Vacuumized nitrogen filling and plugging device

A plugging device and vacuuming technology, applied in the fields of medical packaging machinery and food, can solve the problems of falling into the bottle body, contamination of medicinal liquid, complicated structure of the plugging mechanism, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

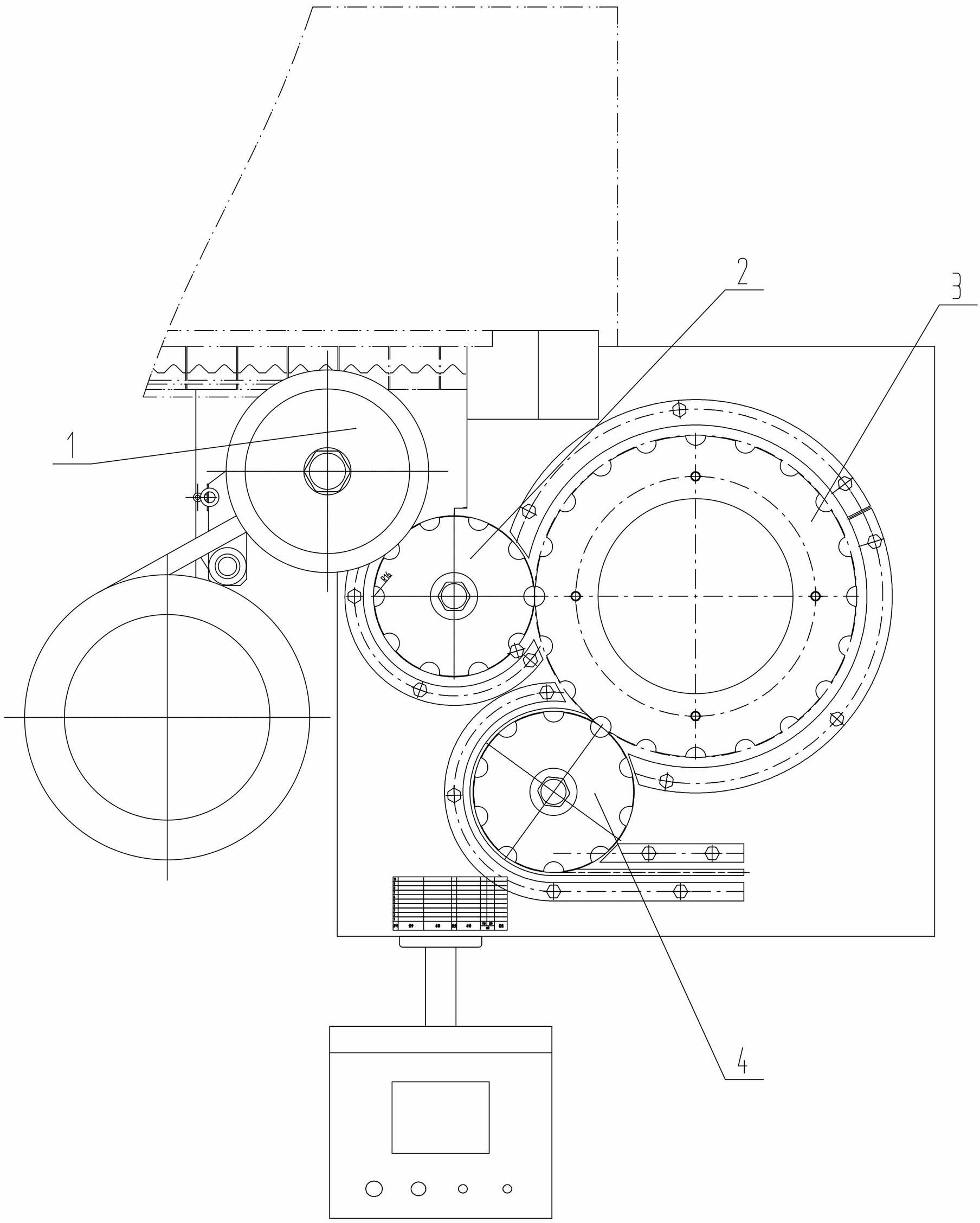

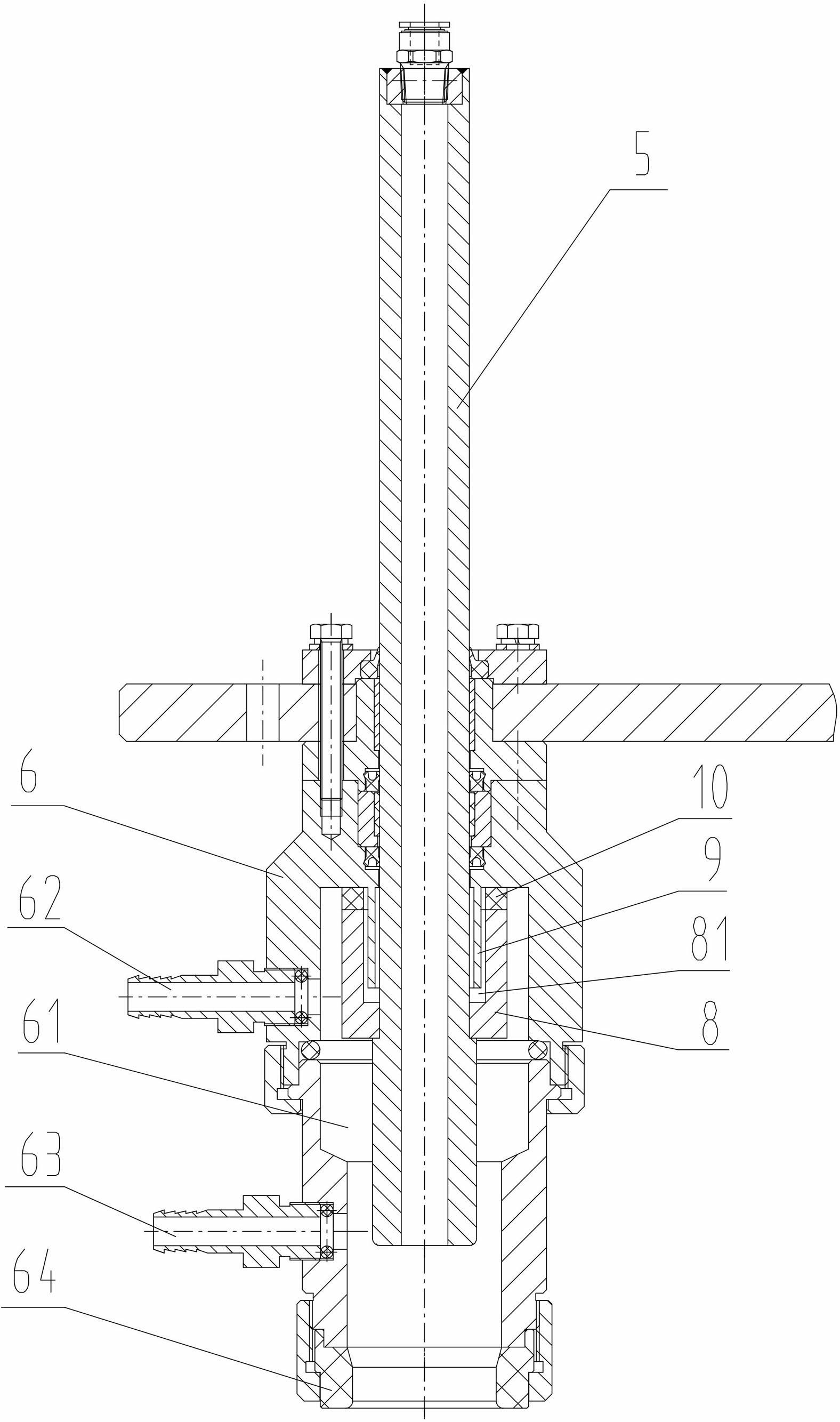

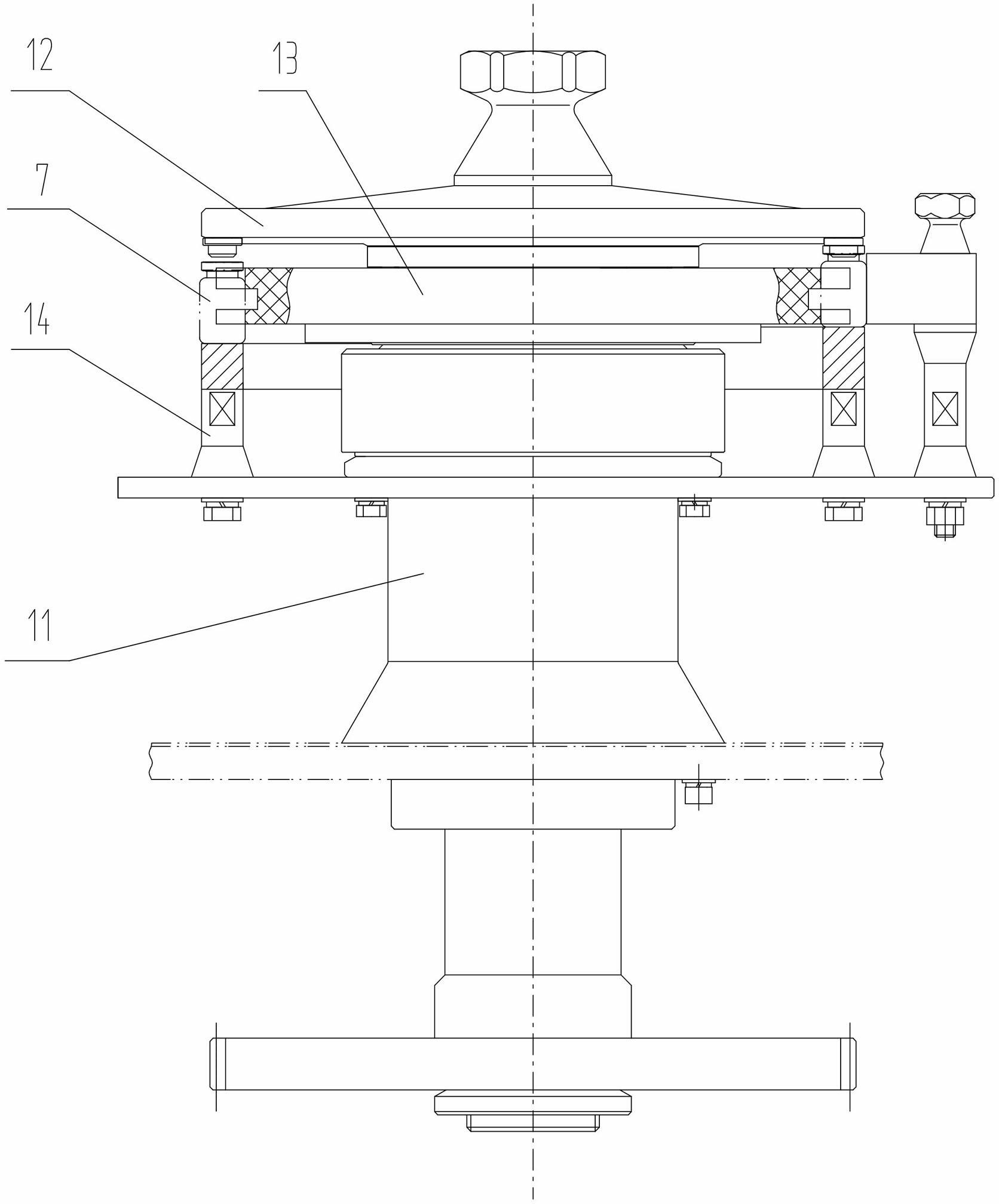

[0024] like figure 1 , figure 2 As shown, the vacuum-pumping and nitrogen-filling plugging device of the present invention includes a plugging part 1 and a vacuum-pumping and nitrogen-filling part 3. After the stoppering is completed, it is transferred to the vacuum pumping and nitrogen filling part 3 by the transition dial assembly 2. Vacuumizing and nitrogen filling part 3 includes lifting shaft 5 with vacuum adsorption function and connecting sleeve 6 provided with vacuuming and nitrogen filling chamber 61. Of course, lifting shaft 5 can also be composed of multiple sections to ensure that the lower adsorption end is suitable for glue. Plug shape and size. The lifting shaft 5 is socketed with the connecting sleeve 6, and the lower part of the lifting shaft 5 is placed in a vacuum-pumped nitrogen-filled chamber 61. The vacuum a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com