Alkylation catalyst

A catalyst and alkylation technology, applied in physical/chemical process catalysts, molecular sieve catalysts, organic chemistry, etc., can solve the problems of short life, rapid activity decline, etc., and achieve the effects of long life, improved conversion rate, and no hydrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

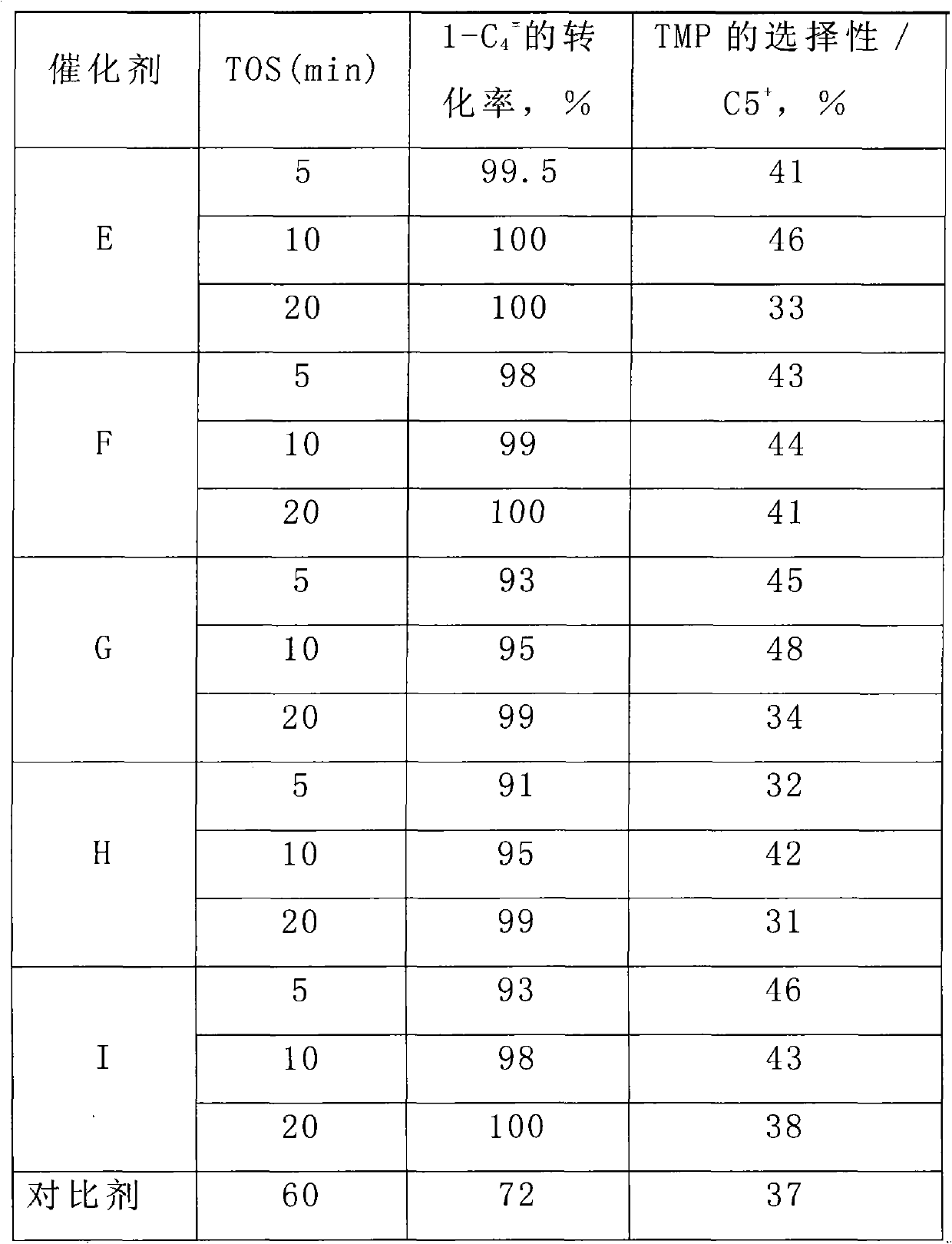

Examples

Embodiment 1

[0020] With 1000 grams of silicon-aluminum ratio being 26 hydrogen type zeolite beta (produced by Zhuozhou Nanda Catalyst Co., Ltd.), getting commercially available silicon-alumina ratio is 1500 grams of HZSM-5 molecular sieve of 60, 0.6M Ce 2 (SO 4 ) 3 800ml of the solution was exchanged. That is, at 40°C, rapidly stir and exchange for 2 hours, then filter the slurry, dry at 110°C for 2 hours, crush and exchange again. After being dried and pulverized, modified zeolite beta A was obtained, wherein the content of cerium was 2.2%, and it was ready for use.

Embodiment 2

[0022] 1000 grams of HY zeolite (produced by Zhuozhou Nanda Catalyst Co., Ltd.) with a silicon-aluminum ratio of 4 were mixed with 0.6M LaCl 3 600ml of the solution was exchanged. That is, at 40°C, rapidly stir and exchange for 2 hours, then filter the slurry, dry at 110°C for 2 hours, crush and exchange again. After drying and crushing, La-modified Y zeolite B was obtained, wherein the La content was 1.5%, which was ready for use.

Embodiment 3

[0024] 1000 grams of hydrogen-type beta zeolite (produced by Zhuozhou Nanda Catalyst Co., Ltd.) with a silicon-aluminum ratio of 26 was exchanged with 800 ml of a 0.2M rare earth chloride solution. That is, at 40°C, rapidly stir and exchange for 2 hours, then filter the slurry, dry at 110°C for 2 hours, crush and exchange again. After being dried and pulverized, modified zeolite beta C is obtained, wherein the mixed rare earth content is 0.6%, which is ready for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| unit cell dimension | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com