Wellhead drill rod sludge scraper

A mud scraper and drill pipe technology, which is applied in the direction of cleaning equipment, earthwork drilling, wellbore/well parts, etc., can solve the problems of high labor intensity and low safety, and achieve the convenience of observing the state of the wellhead and flexible disassembly and assembly , easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

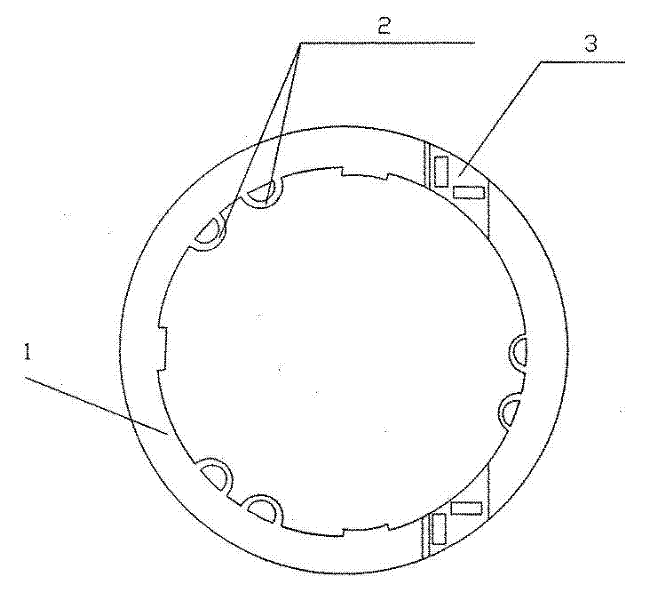

[0030] like figure 1 , 2 , Shown in 7 and 8, it is a split-type load-bearing rope casing wellhead drill pipe mud scraper, which is provided with a bracket and three elastic rope casings. The bracket is a closed type, divided into two parts, one large and one small, which are welded or cast by steel plates, and are fixed together by connectors when in use. There are connecting pins on the bracket, which are used to hang three sets of irons for the mud-scraping rope cover. The hanging rings are evenly distributed on the bracket. Generally, two sets of iron hanging rings are welded on the inner wall of the large part of the bracket, and a set of iron hanging rings are welded on the inner wall of the small part of the bracket for hanging the mud scraping rope cover; Figure 5 shown

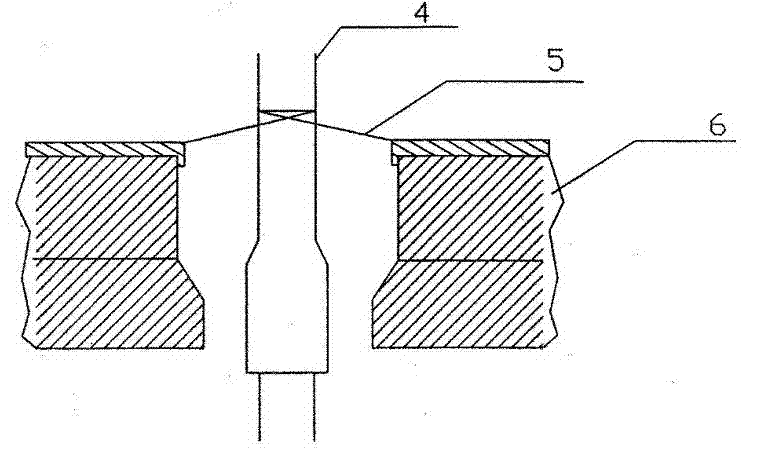

[0031] The mud-scraping rope cover includes a rubber tube and a steel wire rope. The inside and both ends of the filled rubber tube are respectively provided with thin steel wire ropes. The mud-scra...

Embodiment 2

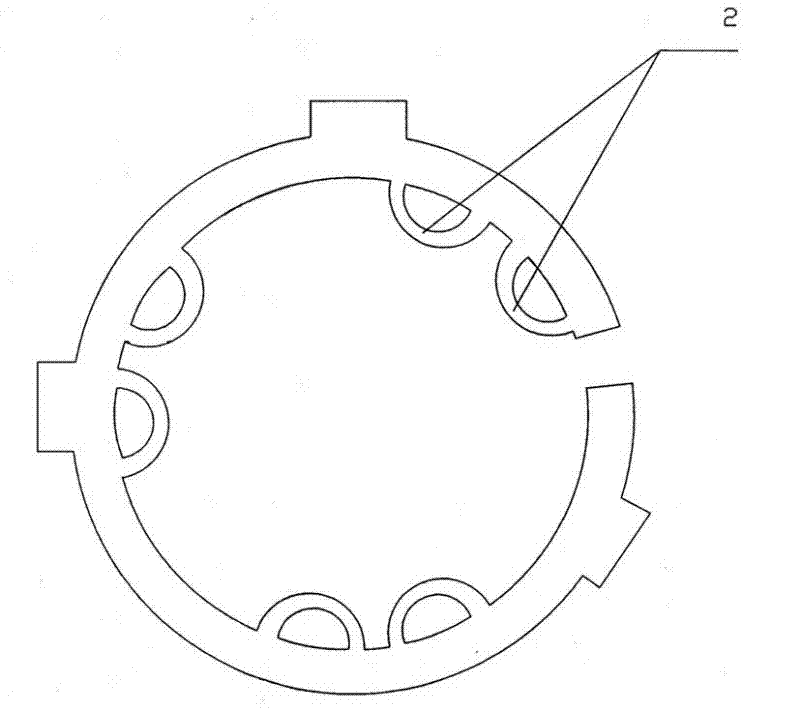

[0034] like image 3 , 4 , 9, and 10 are built-in rope casing wellhead drill pipe mud scrapers. The bracket is set in an open-loop type. The bracket is made of bent spring steel. The inner wall of the bracket is uniformly welded with three sets of steel rings for hanging scraping mud. noose. The structure of mud scraping rope cover is the same as embodiment 1.

[0035] The use process of the present invention is as follows:

[0036] 1. The use process of the split-type load-bearing rope casing wellhead drill pipe mud scraper

[0037] When pulling out the drill, first put the bracket on the kelly or the drill pipe, connect and fix it with connecting pins, and then put the pure rubber tube made of elastic, wear-resistant, and tensile-resistant materials with high elongation at breakage, such as silicone rubber. The filled rubber rope cover is hung around the kelly or drill pipe respectively on each group of iron rings of the split bracket welded or cast with steel plates, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com