Waste gas treatment device of pre-roll-coating aluminum roll production line

A technology of waste gas treatment device and production line, which is applied in the directions of air quality improvement, combustion method, lighting and heating equipment, etc., can solve the problems of increased maintenance expenditure of user units, insufficient combustion of waste gas, high maintenance cost, and achieve good thermal insulation effect. , Improve the utilization rate and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

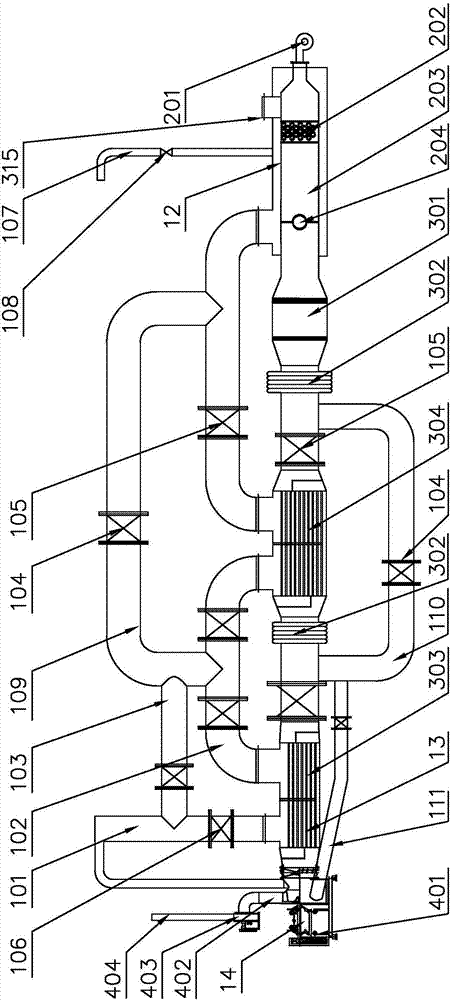

[0034] Such as Figure 1-7 as shown,

[0035] An exhaust gas treatment device for a pre-roll coating aluminum coil production line, including a combustion system 12, a heat exchange system 13, and a spray drying system 14, and the spray drying system 14 includes a spray drying box 401, a clean air outlet 402, and an induced draft fan 403 , Exhaust flue 404, described spray drying case 401 upper side is provided with net gas outlet 402, and described net gas outlet 402 side is provided with induced draft fan 403, and described induced draft fan 403 and net air outlet 402 pass pipeline Connected, the side of the induced draft fan 403 is provided with an exhaust flue 404;

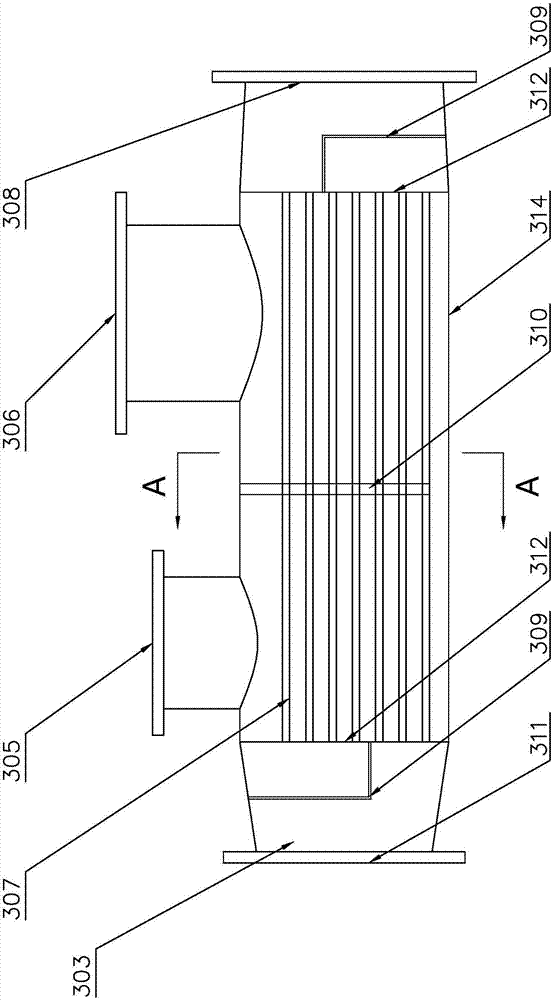

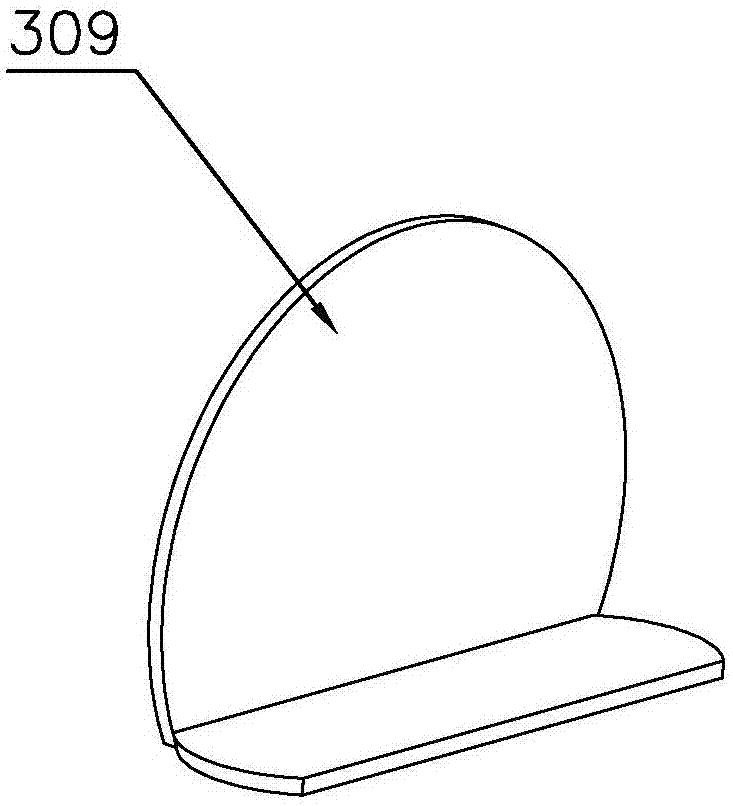

[0036] One side of the spray drying system 14 is provided with a heat exchange system 13, the heat exchange system 13 includes a regenerator 301, a primary heat exchanger 303, and a secondary heat exchanger 304, and the spray drying box 401- There is a primary heat exchanger 303 on the side, and the primary ...

Embodiment 2

[0043] Such as Figure 8 as shown,

[0044]The difference from Embodiment 1 is that a first bypass pipe 103 is provided on one side of the waste gas inlet pipe 101, a bypass pipe valve 104 is provided on the first bypass pipe 103, and a bypass pipe valve 104 is provided on the first bypass pipe 101. 103 is connected to the exhaust gas outlet 306 of the primary heat exchanger 303 and the main pipeline 102. When the primary heat exchanger 303 fails, close the exhaust gas inlet valve 106, open the bypass pipeline valve 104 on the first bypass pipeline 103, and the flue gas Bypass the primary heat exchanger 303 and directly enter the next processing procedure, providing conditions for maintenance personnel to repair the primary heat exchanger 303, avoiding system shutdown caused by the failure of the primary heat exchanger 303, reducing the probability of system shutdown, and indirectly The economic loss caused by system shutdown is greatly reduced. The heat and flue gas generate...

Embodiment 3

[0046] Such as Figure 9-10 as shown,

[0047] The difference from Embodiment 1 and Embodiment 2 is that a second bypass pipe 109 is provided on the side of the main pipe 102 of the waste gas outlet 306 of the primary heat exchanger 303, and a bypass pipe 109 is provided on the second bypass pipe 109. Through the pipeline valve 104, the second bypass pipeline 109 is connected to the main pipeline 102 of the waste gas outlet 306 of the secondary heat exchanger 304, and the hot clean gas inlet 308 and the hot clean gas outlet 311 of the secondary heat exchanger 304 pass through the third The bypass pipeline 110 is connected, and the third bypass pipeline 110 is provided with a bypass pipeline valve 104; when the secondary heat exchanger 304 breaks down, close the main pipeline valve 105 at the waste gas inlet 305 of the secondary heat exchanger 304 and the main pipeline valve 105 at the waste gas outlet 306, open the bypass pipeline valve 104 on the second bypass pipeline 109 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com