Anti-cracking and pressure-resistant brick and preparation method thereof

A pressure-resistant and anti-cracking technology, applied in the field of extrusion-molded floor tiles, can solve the problems of easy generation of fine lines, high drying shrinkage and sintering shrinkage, and large thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

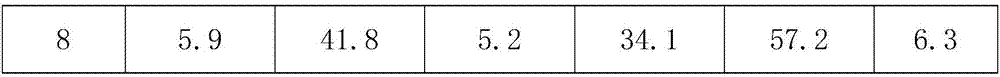

Examples

Embodiment 1

[0023] Step A, according to the percentage by weight, 35% of pure acrylic emulsion, 20% of alkylketene modified cellulose, 5% of phosphate, 5% of polyvinyl alcohol, 15% of bentonite, 5% of polyacrylic acid emulsion and 15% of water, Disperse and grind at a high speed at room temperature until the fineness is 70 μm to obtain the anti-cracking agent;

[0024] Step B, according to the percentage by weight, add 20% of plastic mud, 60% of 15-25 mesh split brick clinker particles, 15% of feldspar solvent and 5% of anti-cracking agent, add water and mix and knead evenly to make mud;

[0025] In step C, the uniform mud mixed in step B is made into mud granules by a screen granulator, and the mud granules are extruded by a vacuum extruder and cut into bricks, wherein the relative vacuum degree of the vacuum extruder is -0.08 ~-0.1MPa, the moisture content of mud particles is 18%;

[0026] Step D, firstly, put the prepared adobe into a microwave drying room, and dry it at a drying temp...

Embodiment 2

[0030] Step A, according to the percentage by weight, 35% of pure acrylic emulsion, 10% of alkyl ketene modified cellulose, 3% of phosphate, 3% of polyvinyl alcohol, 10% of bentonite, 5% of polyacrylic acid emulsion and 34% of water, Disperse and grind at a high speed at room temperature until the fineness is 70 μm to obtain the anti-cracking agent;

[0031] Step B, according to the percentage by weight, add 20% of plastic mud, 60% of 15-25 mesh split brick clinker particles, 15% of feldspar solvent and 5% of anti-cracking agent, add water and mix and knead evenly to make mud;

[0032] In step C, the uniform mud mixed in step B is made into mud granules by a screen granulator, and the mud granules are extruded by a vacuum extruder and cut into bricks, wherein the relative vacuum degree of the vacuum extruder is -0.08 ~-0.1MPa, the moisture content of mud particles is 18%;

[0033] Step D, firstly, put the prepared adobe into a microwave drying room, and dry it at a drying tem...

Embodiment 3

[0037] Step A, according to the percentage by weight, 35% of pure acrylic emulsion, 20% of alkyl ketene modified cellulose, 5% of phosphate, 5% of polyvinyl alcohol, 15% of bentonite, 5% of polyacrylic acid emulsion and 15% of water, Disperse and grind at a high speed at room temperature until the fineness is 70 μm to obtain the anti-cracking agent;

[0038] Step B, according to the percentage by weight, add 20% of plastic mud, 60% of 15-25 mesh split brick clinker particles, 15% of feldspar solvent and 3% of anti-cracking agent, add water and mix and knead evenly to make mud;

[0039] In step C, the uniform mud mixed in step B is made into mud granules by a screen granulator, and the mud granules are extruded by a vacuum extruder and cut into bricks, wherein the relative vacuum degree of the vacuum extruder is -0.08 ~-0.1MPa, the moisture content of mud particles is 18%;

[0040] Step D, firstly, put the prepared adobe into a microwave drying room, and dry it at a drying tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com