Biomass and coal co-gasification system and gasification method

A biomass and co-gasification technology, applied in chemical instruments and methods, steam generation methods using heat carriers, separation methods, etc., can solve problems such as ineffective use of energy, and improve the conversion rate and reactivity of coal gasification Strong, increased reaction time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

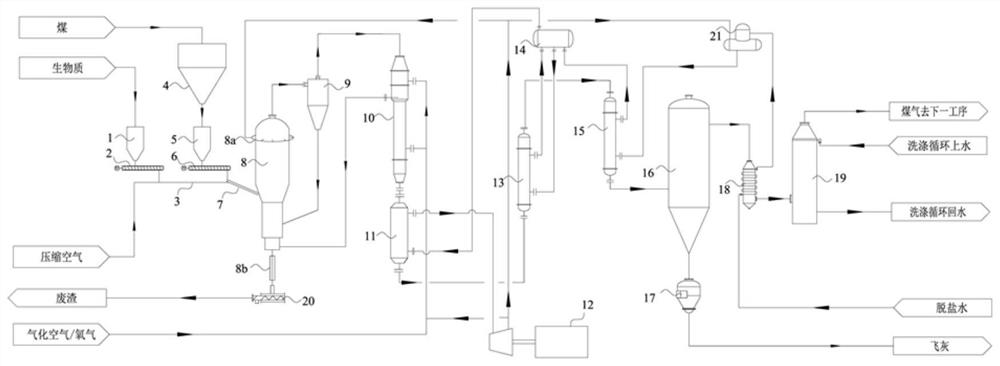

[0039] Such as figure 1 As shown, a biomass and coal co-gasification system includes a raw coal feeding device and a biomass feeding device, both feeding devices are connected to the feeding pipe 7, and the raw coal and biomass are mixed in the feeding pipe 7 The feed pipe 7 is connected to the fluidized bed gasification furnace 8, and the gasification reaction of the mixture occurs in the fluidized bed gasification furnace 8 to generate high-temperature gasification gas; coal is the main component of China's energy structure, and its Compared with biomass resources, the output supply is stable, the particles are more regular, and the energy density is high. Therefore, the co-gasification technology of biomass and coal can well make up for the defects of poor stability, irregular particles, low energy density, and high tar yield in the gasification process when biomass is gasified alone; Disadvantages in terms of resource reserves, greenhouse gas emissions, reactivity, etc., ...

Embodiment 2

[0051] Basically the same as in Example 1, in this implementation, the waste heat recovery device also includes an economizer 15, and the waste heat recovery device 13, the steam drum 14 and the deaerator 21 are respectively connected with the economizer 15, and the setting of the economizer 15 will, on the one hand, The deoxygenated and desalted water in the deaerator 21 is heated before entering the steam drum 14 to reduce the heat absorption of the deoxygenated and desalted water on the heating surface, and the economizer 15 can be used to replace part of the evaporation heating surface with high cost; On the other hand, when the desalted water temperature increases and enters the steam drum 14, the wall temperature difference of the steam drum 14 will be reduced, and the thermal stress will be reduced accordingly, prolonging the service life of the steam drum 14; Deoxygenated and desalinated water is preheated to maximize the utilization of waste heat from gasification gas....

Embodiment 3

[0053] It is basically the same as that in Embodiment 2. In this embodiment, the fluidized bed gasifier 8 includes an upper dilute-phase zone and a lower dense-phase zone. The upper dilute-phase zone is provided with a secondary gasification agent injection device 8a. The secondary gasification agent The injection device 8a is connected to the steam power generation device, and the secondary gasification agent in the secondary gasification agent injection device 8a continues to undergo reduction reaction with the high-temperature gasification gas produced by the gasification reaction, so as to improve the coal gasification efficiency and the quality of the gasification gas , and at the same time perform a chilling effect on the high-temperature gasification gas to reduce the heat load of the subsequent high-temperature preheater 10, reduce the cost input of equipment materials, and improve the service life of the equipment; in this implementation, the secondary gasification agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com