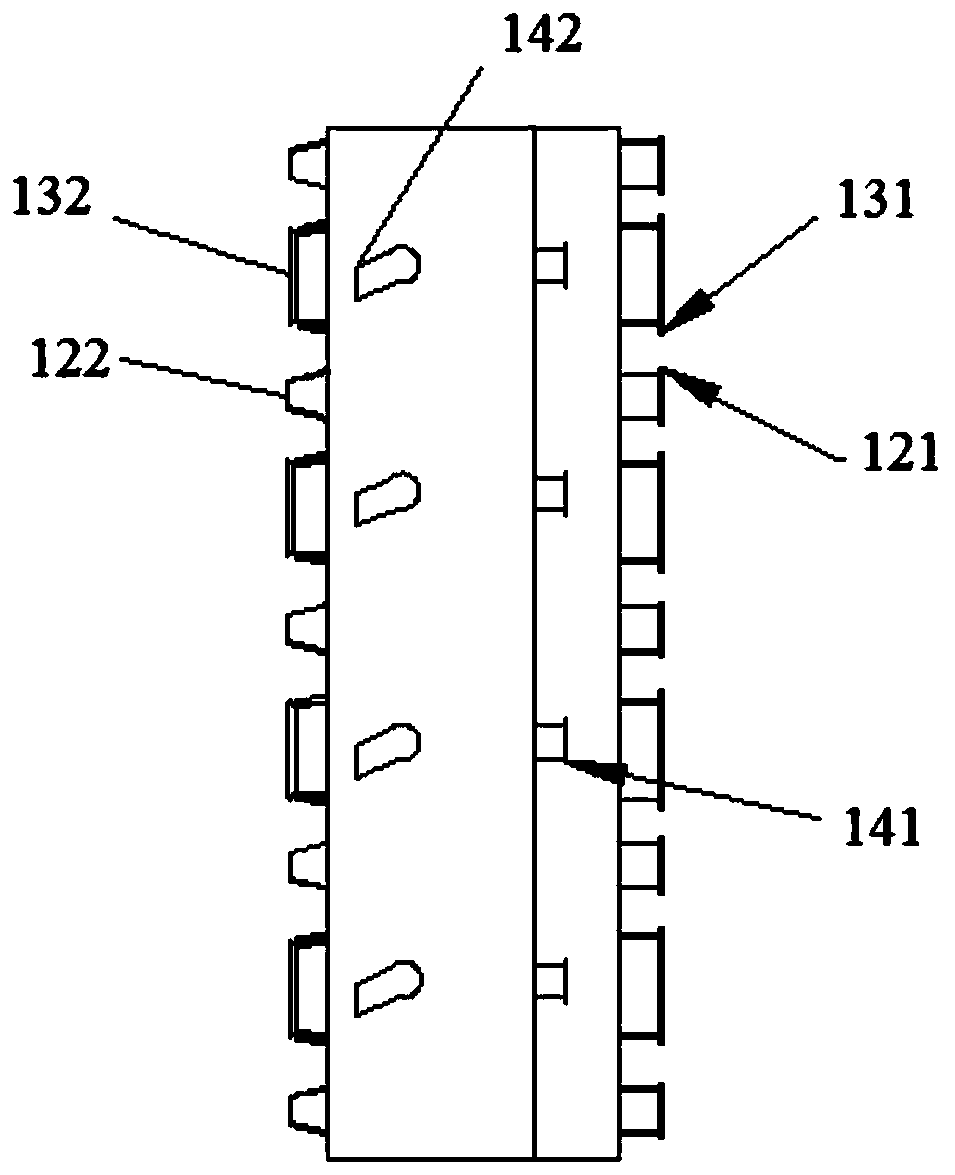

The invention discloses a low-load stable-combustion boiler combustor which comprises combustor bodies and a hearth. The combustor body comprises a shell, a secondary air pipe arranged in the center of the shell, a primary air pipe surrounding the two sides of the secondary air pipe, a biomass fuel pipe tightly attached to the inner wall of the shell, and the combustor bodies are arranged on the four corners of the hearth. The invention further discloses a combustion method of the low-load stable-combustion boiler combustor. During full-load combustion of the hearth, a biomass fuel inlet is closed, only pulverized coal combustion is adopted for hearth combustion, biomass combustion is not adopted, and hearth slag is relieved. During low-load operation, pulverized coal entering the hearth is reduced, the temperature of the hearth is reduced, flame combustion is unstable, in order to ensure stable combustion, the biomass fuel inlet is opened for feeding biomass fuel, and it is ensured that flame combustion is stable by means of the characteristics that biomass is high in volatile component, easy to ignite and good in heating value.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

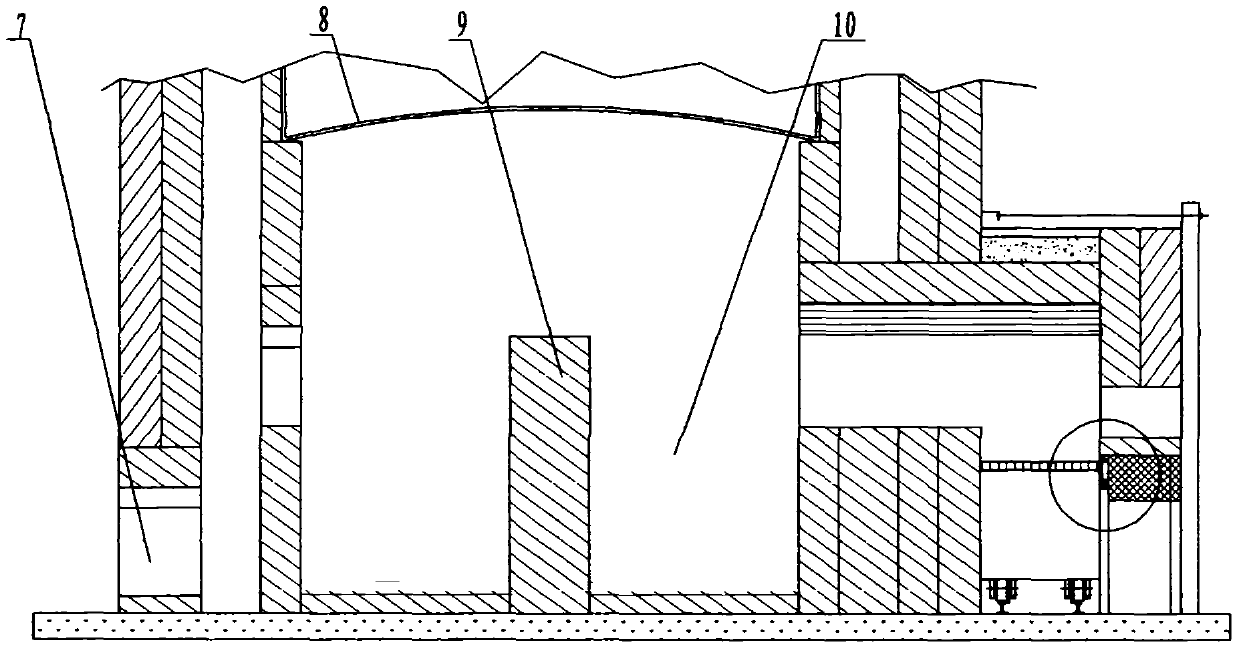

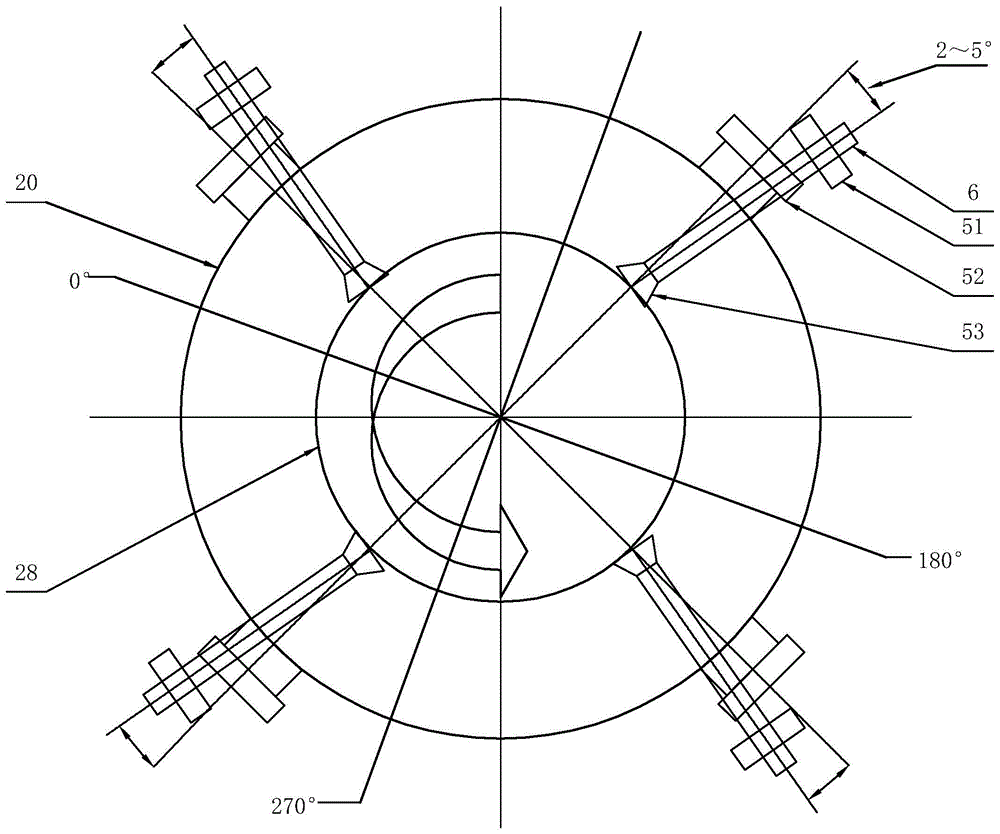

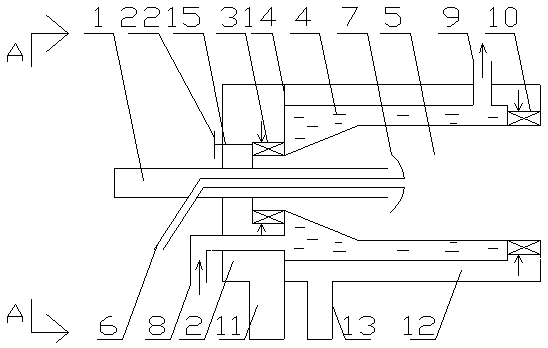

Multi-pass industrial pulverized coal boiler with flue gas recirculation technology and swirl pulverized coal burner on top

ActiveCN107559821AReduce generationIncrease concentrationPulverulent fuel combustion burnersAir/fuel supply for combustionFlue gasEnvironmental engineering

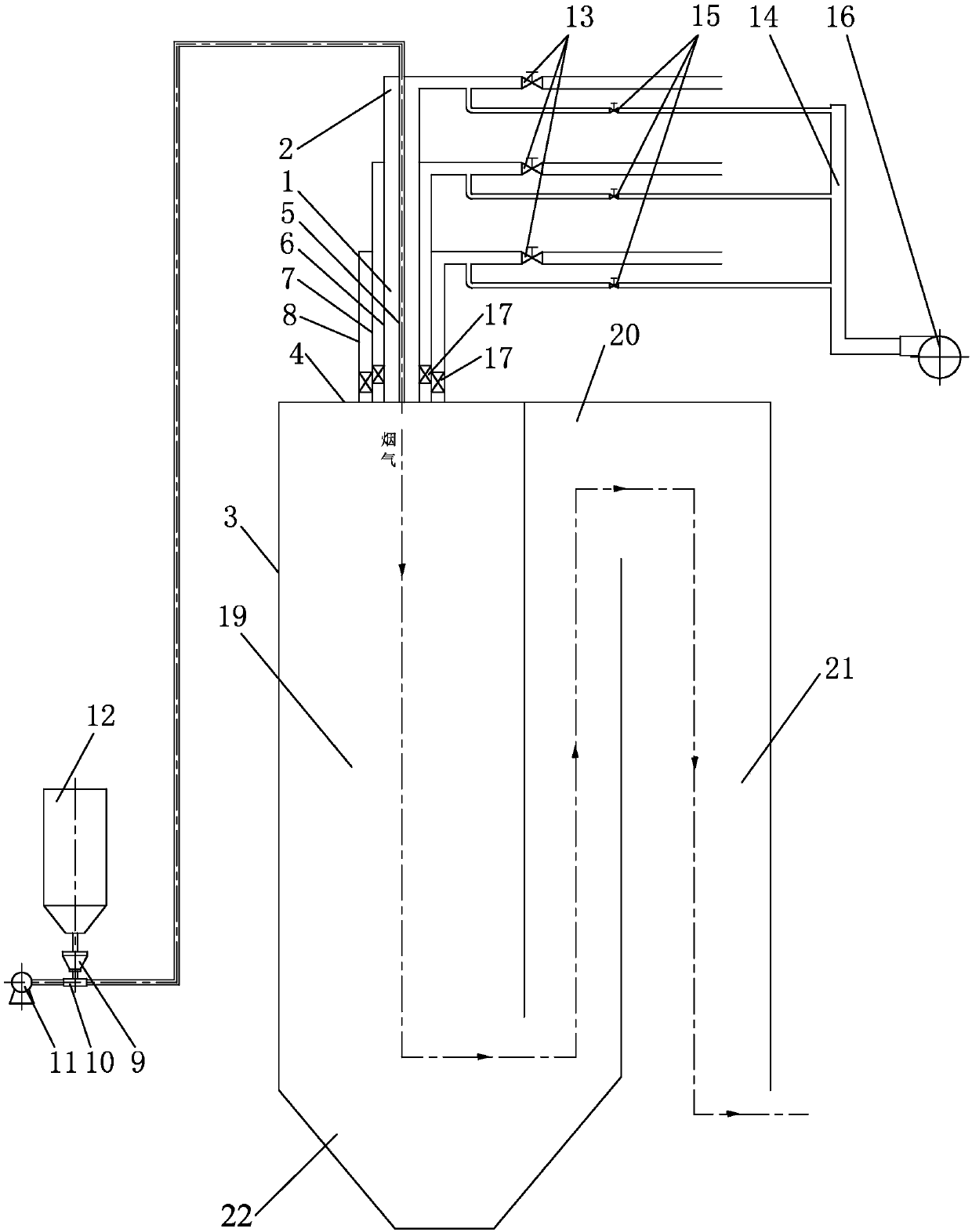

The invention discloses a multi-pass industrial pulverized coal boiler with a flue gas recirculation technology and a swirl pulverized coal burner on the top, and relates to an industrial pulverized coal boiler. The multi-process industrial pulverized coal boiler aims to solve the problems that a NOx emission load is high and burnout performance is poor in the existing industrial pulverized coal boiler. The multi-pass industrial pulverized coal boiler comprises a primary air pipe, a straight-flow secondary air pipe, a swirl inner secondary air pipe and a swirl outer secondary air pipe, and a boiler body is internally provided with a zigzag channel with three flue gas passes; the primary air pipe is arranged in the straight-flow secondary air pipe, the straight-flow secondary air pipe is arranged in the swirl inner secondary air pipe, and the swirl inner secondary air pipe is arranged in the swirl outer secondary air pipe; axial swirl blades are mounted in the swirl inner secondary airpipe and the swirl outer secondary air pipe; nozzles of the primary air pipe, the straight-flow secondary air pipe, the swirl inner secondary air pipe and the swirl outer secondary air pipe are flushwith a boiler top of the boiler body; a flue gas recirculation system communicates with the straight-flow secondary air pipe, the swirl inner secondary air pipe and the swirl outer secondary air pipe;and an outlet of an air-pulverized coal system communicates with the boiler body through the primary air pipe. The multi-pass industrial pulverized coal boiler is used for the manufacturing field ofthe coal-fired industrial boiler.

Owner:HARBIN INST OF TECH

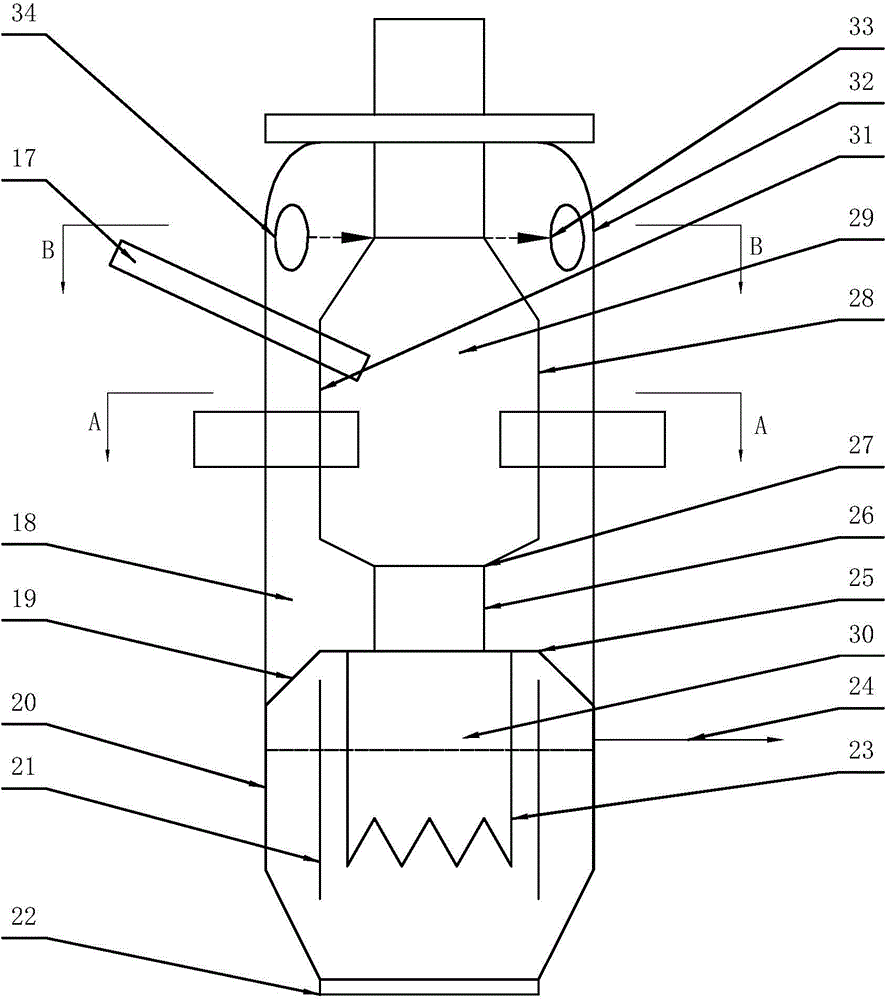

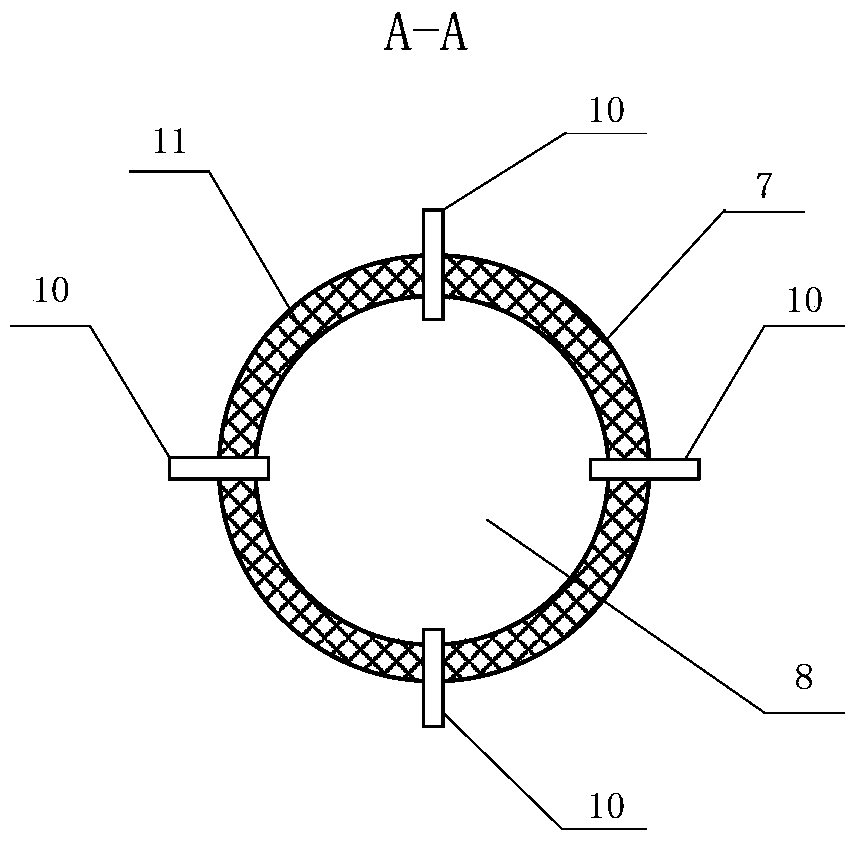

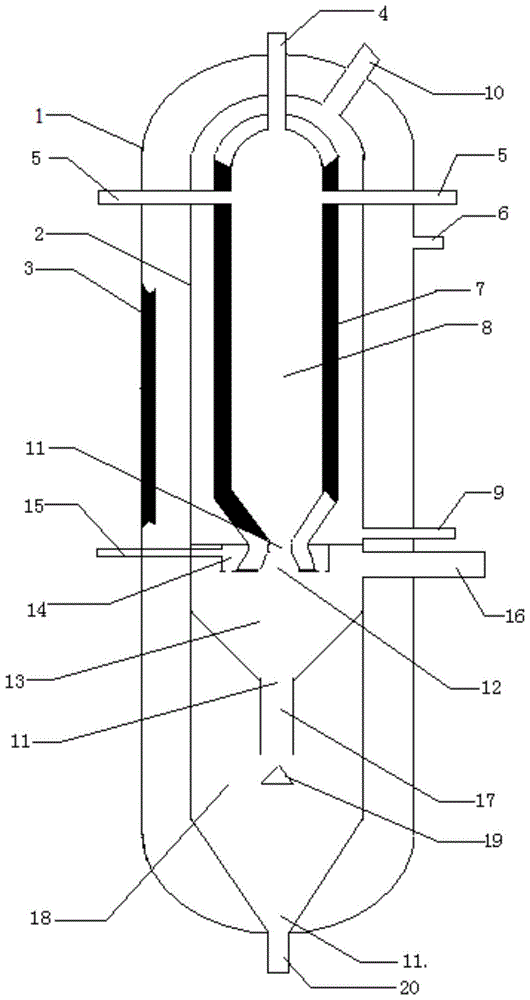

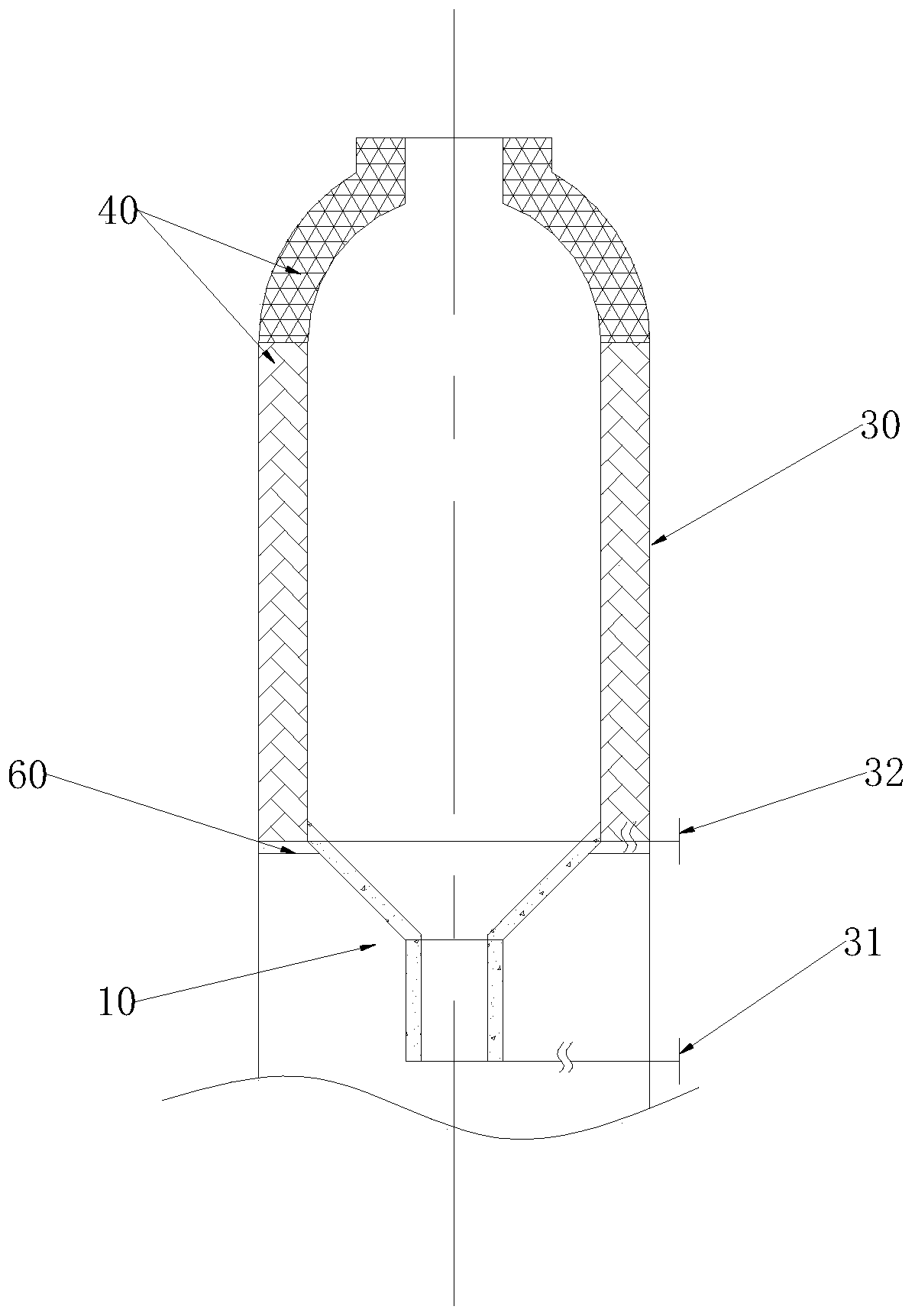

Gasification furnace structure capable of treating pulverized coal and water coal slurry simultaneously

ActiveCN104531221AImprove coal adaptabilityLarge amount of processingGasification processes detailsGranular/pulverulent flues gasificationCombustionSlag

The invention relates to a gasification furnace structure capable of treating pulverized coal and water coal slurry simultaneously. The gasification furnace structure comprises a furnace body, wherein a water cooling wall is arranged in the furnace body and a quenching chamber is arranged under a gasification chamber; the gasification furnace structure is characterized in that a water coal slurry nozzle is arranged at the top part of the furnace body, at least three pulverized coal nozzles are arranged at the upper part of the side wall of the gasification furnace body and are uniformly distributed on the same horizontal circumference along the furnace body, two sets of start-up burners are also symmetrically arranged on the side wall of the furnace body, a slag hole is formed at the bottom of the furnace body, and a slag breaking machine is arranged on the slag hole. The gasification furnace structure has strong coal type adaptive capacity and can treat pulverized coal and water coal slurry simultaneously, inferior coal with high ash melting point, high ash content, high sulphur content and high alkali metal content can be mixed for combustion, and the single furnace has high handling capacity and low energy consumption.

Owner:SINOPEC NINGBO ENG +2

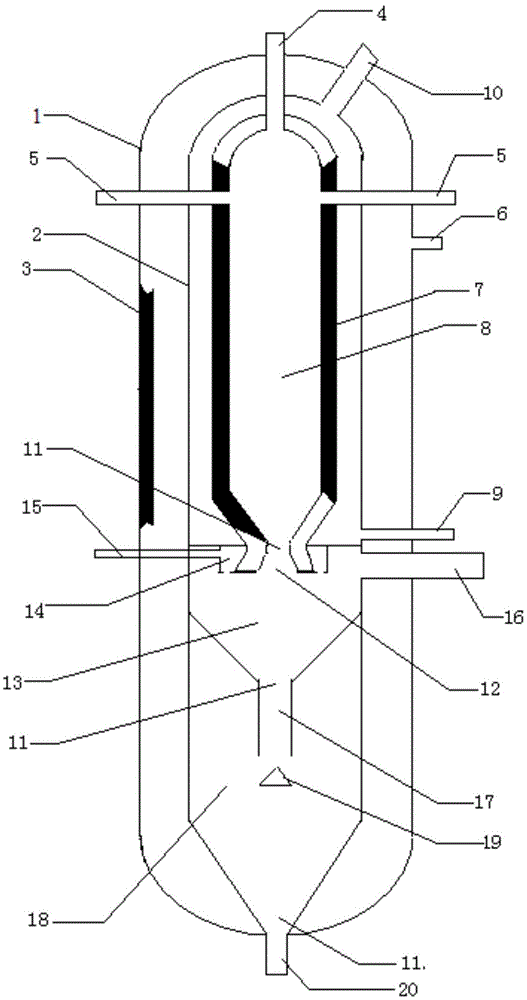

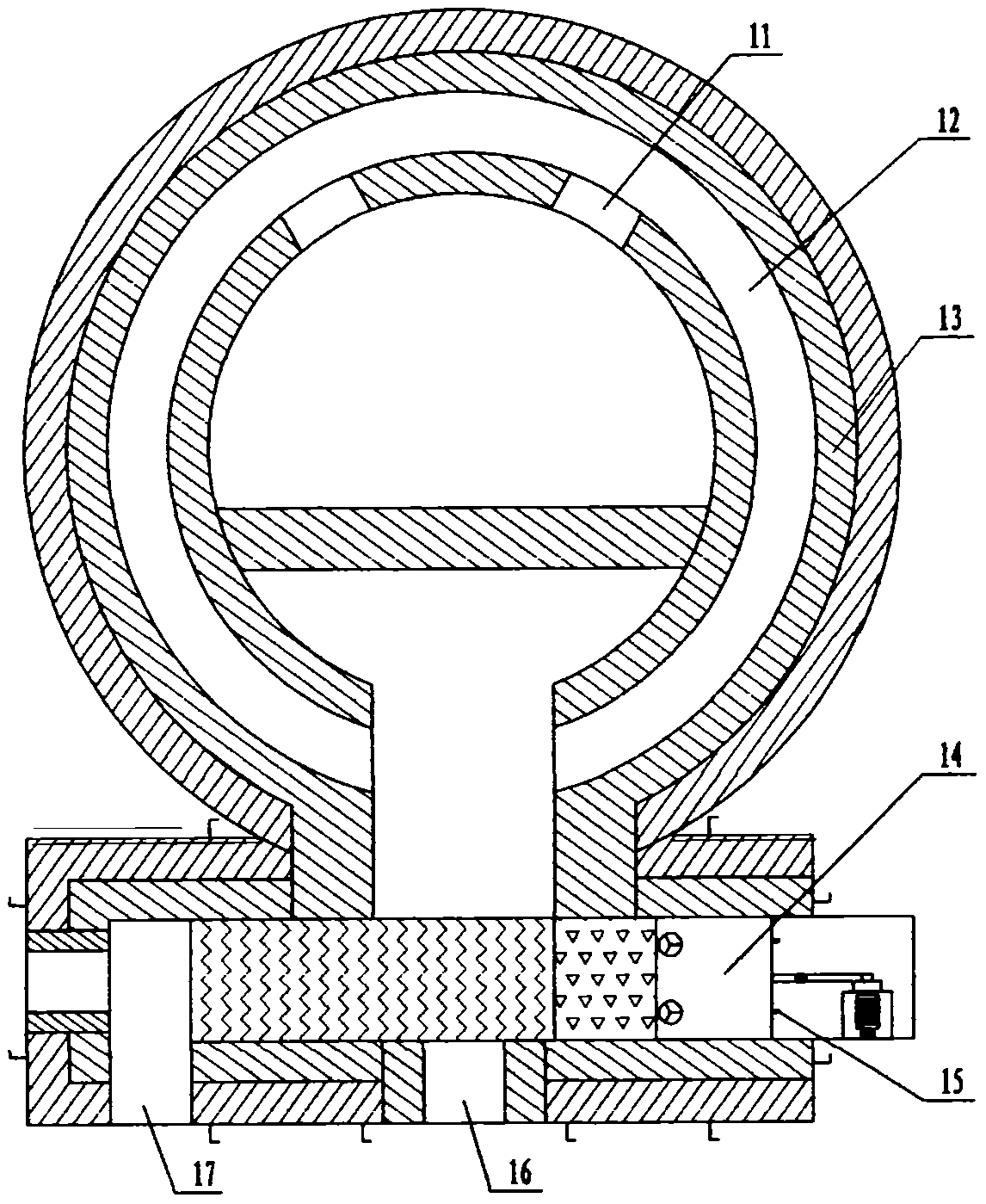

Entrained flow gasifier for swirling melt cinder solidification

ActiveCN104449868ASimple structureExtended service lifeEnergy inputGasification apparatus detailsThermal insulationWear resistant

The invention provides an entrained flow gasifier for swirling melt cinder solidification. The entrained flow gasifier is divided into a pressure resistant jacket and a gasifier liner, wherein a gasification chamber, a swirling cooling chamber and a cinder solidification cooling chamber form the gasifier liner and are respectively separated by virtue of segmenting conical sealing heads; a shell of the gasification chamber is sequentially provided with a thermal insulation material layer, a cooling jacket and a wear resistant material layer from outsides to insides; a cooling water inlet is formed in the bottom of the gasification chamber, and a saturated steam outlet is formed in the side surface of the top part of the gasification chamber; a top nozzle is formed in the center of the top part of the gasification chamber, and more than 3 side nozzles are uniformly formed in the upper part of the gasification chamber along the circumference; a gasification product discharge hole is formed in the center of the segmenting conical sealing head which is arranged at the bottom of the gasification chamber; an atomization water cooling sleeve is arranged at the outer side of a gasification product discharge hole in the swirling cooling chamber, and a gas outlet is formed in the upper part of the swirling cooling chamber; a solidified cinder discharge hole is formed in the center of the segmenting conical sealing head arranged at the bottom of the cooling chamber, is connected with the solidified cinder cooling chamber and is introduced into the middle of the solidified cinder cooling chamber, and a water cooling cinder discharge hole is formed in the center of the segmenting conical sealing head arranged at the bottom of the solidified cinder cooling chamber. With the adoption of the entrained flow gasifier for swirling melt cinder solidification, waste heat is fully utilized, and the difficulty of black water is eliminated.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

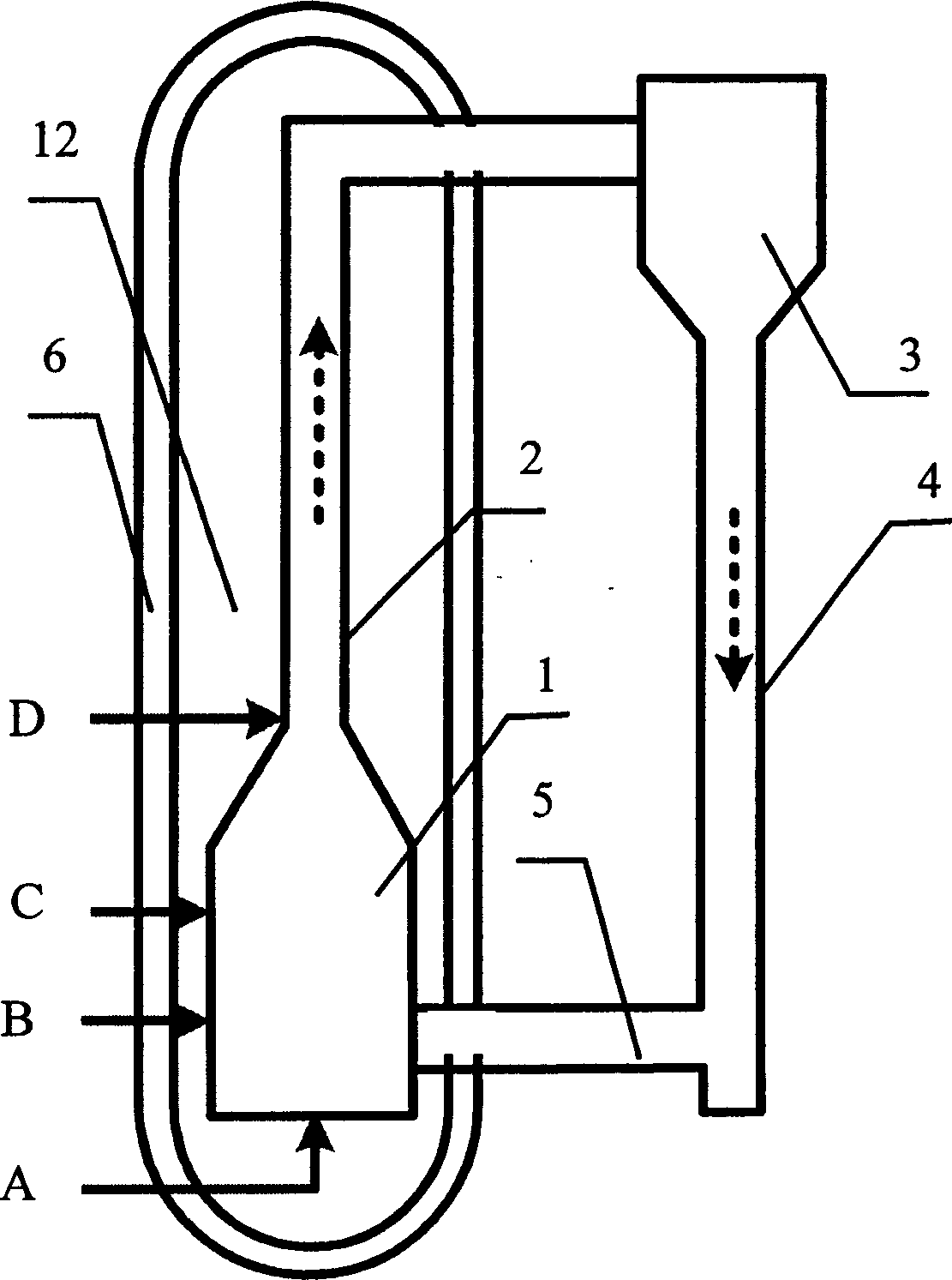

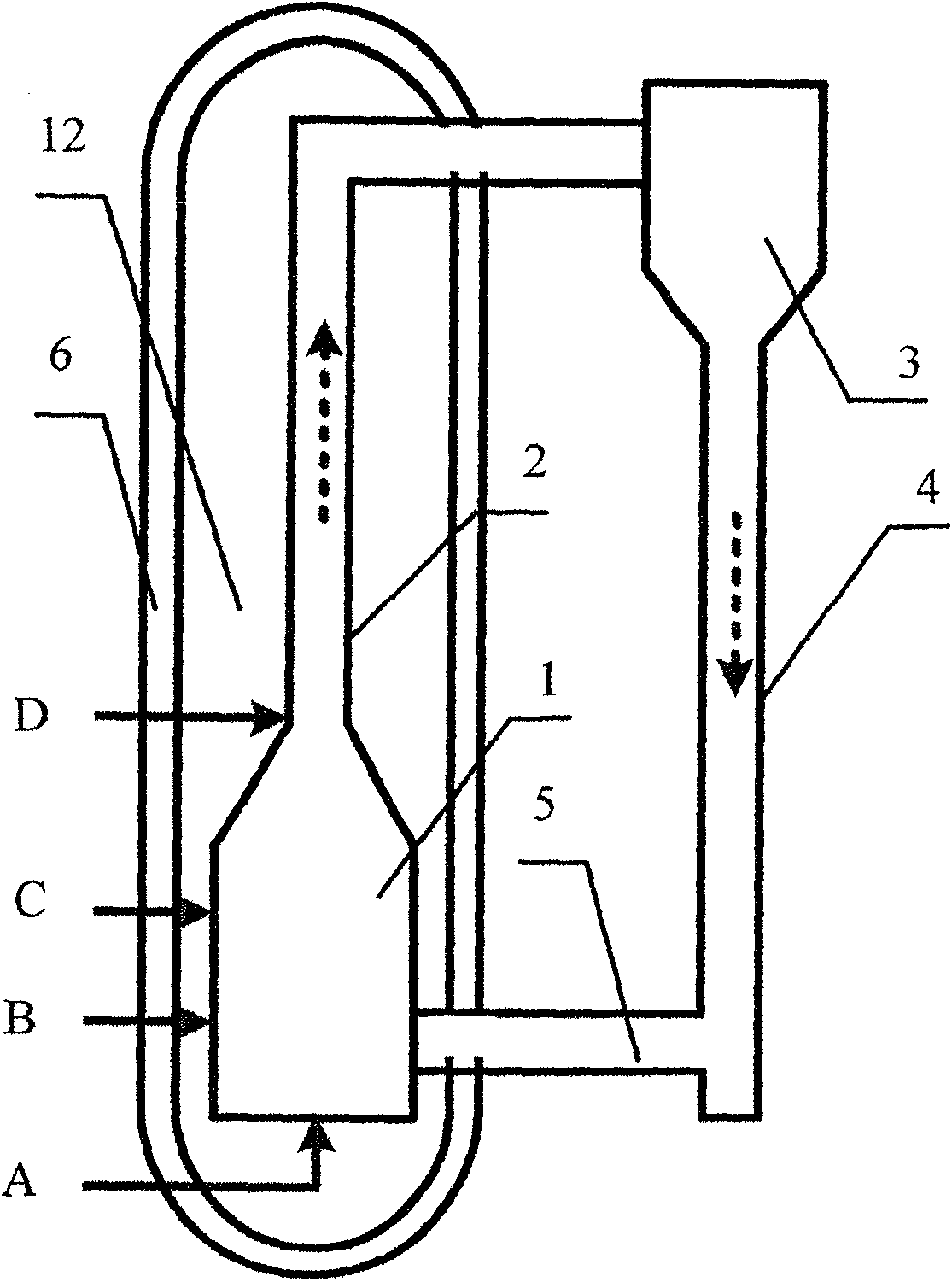

Catalytic coal gasifaction furnace of differential speed bed, and method of catalytic gasification

InactiveCN1916124AImprove removal efficiencyExtended stayCombined combustion mitigationGranular/pulverulent flues gasificationLow speedHearth

This invention discloses method and differential-speed bed furnace for catalytically gasifying high-ash, high-sulfur and high-ash-melting-point coal abundant in China. The hearth is set in a pressure shell. The hearth comprises a lower hearth and an upper hearth. The lower hearth is a chamber with a wide bed diameter, working at a low speed and high temperature. There are inlets for air, coal powder, limestone, steam and catalyst on both the bottom and lateral side of the lower hearth. The upper part of the lower hearth tapers to form the upper hearth working at a high speed and high temperature. The upper hearth has a shorter inner diameter than the lower hearth. The outlet of the upper hearth is connected with a cyclone separator with the lower part connected with a falling pipe. The lower part of the falling pipe is connected with a horizontal L-shaped valve. The other end of the L-shaped valve is connected with the lateral underside of the lower hearth.

Owner:NANTONG SANCHUANG MACHINE MFG +1

Double-channel combustor with thick pulverized coal and thin pulverized coal being separated and use method thereof

PendingCN111895397AReduce maintenance frequencyExtended service lifePulverulent fuel combustion burnersIndirect carbon-dioxide mitigationThermodynamicsCombustor

The invention relates to a double-channel combustor with thick pulverized coal and thin pulverized coal being separated and a use method thereof. The double-channel combustor with the thick pulverizedcoal and the thin pulverized coal being separated comprises a pulverized coal supplying mechanism, a transition channel, an internal secondary air guide duct, an external secondary air guide duct, acombustion stabilizing cavity and a rectifying cavity. The external secondary air guide duct, the combustion stabilizing cavity and the rectifying cavity are sequentially connected. The pulverized coal supplying mechanism comprises an air-pulverized coal pipe and a thick and thin pulverized coal separating device. The air-pulverized coal pipe communicates with the combustion stabilizing cavity. The thick and thin pulverized coal separating device is detachably connected to the air-pulverized coal pipe. The internal secondary air guide duct is coaxially arranged in the outer secondary air guideduct in a spaced manner. The transition channel is coaxially arranged in the internal secondary air guide duct in a spaced manner. The outlet end of the internal secondary air guide duct forms an expanded opening. The angle of the expanded opening is identical with the angle of the combustion stabilizing cavity. By the adoption of the double-channel combustor with the thick pulverized coal and the thin pulverized coal being separated, air can be divided into internal secondary air and external secondary air to respectively enter the combustor, the internal secondary air is combined with the transition channel to sufficiently mix pulverized coal and air, the external secondary air can form a cooling air layer flowing along the wall face of the combustion stabilizing cavity in the combustion stabilizing cavity, and the wall face of the combustion stabilizing cavity is protected against ash accumulation and coking.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

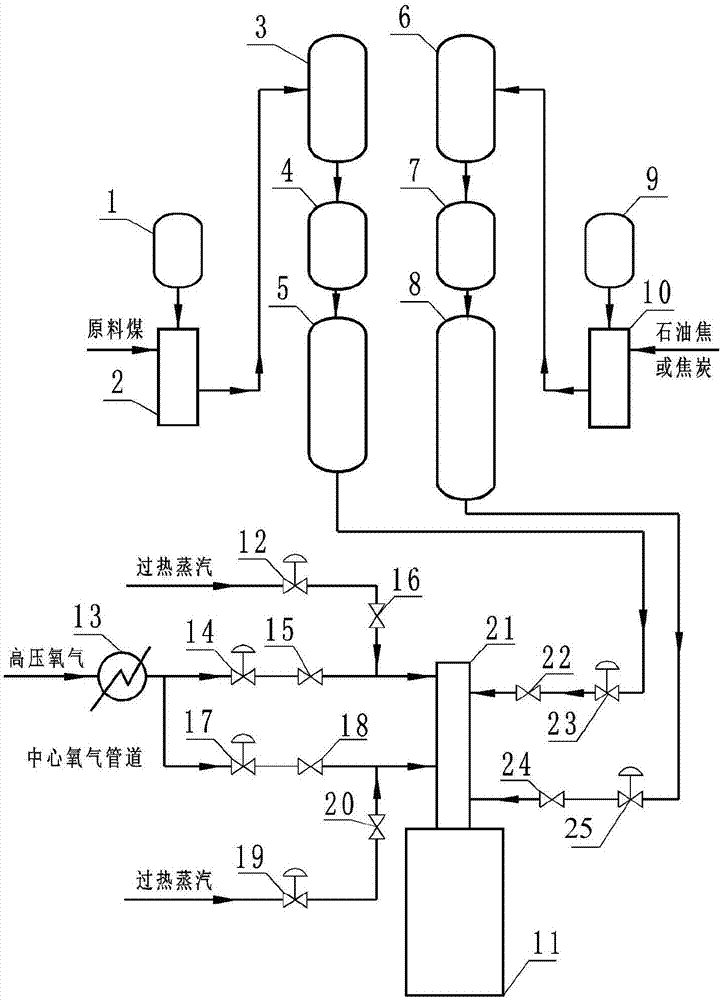

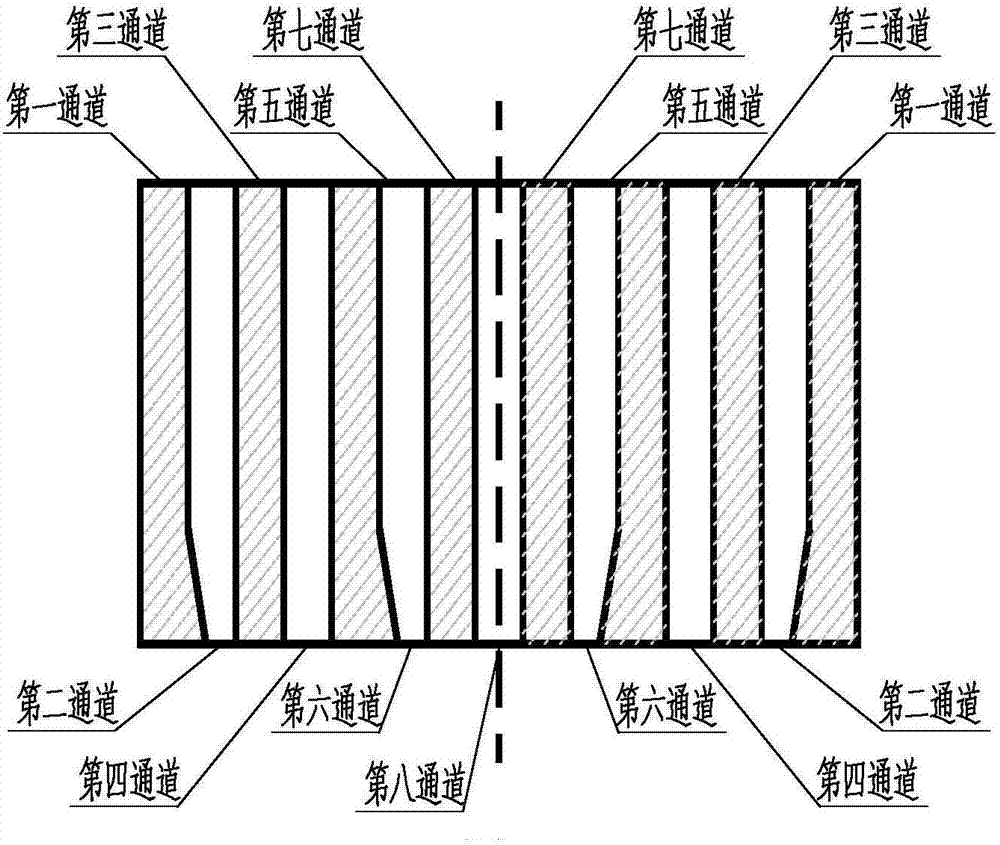

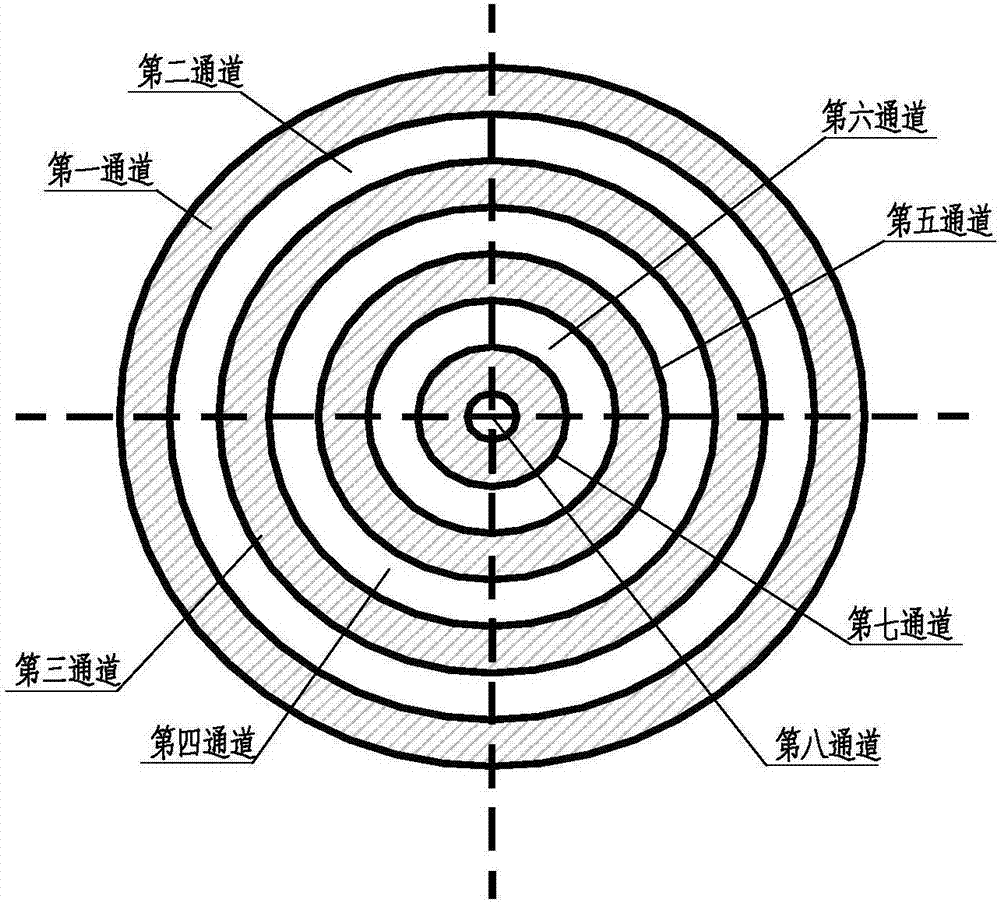

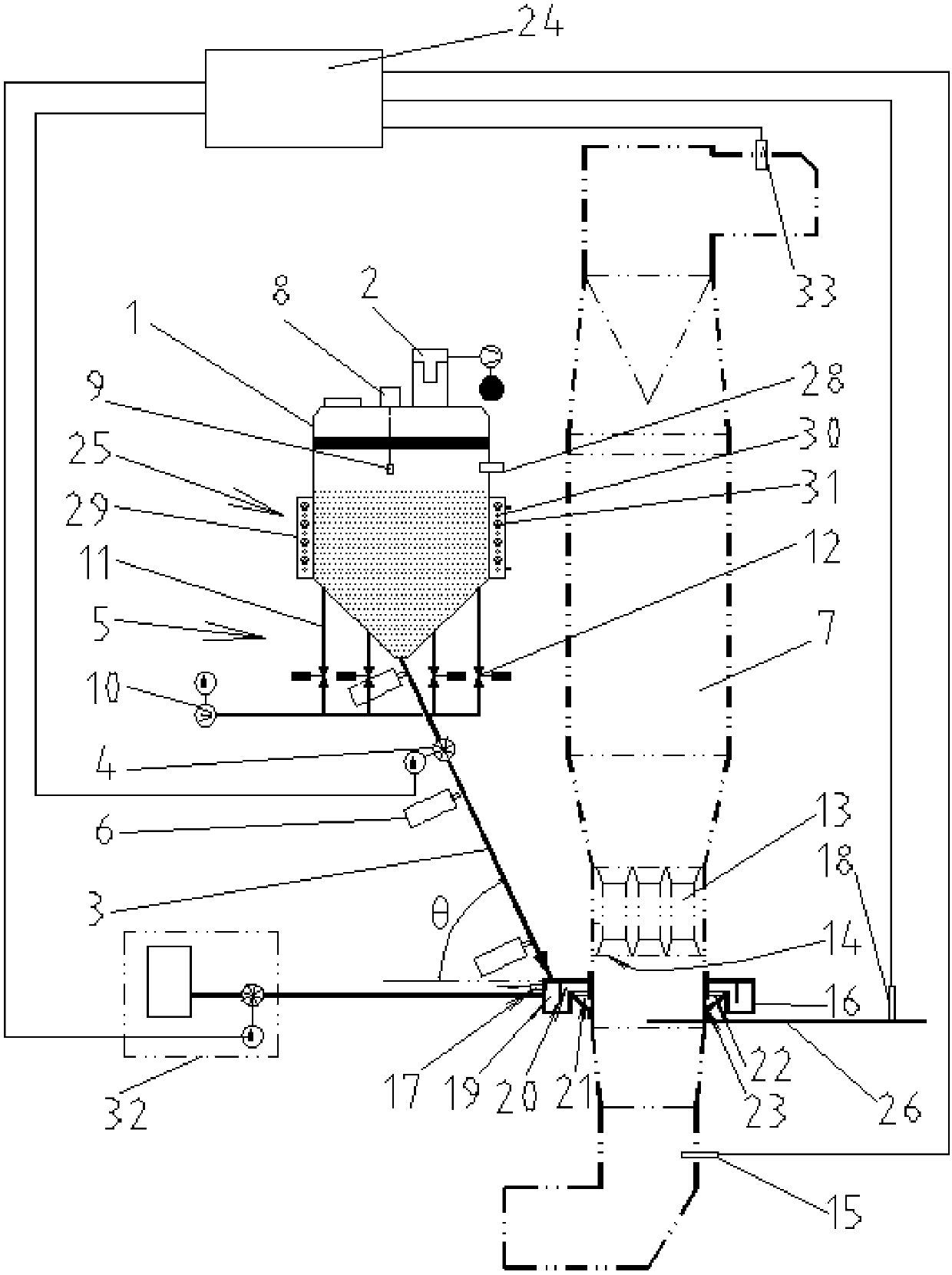

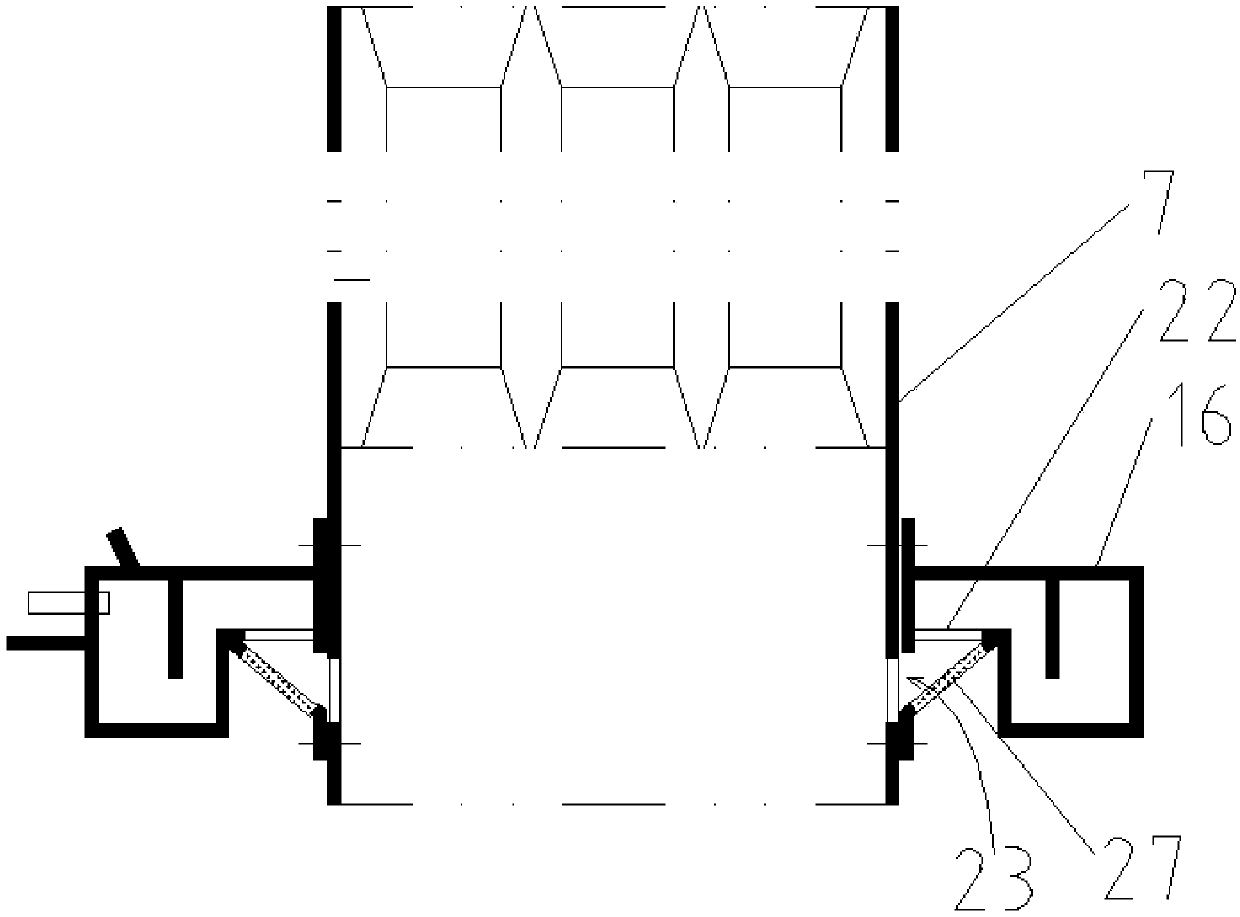

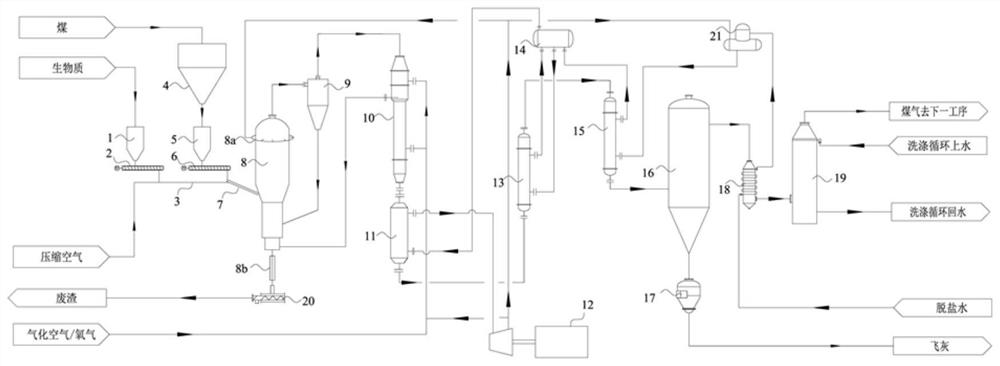

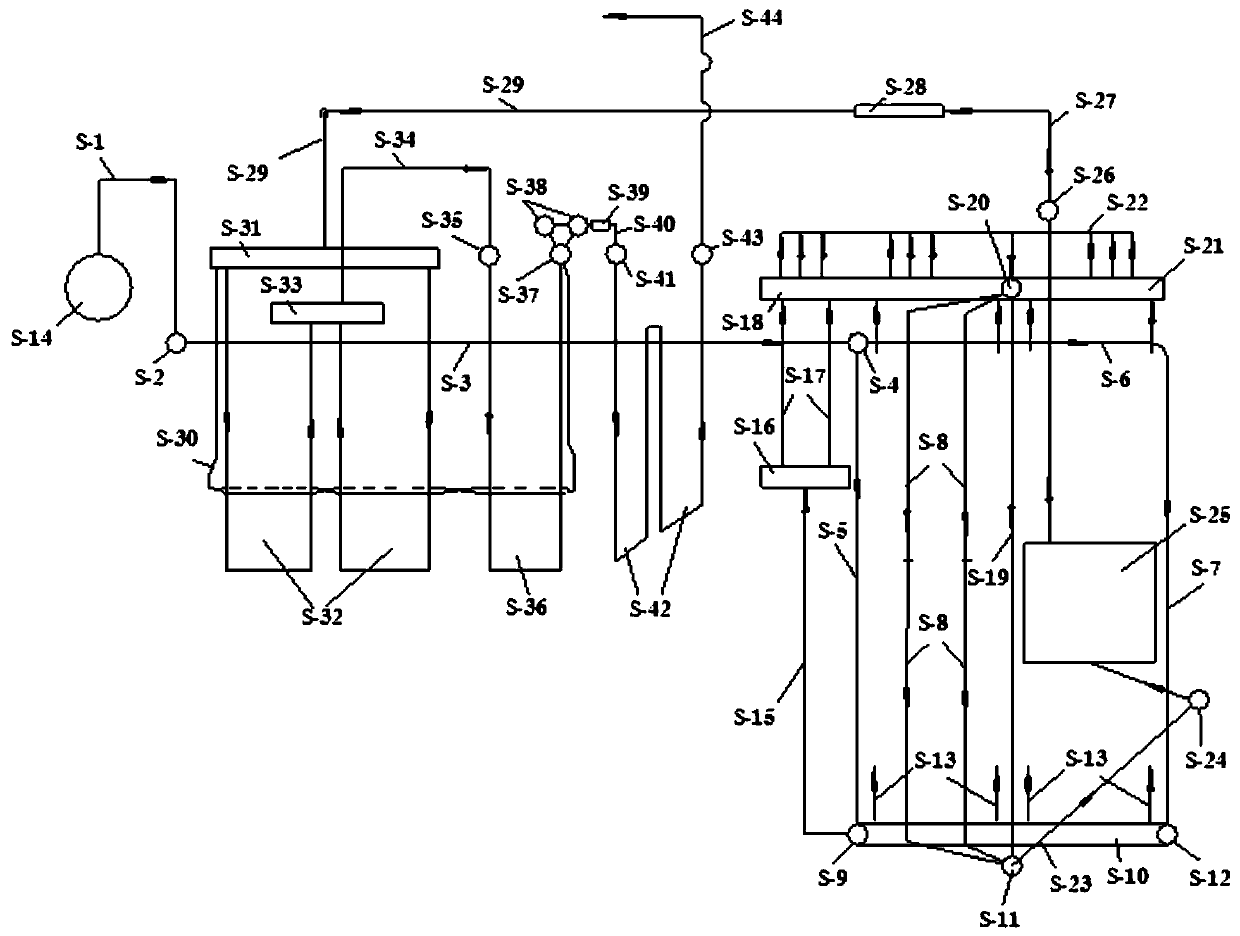

Gasification system and gasification method for pulverized coal and blending combustion combustible materials

PendingCN107118805ARealize large-scaleRealize online maintenanceGasification processes detailsGranular/pulverulent flues gasificationSyngasCombustion

The invention provides a gasification system and a gasification method for pulverized coal and blending combustion combustible materials. The gasification system comprises a feeding system, a multi-channel gasification burner and a pulverized coal gasifier, wherein the multi-channel gasification burner is provided with eight channels which are concentrically arranged; the pulverized coal, the blending combustion combustible materials and oxygen respectively enter respective channels of the multi-channel gasification burner through the feeding system; the ratio of the oxygen to the coal in each layer can be adjusted separately to achieve the effect of controlling the temperature respectively; the carbon conversion rate can be improved, and components of effective gas in syngas can be improved; in addition, the large-scale gasification of the pulverized coal can be realized, and the gasification of low-rank coal and mixed combustion of coal with different characteristics can be realized.

Owner:CHANGZHENG ENG

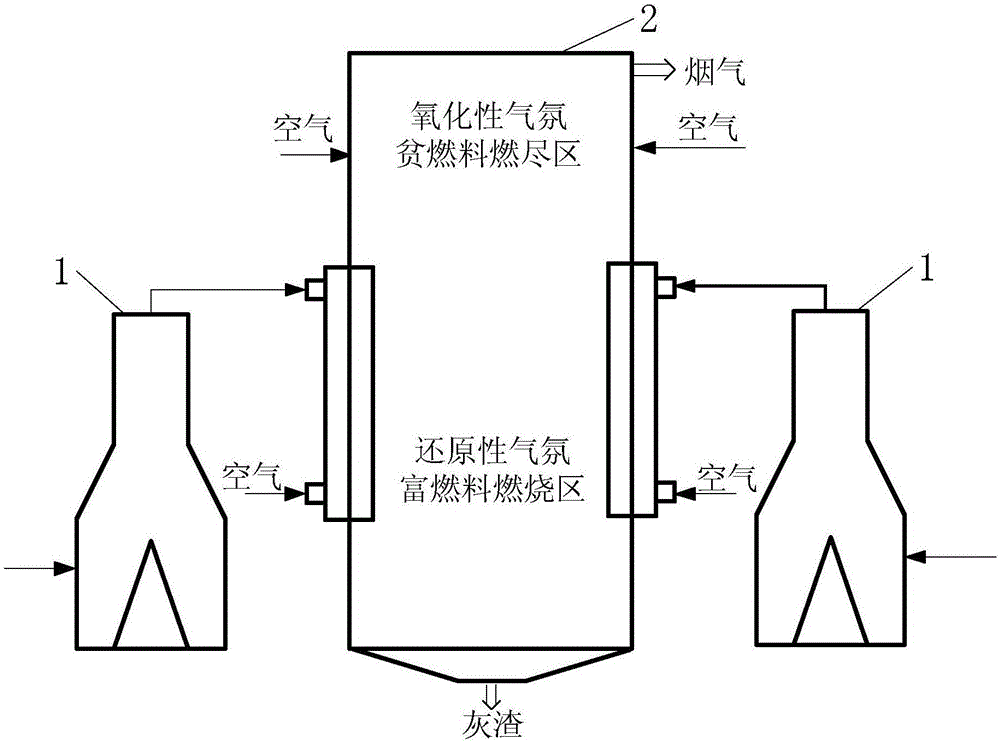

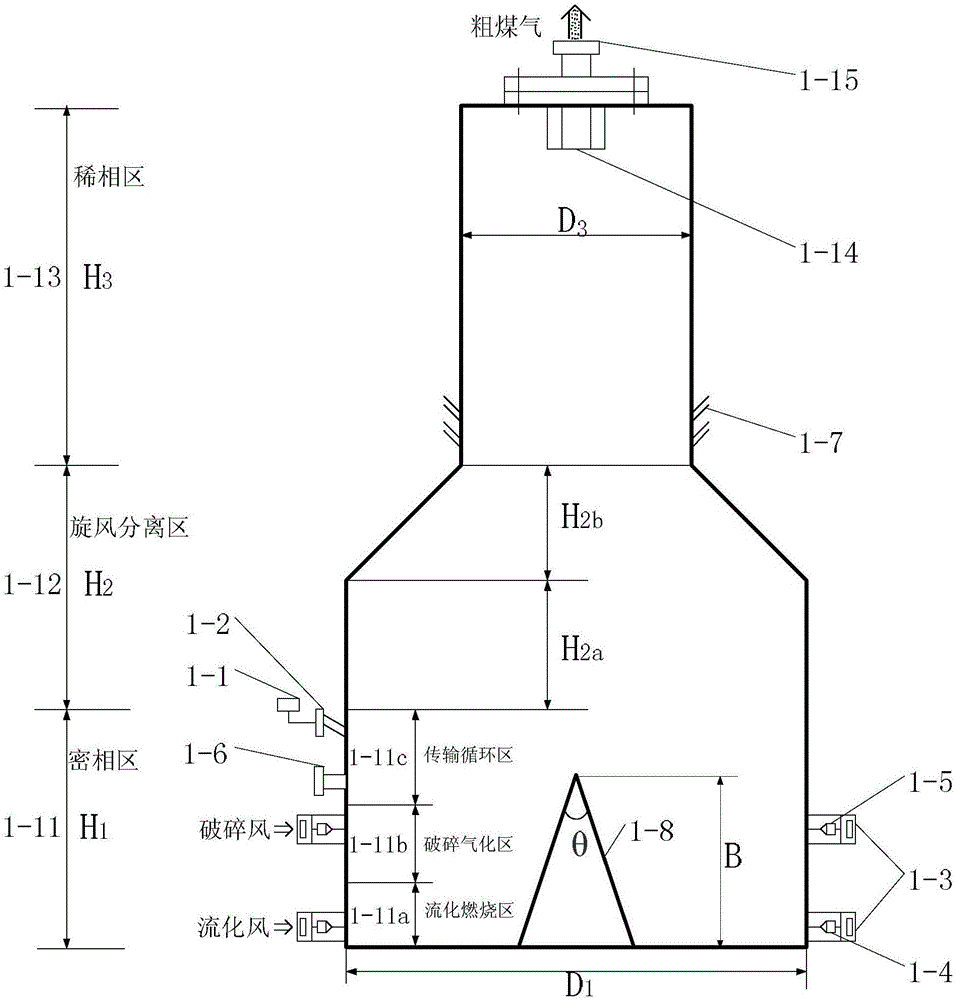

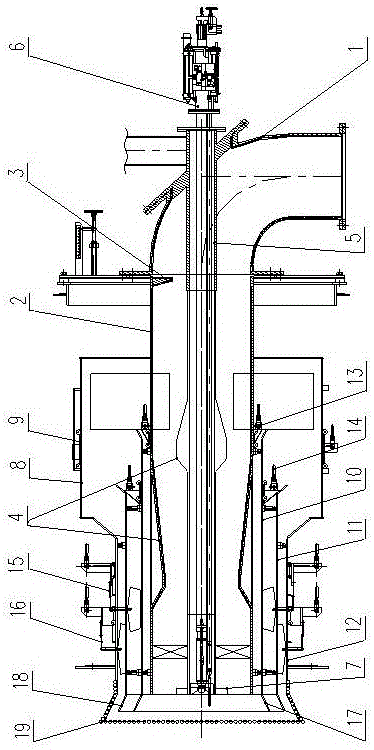

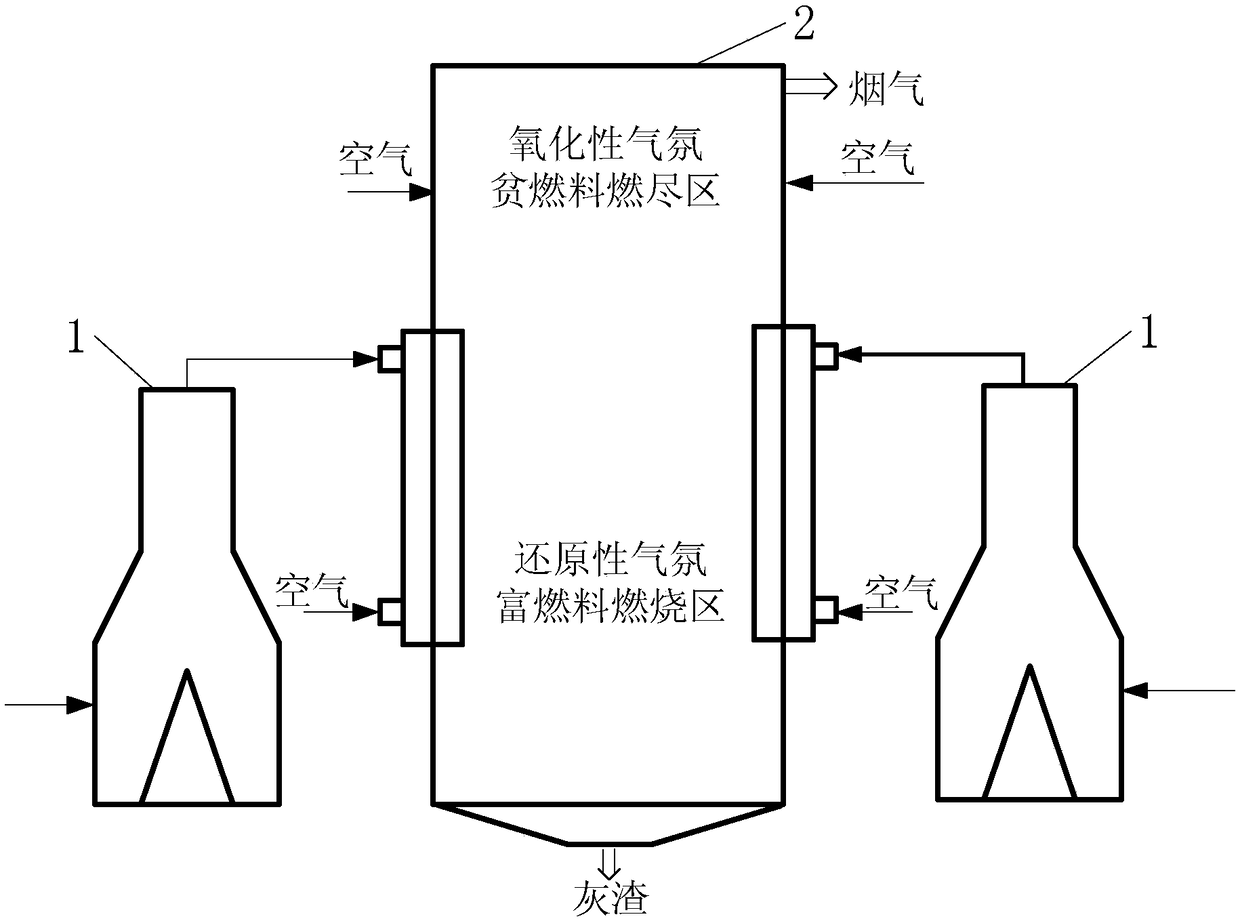

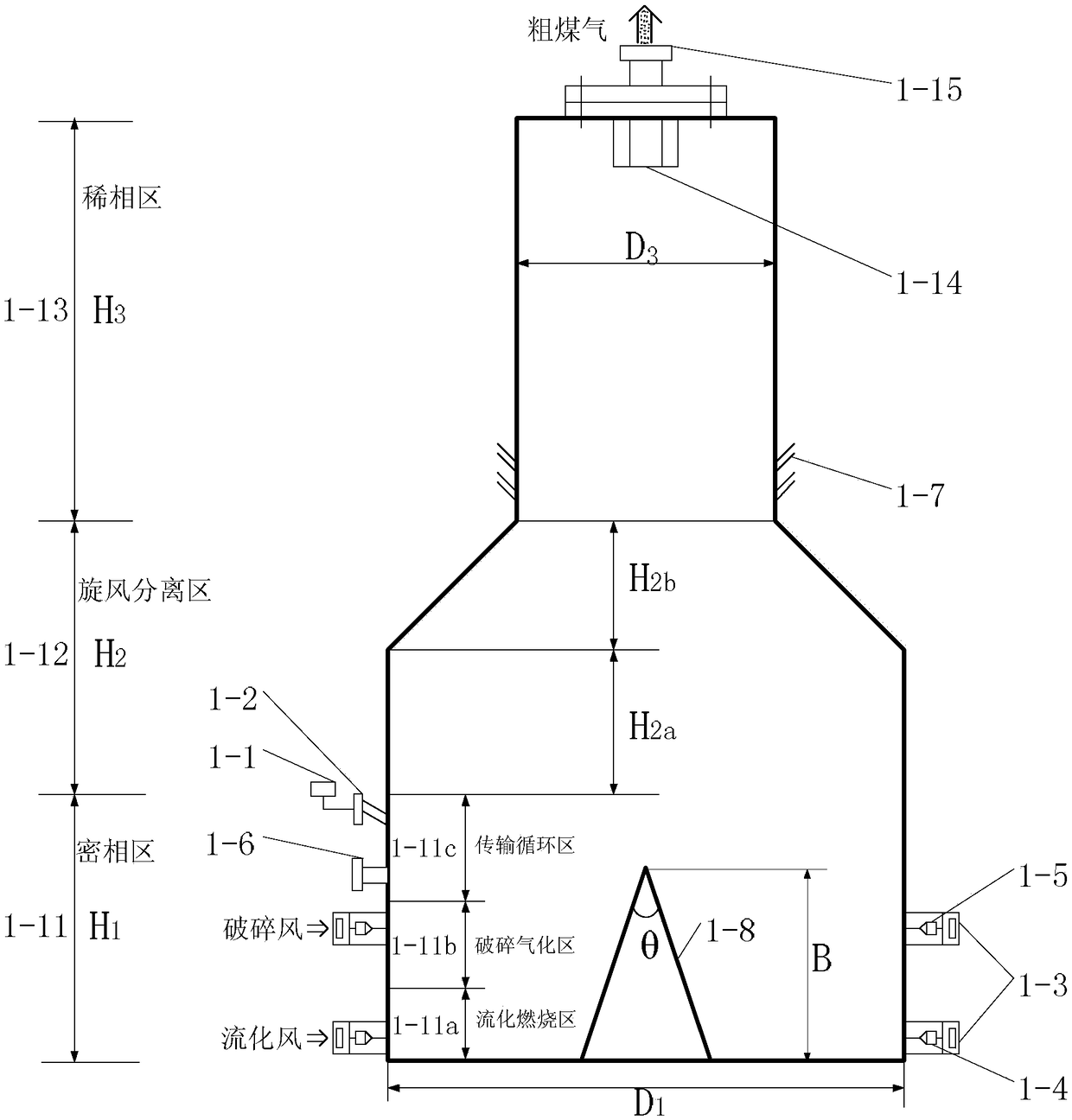

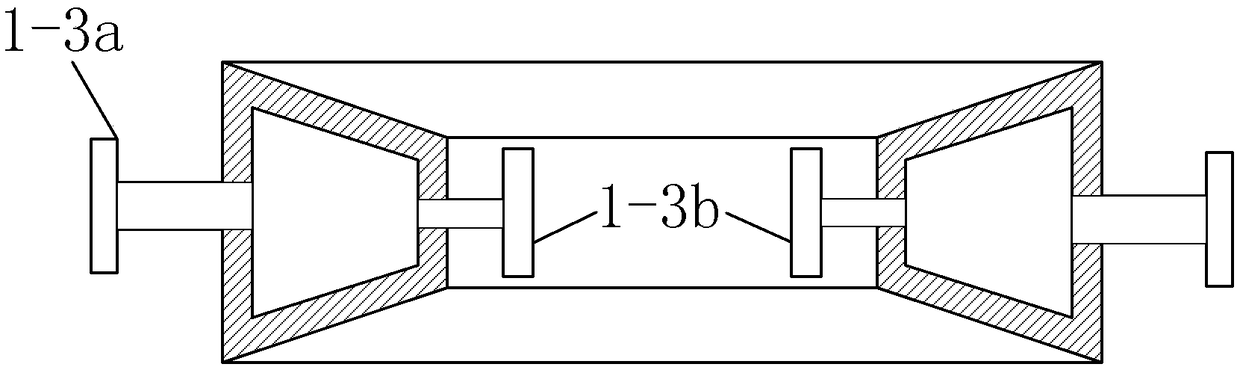

High-efficiency low-NOx staged coupling combustion method for inferior coal

ActiveCN106439793ANon-slagging load responseLow NOx combustionCombustion using gaseous and pulverulent fuelStaged combustionMicrometerPyrolysis

The invention provides a high-efficiency low-NOx staged coupling combustion method for inferior coal, belongs to the technical field of high-efficiency clean coal combustion and aims to solve the problems that an existing coal combustion technology is incapable of simultaneously realizing low NOx emission and high combustion efficiency and needs to be provided with a coal grinding system during a combustion process of an inferior coal fuel. The high-efficiency low-NOx staged coupling combustion method provided by the invention is mainly composed of a fluidized bed and a pulverized coal furnace; the combustion process comprises the following steps: firstly, performing fuel-rich pyrolysis, adiabatic combustion, crushing, gasification and particle separation on coal particles in the fluidized bed; reforming the fuel into raw gas which is at a temperature of 850 to 900 DEG C and only contains particles of which the particle size is equal to or smaller than 75 micrometers; subsequently sending the raw gas to a combustor region of the pulverized coal furnace and performing fuel-rich combustion at the temperature of 1100 DEG C; finally performing fuel-lean after-combustion at the temperature of 1300 DEG C in the upper region of the combustor of the pulverized coal furnace, wherein the three stages of combustion are controlled relatively-independently and are effectively coupled by virtue of a new structure in the furnace. The method provided by the invention is mainly applied to the field of combustion of inferior coal.

Owner:HARBIN INST OF TECH

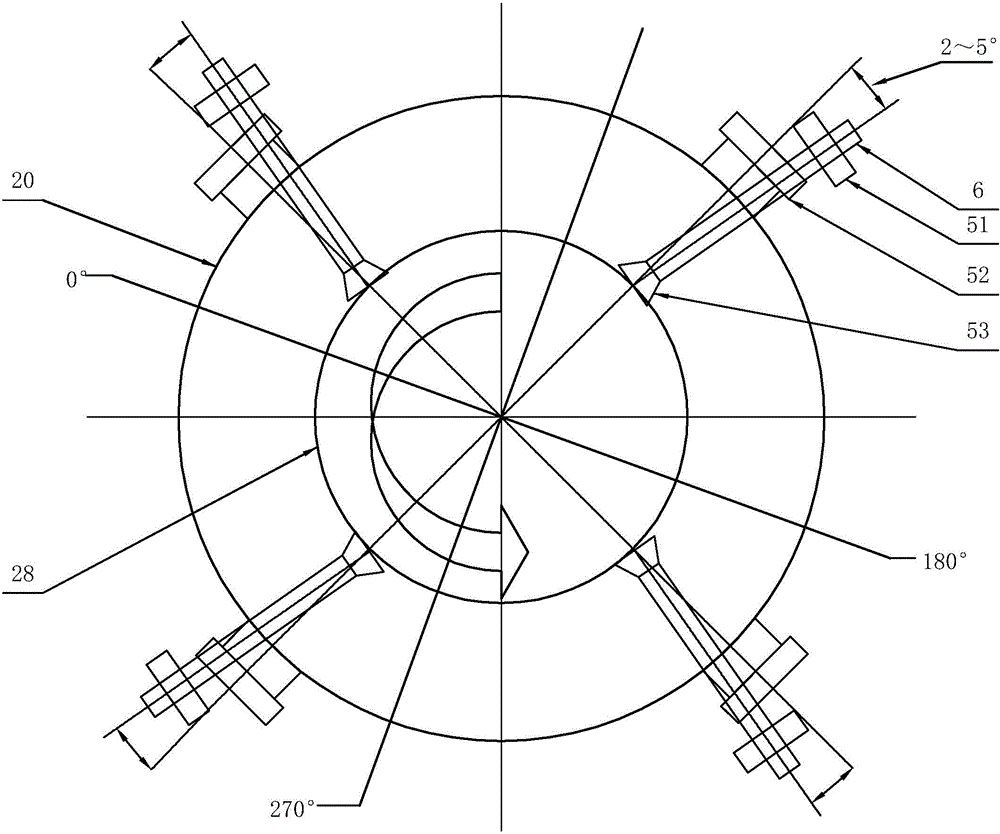

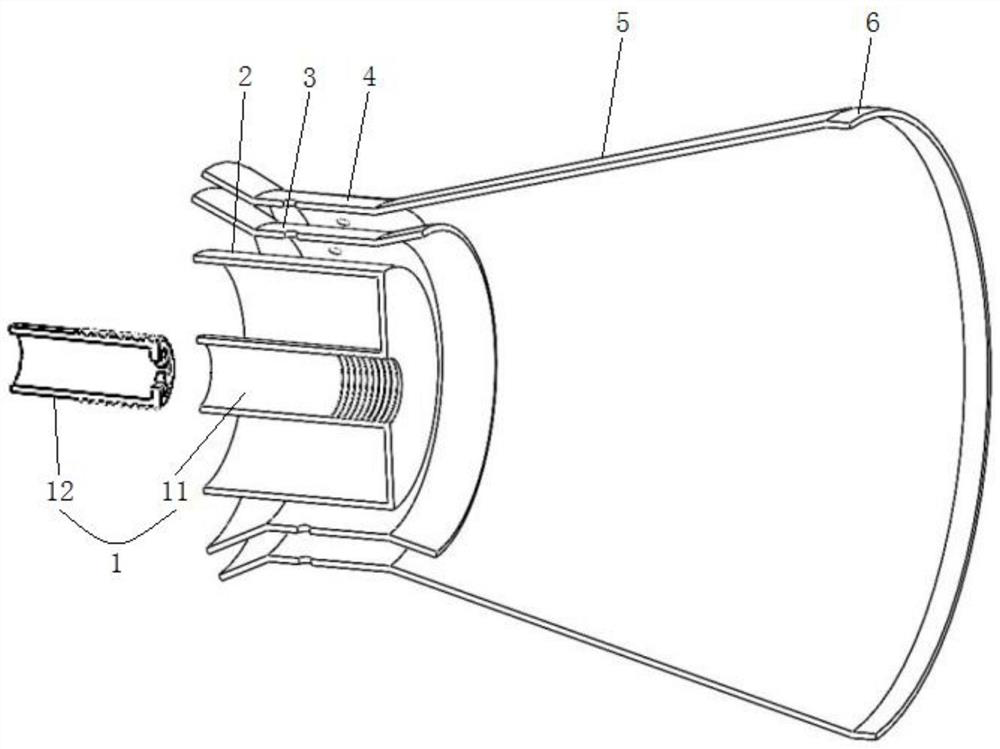

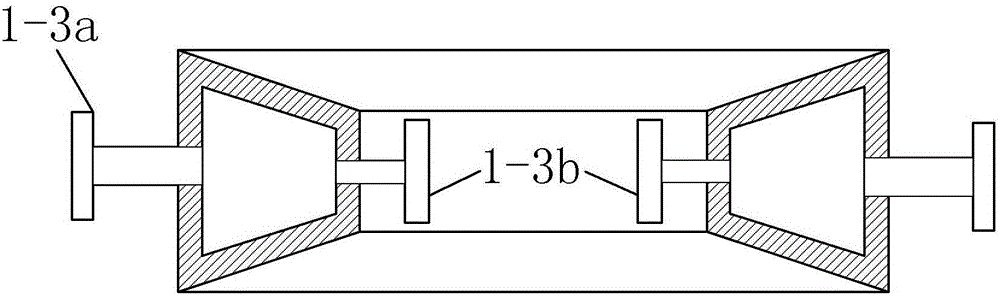

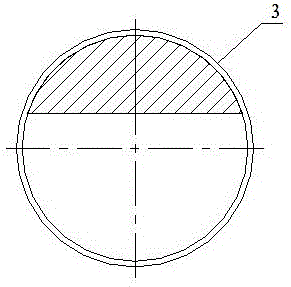

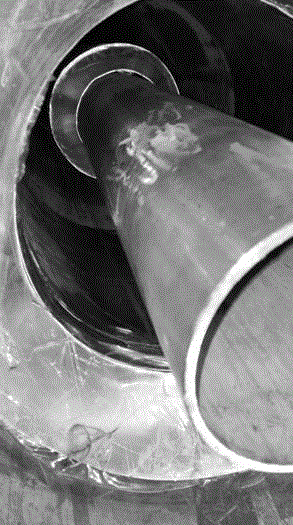

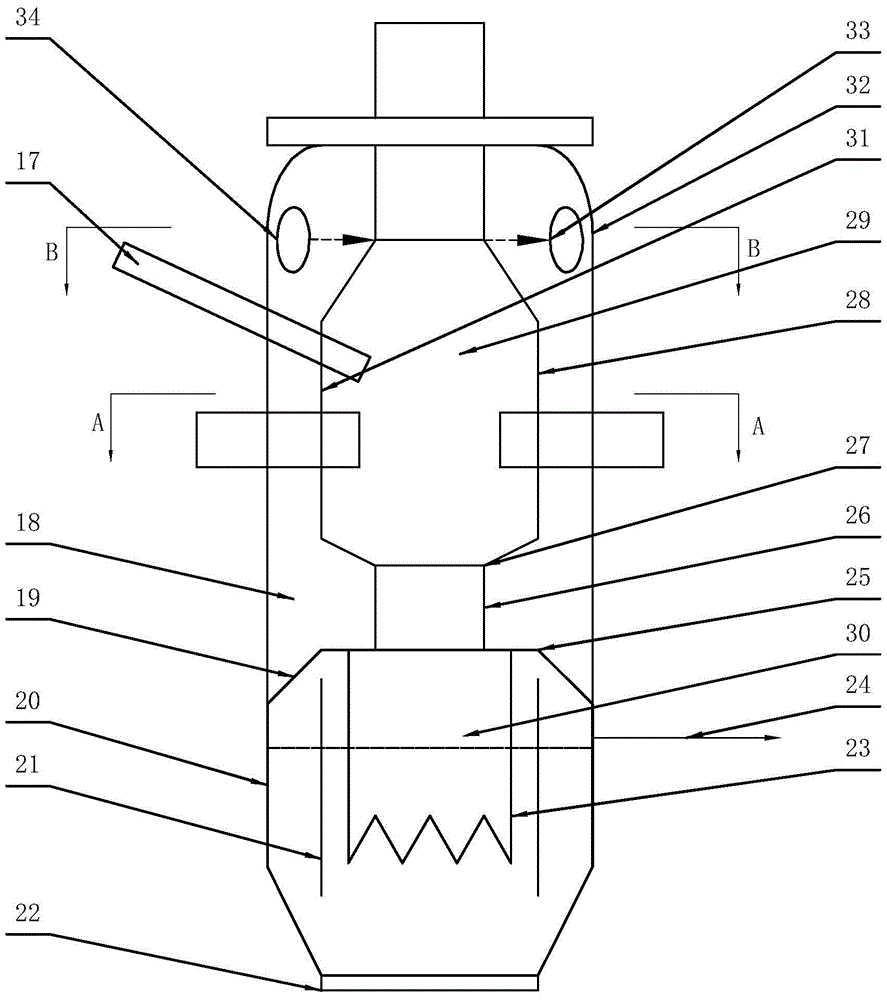

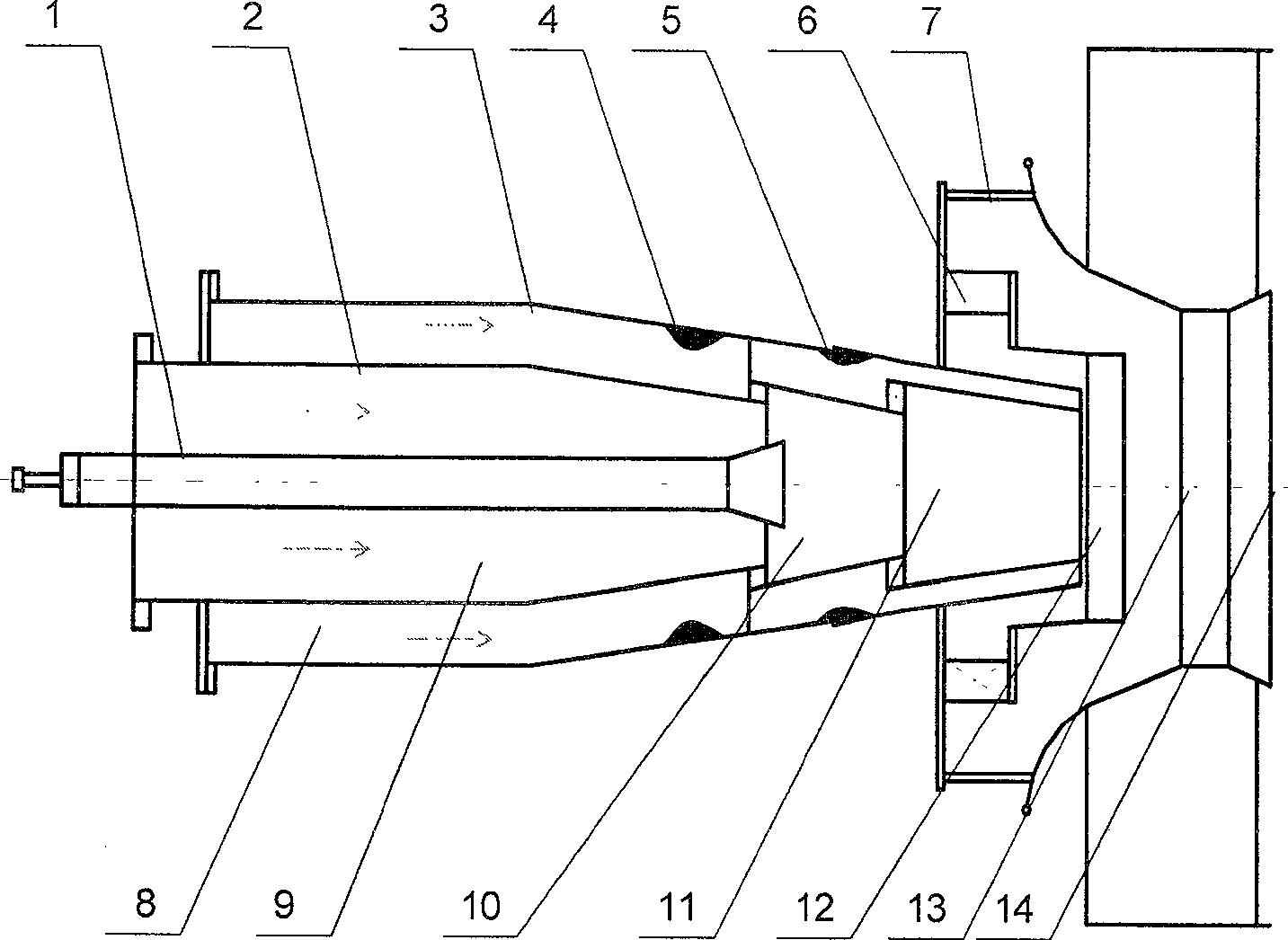

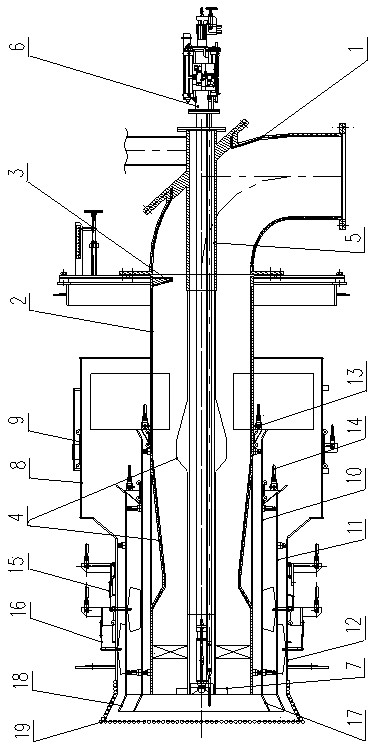

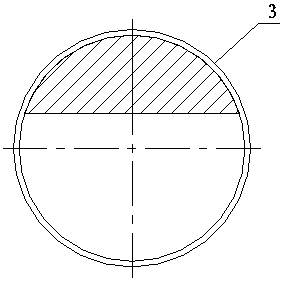

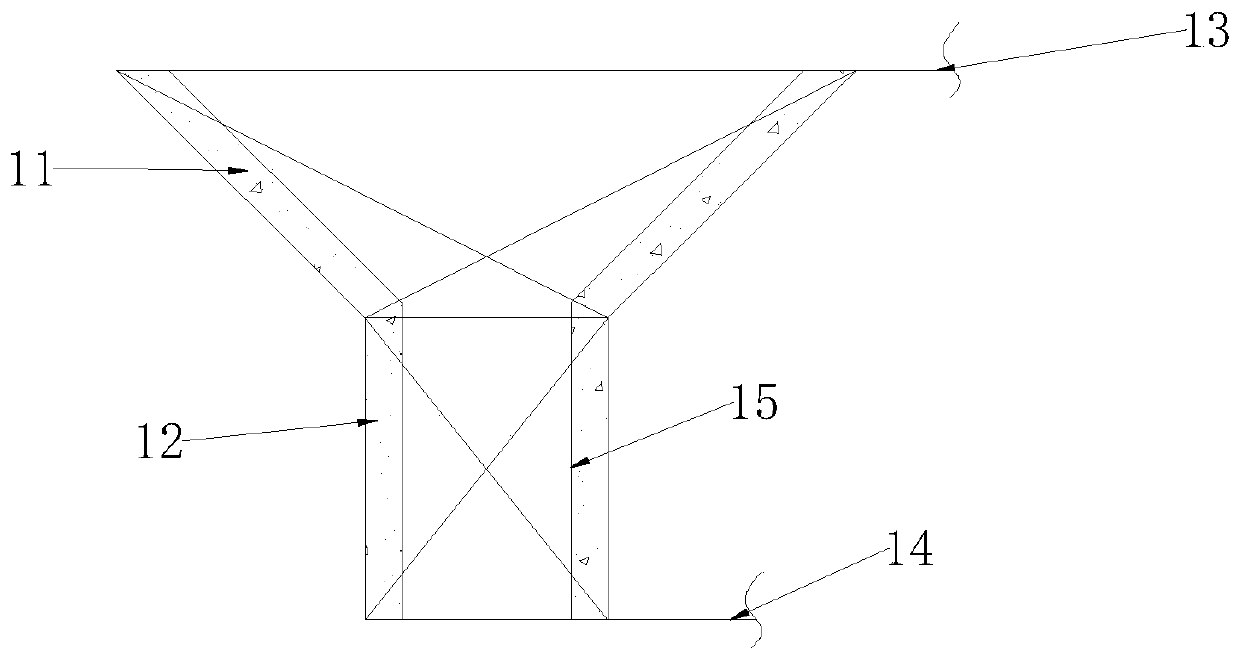

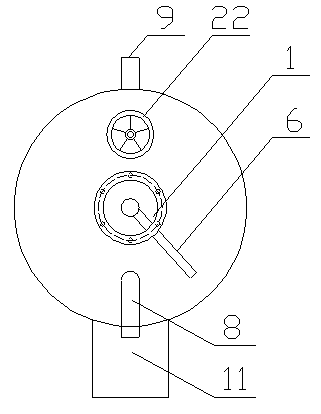

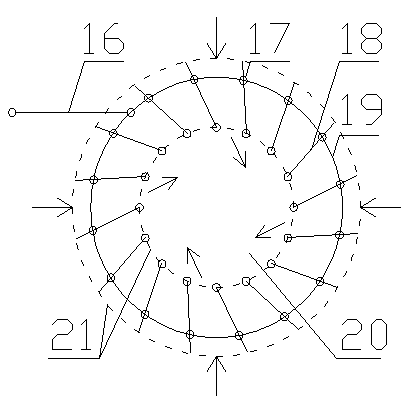

Multistage separation center backflow axial cyclone burner

ActiveCN106051759AImprove coal adaptabilityEmission reductionPulverulent fuel combustion burnersCycloneCombustion

The invention discloses a multistage separation center backflow axial cyclone burner. A traditional cyclone burner technology needs to further reduce NOx emission. A primary wind pipe elbow (1) is connected with a primary wind pipe horizontal section (2); a center wind pipe module (5) and a connected combustion stabilizing ring (7) are arranged in the center of the primary wind pipe horizontal section; a pulverized coal uniform distributor (3) is arranged in an inlet; a venturi pulverized coal concentrator (4) is arranged near an outlet; a secondary wind pipe (10), a secondary wind gate (13) and a secondary wind pipe expanding port (17) are arranged at the external of the primary wind pipe horizontal section; a ternary wind pipe (11), a ternary wind gate (14) and a ternary wind pipe expanding port (18) are arranged at the external of the secondary wind pipe; the ternary wind pipe is provided with a ternary wind cyclone adjusting mechanism (15); a quartic wind pipe (12) is arranged at the external of a ternary wind pipe; the quartic wind pipe is provided with a quartic wind cyclone adjusting mechanism (16); and an outlet of a quartic wind pipe is connected with a water cooling wall pipe screen (19). The invention is applied to the multistage separation center backflow axial cyclone burner.

Owner:HARBIN BOILER

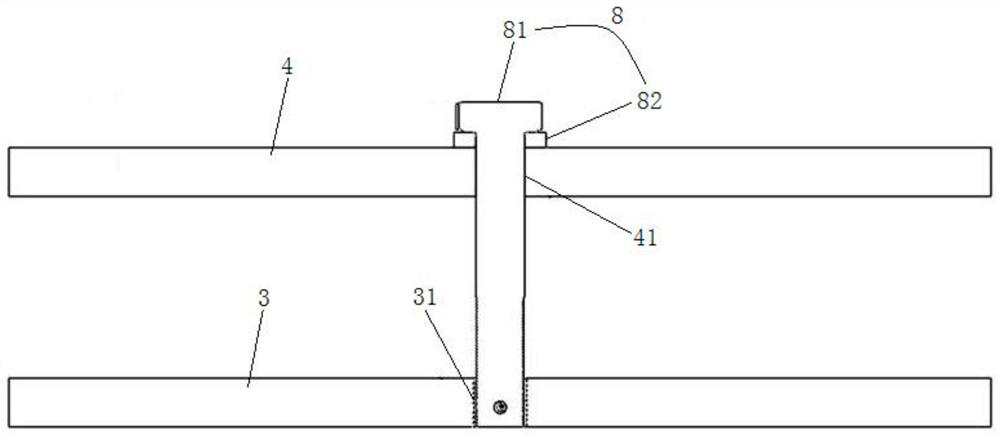

Slaked lime feeding device for half dry desulfurization of coal-fired flue gas

PendingCN107551798AHigh degree of automationRealize automatic feedingDispersed particle separationLoading/unloadingFlue gasEngineering

The invention relates to the technical field of desulfurization of coal-fired flue gas and particularly relates to a slaked lime feeding device for half dry desulfurization of coal-fired flue gas. Thedevice comprises a stock bin, a roof scrubber arranged on the top of the stock bin, a conveying pipeline communicating to the bottom end of the stock bin and extending downward, a variable frequencyflow control electric valve connected to the conveying pipeline in series, a first particle concentration detector arranged in a flue gas inlet channel of a desulfurizing tower, a second particle concentration detector arranged in a circulating ash reflux tank of the desulfurizing tower and a controller; the first particle concentration detector, the second particle concentration detector and thevariable frequency flow control electric valve are electrically connected to the controller, separately; an annular divider is arranged at the discharge port of the lower end of the conveying pipeline; the discharge port of the annular divider communicates to a plurality of feeding holes for feeding distributed along the circumference of the wall of the desulfurizing tower on the desulfurizing tower. The slaked lime feeding device provided by the invention is uniform to charge and high in desulfurizing efficiency.

Owner:JIANGSU YIJIN ENVIRONMENTAL PROTECTION TECH CO LTD

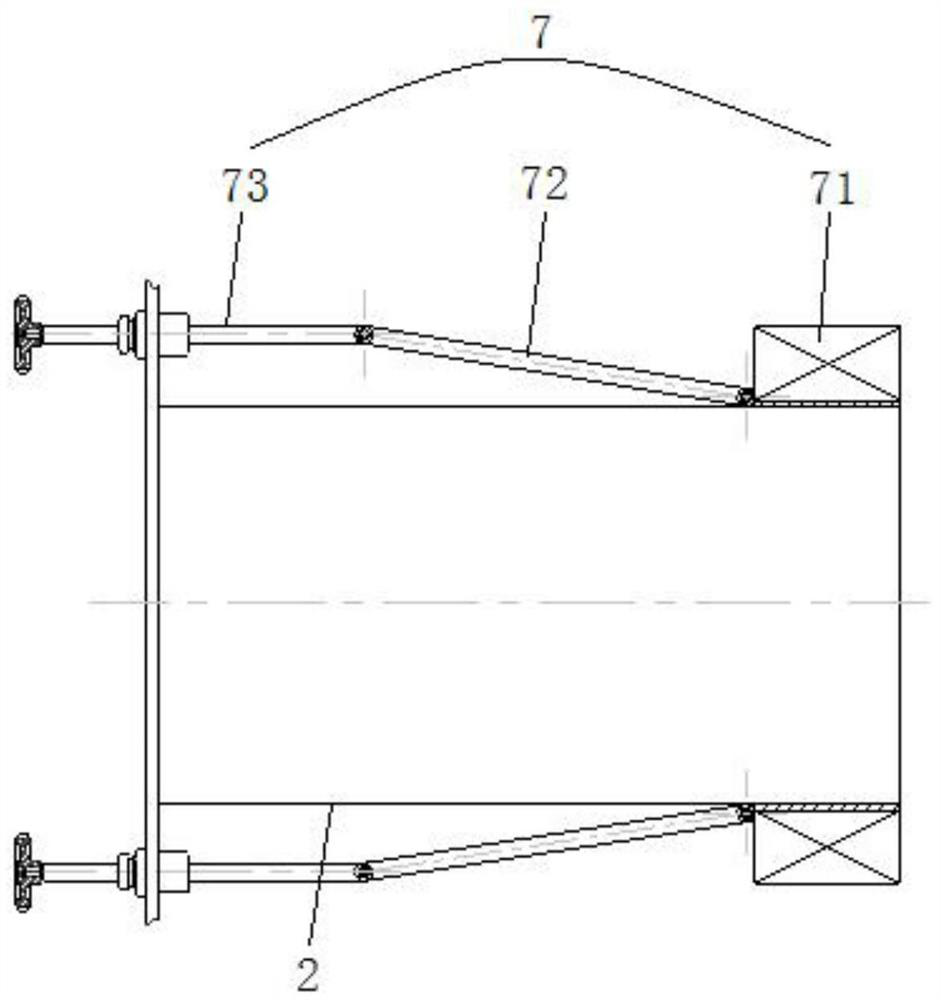

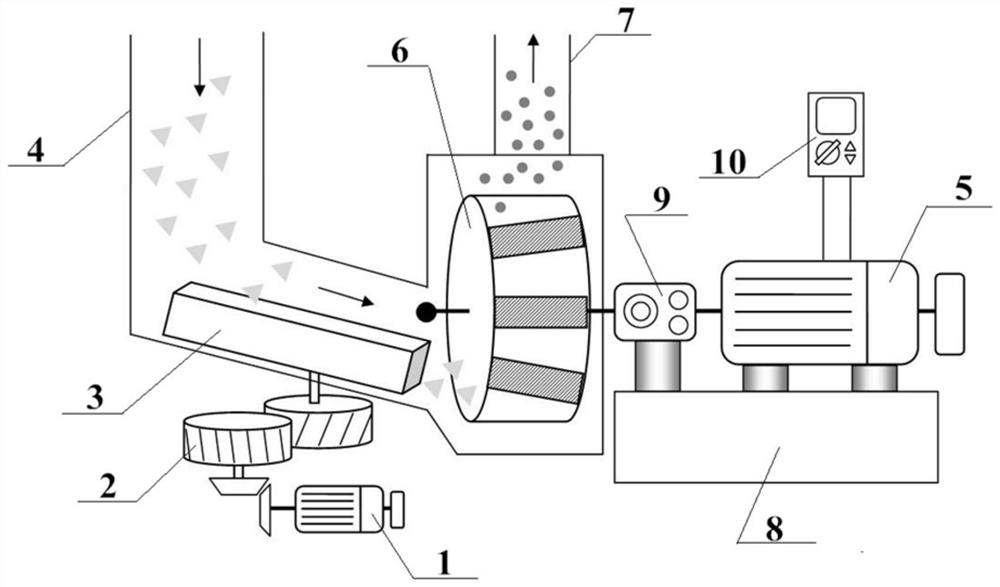

Fan coal mill with both coal groove angle and motor rotating speed being capable of being adjusted

PendingCN111957394AImprove coal adaptabilityMeet fine adjustment requirementsGrain treatmentsCoalEnvironmental geology

The invention discloses a fan coal mill with both the coal groove angle and the motor rotating speed being capable of being adjusted. The fan coal mill comprises a coal falling pipe, a raw coal conveying pipeline, a beating cavity, a coal mill motor, a coal groove motor and a powder discharging pipe. A bottom outlet of the coal falling pipe communicates with an inlet of the raw coal conveying pipeline, and the raw coal conveying pipeline communicates with an inlet of the beating cavity. A beating wheel is arranged in the beating cavity. A coal groove is formed in the raw coal conveying pipeline. An output shaft of the coal mill motor is connected with the beating wheel. An output shaft of the coal groove motor is connected with the coal groove. An outlet of the beating cavity communicateswith the powder discharging pipe. The coal mill motor is connected with a frequency converter. The adjusting range of the fineness of pulverized coal of the coal mill is wide.

Owner:XIAN THERMAL POWER RES INST CO LTD

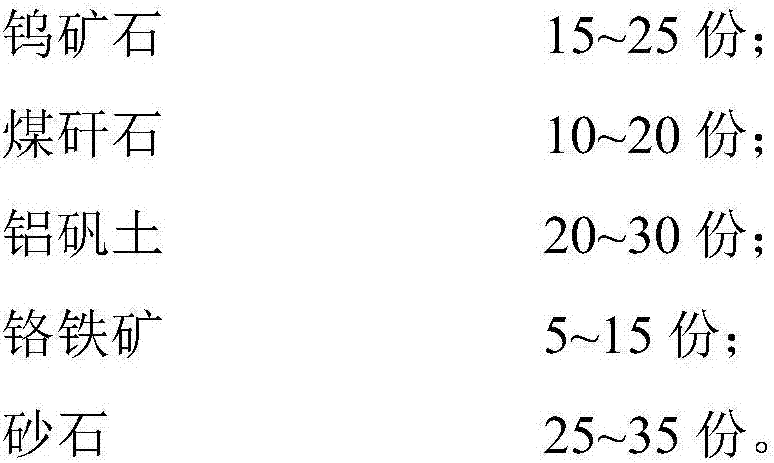

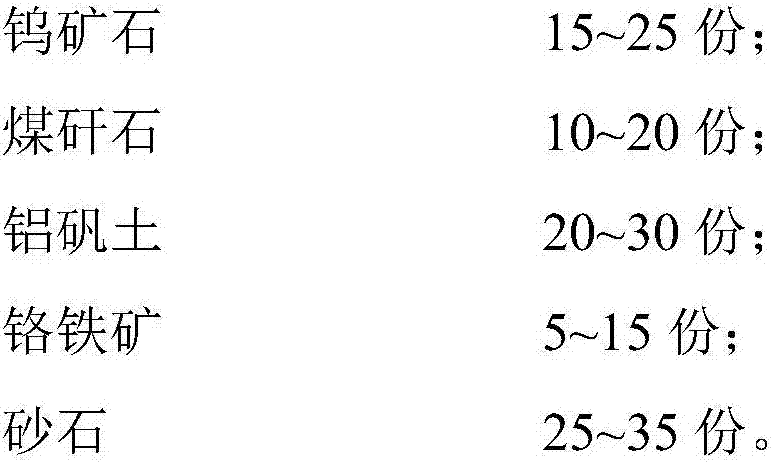

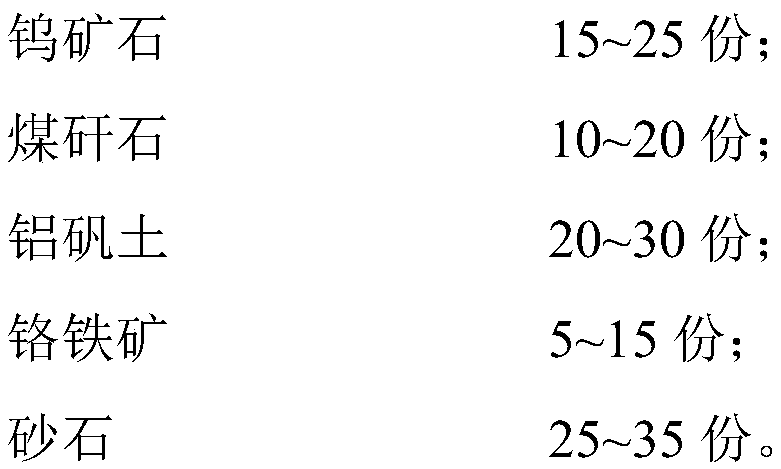

Stain-resistant additive for boiler as well as preparation method and application of stain-resistant additive

The invention relates to a stain-resistant additive for a boiler as well as a preparation method and application of the stain-resistant additive. The additive is prepared from the following components in parts by weight: 15 to 25 parts of tungsten ore, 10 to 20 parts of coal gangue, 20 to 30 parts of bauxite, 5 to 15 parts of chromite and 25 to 35 parts of aggregate. Compared with the prior art, the stain-resistant additive disclosed by the invention has the advantages that on the premise of not changing the structure of the boiler and operation conditions of the boiler, a melting point of easily-stained fuel ash can be effectively improved, the caking property of the easily-stained fuel ash is reduced, the problems of slagging and ash deposition of a fired easily-stained fuel boiler are remarkably reduced, the heat transfer effect of a heat exchange tube is enhanced, the flue gas loss of the boiler is reduced, and the efficiency of the boiler is improved; ventilation power consumption is reduced, and power for factories is saved; the risk that slagging affects normal work of steam and water inside the heated surface is effectively reduced, and the condition that a steam-water pipe bursts due to overheat is prevented; and corrosion of slagging to the metal tube wall is reduced. The invention aims at solving the problems of the slagging and the ash deposition of easily-stained fuel and the application range of the boiler to the easily-stained fuel is widened.

Owner:中国电力建设工程咨询中南有限公司 +1

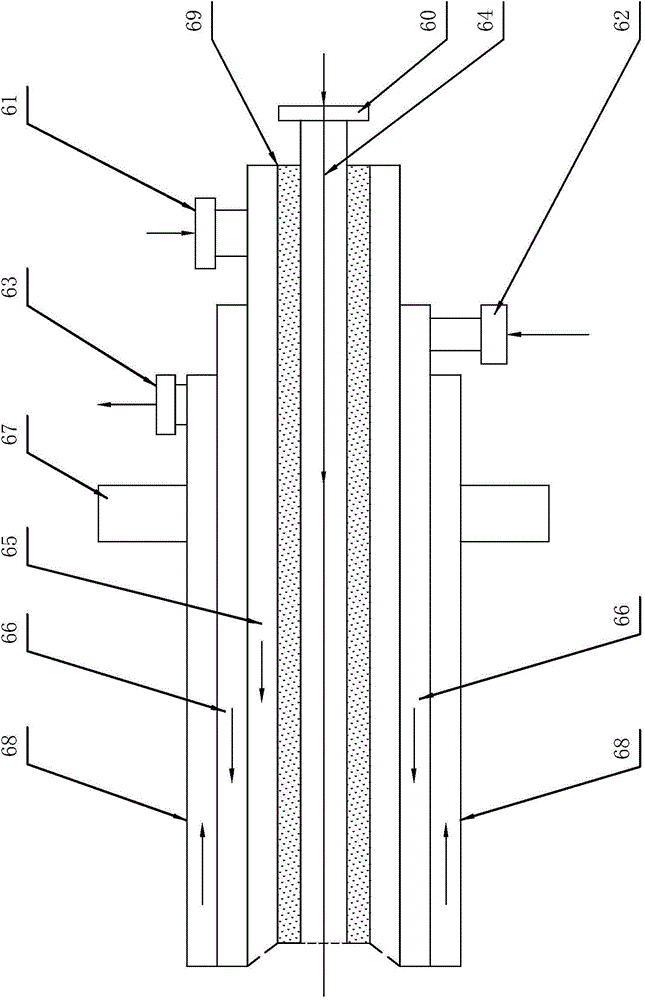

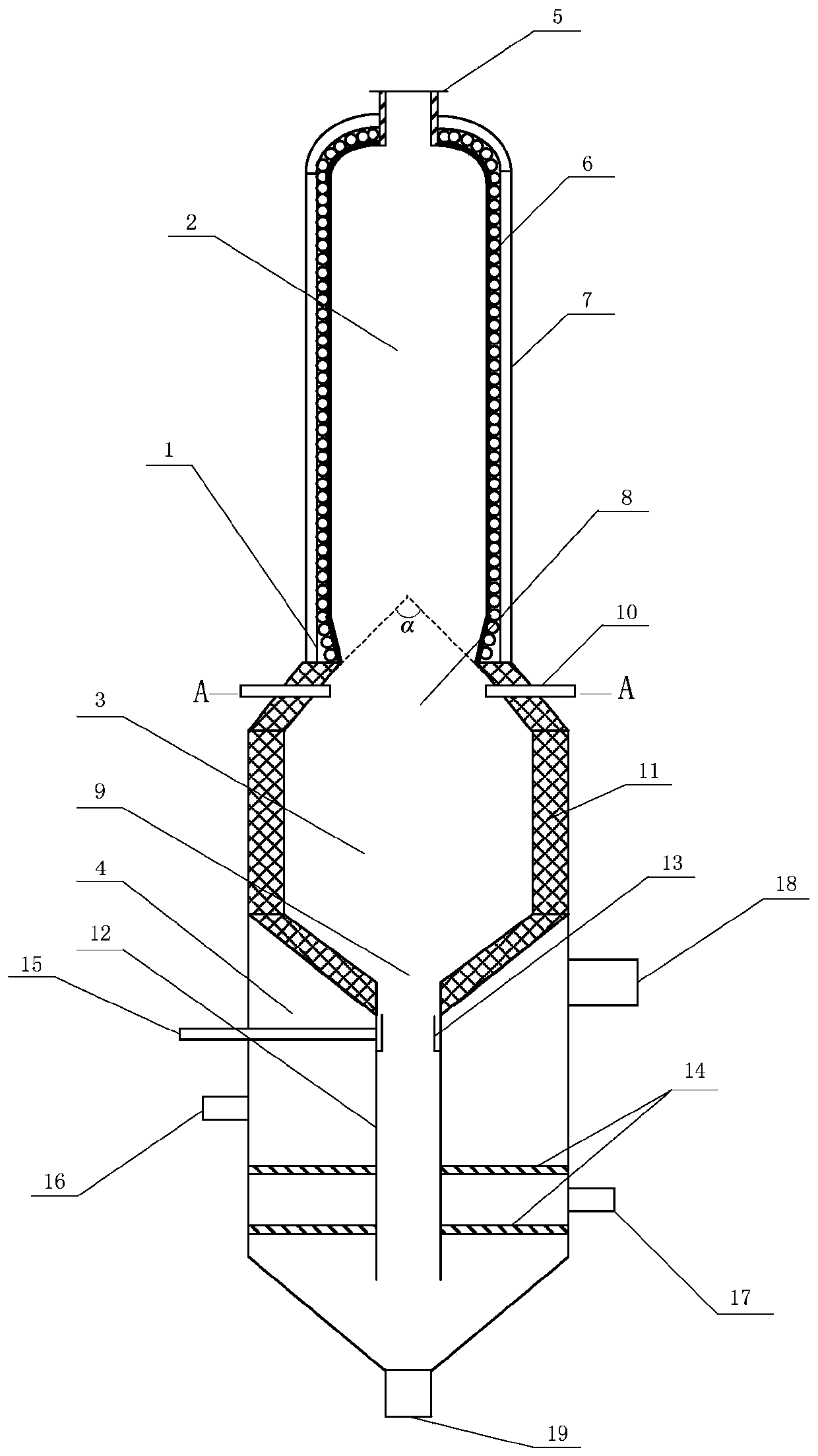

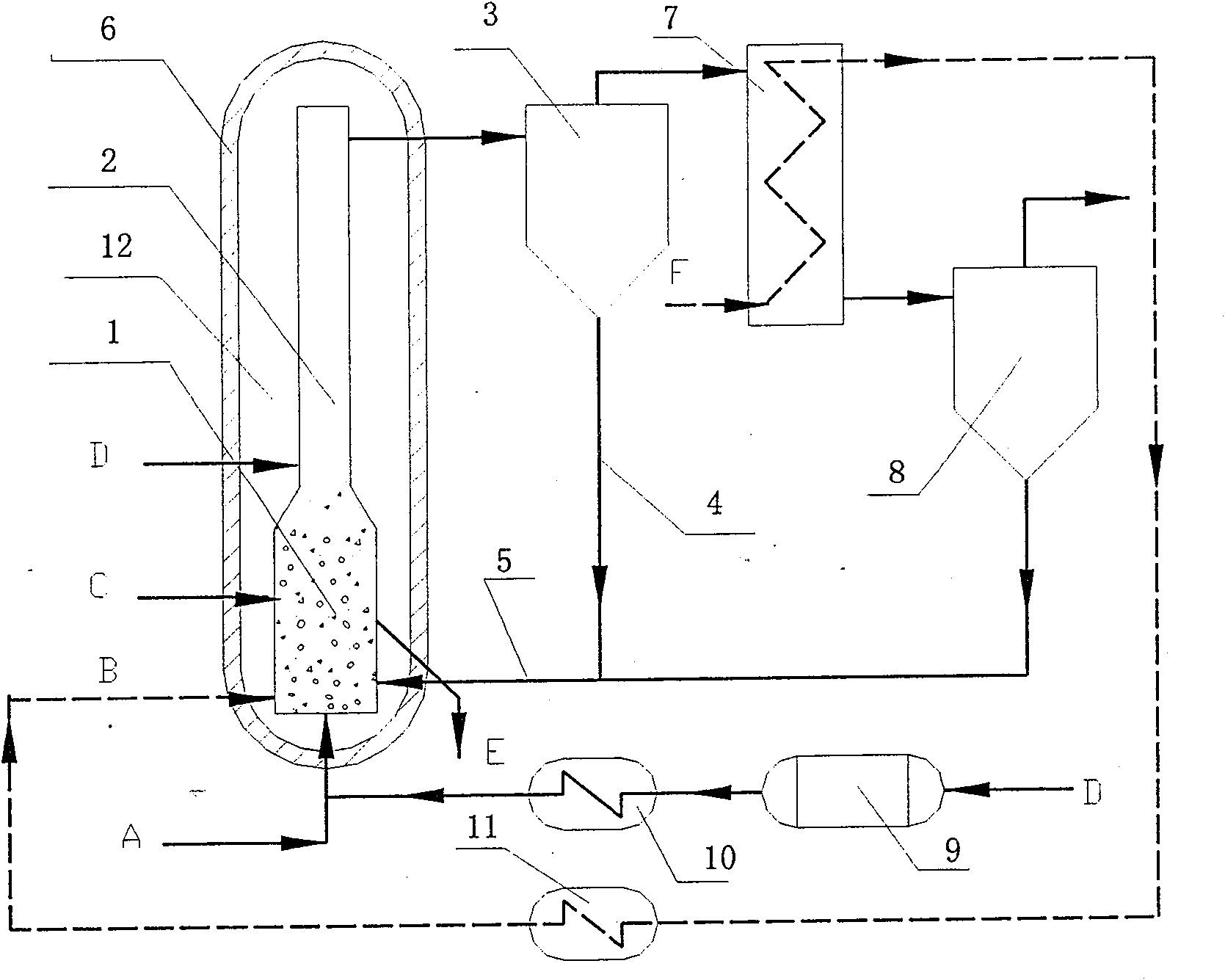

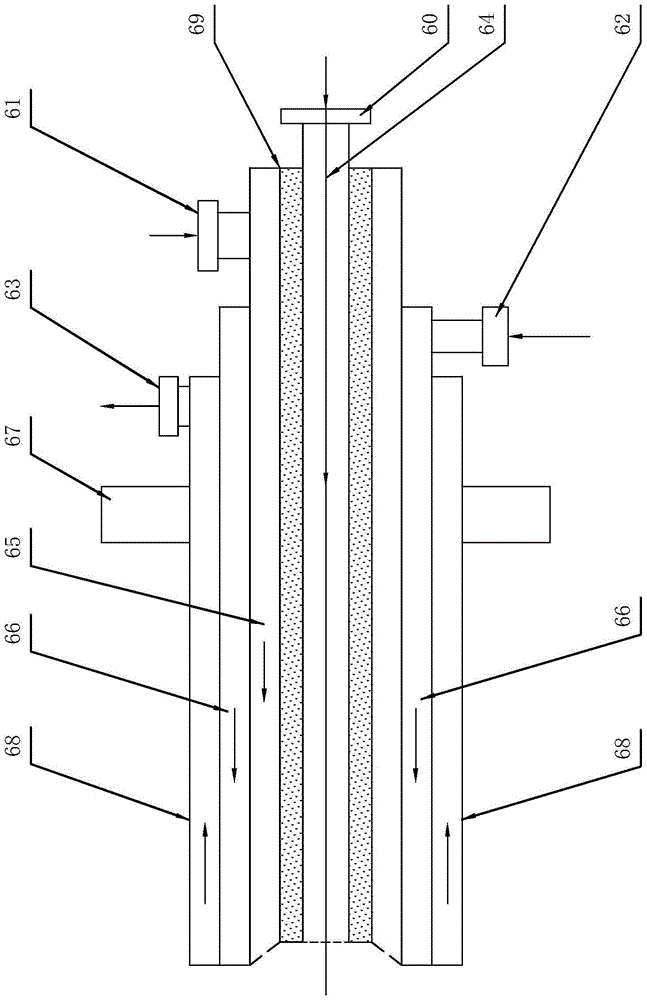

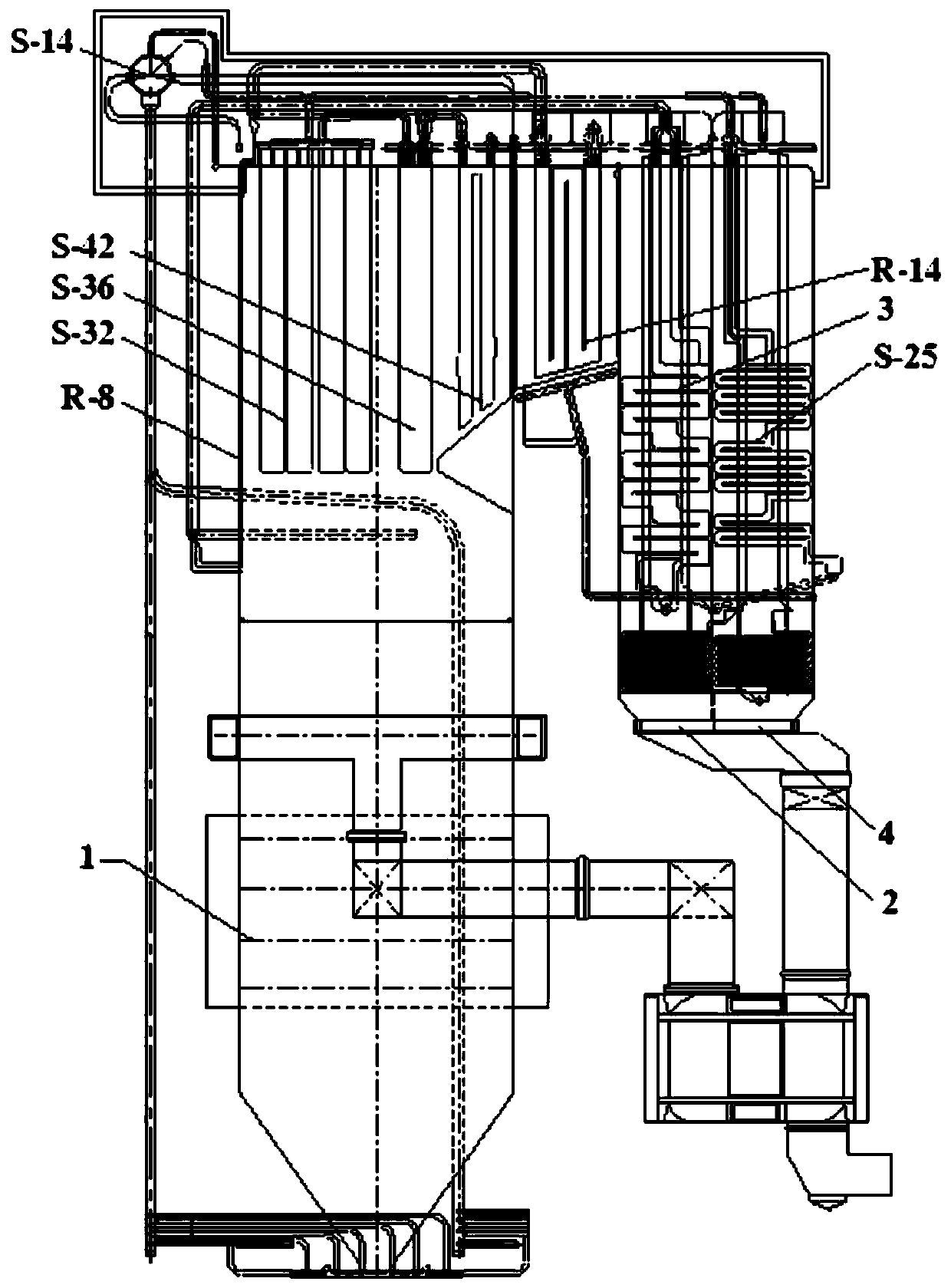

A method and equipment for multi-stage entrained entrained bed coal gasification coupled with high temperature shift

ActiveCN105154140BImprove coal adaptabilityEasy to moveChemical industryGranular/pulverulent flues gasificationWater vaporHydrogen content

A multi-stage entrained-flow coal gasification method capable of realizing coupling high temperature shift comprises the following steps: dry coal powder and a gasifying agent are vertically sprayed into a high-temperature gasification section from a burner of a multi-stage entrained-flow gasifier for coal gasification reaction, generated hot coal gas and molten slag flow downwards into a high-temperature conversion section, converted spray water or low-temperature steam is sprayed into the gasifier from an atomization spray head to be subjected to high-temperature water vapor shift reaction to generate H2, coal gas and ash enter a chilling section through a flow guide pipe, and the coal gas is cooled, washed, discharged out of the gasifier from a crude coal gas outlet, and fed into a post-system to be purified. The method has the advantages that the operation is easy, the thermal efficiency is high, the hydrogen content in coal gas is high, and the adaptability to coal type is good.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Biomass and coal co-gasification system and gasification method

PendingCN111676065AStrong responsivenessExtend warm-up timeLiquid degasificationEnergy inputDust controlSuperheated steam

The invention discloses a biomass and coal co-gasification system and gasification method, and belongs to the field of carbon-based solid fuel energy utilization. The problem that energy cannot be effectively utilized when biomass and coal are gasified together in the prior art is solved. The biomass and coal co-gasification system comprises a raw coal feeding device and a biomass feeding device,the two feeding devices are connected with feeding pipes, the feeding pipes are connected with a fluidized bed gasification furnace, the fluidized bed gasification furnace is connected with a dust removal device, a waste heat recovery device is further arranged between the fluidized bed gasification furnace and the dust removal device, the waste heat recovery device is connected with the steam power generation device, and the steam power generation device provides steam for gasification reaction in the fluidized bed gasification furnace. Sensible heat recovery is conducted on high-temperaturegasified coal gas through the waste heat recovery device, superheated steam generated through recovery is used for power generation of the steam power generation device, the steam power generation device provides steam for gasification reaction, and the energy utilization rate is remarkably increased. The gasification method utilizing the system is simple and convenient to operate and high in safety.

Owner:KEDA MAS CLEAN ENERGY

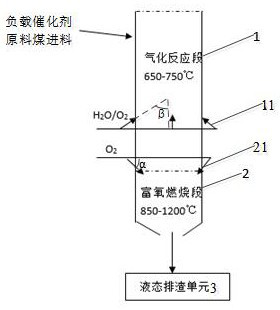

Fluidized bed gasification furnace and gasification process

ActiveCN112480968AImprove coal adaptabilityImprove economyGasification processes detailsGranular/pulverulent flues gasificationProcess engineeringOxygen enrichment

The invention provides a fluidized bed gasification furnace and a gasification process. The fluidized bed gasification furnace comprises a gasification reaction section and an oxygen-enriched combustion section which are sequentially communicated from top to bottom. A catalyst-loaded feed coal inlet and a plurality of gasifying agent nozzles are respectively formed in the upper part and the lowerpart of the gasification reaction section, and each gasifying agent nozzle is obliquely arranged upwards; a plurality of oxygen nozzles are formed in the wall surface of the oxygen-enriched combustionsection, are obliquely arranged downwards along the wall surface, extend into the oxygen-enriched combustion section and are used for conveying oxygen to the oxygen-enriched combustion section, so that ash generated by the gasification reaction section and oxygen are subjected to a combustion reaction, a large amount of heat is released, and a high-temperature area is formed; and further, the ashcontaining the catalyst is molten into a liquid state at high temperature. Oxygen and gasified ash are subjected to a combustion reaction sufficiently to generate a large amount of heat, the ash is ensured to be discharged in a liquid state while heat is provided for the gasification reaction section, the coal type adaptability is improved, and harmless discharge of the ash is achieved.

Owner:ENN SCI & TECH DEV

Catalytic coal gasifaction furnace of differential speed bed, and method of catalytic gasification

InactiveCN100577774CImprove removal efficiencyExtended stayCombined combustion mitigationGranular/pulverulent flues gasificationLow speedHearth

Owner:NANTONG SANCHUANG MACHINE MFG +1

Boiler burner with low load and stable combustion, its combustion method and application

ActiveCN109812803BReduce the temperatureStable combustionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermodynamicsCombustor

The invention discloses a low-load stable-combustion boiler combustor which comprises combustor bodies and a hearth. The combustor body comprises a shell, a secondary air pipe arranged in the center of the shell, a primary air pipe surrounding the two sides of the secondary air pipe, a biomass fuel pipe tightly attached to the inner wall of the shell, and the combustor bodies are arranged on the four corners of the hearth. The invention further discloses a combustion method of the low-load stable-combustion boiler combustor. During full-load combustion of the hearth, a biomass fuel inlet is closed, only pulverized coal combustion is adopted for hearth combustion, biomass combustion is not adopted, and hearth slag is relieved. During low-load operation, pulverized coal entering the hearth is reduced, the temperature of the hearth is reduced, flame combustion is unstable, in order to ensure stable combustion, the biomass fuel inlet is opened for feeding biomass fuel, and it is ensured that flame combustion is stable by means of the characteristics that biomass is high in volatile component, easy to ignite and good in heating value.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

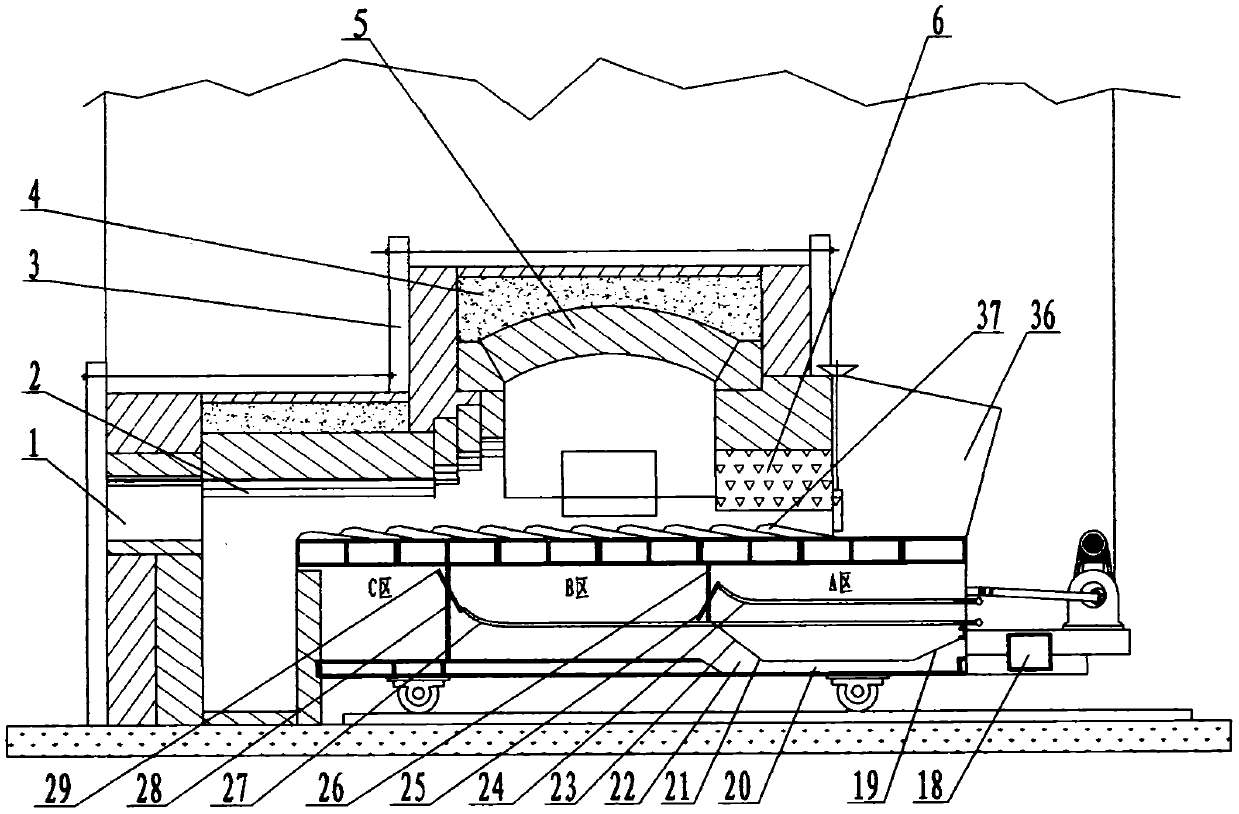

A heating equipment for coal chemical deep processing

InactiveCN103267276BEasy to moveAdaptableSolid fuel combustionSpecial form destructive distillationDistillationPush pull

The invention relates to coalification deep processing heating equipment. The coalification deep processing heating equipment is characterized in that a cavity below a driving fire grate is divided into an area A, an area B and an area C by a separating board AB and a separating board BC, an area A air adjusting push-pull rod is arranged in the area A, an area A air door is arranged on the separating board AB opposite to the area A air adjusting push-pull rod, a double-bottom air channel is arranged below the area A, a fan connecting port is formed outside the area A, a coal inlet, a front furnace arch, a middle furnace middle arch and a rear furnace arch are arranged above the driving fire grate, heat insulating materials are arranged above the middle furnace arch, the outside of the rear furnace arch is communicated with an ash cleaning port, a fire wall is arranged in a purification room, a flame path is arranged outside the purification room, and a distillation still outer wall is arranged outside the flame path. The coalification deep processing heating equipment has the advantages that rolling wheels are arranged on the bottom portion of the coalification deep processing heating equipment, the coalification deep processing heating equipment is convenient to move, and the coalification deep processing heating equipment is small in size, small in occupied area, unique in air distribution mode, strong in coal type adaptability, sufficient in coal seam burning, low in carbon content of ash, stable in heating system, convenient to maintain and capable of solving the problems of large coal consumption of an industrial furnace, poor working conditions and the like well.

Owner:河北齐工环保科技有限公司

An entrained-flow gasifier with solidification of slag in swirl

ActiveCN104449868BSimple structureExtended service lifeEnergy inputGranular/pulverulent flues gasificationWear resistantThermal insulation

The invention provides an entrained flow gasifier for swirling melt cinder solidification. The entrained flow gasifier is divided into a pressure resistant jacket and a gasifier liner, wherein a gasification chamber, a swirling cooling chamber and a cinder solidification cooling chamber form the gasifier liner and are respectively separated by virtue of segmenting conical sealing heads; a shell of the gasification chamber is sequentially provided with a thermal insulation material layer, a cooling jacket and a wear resistant material layer from outsides to insides; a cooling water inlet is formed in the bottom of the gasification chamber, and a saturated steam outlet is formed in the side surface of the top part of the gasification chamber; a top nozzle is formed in the center of the top part of the gasification chamber, and more than 3 side nozzles are uniformly formed in the upper part of the gasification chamber along the circumference; a gasification product discharge hole is formed in the center of the segmenting conical sealing head which is arranged at the bottom of the gasification chamber; an atomization water cooling sleeve is arranged at the outer side of a gasification product discharge hole in the swirling cooling chamber, and a gas outlet is formed in the upper part of the swirling cooling chamber; a solidified cinder discharge hole is formed in the center of the segmenting conical sealing head arranged at the bottom of the cooling chamber, is connected with the solidified cinder cooling chamber and is introduced into the middle of the solidified cinder cooling chamber, and a water cooling cinder discharge hole is formed in the center of the segmenting conical sealing head arranged at the bottom of the solidified cinder cooling chamber. With the adoption of the entrained flow gasifier for swirling melt cinder solidification, waste heat is fully utilized, and the difficulty of black water is eliminated.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A gasifier structure capable of processing pulverized coal and coal-water slurry at the same time

ActiveCN104531221BImprove coal adaptabilityLarge amount of processingGasification processes detailsGranular/pulverulent flues gasificationCoal waterSlag

The invention relates to a gasification furnace structure capable of treating pulverized coal and water coal slurry simultaneously. The gasification furnace structure comprises a furnace body, wherein a water cooling wall is arranged in the furnace body and a quenching chamber is arranged under a gasification chamber; the gasification furnace structure is characterized in that a water coal slurry nozzle is arranged at the top part of the furnace body, at least three pulverized coal nozzles are arranged at the upper part of the side wall of the gasification furnace body and are uniformly distributed on the same horizontal circumference along the furnace body, two sets of start-up burners are also symmetrically arranged on the side wall of the furnace body, a slag hole is formed at the bottom of the furnace body, and a slag breaking machine is arranged on the slag hole. The gasification furnace structure has strong coal type adaptive capacity and can treat pulverized coal and water coal slurry simultaneously, inferior coal with high ash melting point, high ash content, high sulphur content and high alkali metal content can be mixed for combustion, and the single furnace has high handling capacity and low energy consumption.

Owner:SINOPEC NINGBO ENG +2

Coal power furnace decoking agent and application thereof

InactiveCN112300849AImprove coal adaptabilityEliminate focusSolid fuelsFuel additivesBrown iron oxideMagnesium

The invention provides a coal power furnace decoking agent, which is characterized by comprising the following raw material components: sodium chloride, sodium nitrate, sodium chlorate, dolomite powder, quartz powder, kaolin, magnesium oxide, iron oxide red and charcoal, and comprises the following raw materials in parts by weight: 50-65 parts of sodium chloride, 20-33 parts of sodium nitrate, 11-20 parts of sodium chlorate, 4-6.2 parts of dolomite powder, 0.4-1.1 parts of quartz powder, 1.2-3.5 parts of kaolin, 1.20-2.9 parts of magnesium oxide, 2-5.6 parts of iron oxide red and 0.3-0.9 partof charcoal. By adopting the decoking agent, coke blocks appearing in operation can be eliminated in time, so that the cleanness of a heating surface is effectively kept, and the heat efficiency of the boiler can be continuously operated at a high level.

Owner:李通

A kind of boiler antifouling additive and its preparation and application

The invention relates to a stain-resistant additive for a boiler as well as a preparation method and application of the stain-resistant additive. The additive is prepared from the following components in parts by weight: 15 to 25 parts of tungsten ore, 10 to 20 parts of coal gangue, 20 to 30 parts of bauxite, 5 to 15 parts of chromite and 25 to 35 parts of aggregate. Compared with the prior art, the stain-resistant additive disclosed by the invention has the advantages that on the premise of not changing the structure of the boiler and operation conditions of the boiler, a melting point of easily-stained fuel ash can be effectively improved, the caking property of the easily-stained fuel ash is reduced, the problems of slagging and ash deposition of a fired easily-stained fuel boiler are remarkably reduced, the heat transfer effect of a heat exchange tube is enhanced, the flue gas loss of the boiler is reduced, and the efficiency of the boiler is improved; ventilation power consumption is reduced, and power for factories is saved; the risk that slagging affects normal work of steam and water inside the heated surface is effectively reduced, and the condition that a steam-water pipe bursts due to overheat is prevented; and corrosion of slagging to the metal tube wall is reduced. The invention aims at solving the problems of the slagging and the ash deposition of easily-stained fuel and the application range of the boiler to the easily-stained fuel is widened.

Owner:中国电力建设工程咨询中南有限公司 +1

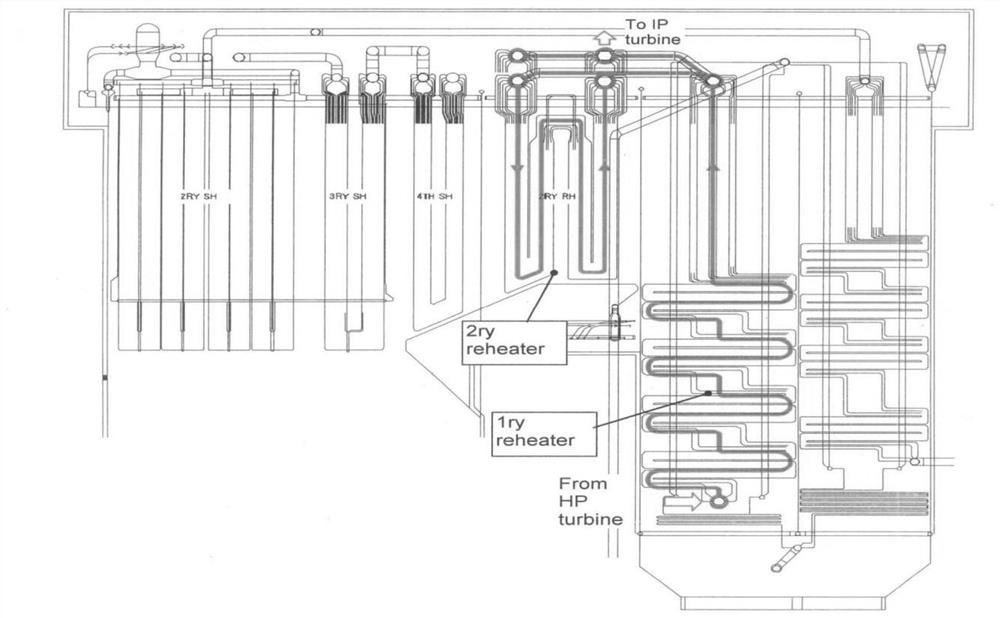

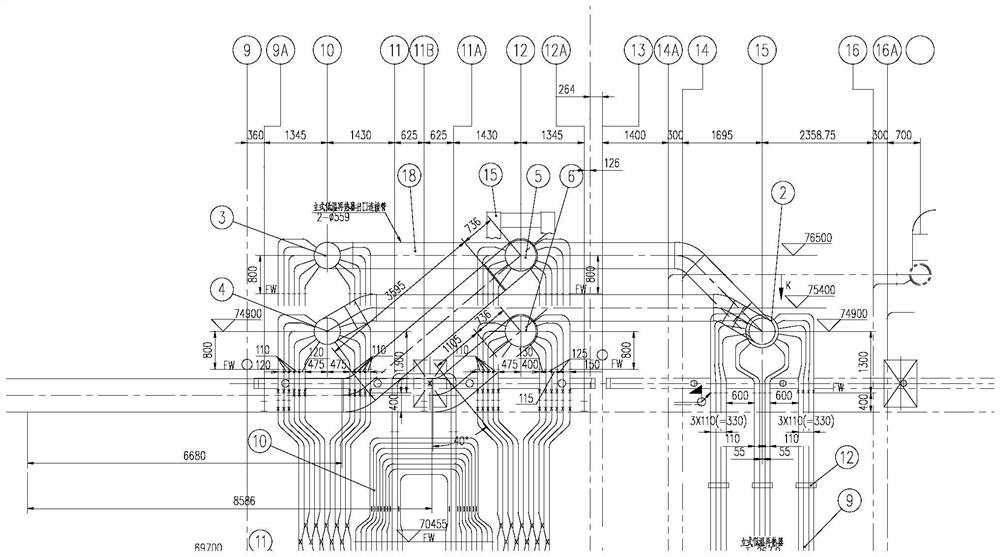

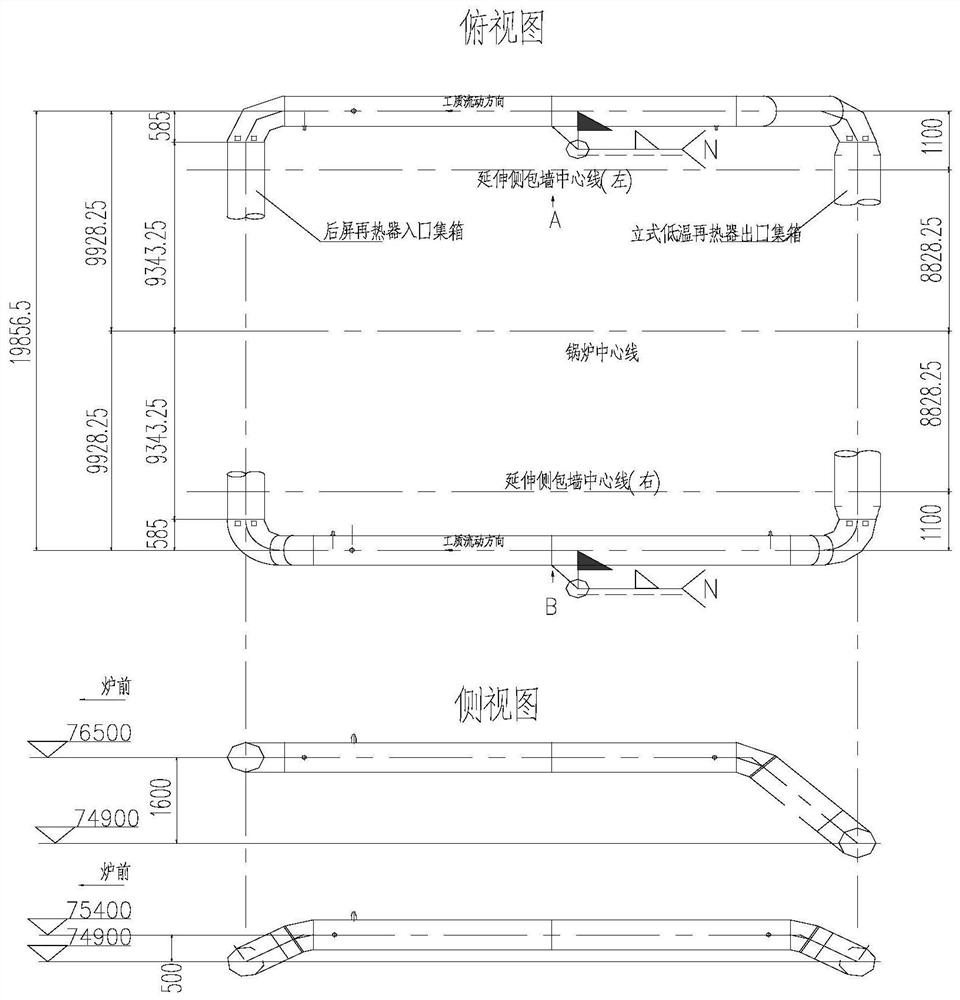

200 MW grade high-efficiency subcritical boiler

InactiveCN109973981AImprove efficiencyReduce coal consumptionSuperheating controlBoiler water tubesSteam pressureSuperheater

The invention relates to a 200 MW grade high-efficiency subcritical boiler, and relates to a 200 MW grade boiler. The boiler aims to solve the problems of low main steam pressure, low main steam temperature and low reheating steam temperature of an existing 200 MW boiler unit. The 200 MW grade high-efficiency subcritical boiler adopts a unit with tail double flues, and a radiant reheater is arranged on the unit with the tail double flues; a swing burner is installed in the middle of a water cooling wall; and a reheater side temperature adjusting baffle plate and a superheater side temperatureadjusting baffle plate are arranged. The boiler has the beneficial effects that steam parameters are realized, specifically, the main steam pressure is 17.5MPa.g, the main steam temperature is 571 DEGC, and the reheating steam temperature is 569 DEG C, and the invention mainly relates to preparation of the 200 MW grade high-efficiency subcritical boiler.

Owner:HARBIN BOILER

Eddy flow powdered coal burner lit up by tiny oil

InactiveCN100470128CReduce outputGuaranteed not to cokePulverulent fuel combustion burnersStopped workCombustor

This invention relates to a wall-laid little oil ignition coal burner including a primary air pipe, a central air pipe, a high energy oil gun set horizontally in the central air pipe, inlet for inner secondary wind, an inlet for outer secondary wind, spouts of primary wind and secondary wind and a spout of a burner characterizing in setting one stage or multiple stages of diversion condensed rings on the internal wall of the primary air pipe and setting one or multiple stages of precombustion chamber at the front of the central pipe, which realizes four-stage ignition process with tiny oil and higher oil-saving rate when adjusting the peak deeply and has the function of stable and low NOx burning when the oil gun stops working.

Owner:TSINGHUA UNIV

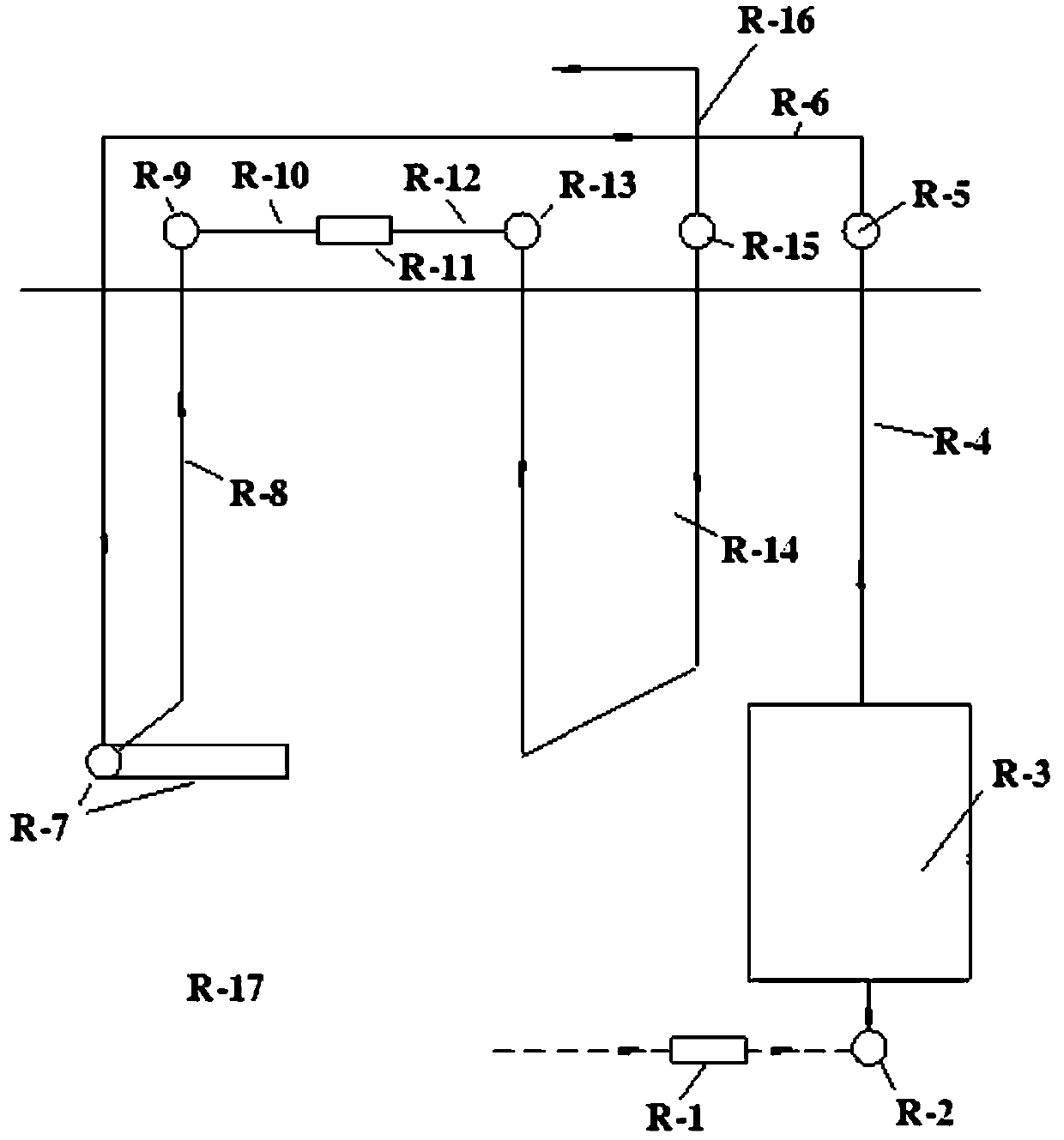

Method for rapidly adjusting temperature of reheat steam

PendingCN112856385AHigh sensitivityConducive to the adaptability of coal typesSuperheating controlProcess engineeringCoal

The invention discloses a method for rapidly adjusting temperature of reheated steam, and belongs to the technical field of thermal power generation. The method for rapidly adjusting the temperature of the reheated steam comprises a low-temperature reheater, wherein an outlet of the low-temperature reheater is a single header, a high-temperature reheater is arranged on one side of the low-temperature reheater, and an inlet and an outlet of the high-temperature reheater are arranged in a double header mode; a connecting guide pipe communicates between the low-temperature reheater and the high-temperature reheater, and a temperature reducing device is installed on the connecting guide pipe. The method adapts to the characteristics of variability of combustion coal types and diversity of load changes of an existing boiler unit, wall temperature of the high-temperature reheater can be adjusted in time after a desuperheater is additionally arranged between the low-temperature reheater and the high-temperature reheater from aspects of operation stability, safety and economy of a boiler,.the sensitivity of unit operation load to steam temperature change is improved, unit load change and coal type adaptability are facilitated, and meanwhile response speed and adaptability of a unit to deep peak regulation and a tip peak are improved.

Owner:HUANENG POWER INTERNATIONAL

Multistage Separation Center Return Type Axial Swirl Burner

ActiveCN106051759BImprove coal adaptabilityEmission reductionPulverulent fuel combustion burnersCycloneCombustion

The invention discloses a multistage separation center backflow axial cyclone burner. A traditional cyclone burner technology needs to further reduce NOx emission. A primary wind pipe elbow (1) is connected with a primary wind pipe horizontal section (2); a center wind pipe module (5) and a connected combustion stabilizing ring (7) are arranged in the center of the primary wind pipe horizontal section; a pulverized coal uniform distributor (3) is arranged in an inlet; a venturi pulverized coal concentrator (4) is arranged near an outlet; a secondary wind pipe (10), a secondary wind gate (13) and a secondary wind pipe expanding port (17) are arranged at the external of the primary wind pipe horizontal section; a ternary wind pipe (11), a ternary wind gate (14) and a ternary wind pipe expanding port (18) are arranged at the external of the secondary wind pipe; the ternary wind pipe is provided with a ternary wind cyclone adjusting mechanism (15); a quartic wind pipe (12) is arranged at the external of a ternary wind pipe; the quartic wind pipe is provided with a quartic wind cyclone adjusting mechanism (16); and an outlet of a quartic wind pipe is connected with a water cooling wall pipe screen (19). The invention is applied to the multistage separation center backflow axial cyclone burner.

Owner:HARBIN BOILER CO LTD

A high-efficiency and low-nox segmental coupled combustion method for inferior coal

ActiveCN106439793BRealize ignition and stable combustionEfficient combustionCombustion using gaseous and pulverulent fuelStaged combustionCombustorMicrometer

A high-efficiency and low-NOx segmented coupling combustion method for inferior coal belongs to the field of high-efficiency clean coal combustion technology. It solves the problem that existing coal combustion technology cannot achieve low NOx emissions and high combustion efficiency at the same time when using low-quality coal fuel, and that a coal grinding system needs to be equipped during the combustion process. The method of the present invention is implemented by using a high-efficiency and low-NOx segmented coupling combustion device for inferior coal. The combustion device is mainly composed of a fluidized bed and a pulverized coal furnace. The combustion process is as follows: first, fuel-rich pyrolysis of coal particles is performed in the fluidized bed; Adiabatic combustion, crushing, gasification, particle sorting, reforming the fuel into crude gas containing only particles with a particle size of less than 75 microns at 850°C to 900°C, and then sending the crude gas to the burner area of the pulverized coal furnace for processing at 1100°C Fuel-rich combustion, and finally lean fuel burnout at 1300°C in the upper area of the pulverized coal furnace burner, the three stages of combustion are relatively independently controlled and effectively coupled through the new structure in the furnace. The invention is mainly used in the field of inferior coal combustion.

Owner:HARBIN INST OF TECH

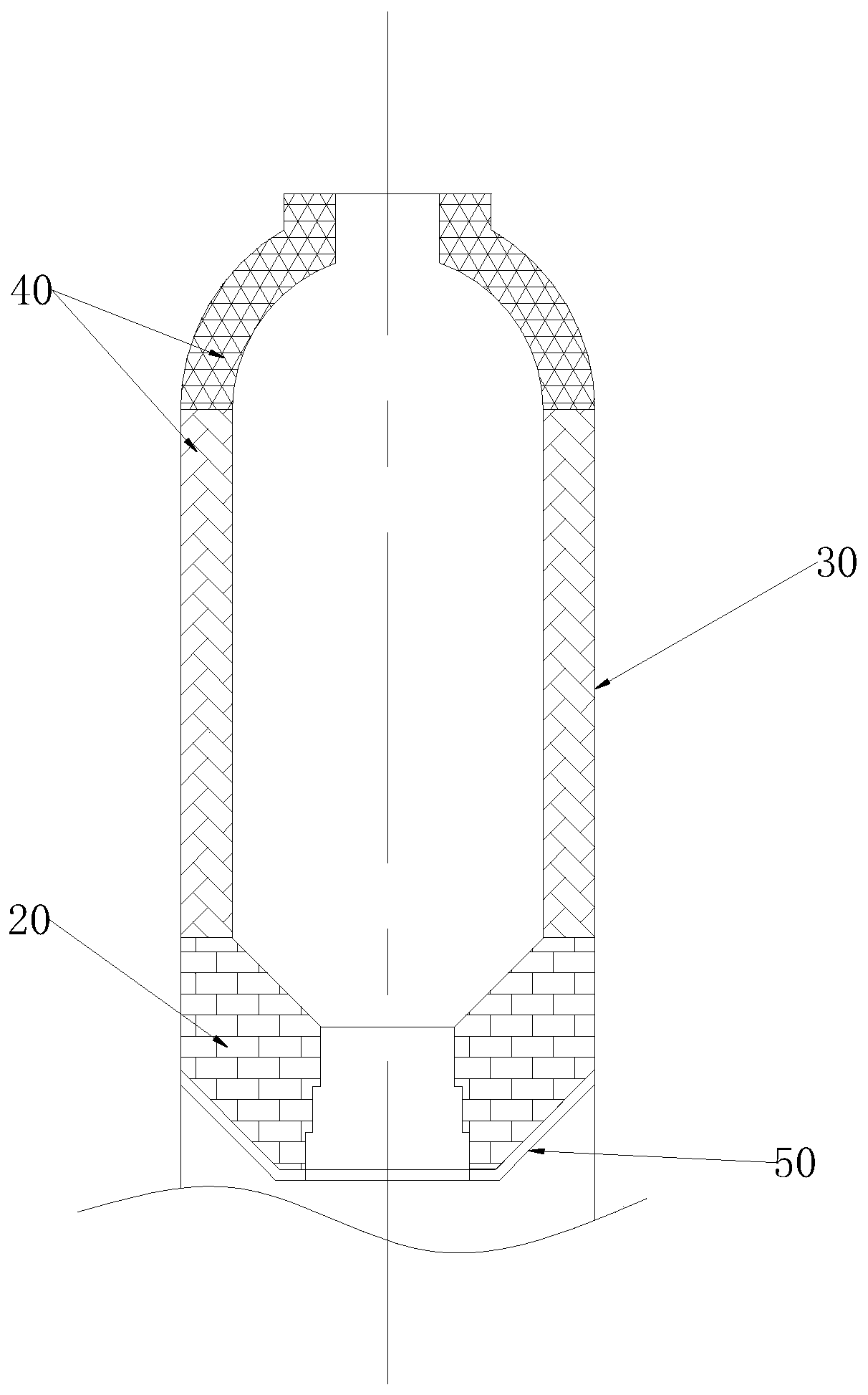

Water-cooling hopper assembly, and transformation method for existing firebrick gasifier

The embodiment of the invention discloses a water-cooling hopper assembly, and a transformation method for an existing firebrick gasifier. The water-cooling hopper assembly comprises a reducing section and a straight cylinder section located below the reducing section, the reducing section is in a big-end-up funnel shape, a water-cooling hopper water outlet connector is arranged at the upper end of the reducing section, the lower end of the reducing section is connected and communicated with the upper end of the straight cylinder section, and a water-cooling hopper water inlet connector is arranged at the lower end of the straight cylinder section. The water-cooling hopper assembly has a small size and light weight, and can conveniently enter the gasifier from a slag discharging port onlyby removing a slag breaker connected below the slag discharging port of the gasifier, so the purposes of improving the coal type adaptability of the firebrick gasifier and increasing the components ofeffective gas produced by the gasifier are achieved through optimization and transformation without cutting off the shell of the existing firebrick gasifier. Firebricks at the upper part are reservedin the transformation process, so that nearly one month taken by removing and rebuilding of the bricks can be saved, and the transformation procedure is greatly simplified.

Owner:BEIJING QING CHUANG JIN HUA TECH CO LTD

Graded air-feed dual-swirled pulverized coal industrial furnace combustor

InactiveCN102607018BWell mixedImprove heat transfer effectPulverulent fuel combustion burnersCombustion apparatusCombustorWater cooling

The invention discloses a graded air-feed dual-swirled pulverized coal industrial furnace combustor, solving the problem of lower combustion efficiency of the conventional coal industrial furnace. The graded air-feed dual-swirled pulverized coal industrial furnace combustor comprises two parts, namely a secondary air box and a graded air box which are partitioned by an annular baffle plate; a pre-combustion chamber is arranged in the region which is enclosed by the secondary air box and the graded air box; the front section of the pre-combustion chamber is cylindrical; the middle section of the pre-combustion chamber is of a divergent conical cylinder shape; the rear section of the pre-combustion chamber is a cylinder; the front section of the pre-combustion chamber is enclosed in the secondary air box, and communicated with the secondary air box through a secondary air swirler; the middle section of the pre-combustion chamber and the rear section of the pre-combustion chamber are enclosed in the graded air box, and separated from the graded air box through an annular water cooling jacket; a graded air swirler is arranged in the outlet of the pre-combustion chamber; a primary air pipe is inserted into the pre-combustion chamber after penetrating through the secondary air box; a reflective ignition gun is inserted into the pre-combustion chamber through the centre of the primary air pipe; and the ignition position of the reflective ignition gun is arranged in the centre of the pre-combustion chamber. According to the graded air-feed dual-swirled pulverized coal industrial furnace combustor, disclosed by the invention, pulverized coal and air can be better ensured to be mixed uniformly, so that a better heat-exchange effect is reached.

Owner:CHINA JILIANG UNIV

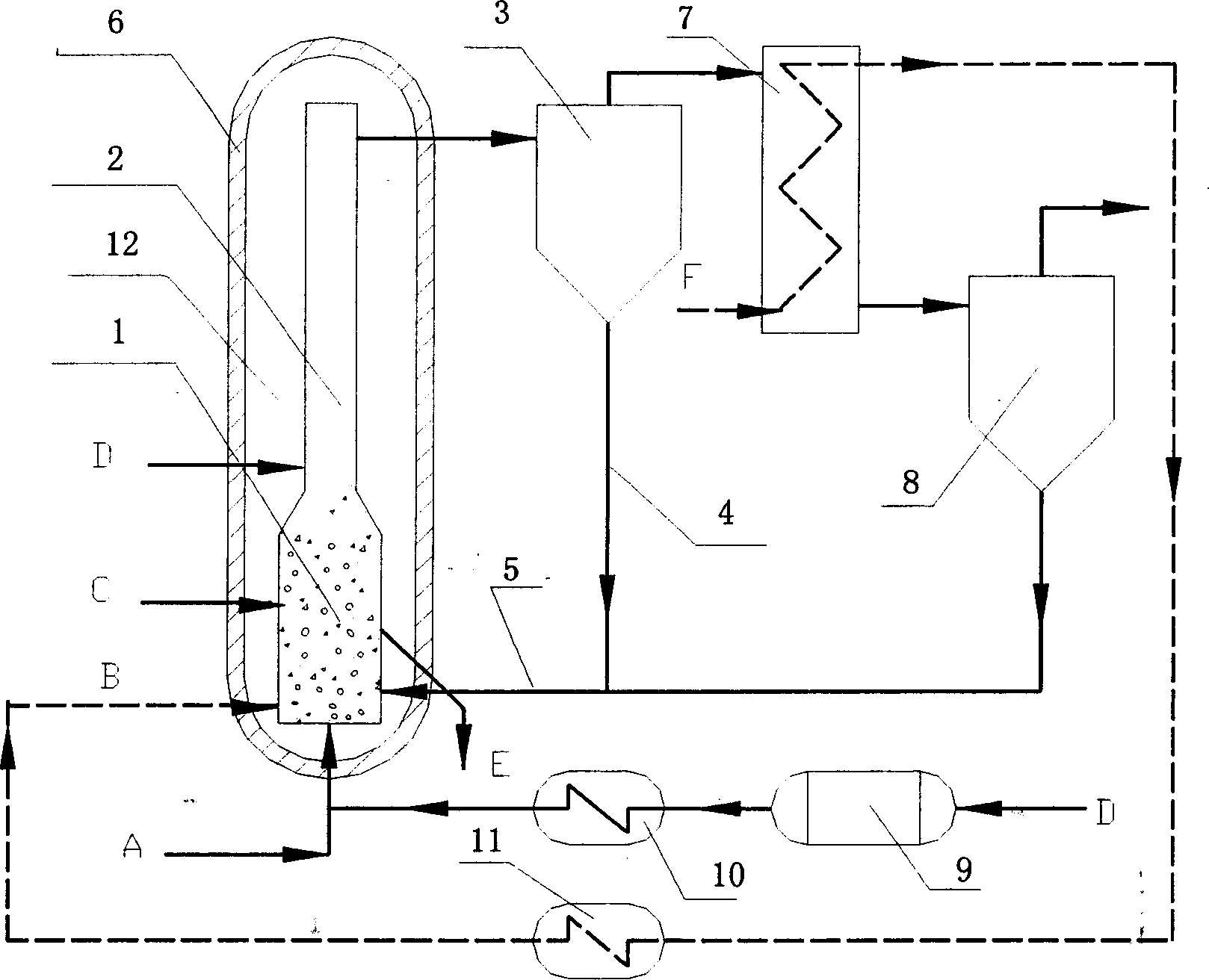

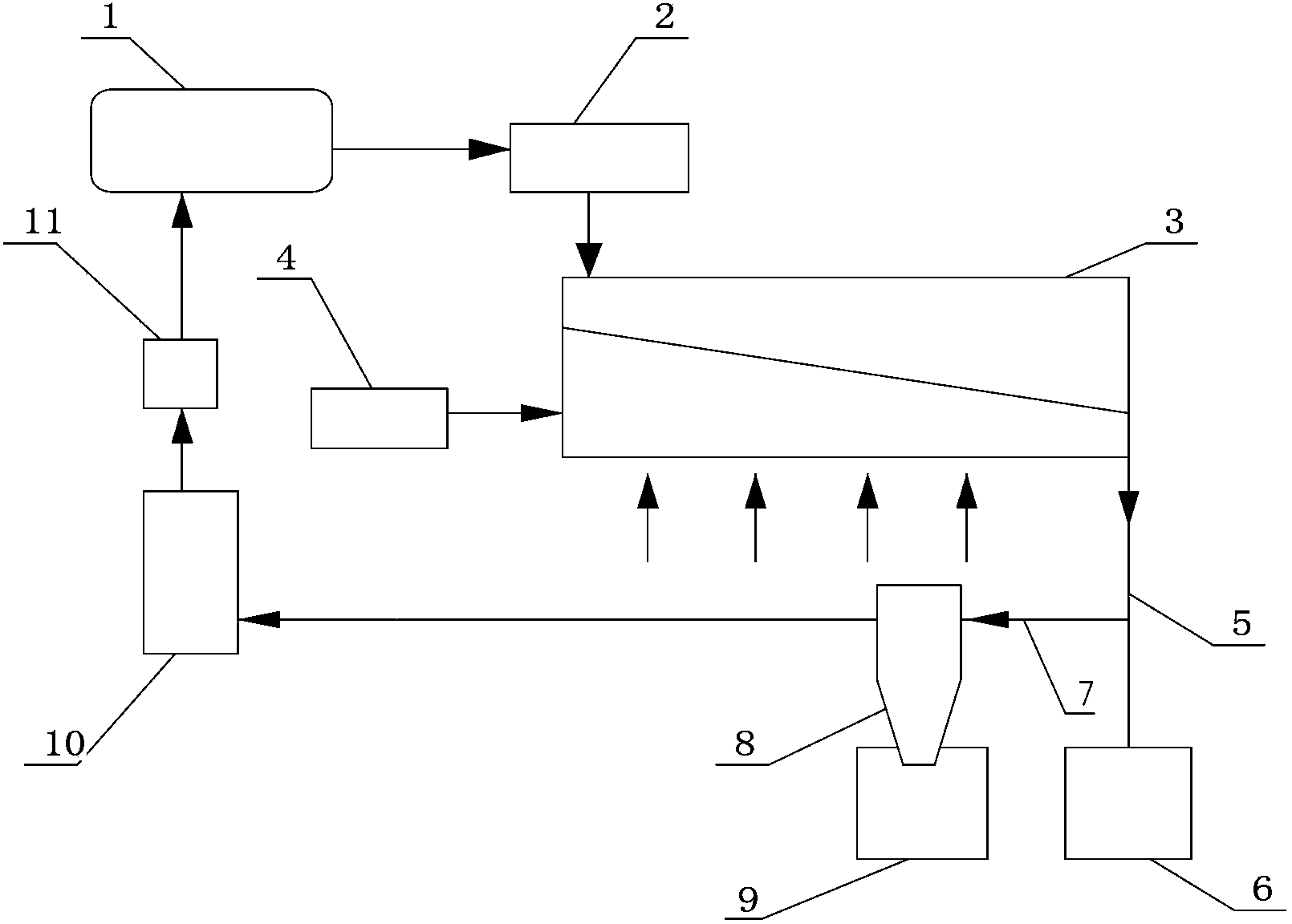

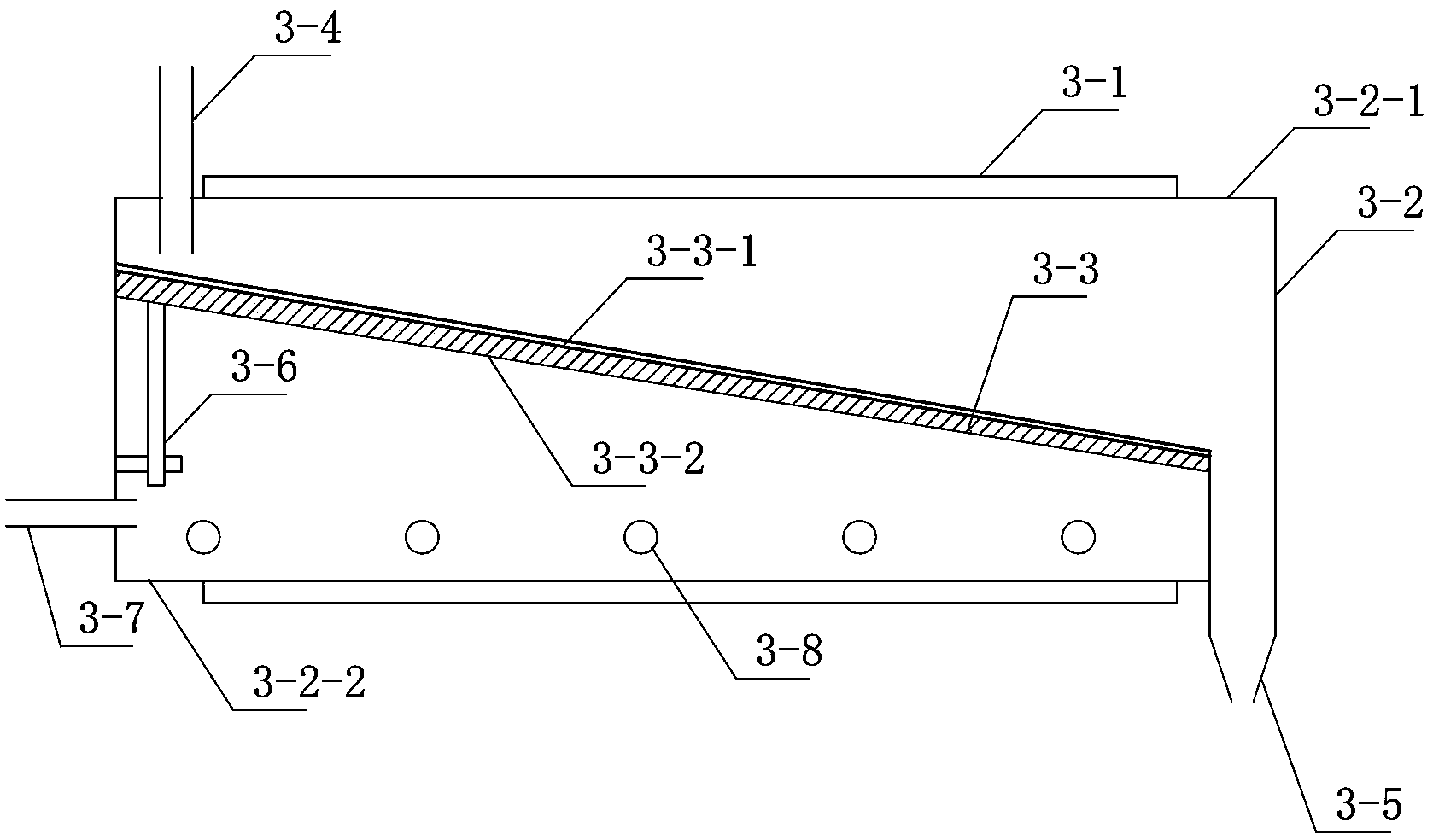

Modification quality upgrading system of brown coal

InactiveCN103160300BImprove qualityImprove removal efficiencyDirect heating destructive distillationSpecial form destructive distillationBrown coalFlue gas

The invention relates to a modification quality upgrading system of brown coal, which belongs to a brown coal quality upgrading apparatus, and solves the problem that current modification quality upgrading system removes pollutants such as sulfur and mercury with low efficiency, and generated contamination gas and dust are failed to obtain effective treatment. The modification quality upgrading system also solves the problem of ineffective utilization of boiler tail gas. The modification quality upgrading system comprises an original coal bunker, a feeding apparatus, a fluidization pyrolysis apparatus, a constant flow pump, a vertical pipeline, a first-grade quality upgrading coal bunker, a horizontal pipeline, a cyclone separator, a secondary-grade coal bunker, a gas purifying apparatus and an induced draught fan. According to the invention, brown coal in the original coal bunker is predried through flue gas, and is sent to the fluidization pyrolysis apparatus through the feeding apparatus for pyrolysis quality upgrading, the coal after quality upgrading can be separated and collected through two-grade quality upgrading coal bunkers and the cyclone separator, the pyrolysis flue gas flows through the gas purifying apparatus and is introduced in the original coal bunker as a heat source for predrying and dehydrating of raw coal. The modification quality upgrading system of brown coal has the advantages of high reliability and strong coal adaptability, enhance the quality of the quality upgraded coal, and increase the cooperation removal efficiency of the pollutants such as sulfur and mercury.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com