Energy-saving flash suspension kiln system

A flash and kiln technology, applied in the field of energy-saving flash suspension kiln systems, can solve the problems of small particle size range of raw materials, high pollution, high energy consumption, and achieve reduced kiln load, high heat and mass transfer rate, and energy efficiency. low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

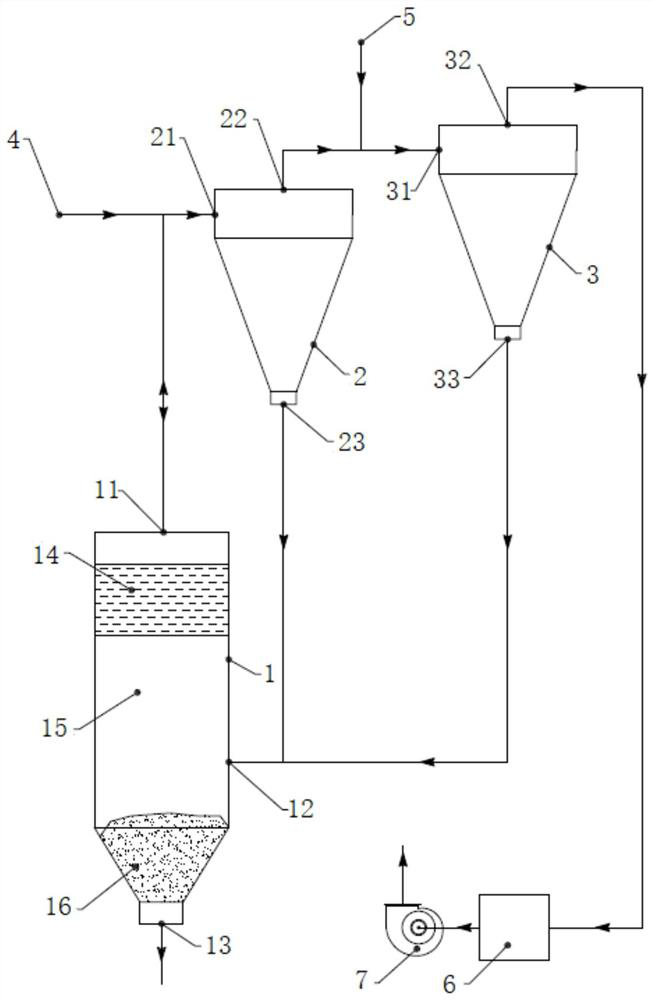

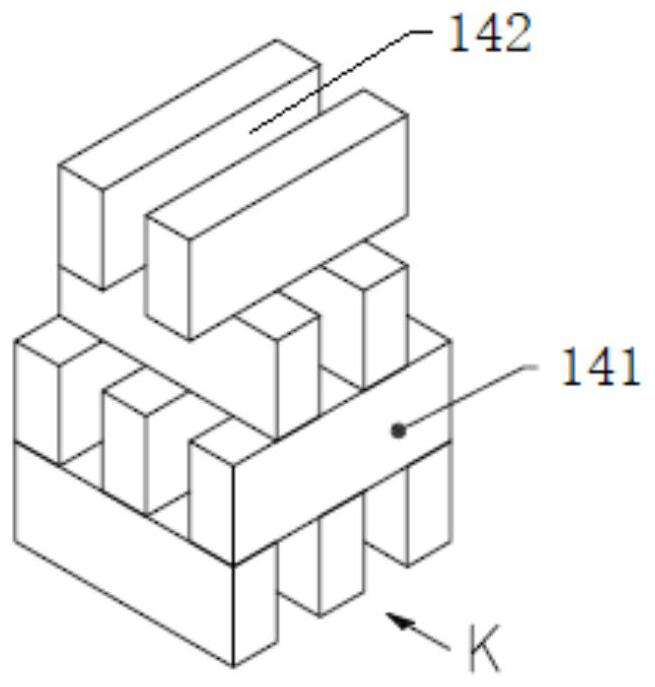

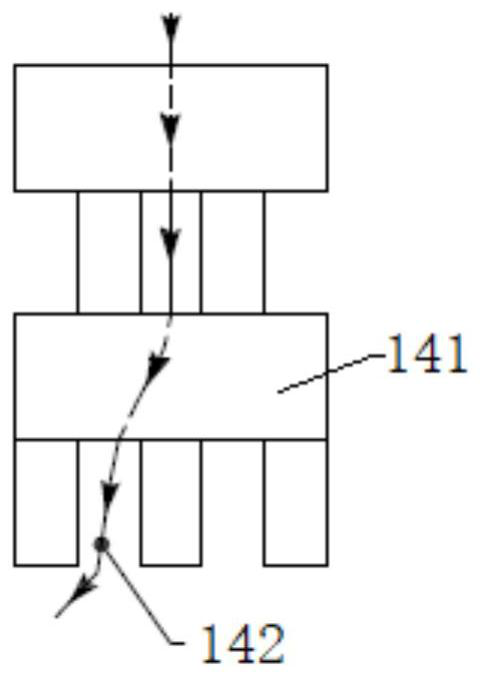

[0026] Such as figure 1 As shown, an energy-saving flash suspension kiln system includes a kiln 1 , a first gas-solid separator 2 and a first feeding point 4 . The kiln 1 includes a first feed inlet 11 on the upper part of the kiln 1, a second feed inlet 12 on the side of the kiln 1, and a clinker outlet 13 on the lower part of the kiln 1. The inside of the kiln 1 is along the first feed inlet. The port 11 to the clinker outlet 13 are divided into a damping section 14 , a burning section 15 and a reflecting section 16 in turn. That is, the damping section 14 is located at the lower part of the first material inlet 11 , the firing section 15 is located at the lower part of the damping section 14 , the reflecting section 16 is located at the lower part of the firing section 15 , and the clinker outlet 13 is located at the lower part of the reflecting section 16 . The burning section 15 communicates with the second feed port 12, and the burning section 15 is provided with an inl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com