Patents

Literature

56results about How to "Extend warm-up time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

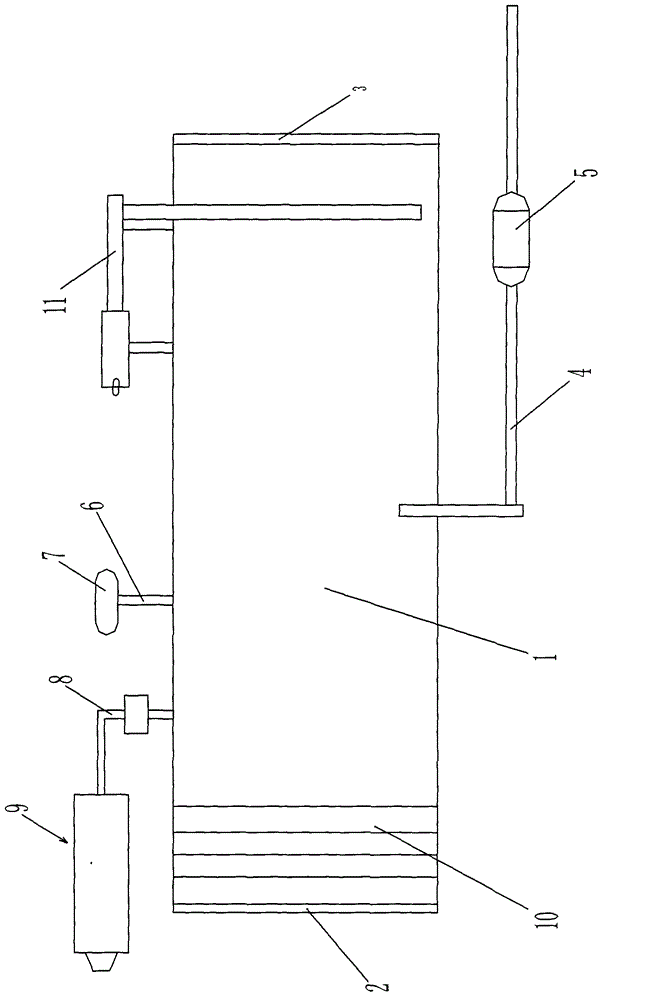

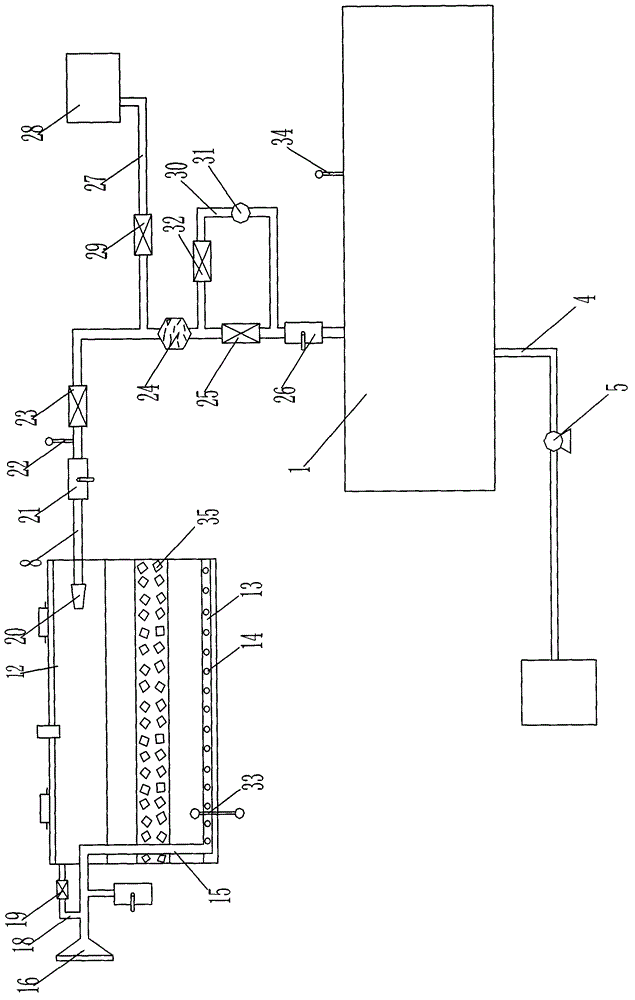

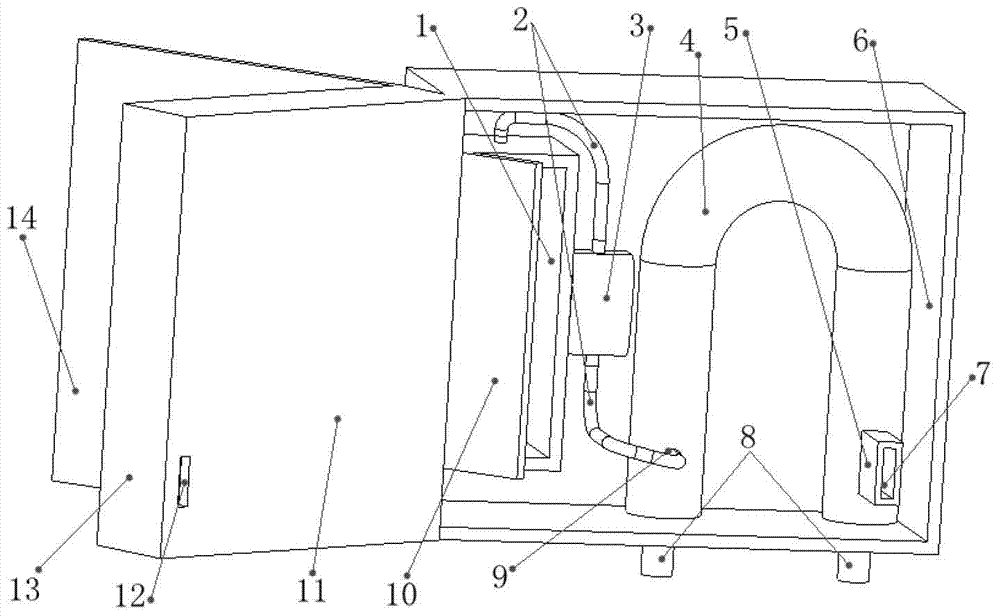

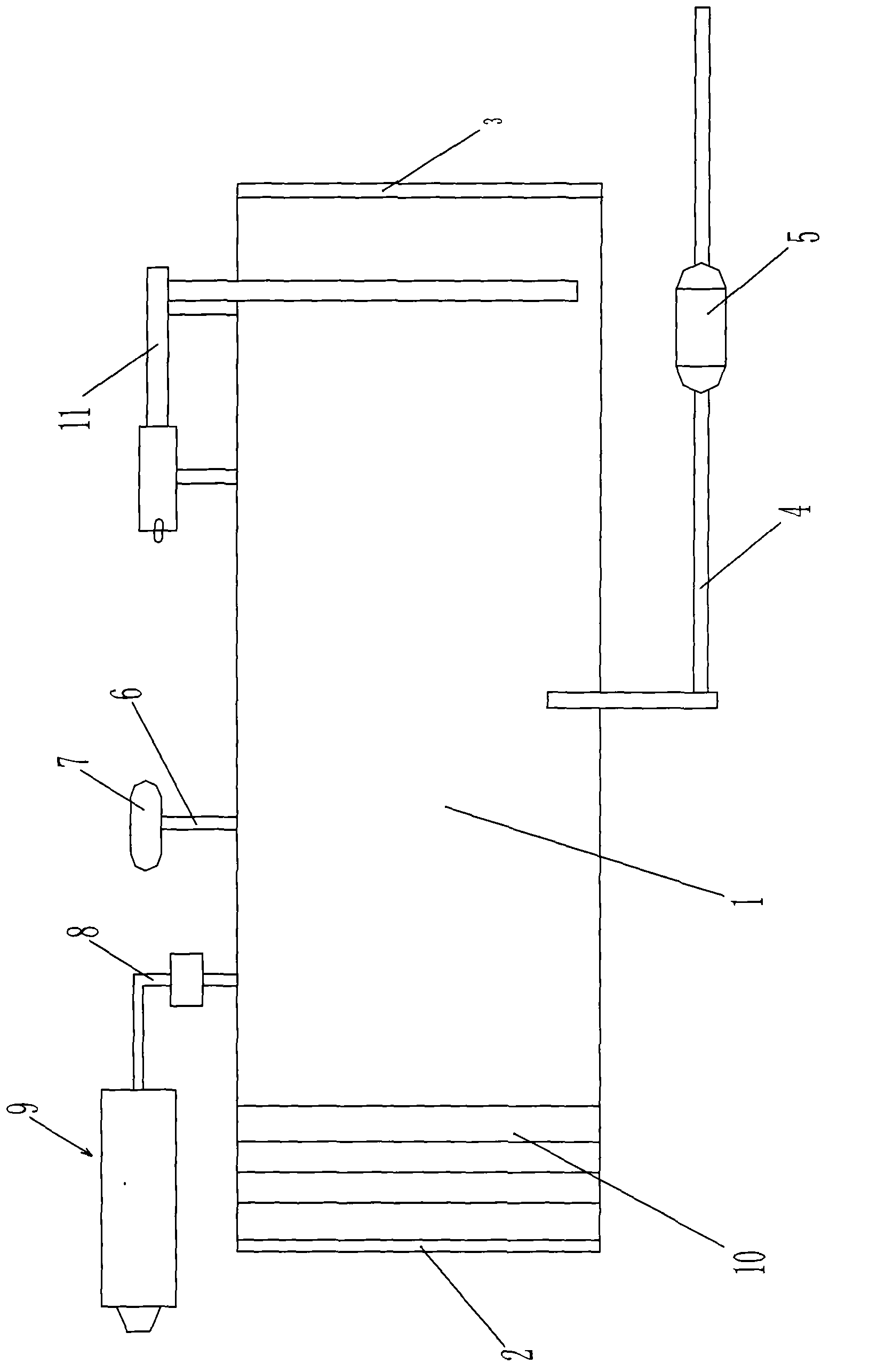

Ethylene oxide preheating, sterilization and resolution integrated cabinet and sterilizing method

ActiveCN102743773AReduce construction areaAvoid lossLavatory sanitoryChemicalsEthylene oxideWater jacket

The invention relates to an ethylene oxide preheating, sterilization and resolution integrated cabinet and a sterilizing method. The integrated cabinet comprises a cabinet body, wherein a sealing door is arranged on the front part of the cabinet body; a cavity in the cabinet body is connected with a vacuum pump through a vacuumizing pipeline; the cavity in the cabinet body is connected with a humidifying device through a humidifying pipeline; the cavity in the cabinet body is connected with wet and hot air making devices through wet and hot air delivery pipelines; a heating water jacket is arranged outside the cabinet body; a circulating air pipeline is arranged on the outer side of the cabinet body; a fan is connected in series to the circulating air pipeline; an air inlet of the circulating air pipeline is arranged on one side in the cabinet body; an air outlet of the circulating air pipeline is arranged on the other side in the cabinet body; and the cabinet body is connected with an ethylene oxide container through a pipeline provided with a valve. The ethylene oxide preheating, sterilization and resolution integrated cabinet has the advantages of high operating efficiency, few matched facilities, low fault rate, short construction period, low daily using cost and low energy loss, and can reduce pollution to human body and environment and improve the comprehensive benefit by over 40 percent.

Owner:北京长丰诚耀技术服务中心

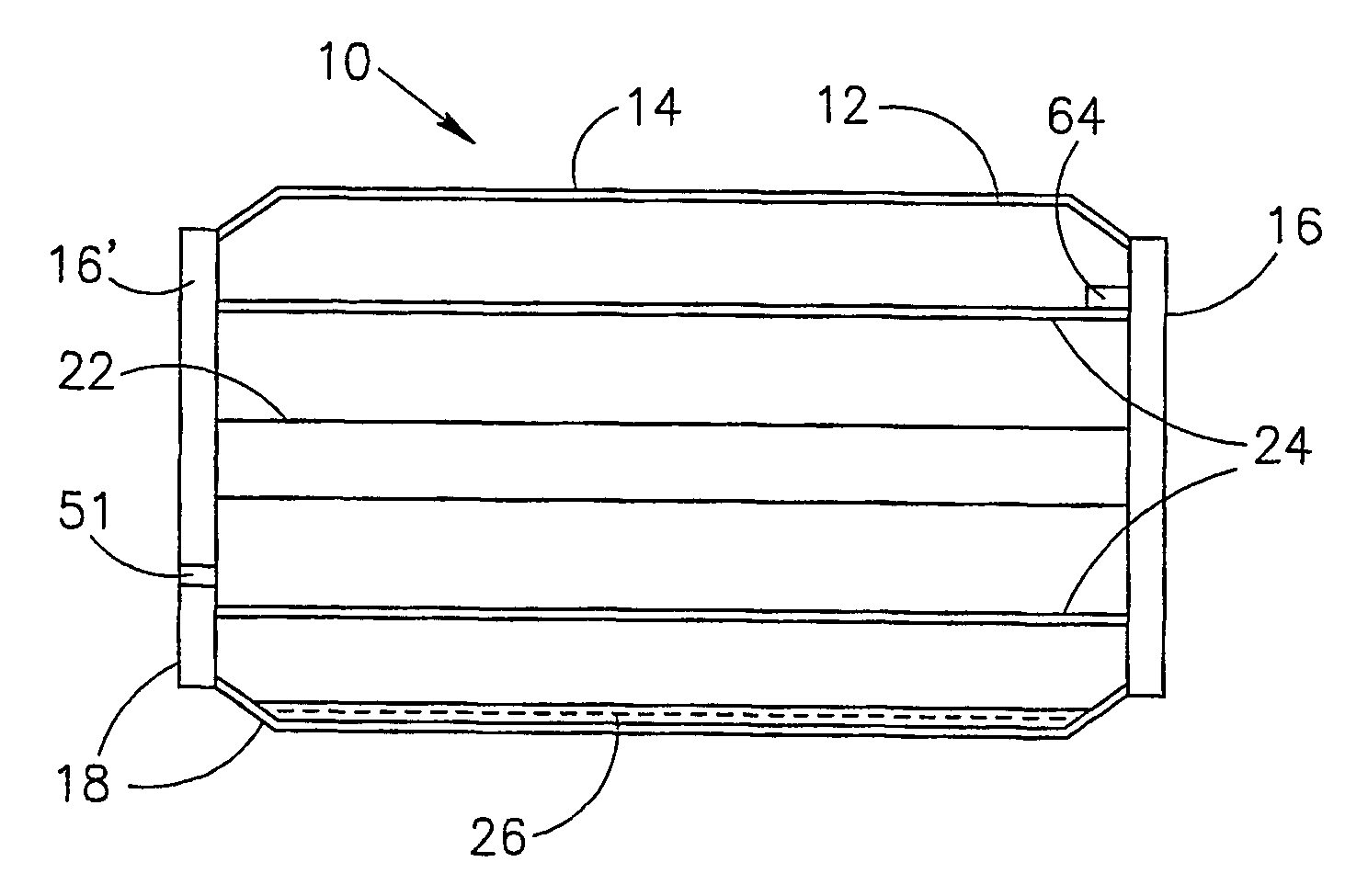

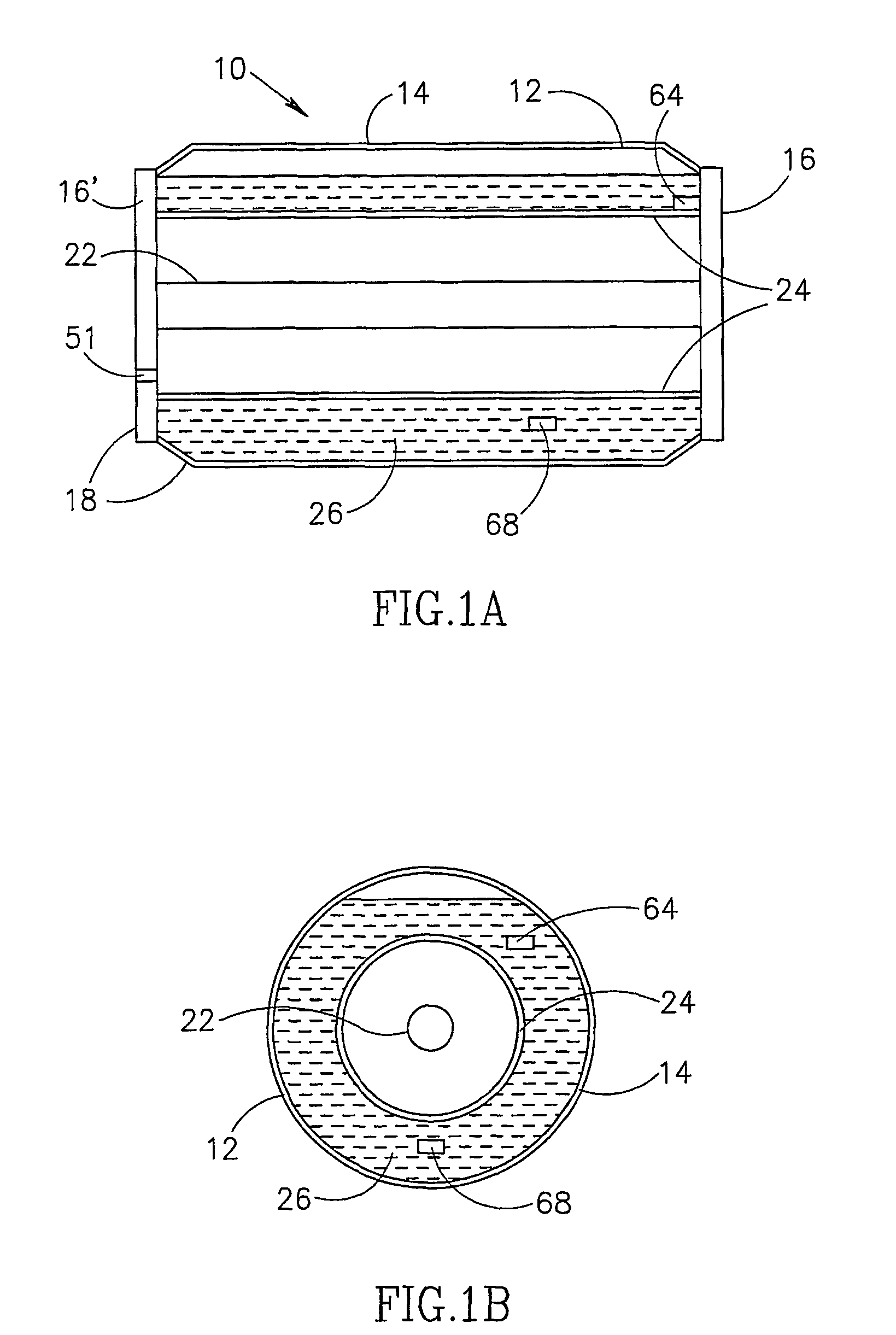

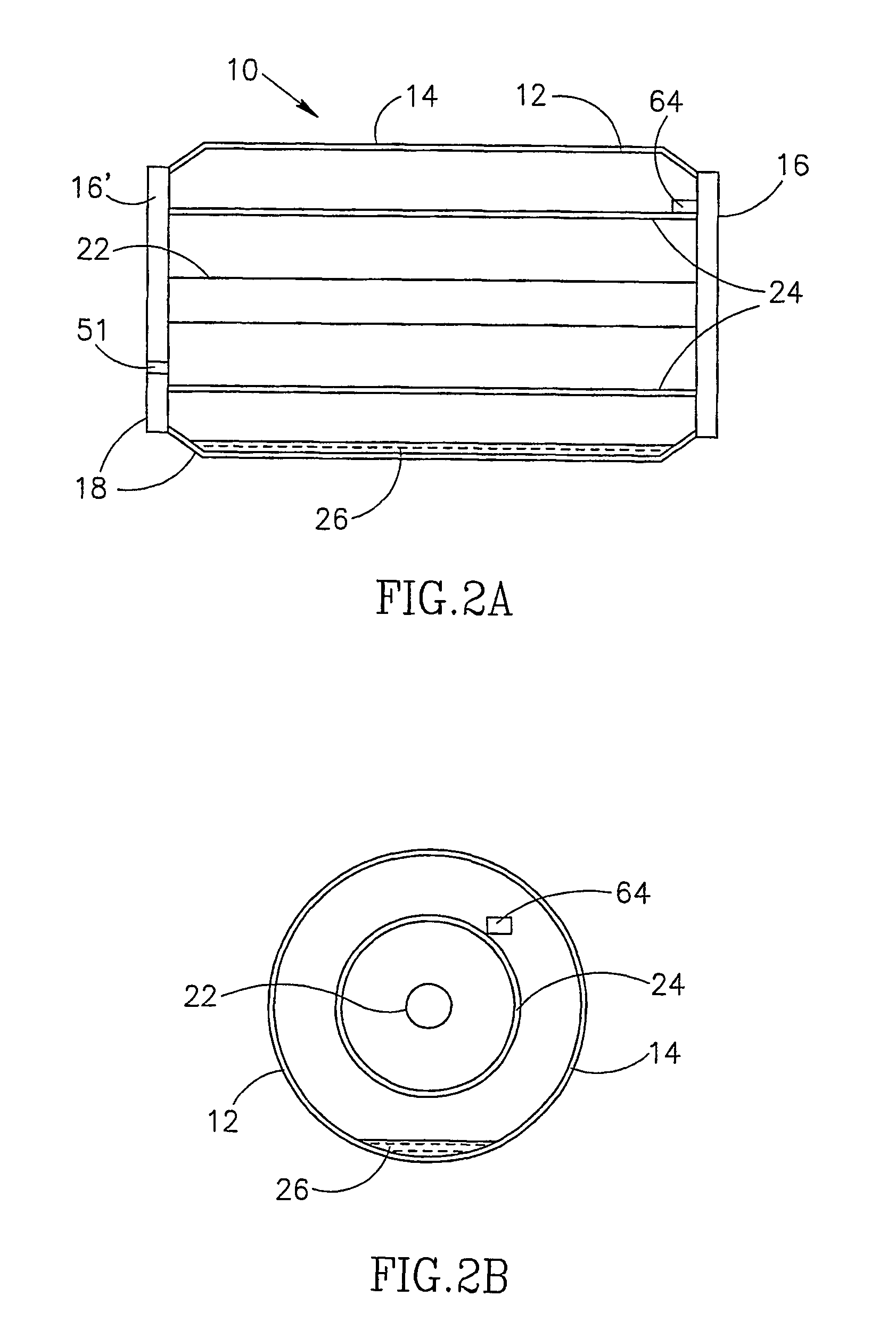

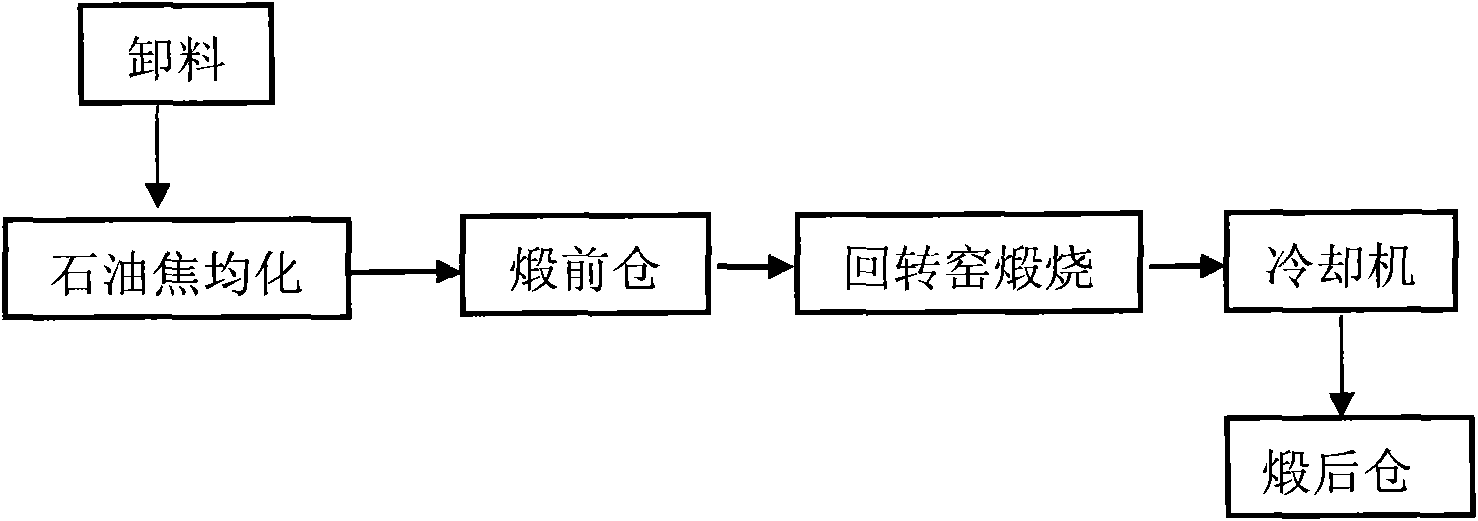

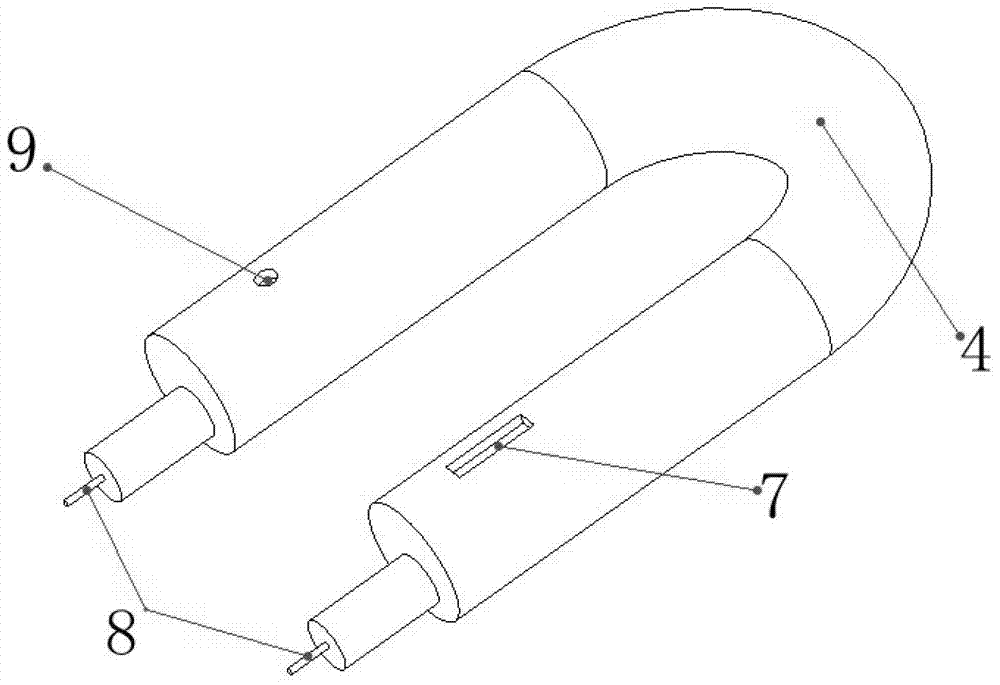

Fuser and intermediate transfer drums

InactiveUS7092667B1Extend warm-up timeIncrease the amount of fluidOhmic-resistance heatingElectrographic process apparatusEngineeringOperating temperature

Apparatus for transferring visible images from a first surface to a second surface and / or for fusing or fixing a visible image to a substrate, comprising: a cylindrical member secured between two round end plates to form a cylindrical structure; a volatile liquid incorporated within the cylindrical structure in a cavity, at least one wall of which is thermally connected to the cylindrical member; and a heater that heats the liquid to an operating temperature, wherein the amount of the volatile liquid is such that all of the volatile liquid would be evaporated at a temperature that is less than about 20° C. above the operating temperature.

Owner:HEWLETT PACKARD INDIGO BV

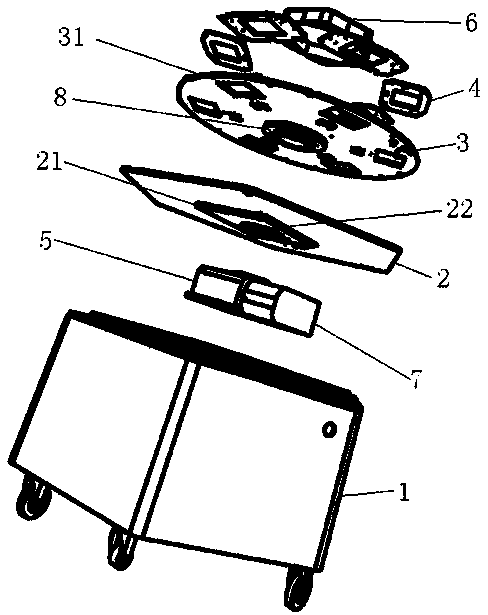

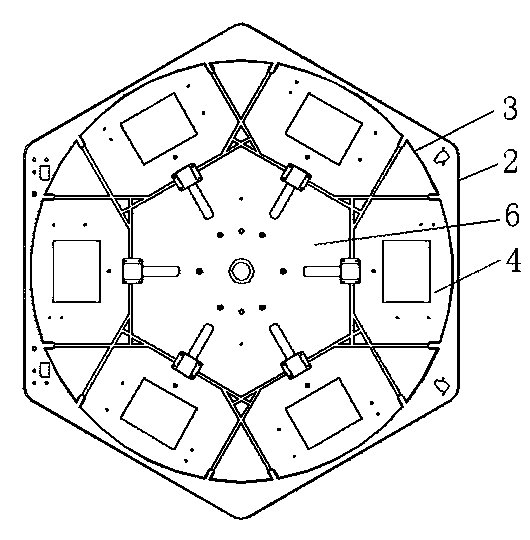

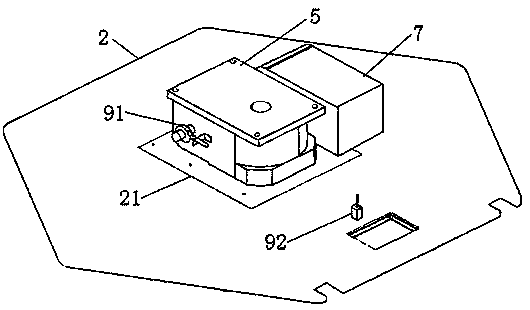

Multistage rotary-disk mechanism of CCD detection machine

InactiveCN104390764AImprove efficiencyImprove compatibilityTesting optical propertiesElectric machineEngineering

The invention discloses a multistage rotary-disk mechanism of a CCD detection machine. The rotary-disk mechanism comprises a machine frame, a rotary disk, a plurality of station jigs, a rotary disk supporting plate and a divider. The rotary disk supporting plate is mounted on the machine frame; the rotary disk is fixedly arranged on the rotary disk supporting plate through a bearing; the rotary disk is electrically connected with the divider; the divider is driven by a motor to drive the rotary disk to rotate on the rotary disk supporting plate; a plurality of stations are evenly distributed in the peripheral direction of the rotary disk; and the station jigs are fixed to the stations respectively. Through the mode above, the number of the stations on the rotary disk can be increased; preheating time of a detected product is increased; work efficiency of the machine is improved; output is improved; and labor intensity is reduced.

Owner:RADIANT OPTO ELECTRONICS NANJING

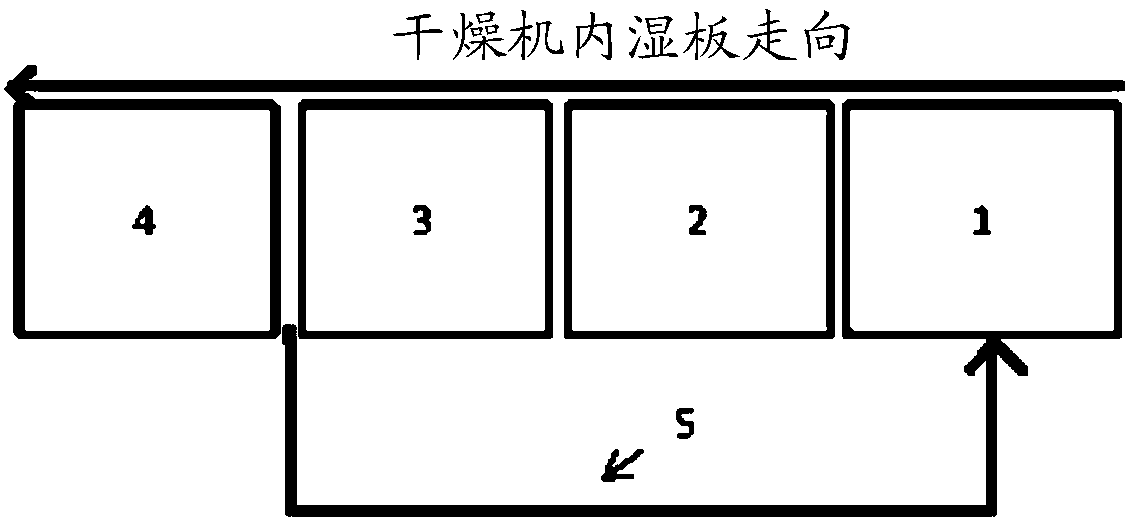

Gypsum board drying machine and application thereof

ActiveCN110645772AReduce pittingImprove appearance qualityDrying gas arrangementsCeramic shaping apparatusExhaust fumesEngineering

The invention relates to a gypsum board drying machine and an application thereof. The drying machine comprises an inlet preheating section, a drying machine first area, a drying machine second ares and a drying machine third area which are sequentially arranged, and further comprises a second heat exchanger, a second preheating fan, a second waste gas fan and a hot air pipeline, wherein the second heat exchanger is arranged at the joint of the drying machine second area and the drying machine third area, the second preheating fan is connected with the second heat exchanger and is used for blowing external air into the second heat exchanger, the second waste gas fan is connected with the drying machine second area and the second heat exchanger and is used for blowing wet hot gas dischargedfrom the drying machine second area into the second heat exchanger, so that the wet heat gas and the external air are subjected to heat exchange in the second heat exchanger, and the hot air pipelineis connected with the inlet preheating section and the second heat exchanger and is arranged to introduce hot air obtained after heat exchange into the inlet preheating section. The gypsum board drying machine has the advantages that the problem of pits in a gypsum board surface can be effectively solved, meanwhile, the production efficiency is improved, the energy consumption is reduced, and theproduction cost is reduced.

Owner:HUAINAN BEIXIN BUILDING MATERIAL +1

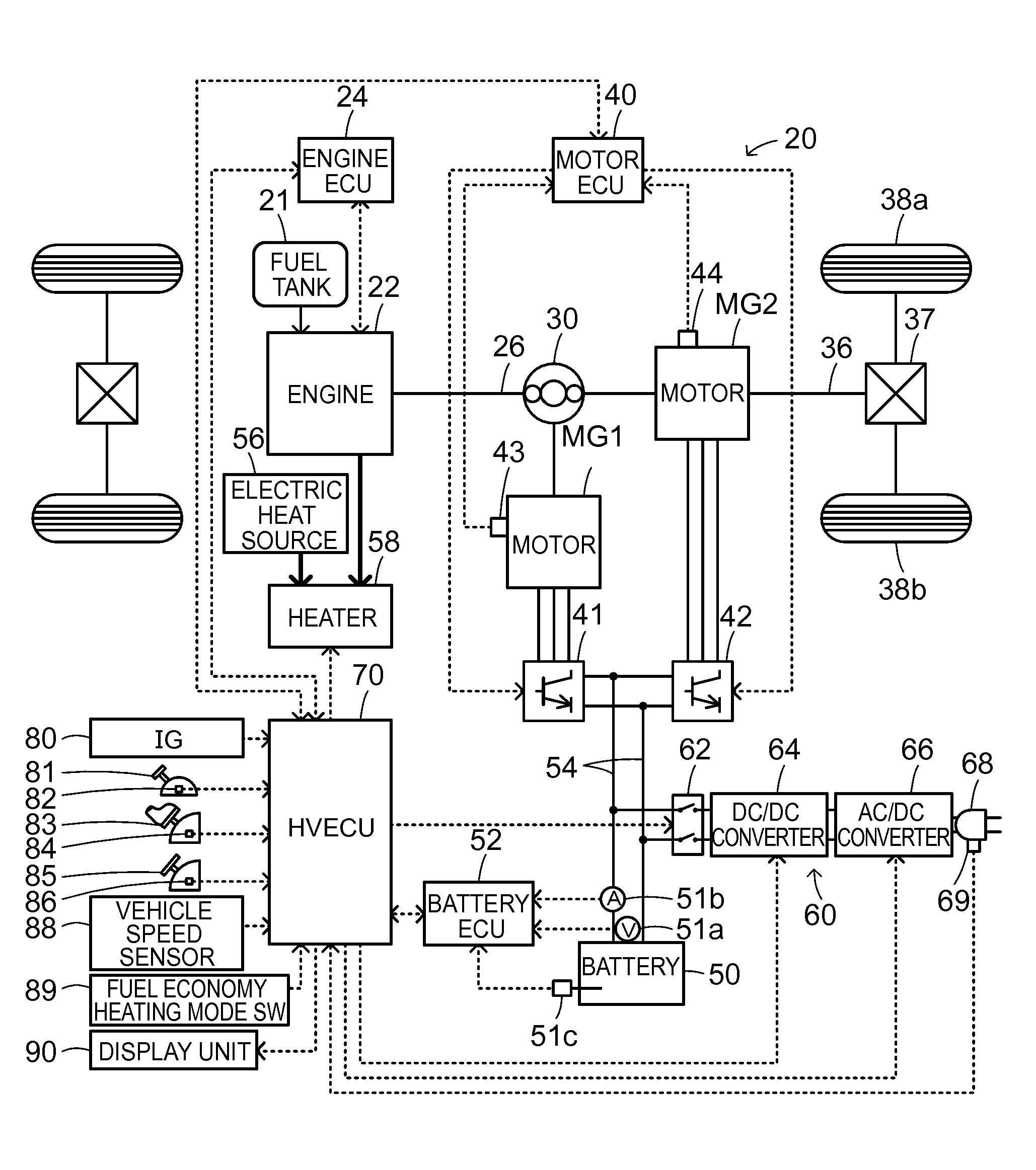

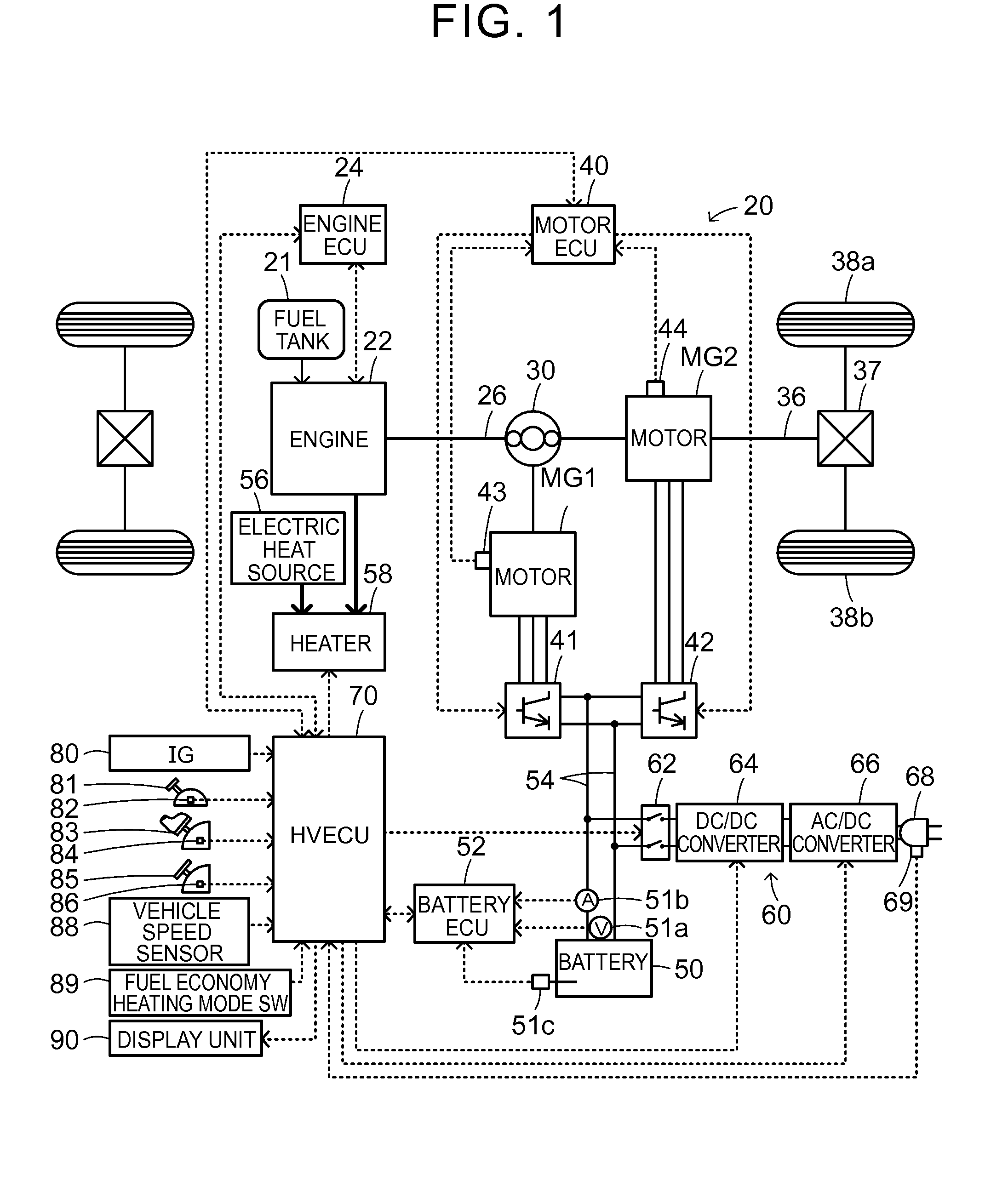

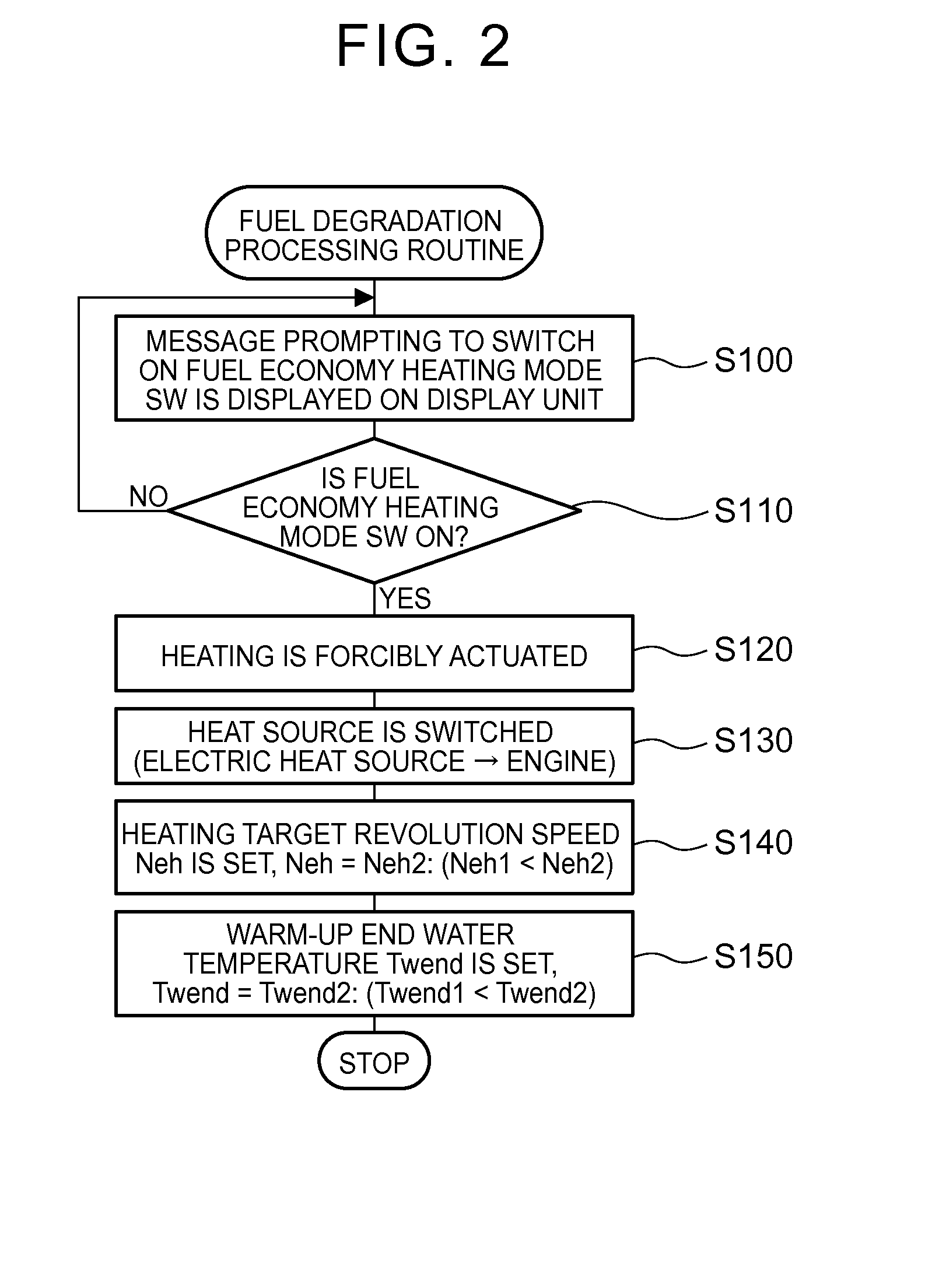

Control apparatus for hybrid vehicle

InactiveUS20140288740A1Increase consumptionExtend warm-up timeHybrid vehiclesDigital data processing detailsHybrid vehicleControl equipment

A control apparatus for a hybrid vehicle includes an engine for traveling, a motor for traveling, and a battery exchanging electric power with the motor. the control apparatus including: a heater is configured to perform heating inside a cabin of the hybrid vehicle by using the engine or an electric heat source as a heat source; and a controller is configured to operate the engine intermittently, the controller is configured to select the heat source for the heater, the controller is configured to determine whether or not a fuel for the engine is degraded when the engine is stopped, and the controller is configured to start the engine and select the engine as the heat source when the controller determines that the fuel is degraded.

Owner:TOYOTA JIDOSHA KK

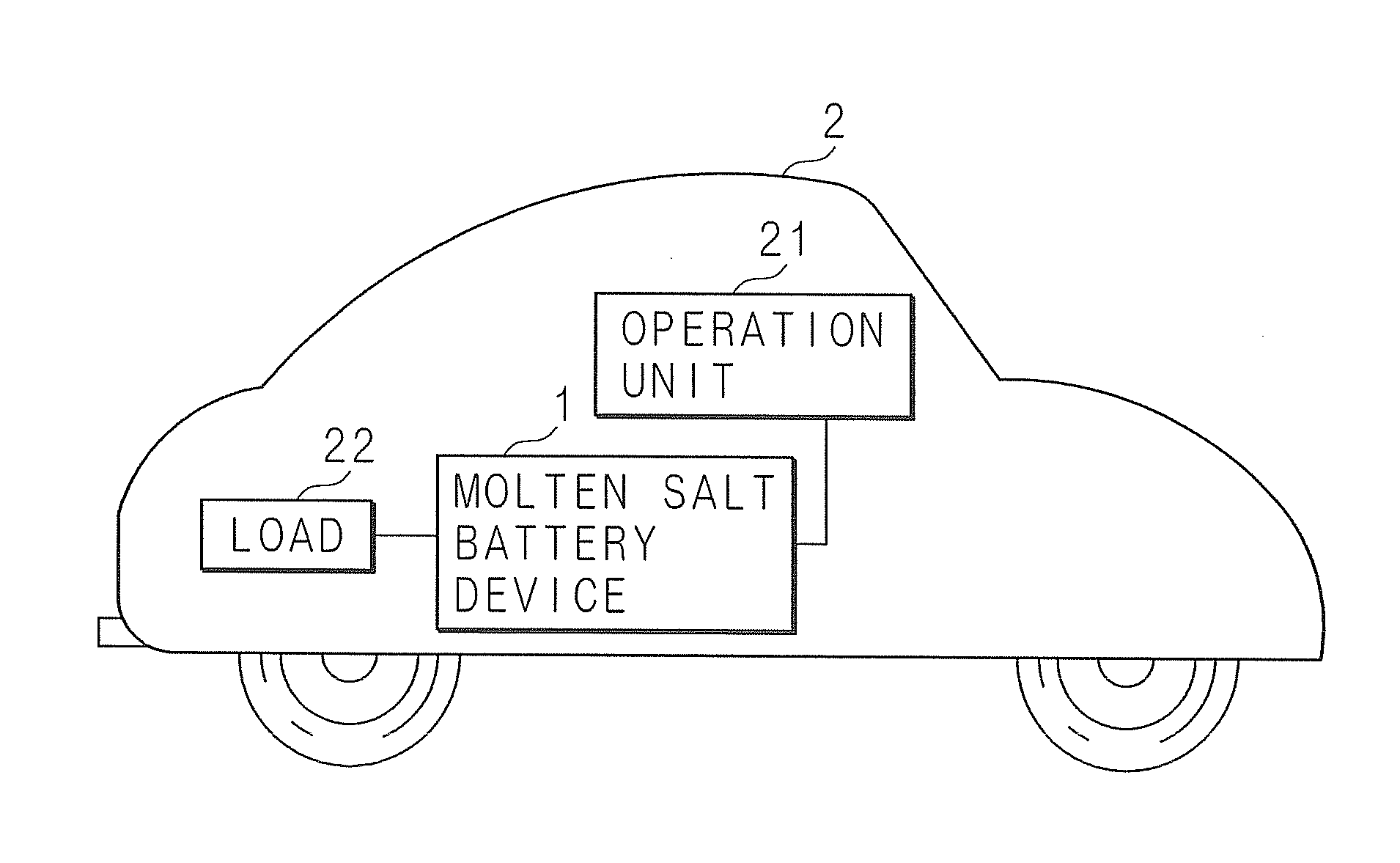

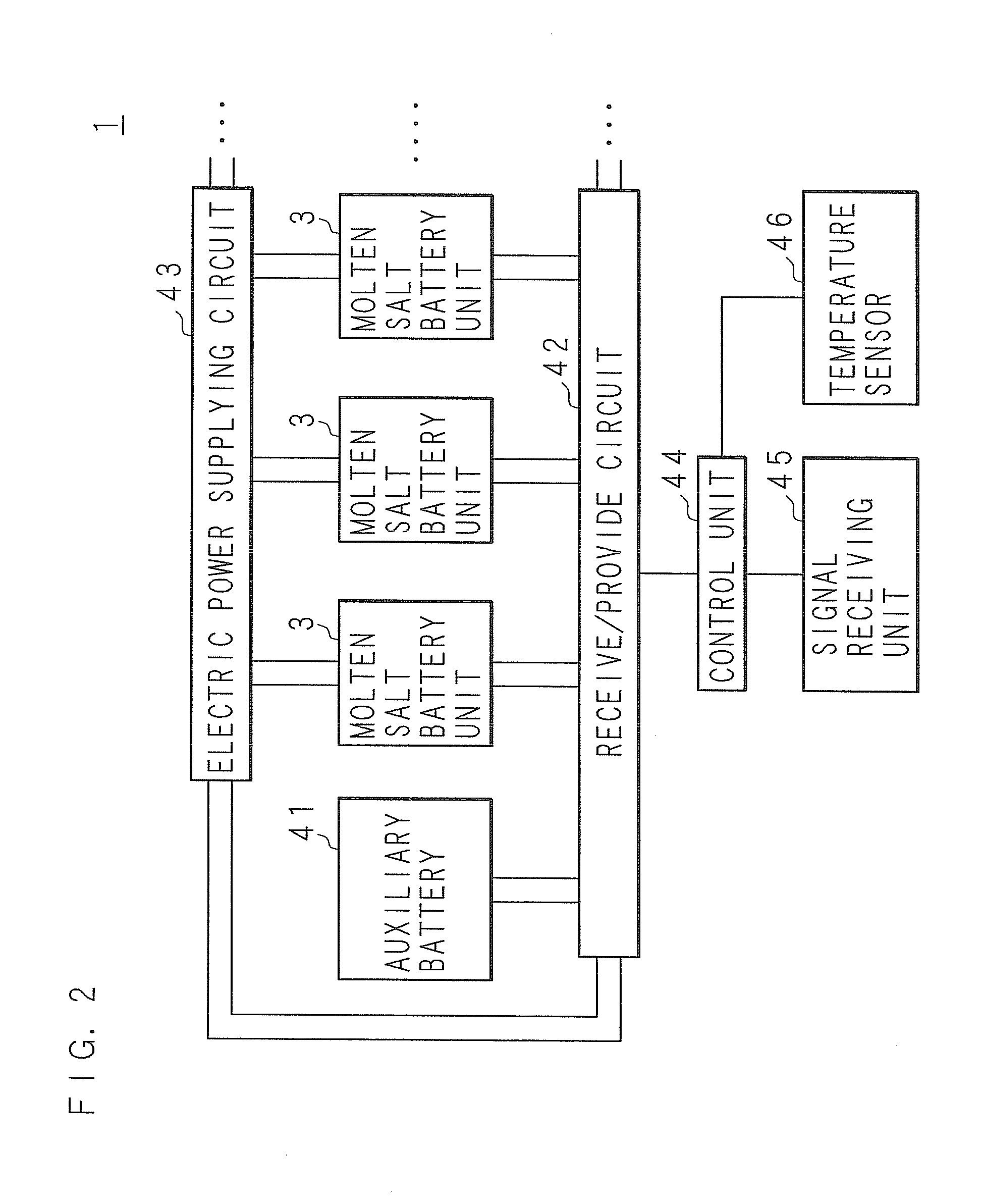

Molten salt battery device and control method for molten salt battery device

InactiveUS20140272486A1Increase capacityExtend warm-up timeBatteries circuit arrangementsCell temperature controlElectric power systemRoom temperature

A molten salt battery device includes: a plurality of molten salt battery units; and an auxiliary battery (an electric power source) capable of operating at room temperature. Each molten salt battery unit includes a heater. At the time of startup, the auxiliary battery supplies electric power to the heater of one molten salt battery unit so that the one molten salt battery unit is heated by the heater and thereby allowed to operate. The one molten salt battery unit allowed to operate supplies electric power to the heaters of the other molten salt battery units so that the other molten salt battery units are heated by the heaters and thereby allowed to operate. The molten salt battery is easily heated without the necessity of a large amount of energy and hence the molten salt battery device starts up in a short time.

Owner:SUMITOMO ELECTRIC IND LTD

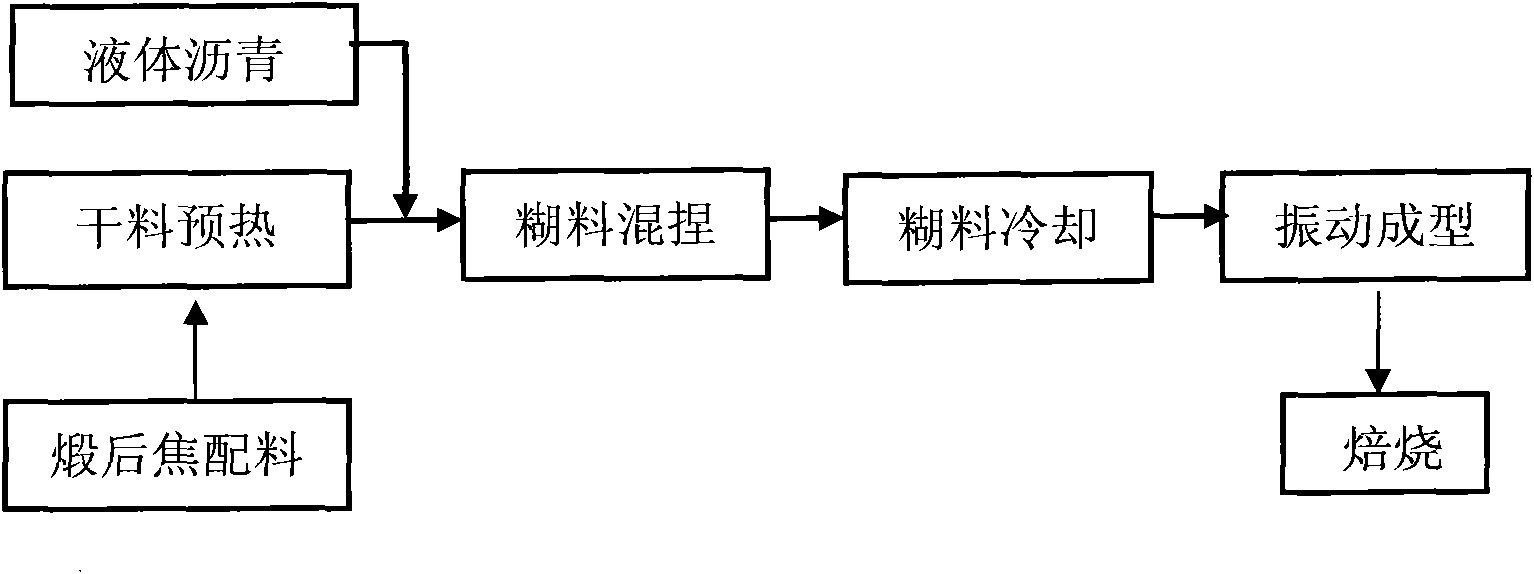

Method for increasing true density of calcined coke for prebaked anode for aluminum electrolysis

InactiveCN101982407ACalcination temperature is highHigh desulfurization rateElectrolysisCompressive strength

The invention relates to a method for increasing the true density of calcined coke for a prebaked anode for aluminum electrolysis. The method is characterized by comprising the following steps: quantitatively feeding petroleum coke from a storage bin of materials to be calcined into a rotary kiln by means of a weighing system; gradually heating the raw petroleum coke in the rotary kiln to 1300-1500 DEG C, calcining for 70-100 minutes to effectively dewater;thoroughly separating out volatile constituents, introducing the calcined coke into a cooling machine;and directly spraying water to cool the calcined coke in the cooling machine so as to obtain the calcined coke for a prebaked anode for aluminum electrolysis. The invention increases the calcining temperature to 1300-1500 DEG C, while the temperature in the traditional process is 1250 DEG C; the desulfurization rate is increased to 20% or so; the calcining zone is shortened, burning loss of the petroleum coke is reduced, the extraction yield is increased by 1.5%, and 4630 tons of petroleum coke can be saved every year; the preheating time of the petroleum coke in the kiln can be greatly prolonged, so that the volatile constituents can be separated out sufficiently; and the volume density, the compression strength, the thermal shock resistance and the conductibility of the prebaked anode can be obviously improved.

Owner:YUNNAN YUANXIN CARBON CO LTD

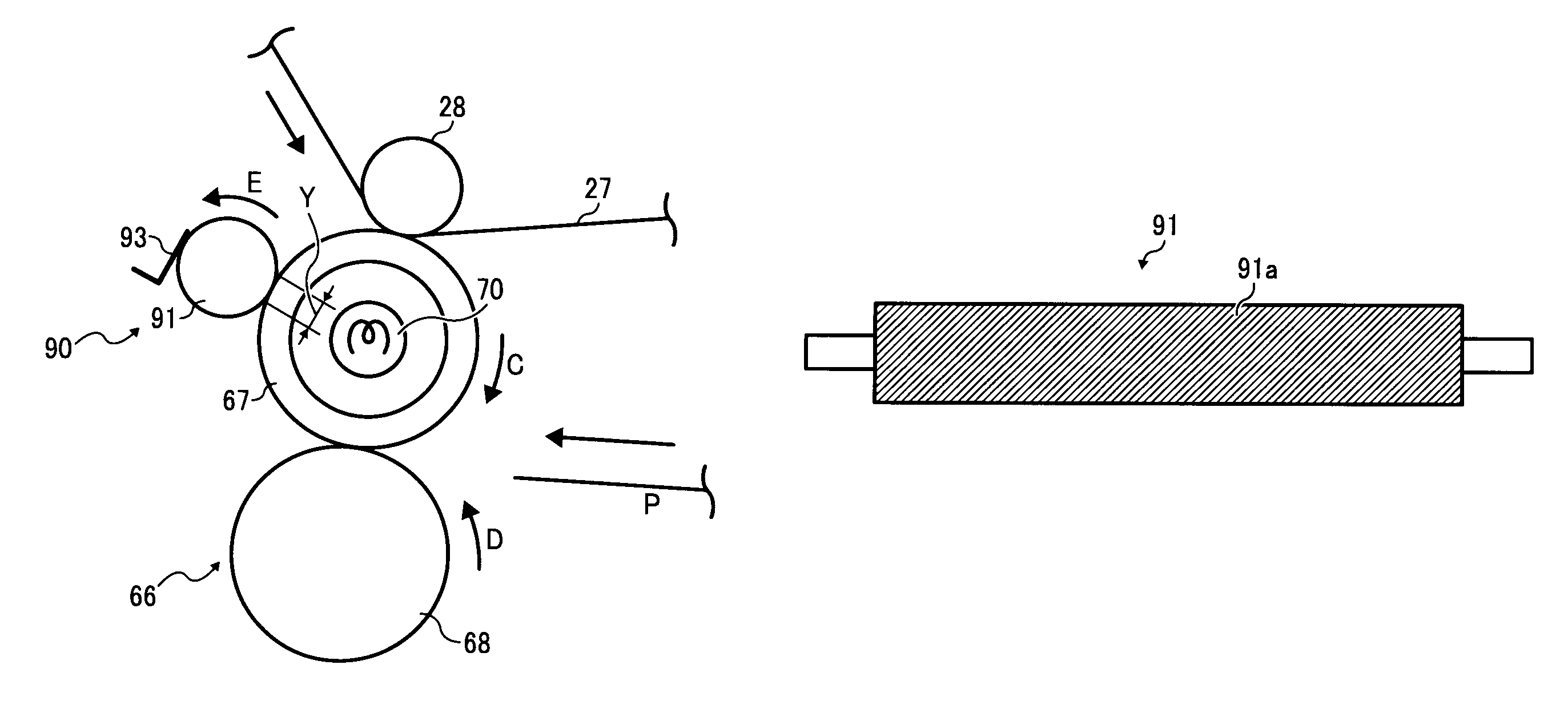

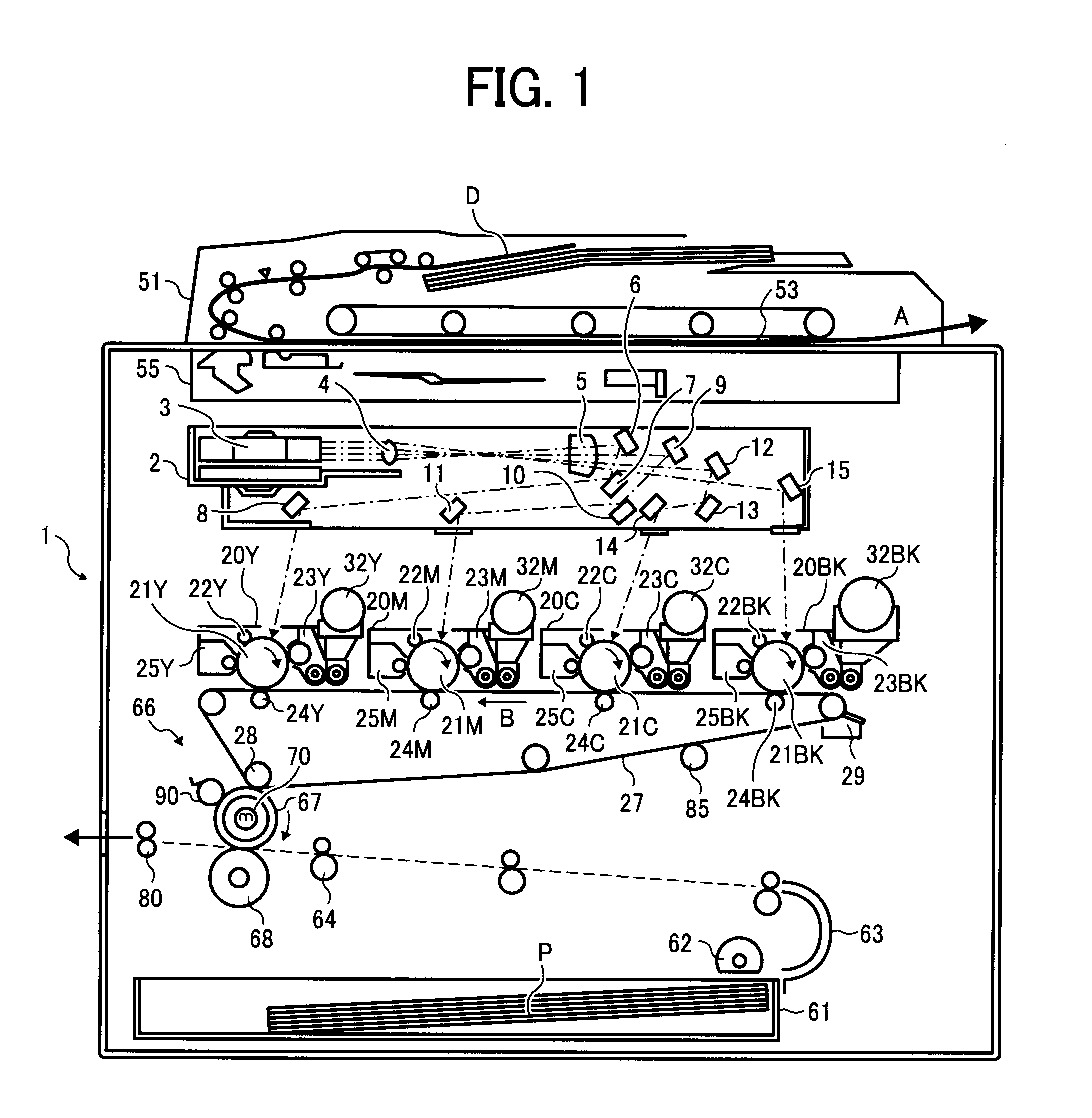

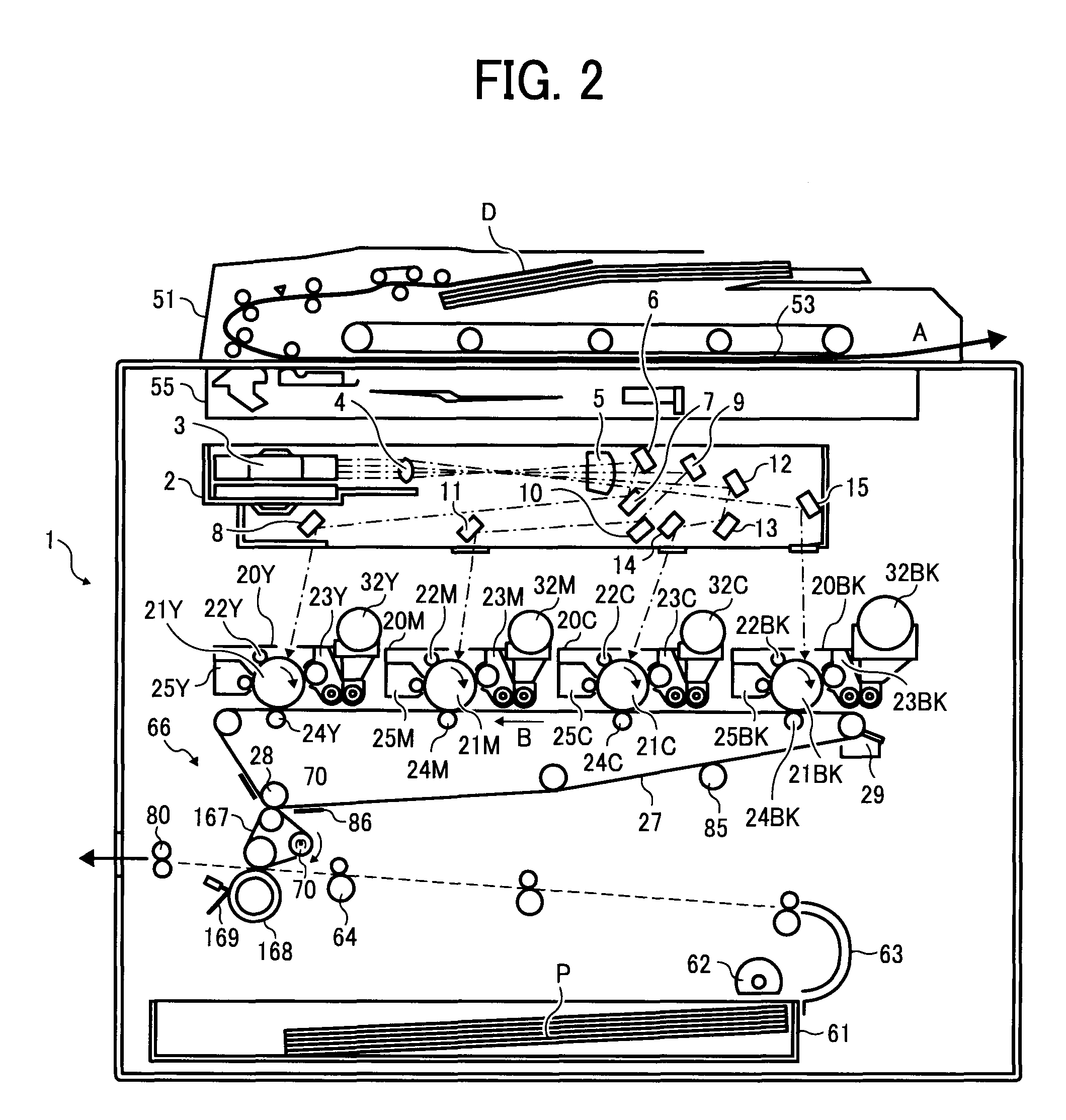

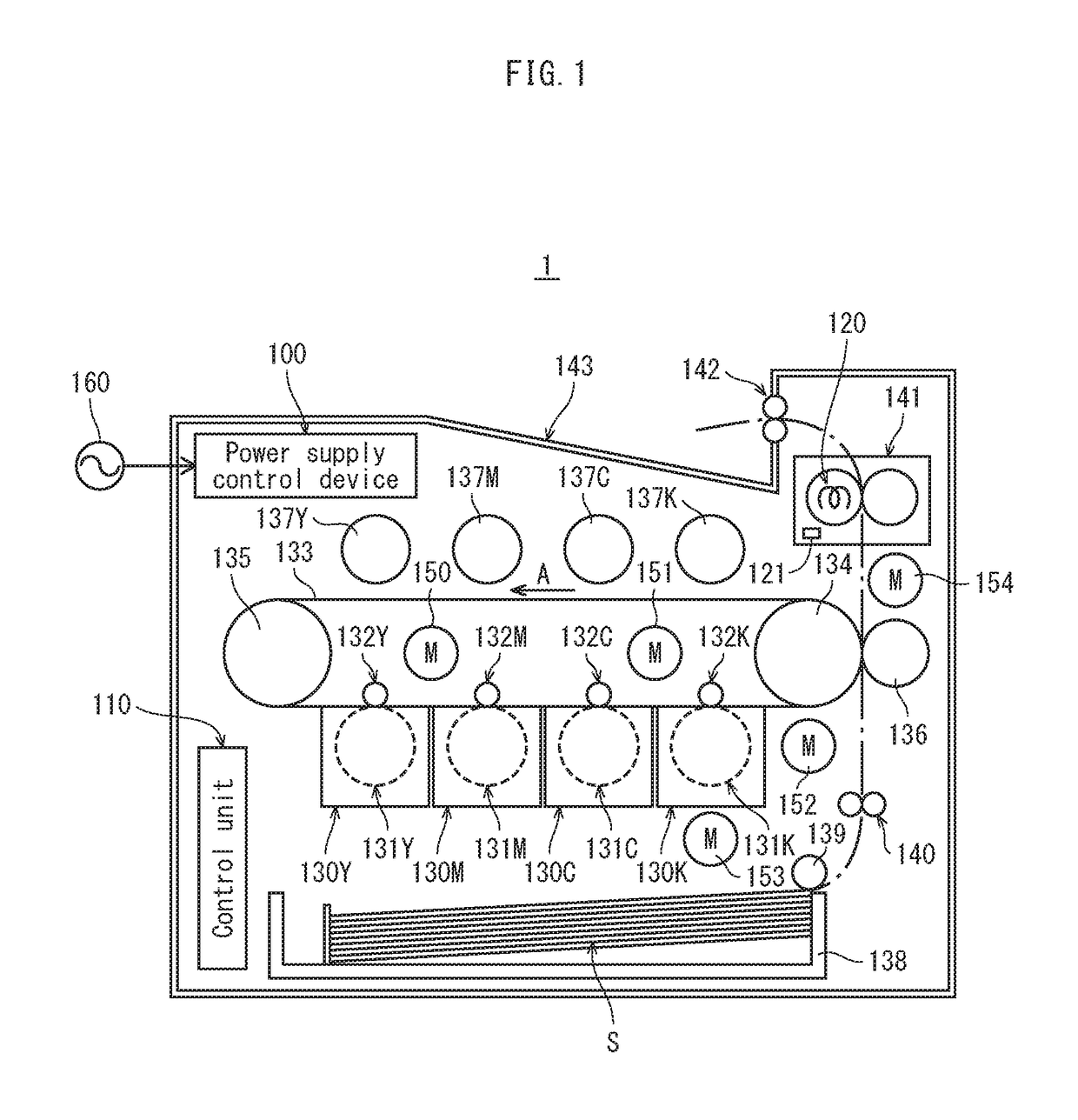

Cleaning device, fixing device, and image forming apparatus

InactiveUS7869752B2Reliably removedExtend warm-up timeElectrographic process apparatusEngineeringMechanical engineering

Owner:RICOH KK

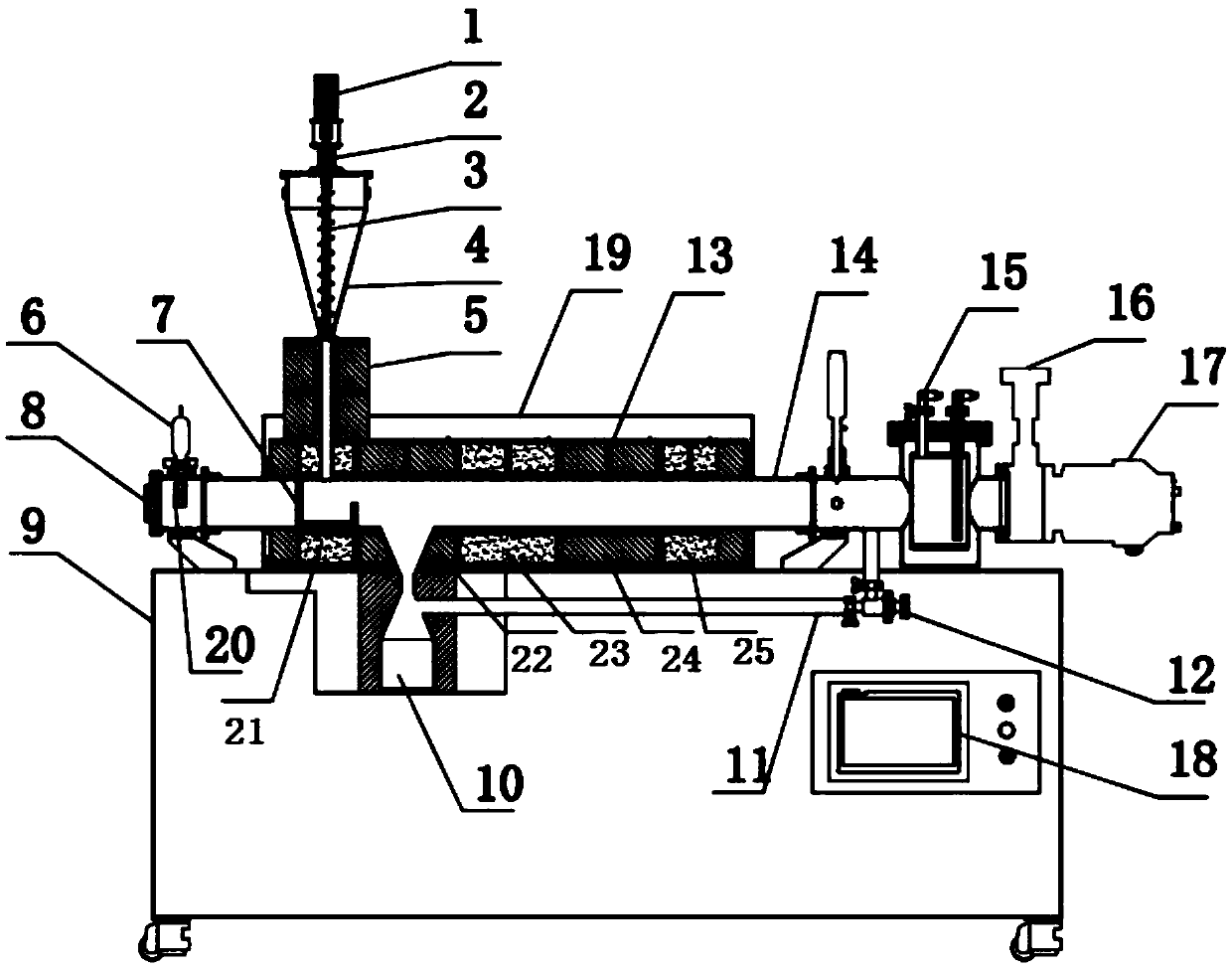

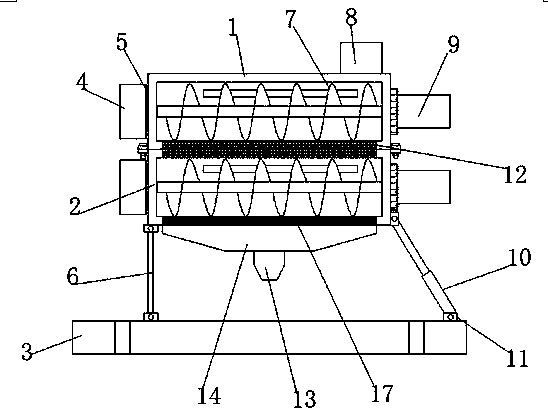

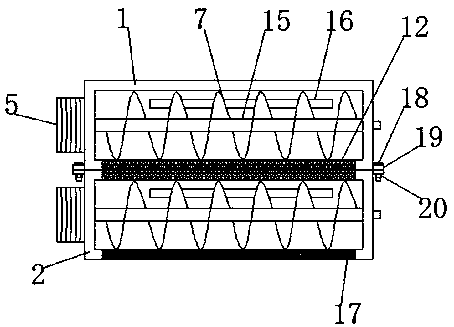

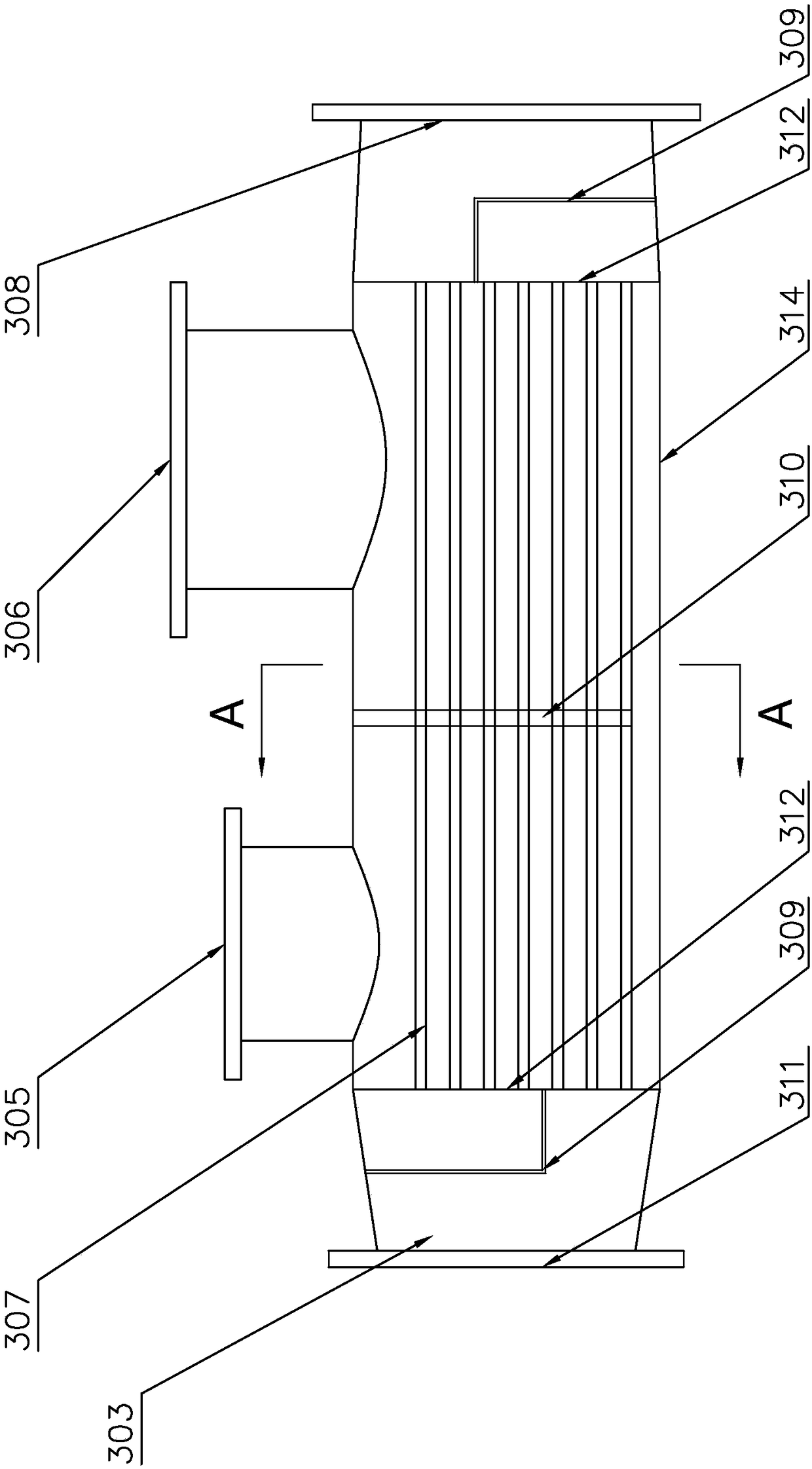

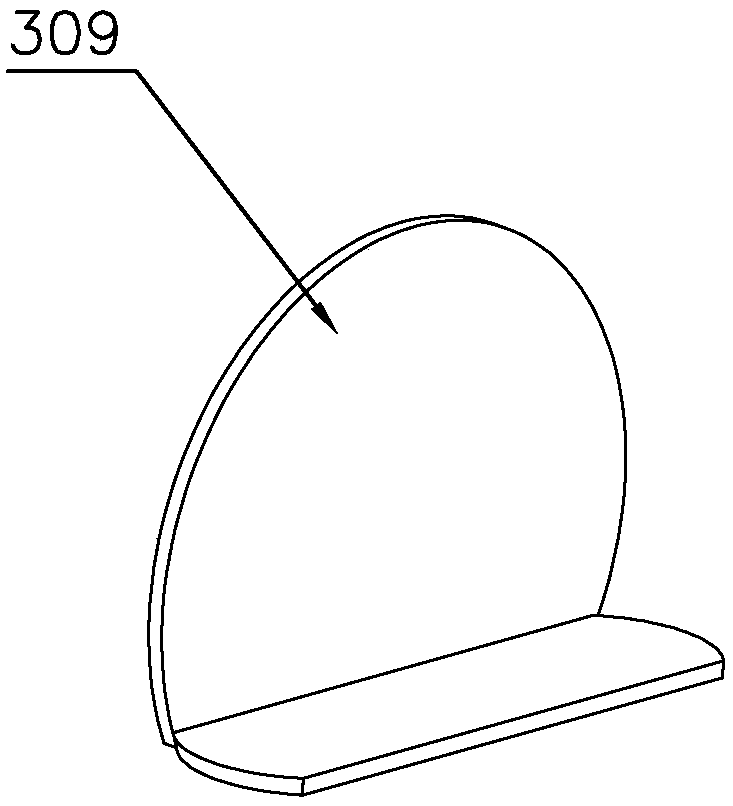

Equipment special for purification of high-vacuum organic micro-molecules during continuous feeding and discharging

PendingCN109646987AGuaranteed starting temperatureFast sublimationSublimationElectric machineProcess engineering

The invention discloses equipment special for purification of high-vacuum organic micro-molecules during continuous feeding and discharging. The equipment comprises a motor, a magnetic fluid sealing shaft, a worm, a storage barrel, a heating furnace inner container, a vacuum gauge, a quartz boat, an observation window, an equipment frame, a collection tank, a pipeline and a five-temperature-zone heating furnace body; the top of the storage barrel is fixedly connected with the motor, the motor is rotatably connected with the top of the worm through the magnetic fluid sealing shaft, and the wormextends into the storage barrel; a discharging port of the storage barrel is fixedly connected with the top of the vertical heating furnace inner container, a discharging port of the heating furnaceinner container is connected with a quartz tube feeding port running through the five-temperature-zone heating furnace body, and a thermocouple is arranged between the five-temperature-zone heating furnace body and a quartz tube. According to the equipment, the problems in existing equipment that a sublimation process is not continuous under a vacuum high-temperature condition, continuous operation cannot be achieved, correspondingly prepared dosages are relatively low under the same condition of time, and therefore the yield of the purified organic micro-molecules is influenced.

Owner:合肥百思智能装备有限公司

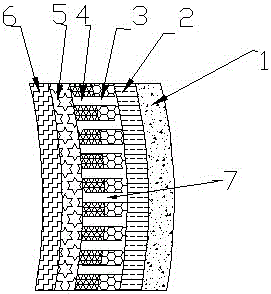

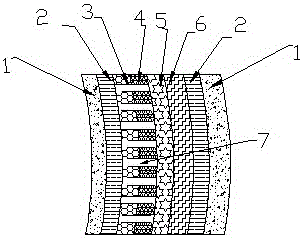

Anti-cracking and pressure-resistant brick and preparation method thereof

InactiveCN107879725AReduce the probability of crackingSlow warm-upCeramic materials productionClaywaresBrickSodium Bentonite

The invention discloses an anti-cracking and pressure-resistant brick and a preparation method thereof. The anti-crack and pressure-resistant brick comprises the following raw materials in percentageby weight: 20%-40% of plastic clay material, 40%-60% of 15-25 mesh split brick clinker particles, 10%-25% of feldspar solvent, and 2%-5% of anti-cracking agent, wherein the anti-cracking agent consists of the following components in percentage by weight: 20%-40% of pure acrylic emulsion, 5%-20% of alkyl vinyl ketone modified cellulose, 1%-5% of phosphate, 1%-5% of polyvinyl alcohol, 10%-15% of bentonite, 2%-5% of polyacrylic emulsion, and 15%-35% of water; and the anti-crack and pressure-resistant brick has a thickness of >=30mm. According to the anti-cracking and pressure-resistant brick andthe preparation method thereof, dry crack resistance of unburned bricks is improved, and generation of sintering cracks is avoided; under the premise of not damaging strength and firing strength of the unburned bricks, shrinkage deformation performance of the unburned bricks can be effectively reduced; and the using amount of the plastic clay material during extrusion molding can be greatly reduced, and the using amount of large-particle ceramic waste can be greatly improved to avoid occurrence of fine cracks and stealth cracks in a burned finished product.

Owner:FOSHAN HENGTAI HONGSHI CERAMIC CO LTD

Steam sterilization method and steam sterilizer utilizing contact type downward eccentric pipeline

ActiveCN103394105AImprove disinfection effectIncrease contact areaHeatBiochemical engineeringContact type

The invention discloses a steam sterilization method utilizing a contact type downward eccentric pipeline. The steam sterilization method is characterized in that the water supply flow is controlled through a pump, supplied water enters the eccentric pipeline, and by utilizing the eccentric pipeline, the water is in direct contact with a heater arranged in the eccentric pipeline, and the contact area is also increased, so that the highe evaporation rate and the short preheating time are obtained, the scale formation amount and the reaction time are reduced, and the purpose of reducing the scale formation is achieved. A steam sterilizer comprises a tank body, a tank cover, a sterilization container and a sterilization outer cover, wherein the sterilization container is arranged on the tank cover, a water tank, the pump and the eccentric pipeline which are sequentially connected with one another are arranged in the tank body, the heater is arranged in the eccentric pipeline, a waterway inlet is formed in one end of the eccentric pipeline, a steam outlet is formed in the other end part of the eccentric pipeline, and an extension pipeline is arranged at the steam outlet and communicated with a steam inlet formed in the tank cover. The steam sterilization method and the steam sterilizer can be used for reducing the scale formation, improving the sterilization effect, also shortening the preheating time, and guaranteeing the service life.

Owner:JIAXING NIYA OPTOELECTRONICS CO LTD

Waste gas treatment device of pre-roll-coating aluminum roll production line

ActiveCN107044647AImprove combustion efficiencyIncrease profitIndirect carbon-dioxide mitigationIncinerator apparatusProduction lineCombustion system

The invention discloses a waste gas treatment device of a pre-roll-coating aluminum roll production line. The waste gas treatment device of the pre-roll-coating aluminum roll production line comprises a combustion system, a heat exchange system and a spray drying system. The spray drying system comprises a spray drying tank, a clean air outlet, an induced draft fan and an exhaust flue. The heat exchange system is arranged on one side of the spray drying system and comprises a heat accumulation chamber, a primary heat exchanger and a secondary heat exchanger. The combustion system is arranged on one side of the heat accumulation chamber and comprises a combustion engine, a mixer, a combustor and a fireproof plate. By adoption of the primary heat exchanger and the secondary heat exchanger, waste heat generated after combustion of waste gas is reused, on the one hand, preheating is conducted before combustion of the waste gas, so that the combustion efficiency of the waste gas is improved, and on the other hand, heat is provided for the spray drying tank, consumption of energy is reduced, the utilization rate of energy is improved, and protection on the environment is achieved.

Owner:山东中创新材料科技有限公司

Anti-cracking surface-grinded brick and preparation method thereof

InactiveCN107879724AReduce the probability of crackingImprove dry crack resistanceCeramic materials productionClaywaresBrickPolymer science

The invention discloses an anti-cracking surface-grinded brick and a preparation method thereof. The anti-cracking surface-grinded brick has a raw material formula which comprises the following raw materials in percentages by weight: 20% to 40% of plastic pug, 20% to 30% of full-body brick clinker particles with a particle size of 10 to 15 meshes, 10% to 15% of vitrified brick clinker particles with a particle size of 20 to 30 meshes, 20% to 35% of a feldspar solvent and 1% to 3% of an anti-cracking agent, wherein the anti-cracking agent has a formula composed of the following components in percentages by weight: 20% to 40% of a pure acrylic emulsion, 5% to 20% of alkyl ethenone modified cellulose, 1% to 5% of phosphate, 1% to 5% of polyvinyl alcohol, 10% to 15% of bentonite, 2% to 5% of apolyacrylic emulsion and 15% to 35% of water. According to the invention, on the premise of no damage to green-brick strength and sintering strength, the shrinkage deformability of a green brick is effectively reduced; the usage amount of the plastic pug is greatly reduced in the process of extrusion molding; the usage amount of large waste ceramic particles can be greatly improved; the strengthof the green brick is improved; a drying shrinkage rate and a sintering shrinkage rate are low; plasticity is strong; and drying cracks and sintering cracks are avoided from generation.

Owner:FOSHAN HENGTAI HONGSHI CERAMIC CO LTD

Injection molding device used for production of plastic products

The invention discloses an injection molding device used for the production of plastic products. The injection molding device comprises a coarse material box, a fine material box is arranged at the bottom part of the coarse material box, injection molding rods are arranged in the middle parts of the coarse material box and the fine material box, the outer sides of the injection molding rods are fixedly provided with feeding screws, the top parts of the inner back wall in the coarse material box and the fine material box are fixedly provided with electric heating pipes, driving motors are fixedly arranged on the right outer walls of the coarse material box and the fine material box, and the injection molding rods penetrate through the right walls of the coarse material box and the fine material box. According to the injection molding device used for the production of the plastic products, a coarse screen and a fine screen are arranged, during the material heating and injection molding,the feeding screws of the injection molding rods can be driven to rotate through the driving motors, the outer layer of the materials is heated to melt, during the feeding screws driving the melted materials to move, the outer layer of the partially melted materials is extruded by the coarse screen to flow to the lower side of the coarse screen, in the same way, the fine screen can separate the outer layer of the materials twice, so that the heating rate of the hard core in the inner parts of the materials is improved, the time required for melting is reduced, and the injection molding deviceis suitable for extensive promotion and use.

Owner:南通塑之源科技有限公司

Method capable of improving coating film uniformity and graphite carrier

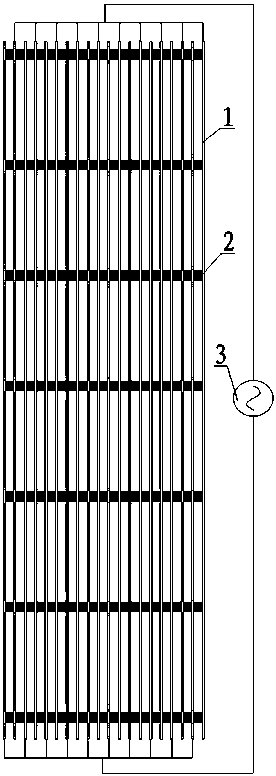

PendingCN108666242AEffective control of deposition rateImprove thickness uniformityFinal product manufactureSemiconductor/solid-state device manufacturingOptoelectronicsGraphite

The invention discloses a method capable of improving coating film uniformity and a graphite carrier. A plurality of graphite boats capable of loading solar crystalline silicon battery pieces are arranged in a deposition furnace, wherein the graphite boats are arranged side by side transversely; each graphite boat is supported and fixed through a supporting frame; the adjacent supporting frames are separated and supported through a ceramic supporting sleeve, and the distances between the supporting frames are uneven; the distance between the solar crystalline silicon battery pieces in the graphite boat on the supporting frame on the outer side is longer than the distance between the solar crystalline silicon battery pieces in the graphite boat on the supporting frame on the inner side; andthe distances between the solar crystalline silicon battery pieces in the graphite boats on the supporting frames are gradually shortened from the outer side to the inner side, so that the electric field intensity can be improved, different film layer deposition speeds caused by different temperatures can be compensated, effective control on the deposition speed of the film layers is realized, and the thickness uniformity of the film layers is more excellent.

Owner:JINENG CLEAN ENERGY TECH LTD

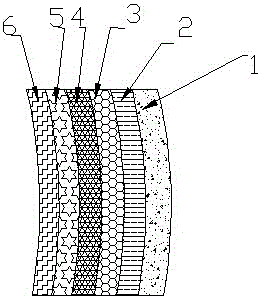

Curved solar car sunroof and manufacturing method thereof

ActiveCN104916722BExtend warm-up timeReduce damage and other problemsFinal product manufactureElectric/fluid circuitElectrical batteryEngineering

The invention discloses a curved surface solar energy automobile skylight and a manufacture method for the same, and particularly relates to a curved surface solar energy automobile skylight and the manufacture method for the same. The curved surface solar energy automobile skylight has curved-surface-shaped single layer or double-layer skylight glass; a solar energy battery sheet is composited on the inner side of the single layer skylight or between the double-layer glass; the solar energy battery sheet comprises a super-thin glass substrate, the curved surface shape of which is identical to or similar to the skylight glass; a first electrode, a photoelectric conversion layer and a second electrode are successively plated on the super-thin glass substrate; and the solar energy battery sheet is adhered to the skylight glass through a adhesive layer. The curved surface solar energy automobile skylight and the manufacture method for the same disclosed by the invention can greatly reduce the cracking and damage caused by the strain force in the process of lamination, can improve the yield and can reduce the manufacture cost.

Owner:安徽山迪光能技术有限公司

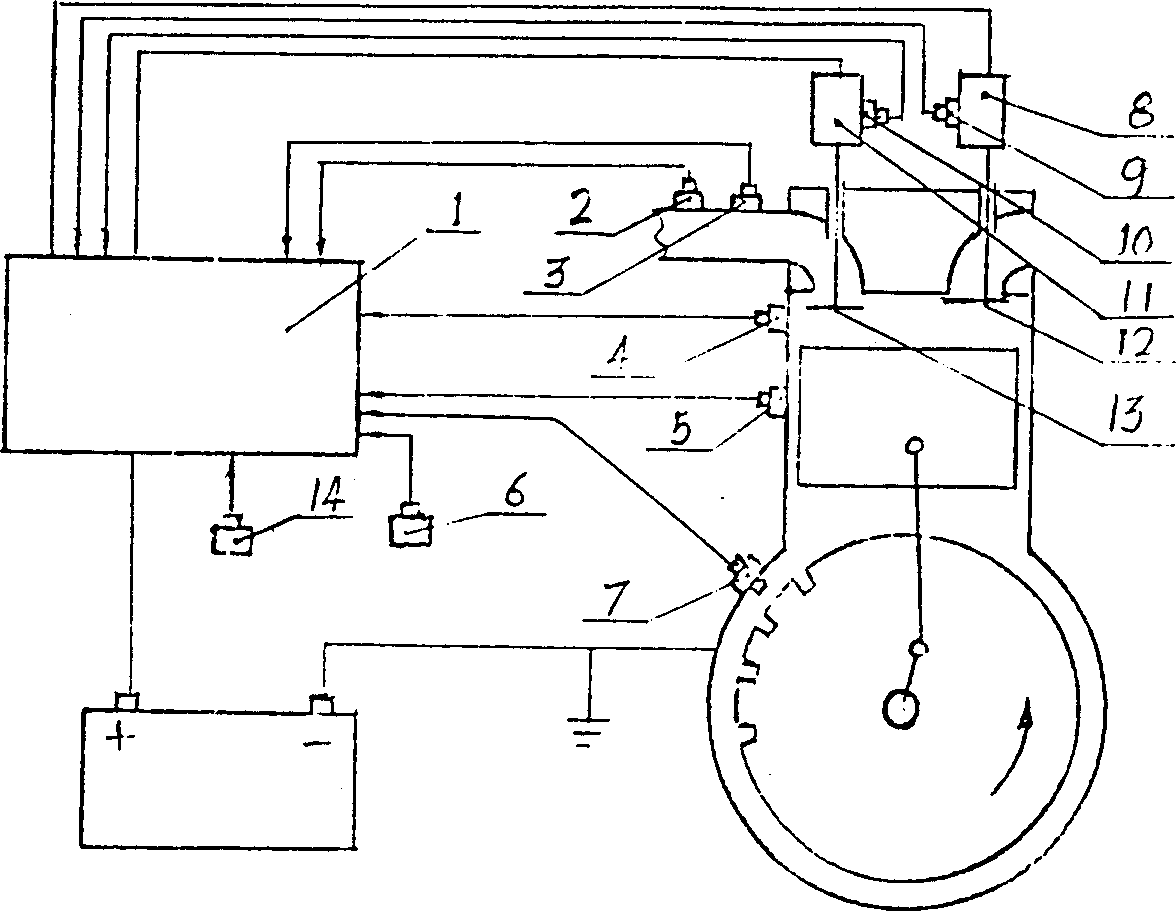

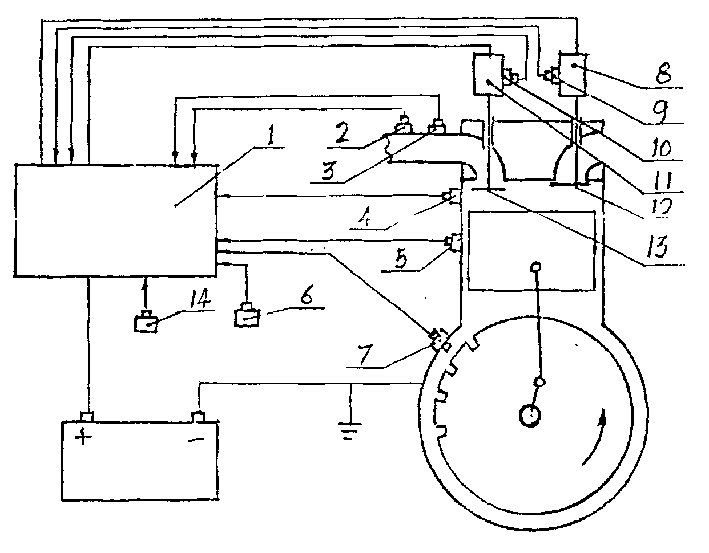

Variable compression ratio and variable air distributing phase

InactiveCN1167870CReduce friction lossImprove mechanical efficiencyElectrical controlMachines/enginesMicrocomputerMicrocomputer control

A microcomputer controlled variable compression ratio and variable air distribution phase is disclosed, and can increase the thermal efficiency, volume efficiency and mechanical efficiency of engine, save fuel, decrease the preheat time and prevent overhigh cooling temp. and decrease the abrasion of brake. The acceleration position sensor and other sensors output the electric signals to the microcomputer for controlling the controllers of air inlet and outlet valves. When corking conditions of 4-stroke engine change, the air inlet and outlet valves can be controlled at correct positions of crankshaft.

Owner:边永安

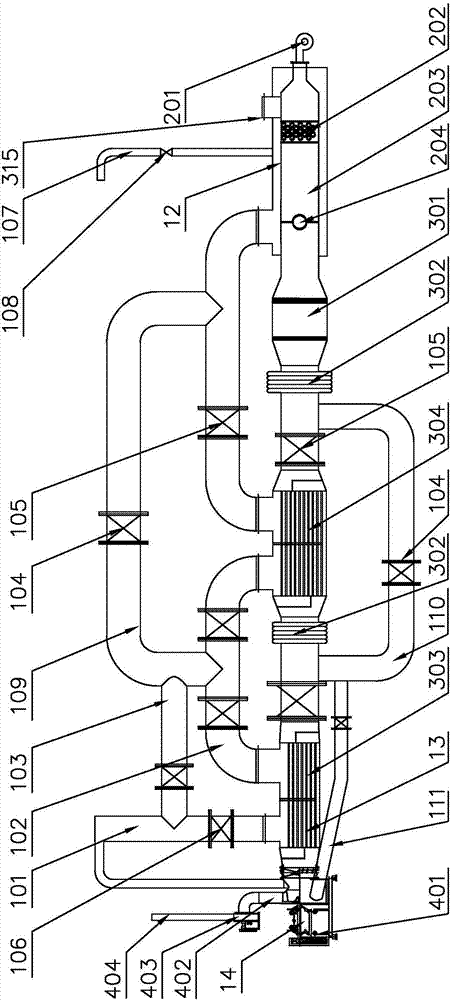

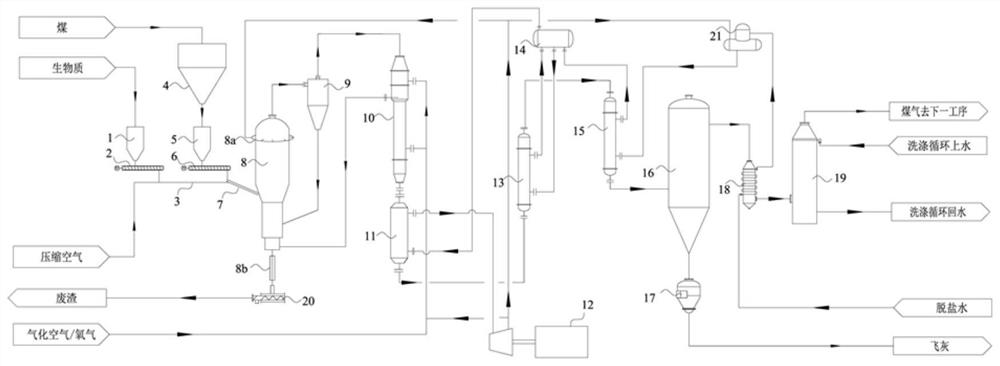

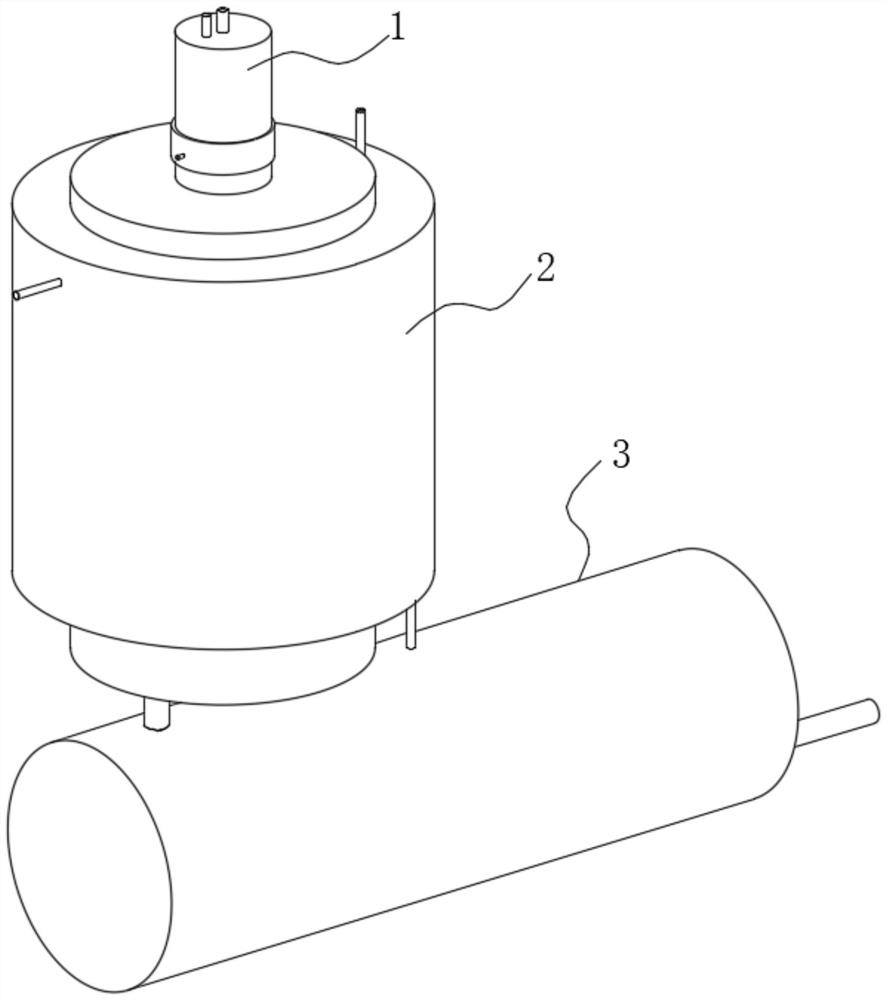

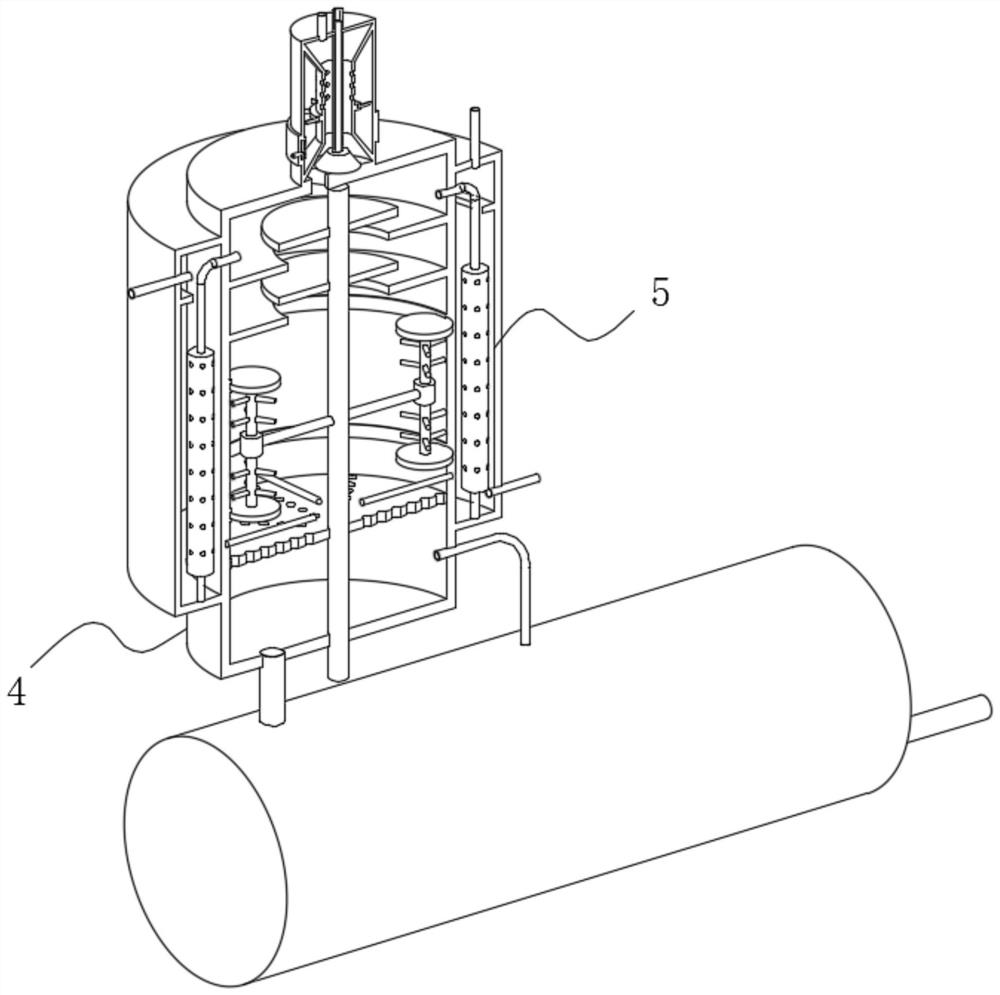

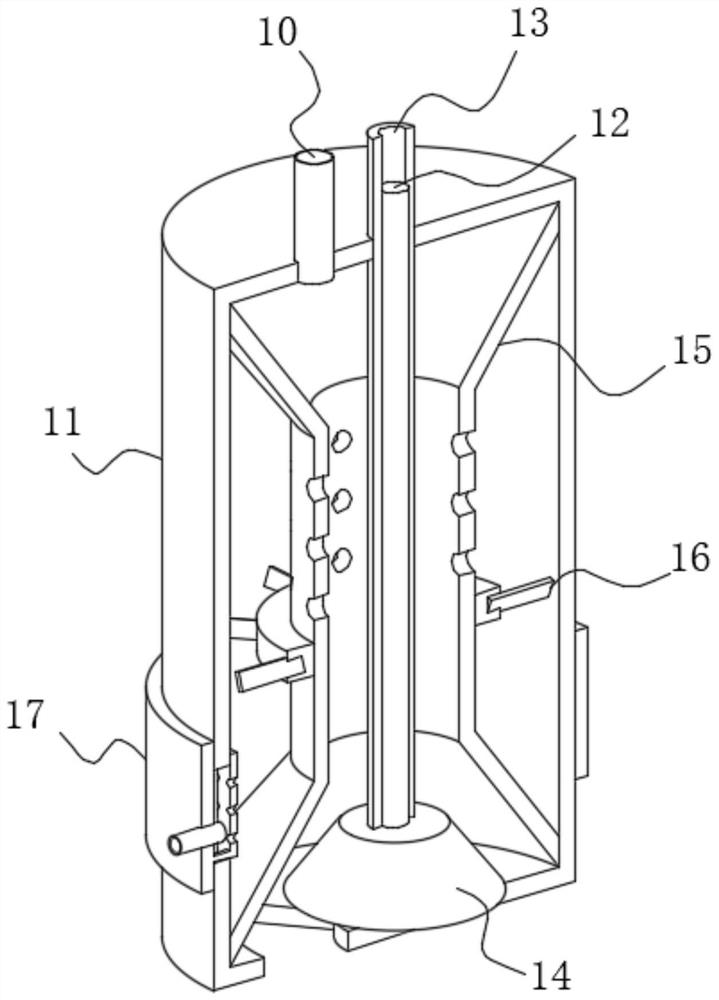

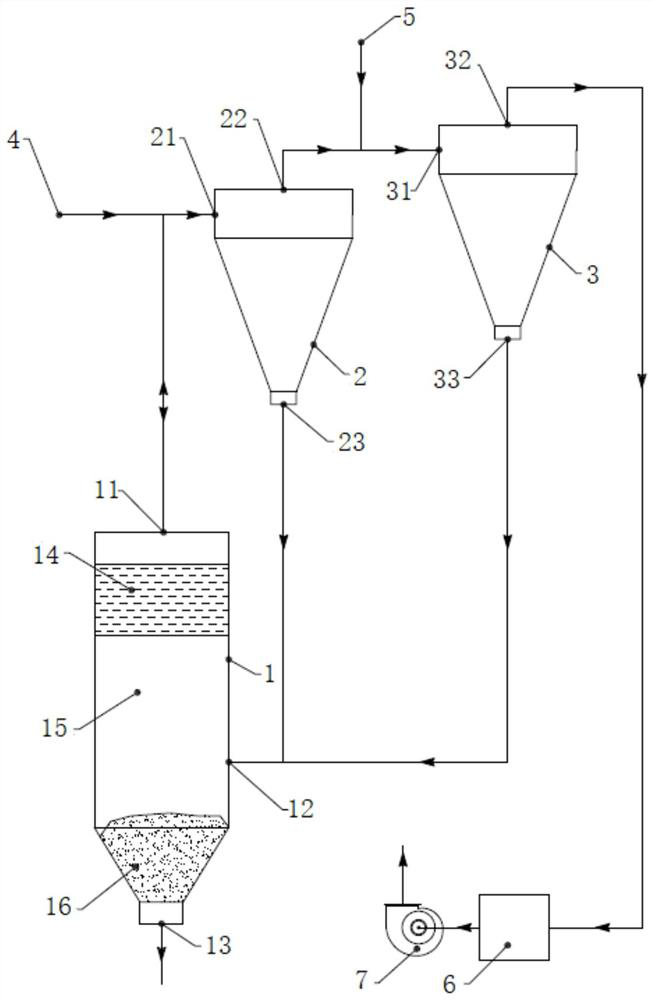

Biomass and coal co-gasification system and gasification method

PendingCN111676065AStrong responsivenessExtend warm-up timeLiquid degasificationEnergy inputDust controlSuperheated steam

The invention discloses a biomass and coal co-gasification system and gasification method, and belongs to the field of carbon-based solid fuel energy utilization. The problem that energy cannot be effectively utilized when biomass and coal are gasified together in the prior art is solved. The biomass and coal co-gasification system comprises a raw coal feeding device and a biomass feeding device,the two feeding devices are connected with feeding pipes, the feeding pipes are connected with a fluidized bed gasification furnace, the fluidized bed gasification furnace is connected with a dust removal device, a waste heat recovery device is further arranged between the fluidized bed gasification furnace and the dust removal device, the waste heat recovery device is connected with the steam power generation device, and the steam power generation device provides steam for gasification reaction in the fluidized bed gasification furnace. Sensible heat recovery is conducted on high-temperaturegasified coal gas through the waste heat recovery device, superheated steam generated through recovery is used for power generation of the steam power generation device, the steam power generation device provides steam for gasification reaction, and the energy utilization rate is remarkably increased. The gasification method utilizing the system is simple and convenient to operate and high in safety.

Owner:KEDA MAS CLEAN ENERGY

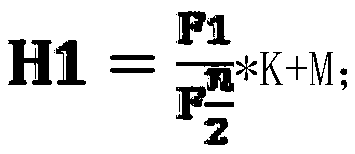

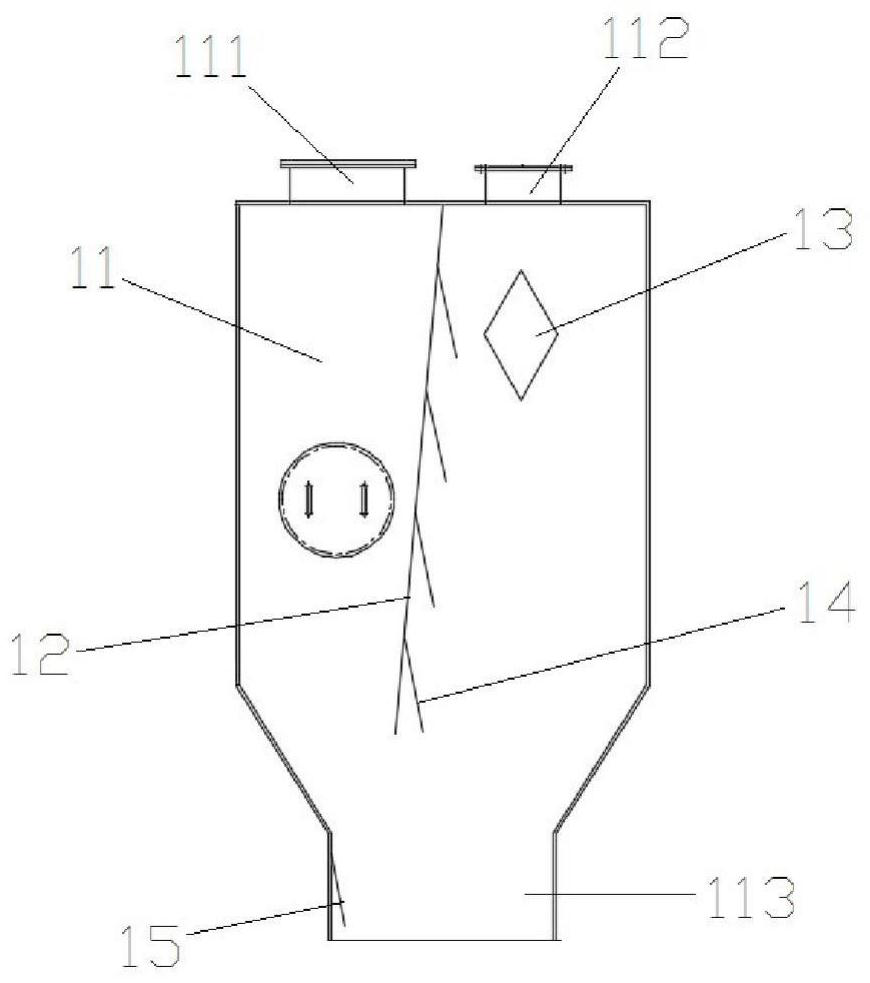

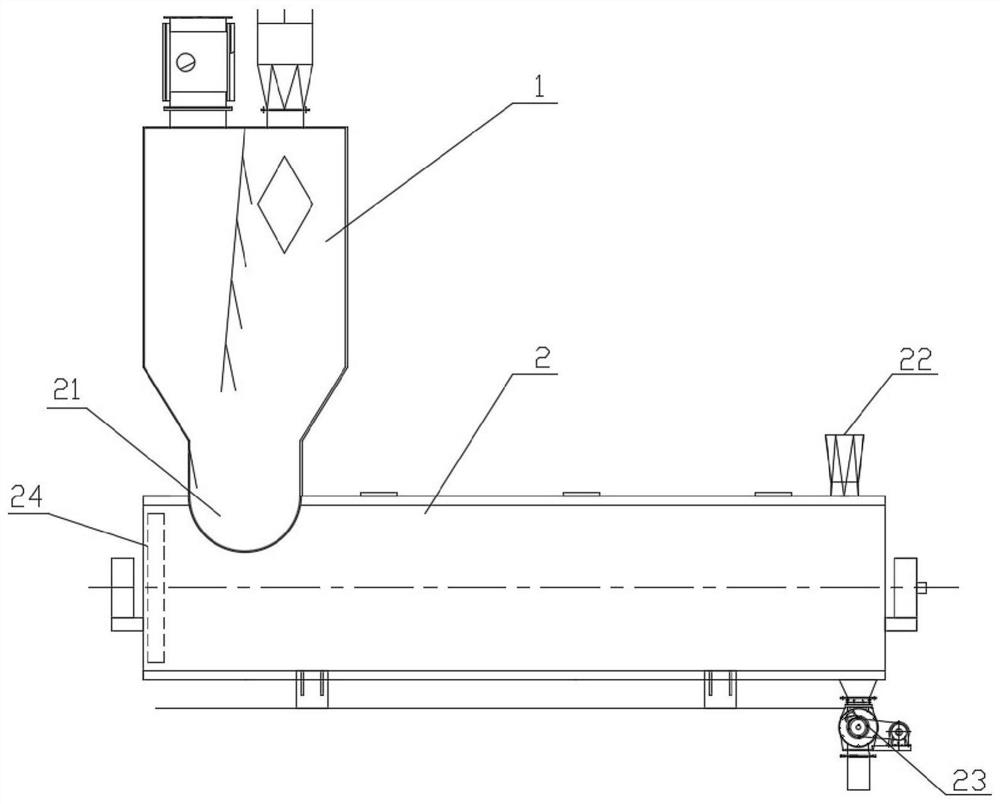

Ceramsite sand preheating discharging device and discharging preheating method

PendingCN114440646APrevent splashPrevent leakageRotary drum furnacesIncreasing energy efficiencyThermodynamicsExpanded clay aggregate

The invention discloses a ceramsite sand preheating and discharging device which comprises a discharging device, a preheating device is arranged at the bottom of the discharging device, a rotary kiln is arranged at the bottom of the preheating device, the preheating device comprises a mixing device, and a heat preservation device is arranged outside the mixing device. According to the ceramsite sand preheating and discharging device and the discharging and preheating method, the preheating device and the discharging device are arranged to control the feeding amount of materials, hot air in the rotary kiln enters the mixing device, the heat preservation device delays the heat leakage speed of equipment through heat circulation and water circulation, and under the action of the stirring device, the falling speed of the materials is deferred; the stirring frequency is increased, the preheating time of the materials is prolonged, the materials are preheated by utilizing redundant heat generated during working of the rotary kiln, the heat utilization rate is increased, the energy consumption is reduced, and the problems that traditional preheating equipment is low in heat utilization rate and high in energy consumption and does not conform to the green and environment-friendly production concept are solved.

Owner:江苏睿新世越环保新材料科技有限公司

A kind of anti-crack pressure brick and preparation method thereof

InactiveCN107879725BReduce the probability of crackingSlow warm-upCeramic materials productionClaywaresCrack resistanceBrick

The invention discloses an anti-cracking and pressure-resistant brick and a preparation method thereof. The anti-crack and pressure-resistant brick comprises the following raw materials in percentageby weight: 20%-40% of plastic clay material, 40%-60% of 15-25 mesh split brick clinker particles, 10%-25% of feldspar solvent, and 2%-5% of anti-cracking agent, wherein the anti-cracking agent consists of the following components in percentage by weight: 20%-40% of pure acrylic emulsion, 5%-20% of alkyl vinyl ketone modified cellulose, 1%-5% of phosphate, 1%-5% of polyvinyl alcohol, 10%-15% of bentonite, 2%-5% of polyacrylic emulsion, and 15%-35% of water; and the anti-crack and pressure-resistant brick has a thickness of >=30mm. According to the anti-cracking and pressure-resistant brick andthe preparation method thereof, dry crack resistance of unburned bricks is improved, and generation of sintering cracks is avoided; under the premise of not damaging strength and firing strength of the unburned bricks, shrinkage deformation performance of the unburned bricks can be effectively reduced; and the using amount of the plastic clay material during extrusion molding can be greatly reduced, and the using amount of large-particle ceramic waste can be greatly improved to avoid occurrence of fine cracks and stealth cracks in a burned finished product.

Owner:FOSHAN HENGTAI HONGSHI CERAMIC CO LTD

Novel offset printing and digital printing integrated environment-friendly printing process

PendingCN114643794AKeep healthyImprove working environmentDuplicating/marking methodsPattern printingDigital printingProcess engineering

The invention discloses a novel offset printing and digital printing integrated environment-friendly printing process, which relates to the field of printing and comprises the following specific steps of: (1) designing characters and patterns to be printed on a computer according to requirements; and (2) the designed characters and patterns are transmitted into a printing system, the printing system receives and stores the received file, and a printing task is established in system software. When printing ink is dried, an activated carbon filtering layer and an adsorption resin layer are adopted for filtering and adsorbing irritant gas in hot gas, then the hot gas can be purified, the body health of workers is guaranteed, the working environment of the workers is improved, the dried printed matter is flattened, and the printing quality of the printed matter is improved. And wrinkles generated after the printed matter is dried can be removed, so that the printed matter can be smoother, and the quality of the printed matter is improved.

Owner:福州印友数字印刷有限公司

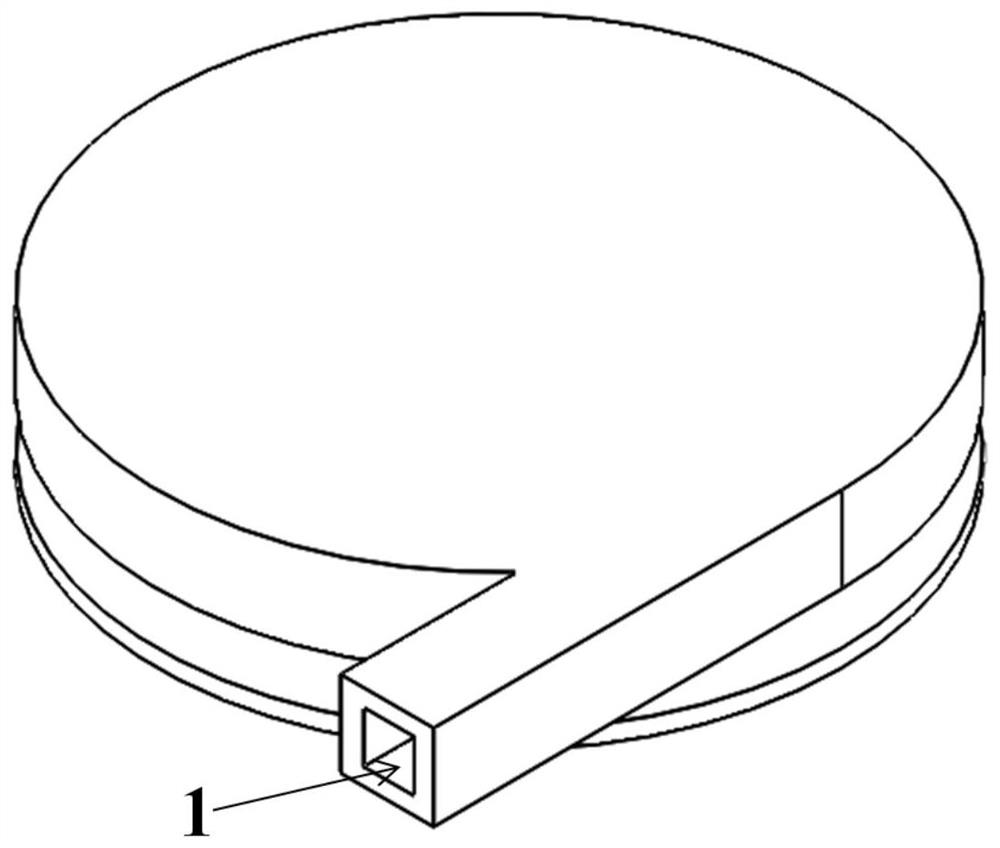

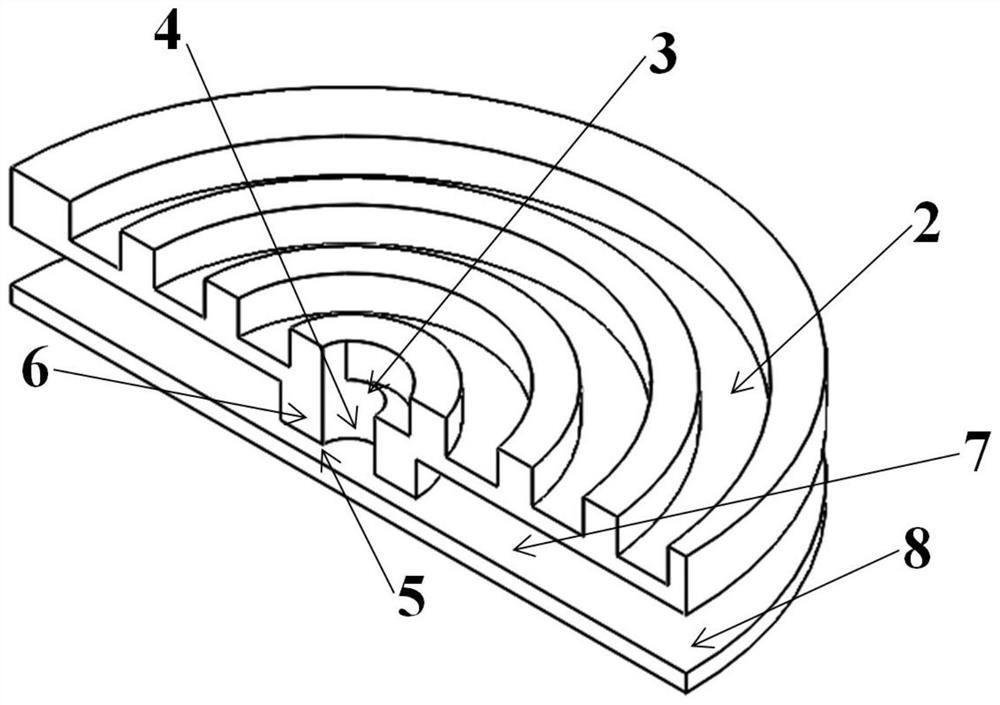

A Small Disc Premixed Burner with Efficient Preheating and Flashback Prevention

ActiveCN110906328BPrevent backfireRaise the initial temperature of the reactionIndirect carbon-dioxide mitigationGaseous fuel burnerCircular discThermodynamics

The invention belongs to the small-scale combustion technology field, and especially discloses an efficient preheating anti-backfire small disc premixing combustor. The combustor comprises a fuel preheating body, an annular boss and a combustion chamber lower disc. The fuel preheating body comprises an upper cover plate, a lower wall plate and a fuel preheating channel arranged between the upper cover plate and the lower wall plate in a spiral mode. The combustion chamber lower disc and the lower wall plate are arranged at intervals so as to form an annular combustion chamber of the premixingcombustor. One end of the annular boss is fixedly connected with the lower wall plate, the other end and the combustion chamber lower disc are arranged at intervals, and a fuel channel is arranged inthe annular boss. One end of the fuel channel is connected with a through hole which is arranged on the lower wall plate and is used for connecting the annular boss and an air outlet of the fuel preheating channel, and the other end is connected with an inlet of the annular combustion chamber. Efficient preheating and stable and efficient combustion of a fuel premixed gas can be effectively achieved, and the combustor is suitable for various small power or heating devices.

Owner:HUAZHONG UNIV OF SCI & TECH

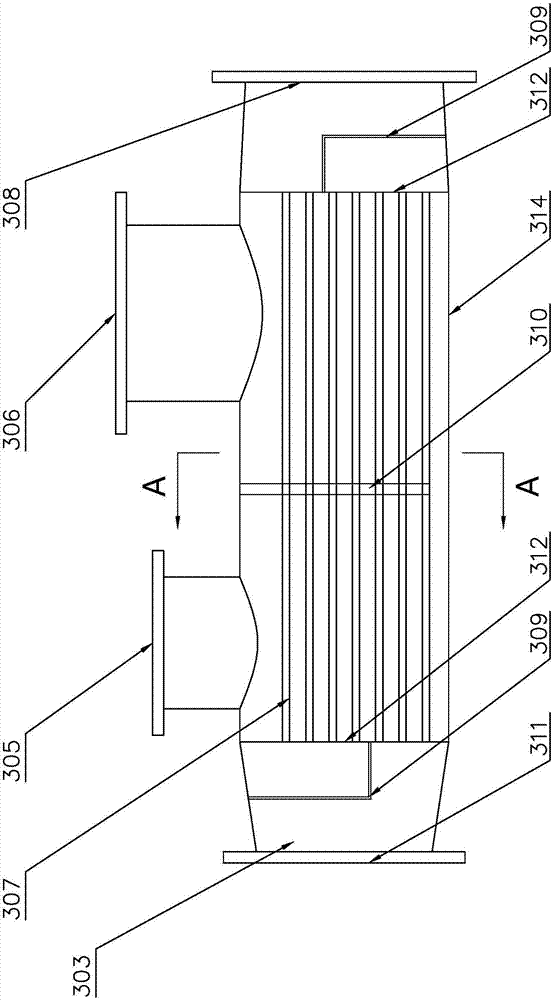

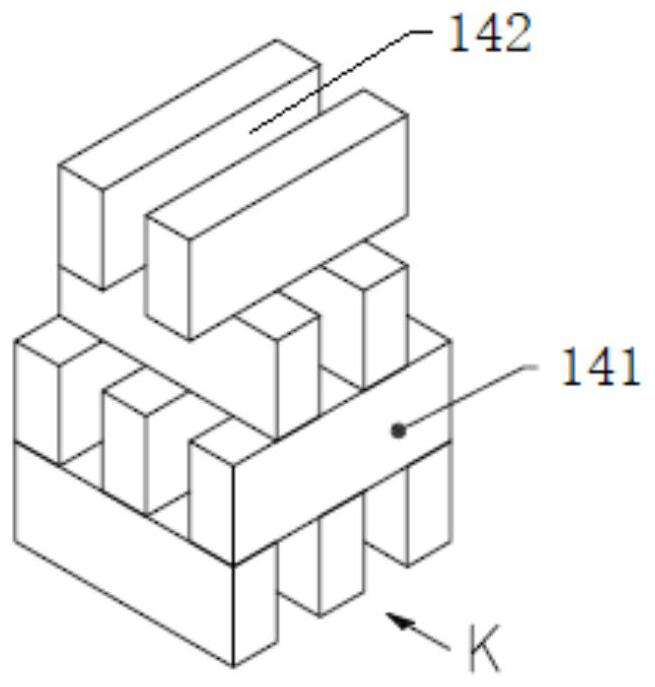

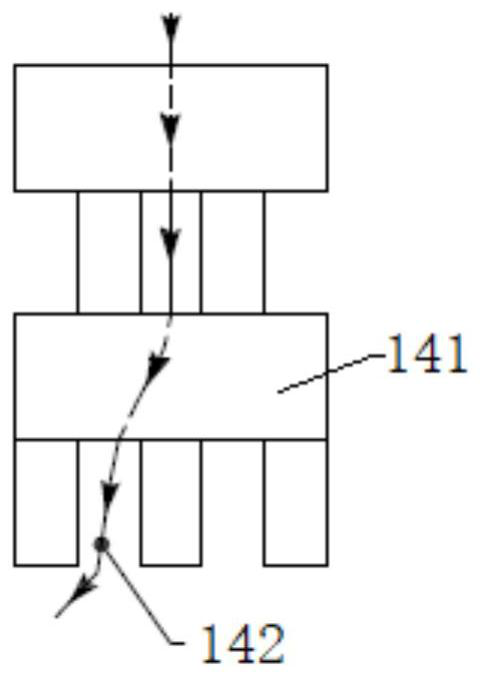

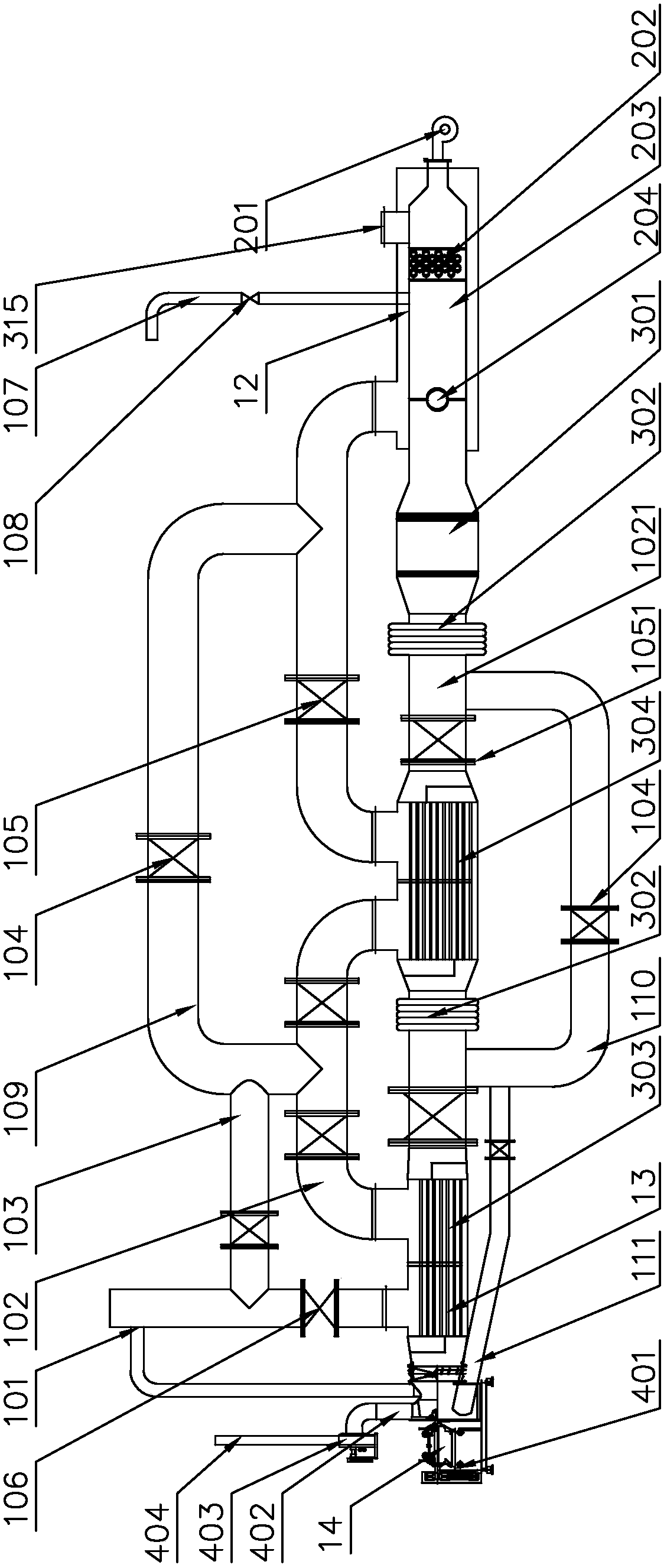

Energy-saving flash suspension kiln system

The invention discloses an energy-saving flash suspension kiln system. The systm comprises a first feeding point, a kiln and a first gas-solid separator, the kiln comprises a first feeding port, a second feeding port, a damping section, a firing section, a reflecting section and a clinker outlet, and the damping section, the firing section and the reflecting section are sequentially arranged from the first feeding port to the clinker outlet; the damping section comprises a damping unit and a flow channel, raw materials penetrate through the damping section from the flow channel, the firing section is communicated with the second feeding port, the first feeding point is connected with the first feeding port, the first gas-solid separator comprises a first gas inlet, a first gas outlet and a first discharging port; the first air inlet is connected with the first feeding port, and the first discharging port is connected with the second feeding port. The energy-saving flash suspension kiln system provided by the invention has the characteristics of low energy consumption, low pollution, stable product quality, simple structure and low one-time investment.

Owner:辽宁荣邦科技有限公司

A waste gas treatment device for a pre-roller coated aluminum coil production line

ActiveCN107044647BImprove combustion efficiencyIncrease profitIndirect carbon-dioxide mitigationIncinerator apparatusProduction lineCombustion system

Owner:山东中创新材料科技有限公司

Ethylene oxide preheating, sterilization and resolution integrated cabinet and sterilizing method

ActiveCN102743773BReduce construction areaAvoid lossLavatory sanitoryChemicalsEthylene oxideWater jacket

The invention relates to an ethylene oxide preheating, sterilization and resolution integrated cabinet and a sterilizing method. The integrated cabinet comprises a cabinet body, wherein a sealing door is arranged on the front part of the cabinet body; a cavity in the cabinet body is connected with a vacuum pump through a vacuumizing pipeline; the cavity in the cabinet body is connected with a humidifying device through a humidifying pipeline; the cavity in the cabinet body is connected with wet and hot air making devices through wet and hot air delivery pipelines; a heating water jacket is arranged outside the cabinet body; a circulating air pipeline is arranged on the outer side of the cabinet body; a fan is connected in series to the circulating air pipeline; an air inlet of the circulating air pipeline is arranged on one side in the cabinet body; an air outlet of the circulating air pipeline is arranged on the other side in the cabinet body; and the cabinet body is connected with an ethylene oxide container through a pipeline provided with a valve. The ethylene oxide preheating, sterilization and resolution integrated cabinet has the advantages of high operating efficiency, few matched facilities, low fault rate, short construction period, low daily using cost and low energy loss, and can reduce pollution to human body and environment and improve the comprehensive benefit by over 40 percent.

Owner:北京长丰诚耀技术服务中心

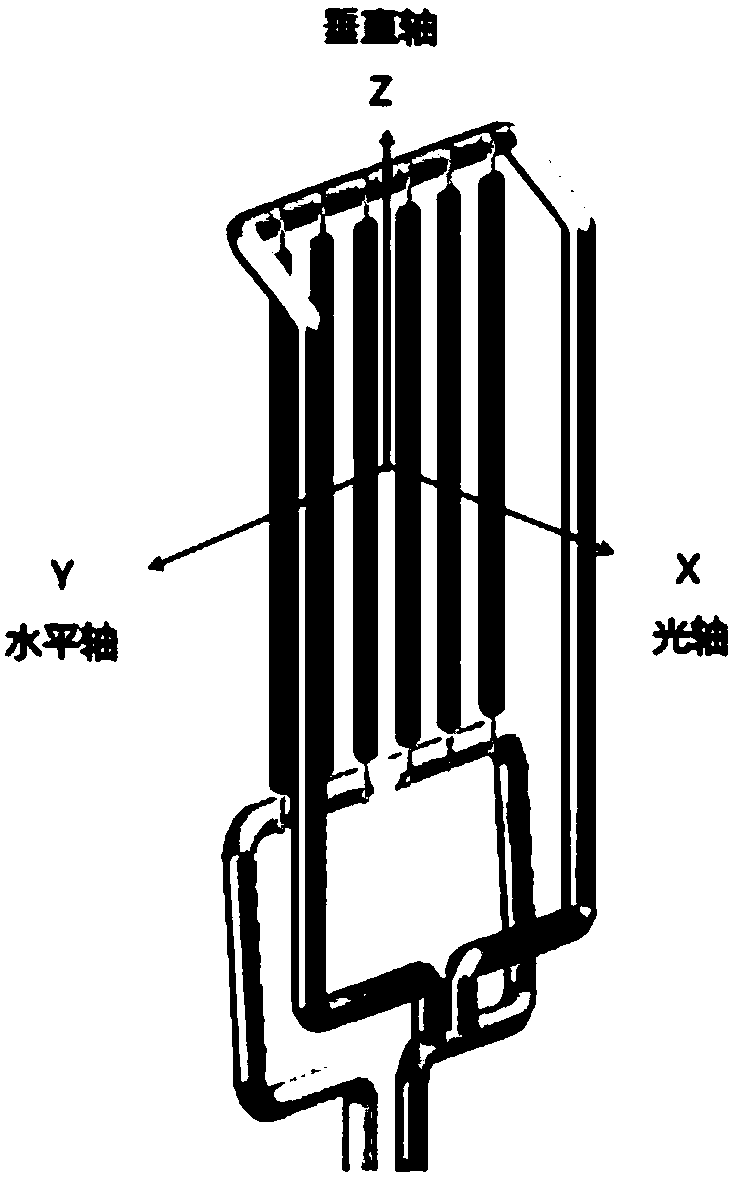

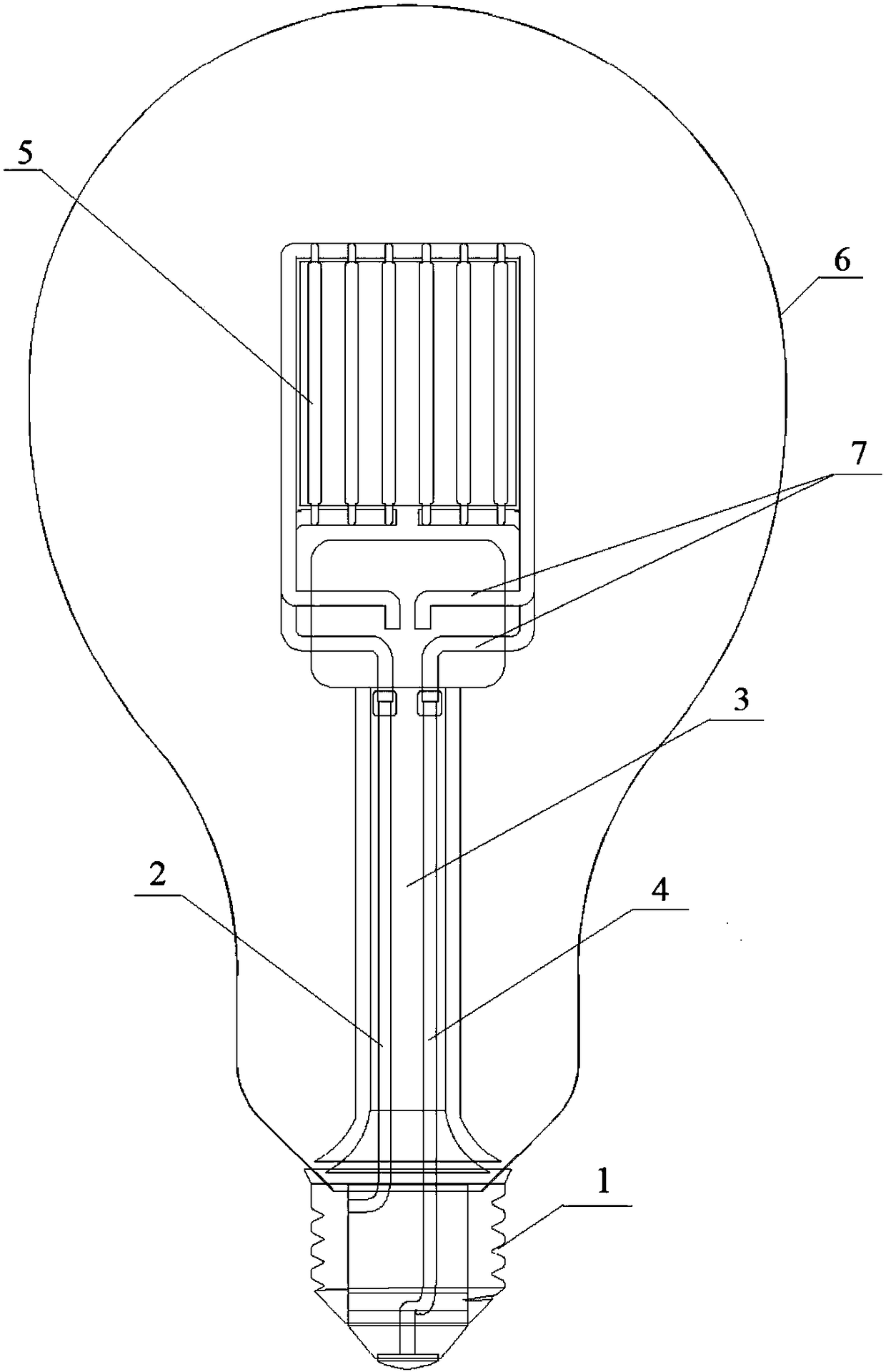

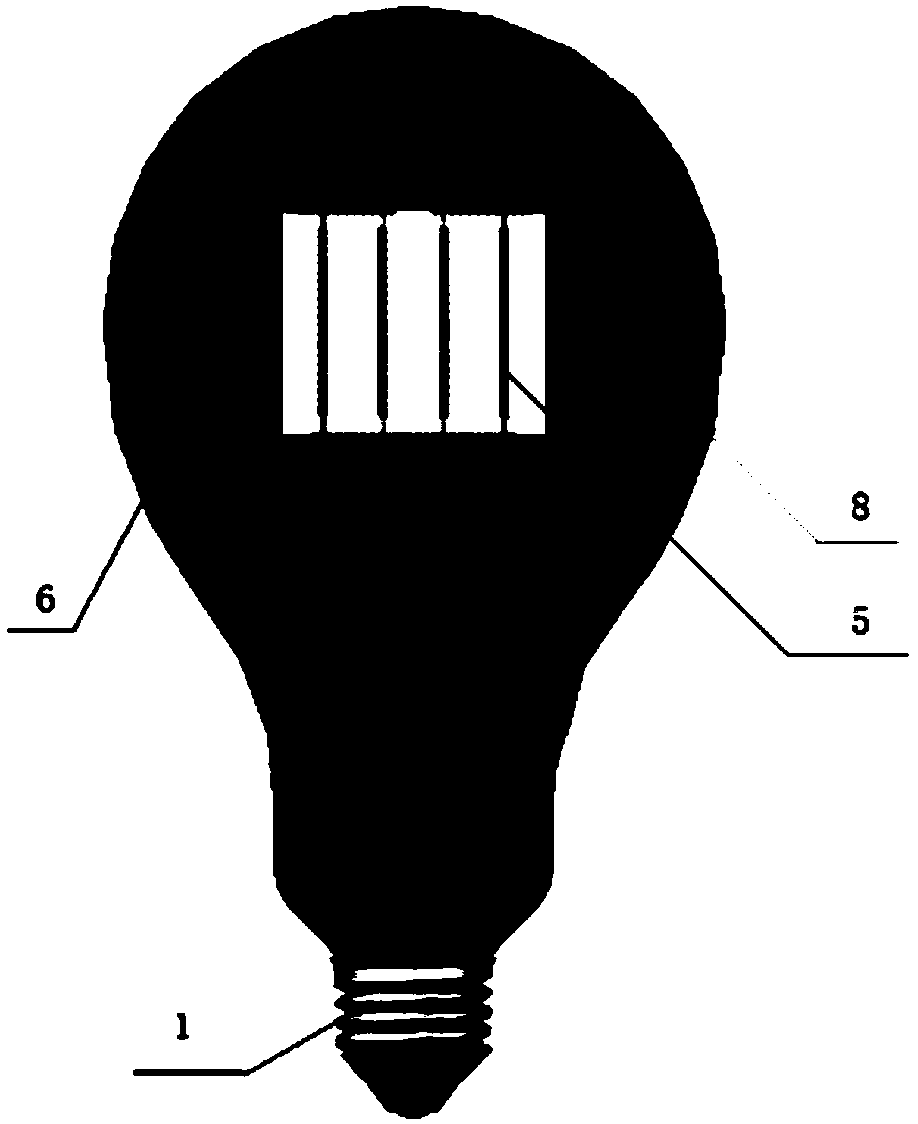

A kind of LED filament luminous intensity standard lamp

ActiveCN105570701BSimple structureEasy to installProtective devices for lightingLight fasteningsLuminous intensityEngineering

Owner:NAT INST OF METROLOGY CHINA

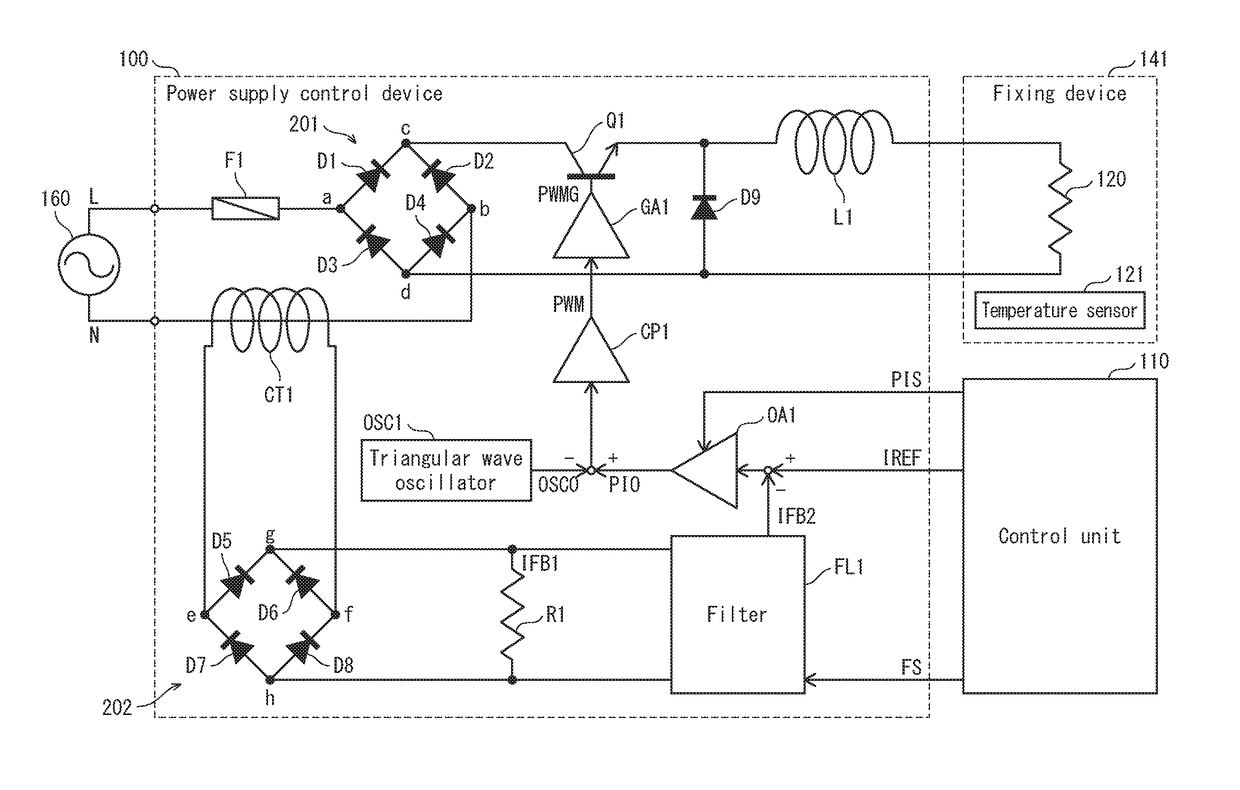

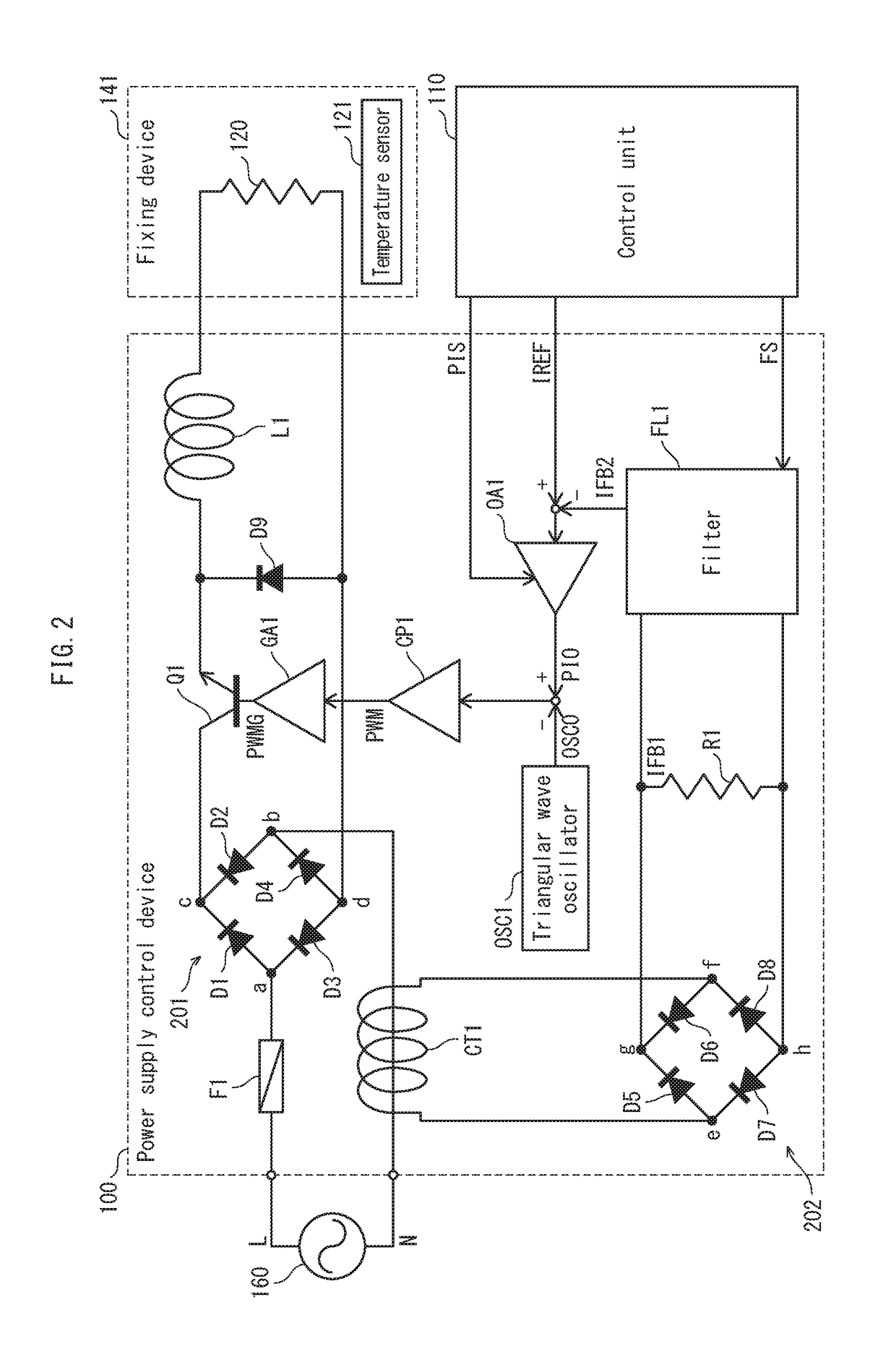

Power supply control device and image forming apparatus

ActiveUS10126692B2Extend warm-up timeSuppress inrush current flowingElectric heatingElectrographic process apparatusHalogenFeedback circuits

A power supply control device including a chopper circuit generating a heater current for a halogen heater, a current feedback circuit generating a current feedback signal indicating a current amount based on an amount of the heater current, and a constant current circuit performing pulse-width modulation of the heater current amount according to a difference between a target heater current amount and the current amount indicated by the current feedback signal. The current feedback circuit switches between methods at least including a first method and a second method for generating the current feedback signal. The current feedback signal indicates a greater current amount with the first method than with the second method, and the current feedback circuit uses the first method during a period with a predetermined time length starting from when the halogen heater is turned on, and uses the second method after elapse of the period.

Owner:KONICA MINOLTA INC

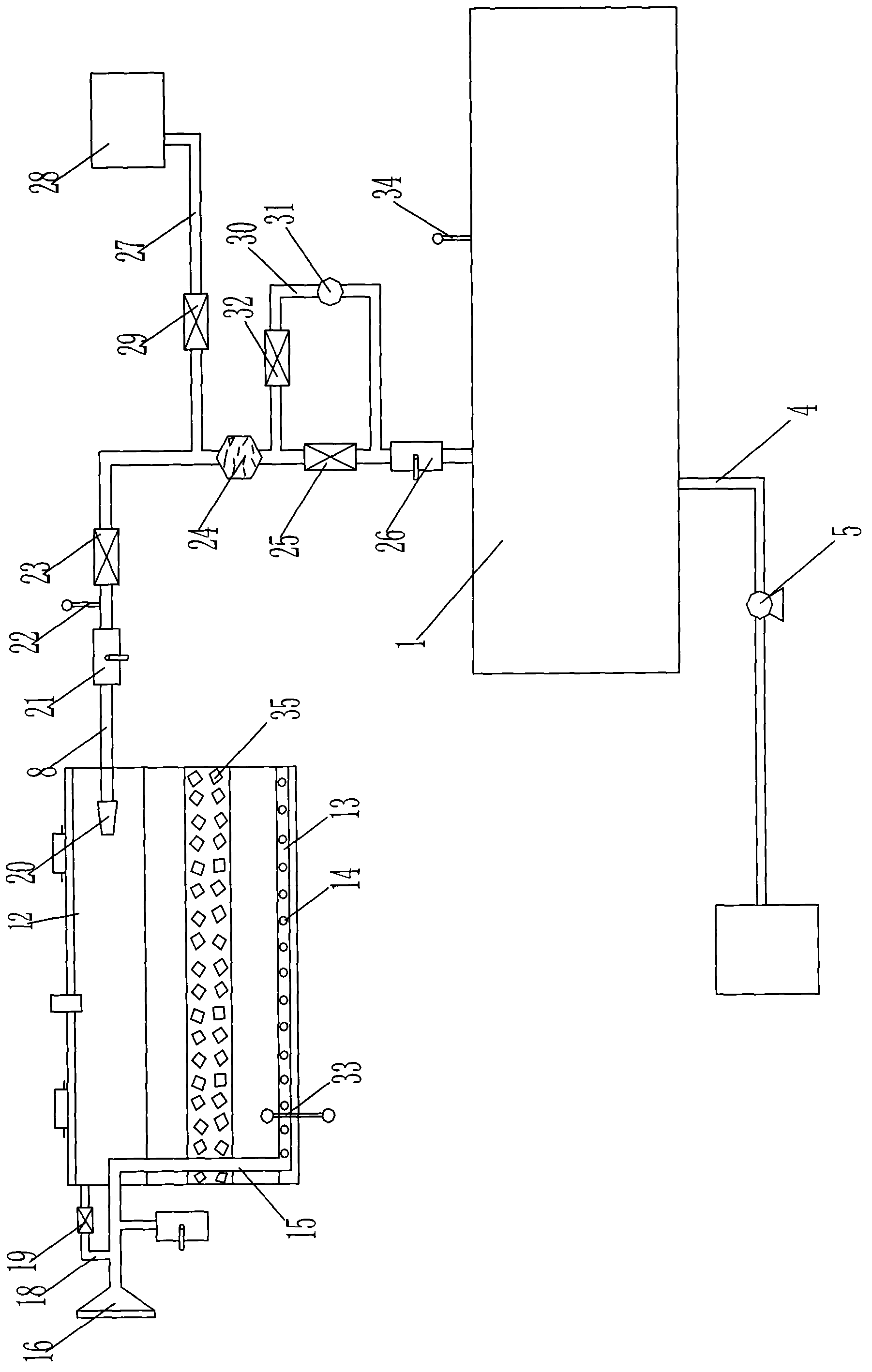

Pre-desolvation gas chamber, horizontal desolvation machine containing the pre-desolution gas chamber and pre-desolution method

ActiveCN108485805BPrevent take outFalling smoothlyFatty-oils/fats productionSolid solvent extractionProcess engineeringGas chamber

The object of the present invention is to provide a kind of pre-desolvation gas chamber and the horizontal desolvation machine and the pre-desolution method containing the pre-desolution gas chamber, which are used to solve the poor desolvation effect of the horizontal desolvation machine in the prior art, The problem of low heat utilization. The pre-desolvation chamber includes a shell and a separation plate; the upper part of the shell is provided with a feed port and an air outlet, and the lower part of the shell is provided with a blanking port that can communicate with the feed port of the horizontal desolventizer. The isolation plate is installed inside the shell and is inclined from top to bottom to the side of the feed opening to isolate the inner cavity of the shell into two chambers whose upper part is independent and the lower part communicates with the feed opening. Several baffles are arranged on the isolation plate, and the upper parts of the several baffles are fixedly installed on the isolation plate and are located on the side away from the feed inlet. The invention introduces the hot air in the horizontal desolventizer into the pre-desolvation gas chamber, preheats and desolventizes the product to be desolvated flowing down the inclined partition plate in the gas chamber, improves the desolventization efficiency and heat utilization rate, and can Reduce the amount of product to be desolvated in the hot air after desolventization.

Owner:SHANDONG YUWANG ECOLOGY FOOD IND

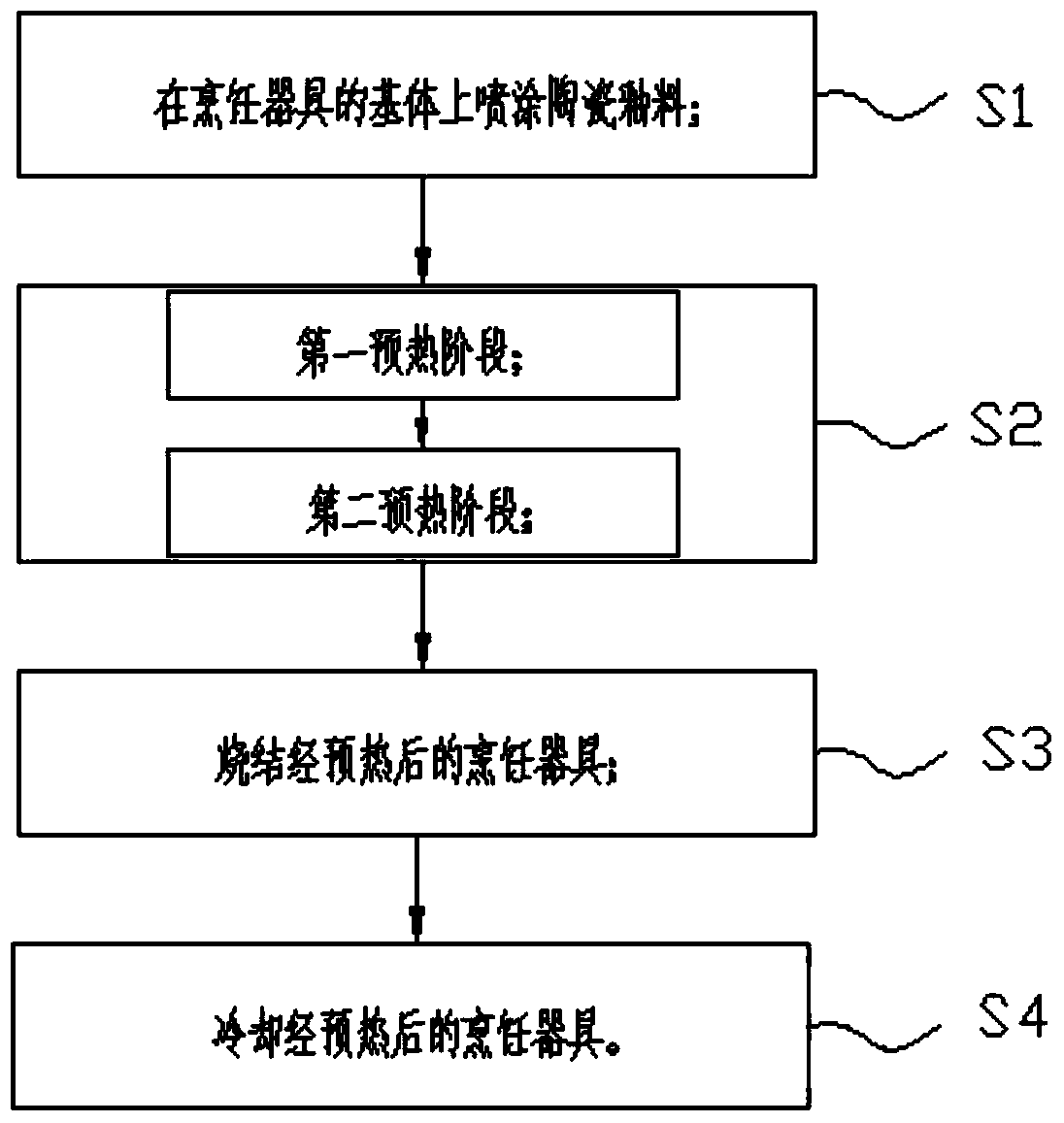

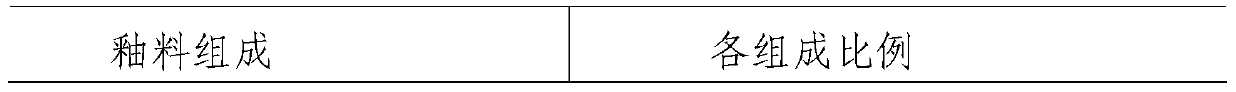

A method of manufacturing a cooking utensil

The invention relates to the technical field of kitchen cookers, particularly a manufacturing method of a cooking utensil. The manufacturing method comprises the following steps: S1. spraying ceramic glaze on a cooking utensil matrix; S2. preheating the cooking utensil with the sprayed ceramic glaze; S3. sintering the preheated cooking utensil; and S4. cooling the sintered cooking utensil. The process S2 comprises the following steps: S21. first preheating period: slowly heating the cooking utensil with the sprayed ceramic glaze from room temperature to 180-220 DEG C within 0.5-1 hour; and S22. second preheating period: slowly heating the cooking utensil with the sprayed ceramic glaze from 180-220 DEG C to 280-320 DEG C within 0.5-1 hour, wherein the heating speed of the second preheating period is lower than the heating speed of the first preheating period. The manufacturing method adopts the multiple preheating periods, so that the sintered cooking utensil has the advantages of favorable smoothness, favorable wear resistance, favorable glossiness, simple technique mode and wide application range.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

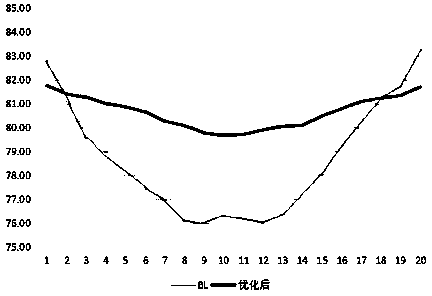

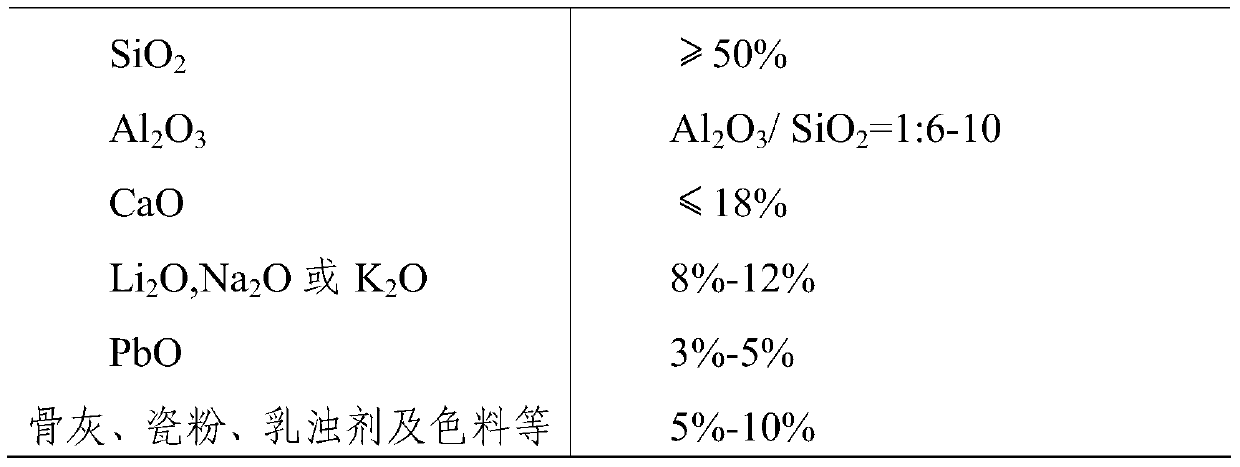

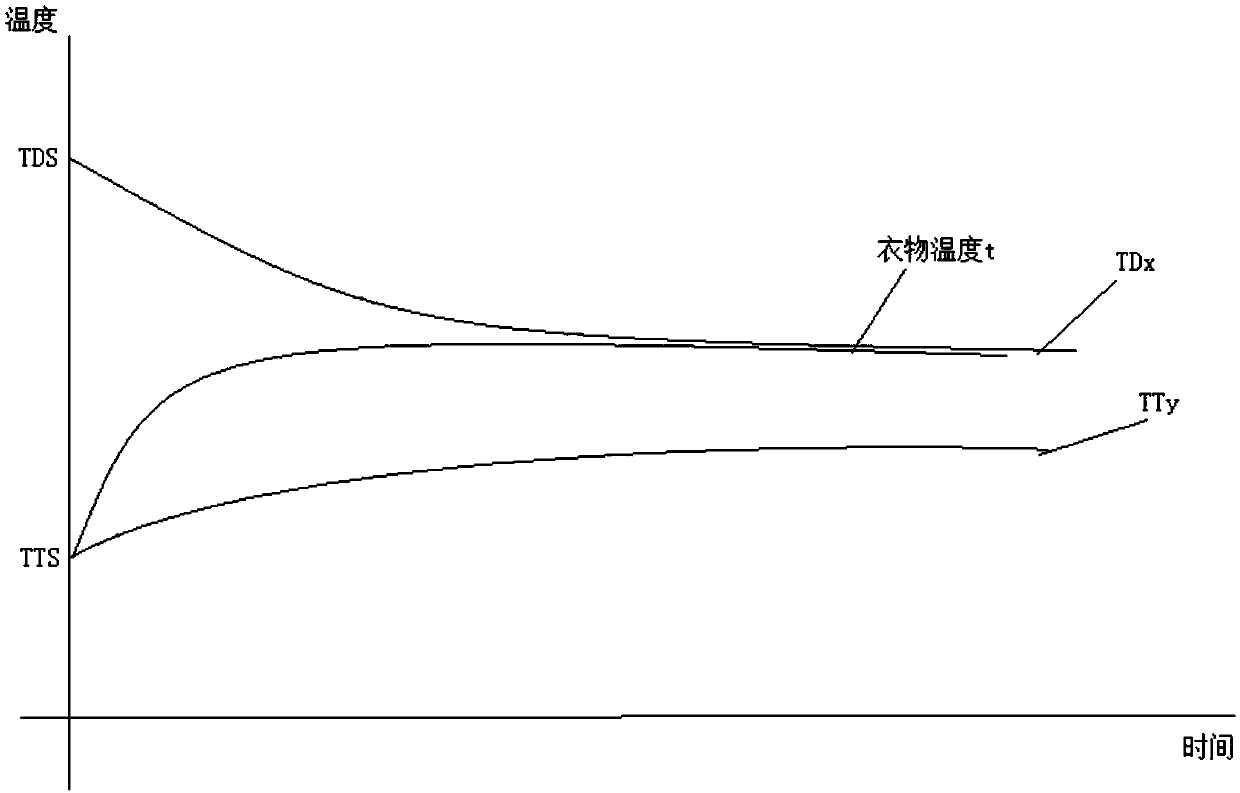

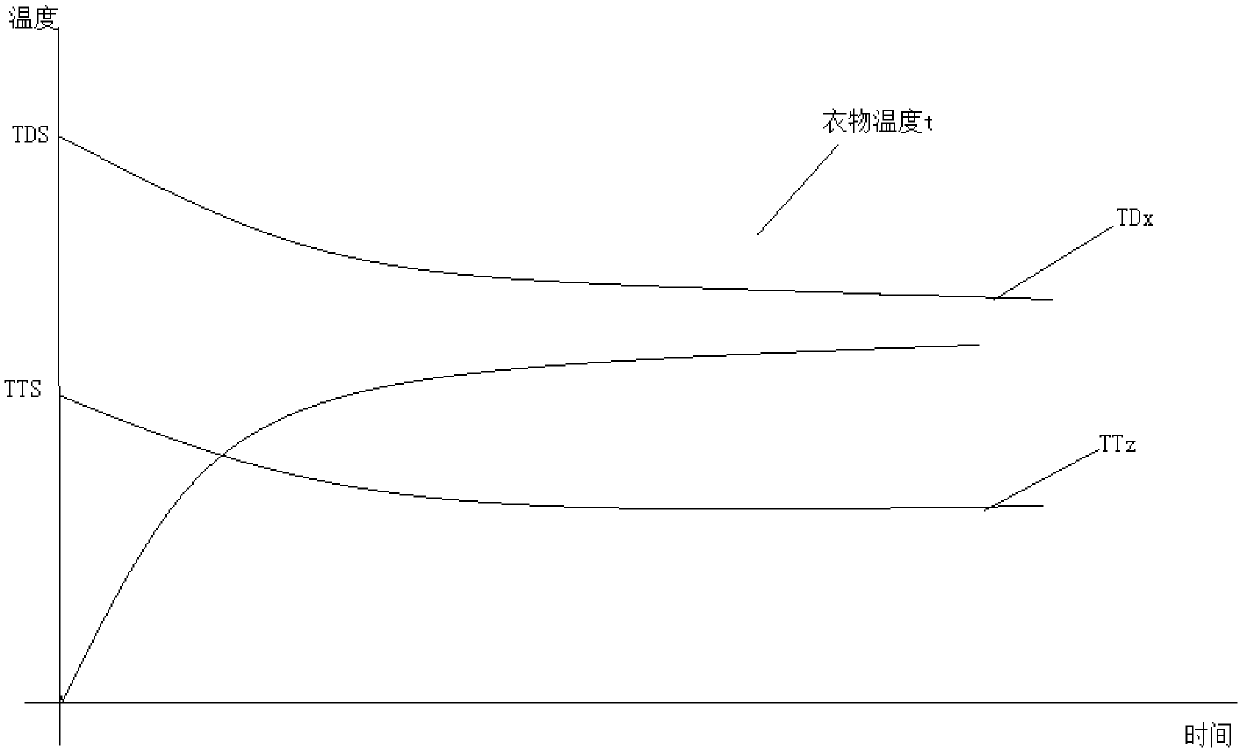

Clothes drying and treatment device temperature control method and clothes drying and treatment device

ActiveCN110438779AIncrease temperatureExtend warm-up timeTextiles and paperLaundry driersTemperature controlProcess engineering

The invention discloses a clothes drying and treatment device temperature control method and a clothes drying and treatment device. A heating device of the clothes drying and treatment device performson / off operation in a temperature interval, when the temperature in a cylinder reaches an upper limit value TDx of the temperature interval under the action of the heating device, the heating deviceis disconnected, and the heating device stops heating; and the upper limit value TDx of the temperature interval decreases as the number x of times the heating device is turned off increases. A high initial turn-off temperature for the heating device is adopted, the temperature in the cylinder is rapidly increased to reach a clothes drying temperature, so that the preheating time is shortened; andsubsequent control parameters for controlling on-off of the heating device is multiplied with a certain coefficient, the coefficient is related to the on-off times, and effects of gradually reducingthe off-temperature of the clothes dryer along with increasing of on-off times, and correspondingly adjusting the on-temperature along with the turn-on times of the heating device are achieved, and the contradiction between high temperature required at the initial stage of the clothes dryer and low temperature required at the later stage of the clothes drying process is effectively balanced.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com