Pre-desolvation gas chamber, horizontal desolvation machine containing the pre-desolution gas chamber and pre-desolution method

A desolventizing machine and pre-desolventizing technology, which is applied in solid solvent extraction, fat production, fat oil/fat production, etc., can solve the problems of poor desolventizing effect and low heat utilization rate of horizontal desolventizers, and achieve long preheating The effect of time and heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

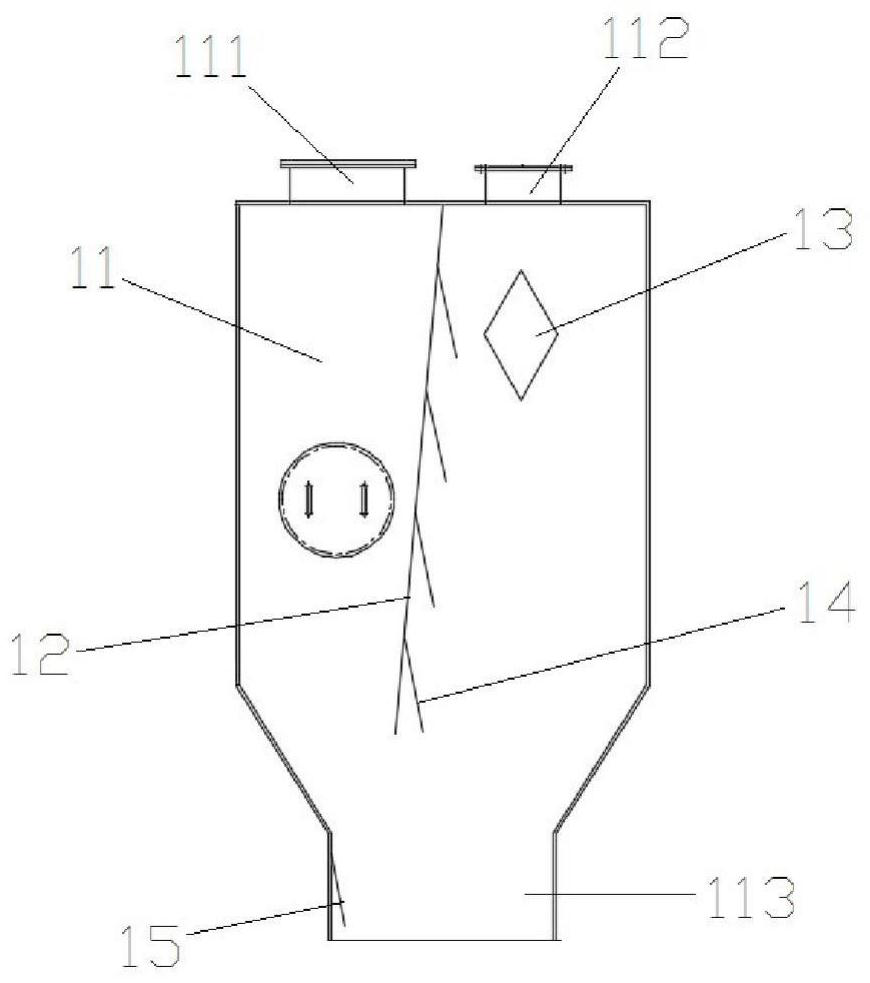

[0027] Such as Figure 1-2 As shown, the present embodiment provides a pre-dissolved gas chamber 1 for the horizontal meter, including the housing 11 and the separator 12; the upper portion of the casing 11 is provided with a feed port 111 and a fan 112, housing. The lower portion of the 11 is provided with a blasting port 113 that is coupled to the injection port 21 of the horizontal die 2, the separator 12 is mounted inside the housing 11 and inclines the housing from the top to the feed port 111 side. The inner cavity of 11 is isolated into a chamber in which the upper independent lower portion and the falling port 113 are connected.

[0028] Before the product to be removed, it enters the feed port 111 of the release gas chamber 1, and then rows from the horizontal. The hot air from the solution is from the feed port 113 of the release gas chamber 1 into and moved from the bottom, and the material to be removed from the insoluble material to be removed from the isolation plate ...

Embodiment 2

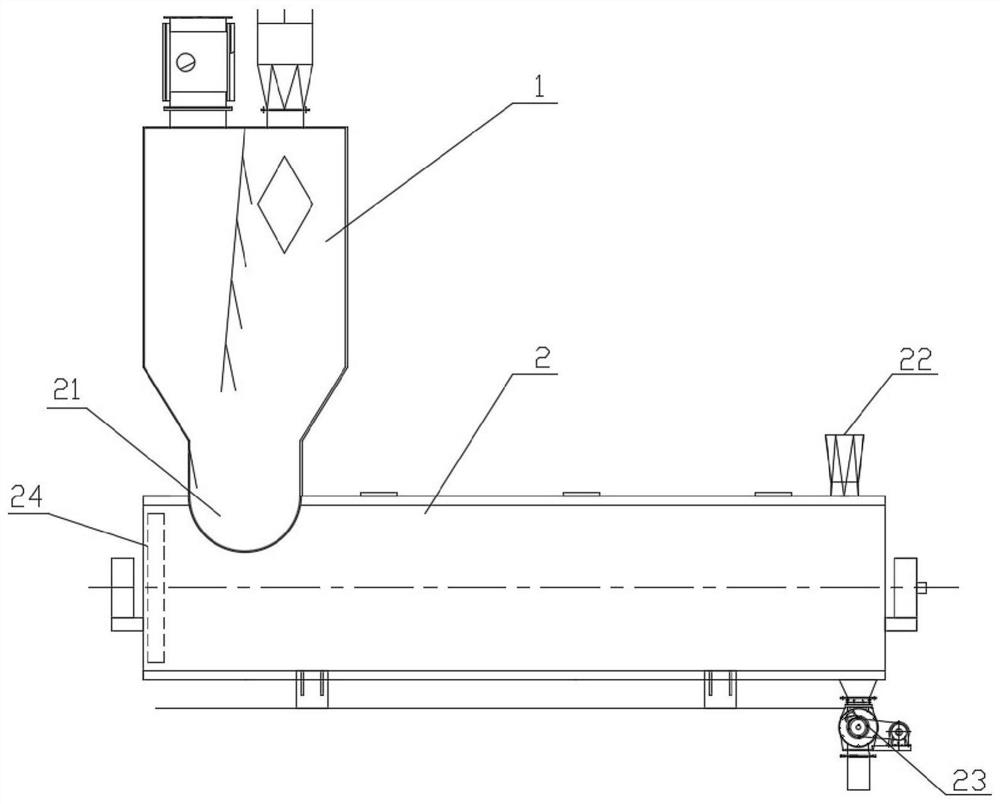

[0037] Such as figure 2 As shown, this embodiment provides a horizontal dexeerating machine including the release gas chamber 1 in Example 1.

Embodiment 3

[0039]This embodiment provides a pre-dissolving method using a pre-dissolving chamber 1 in Example 1, i.e., in upper mounting of a pre-dissolved gas chamber 1 above the injection port 21 of the horizontal die 2, pre-dissolving The blasting port 113 of the gas chamber 1 is in communication with the injection port 21 of the horizontal measuring machine, so that the product to be degraded from the feed port 111 of the release gas chamber 1 enters the pre-dissolving chamber 1, The feeding port 113 of the release gas chamber 1 enters the horizontal demoluration machine, from the hot air entering the air opening 22 from the horizontal die-dissolving machine 2, the injection port 21 of the heited decomposed machine 2 is entered Pre-heating is preheated in the pre-dissolving product in the pre-dissolved gas chamber 1 such that a part of the solvent in the product to be removed is pre-vaporized with the hot air one piece from the extension 112. After destroyed products, the unloading port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com