Defoaming device of plate type falling film evaporator

A falling film evaporator, plate-type technology, applied in evaporator accessories, evaporation, chemical instruments and methods, etc., can solve the problems of unreasonable baffle design, poor defoaming effect, increased production costs, etc., and achieve improved defoaming Foaming effect, reduce production cost, improve defoaming efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

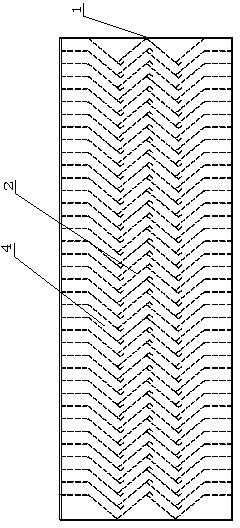

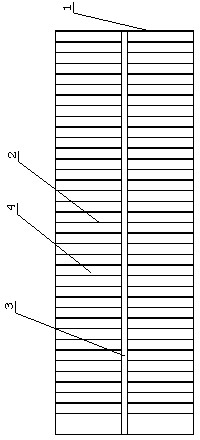

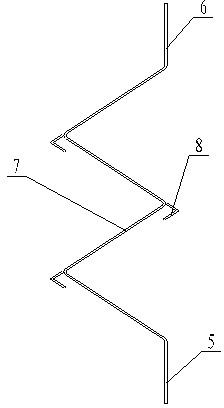

[0014] Such as figure 1 , figure 2 As shown, the defoaming device of the plate type falling film evaporator includes an outer protective frame 1, a number of parallel baffle damping blades 2 arranged in the outer protective frame 1, and a reinforcing plate for fixing a plurality of baffle damping blades 2 3. The defoaming channel 4 is formed between the baffle damping vanes 2, and the baffle damping vanes 2 are bent into an inlet section 5, an outlet section 6, and several times of bending between the inlet section 5 and the outlet section 6 The bent section 7 is formed, the outer corner of the bent section 7 is provided with an L-shaped fin 8 for hindering the steam flow direction, and the baffle damping blade 2 between the inlet section 5 and the outlet section 6 is folded three times. Bend to form a W-shaped bending section 7, and the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com